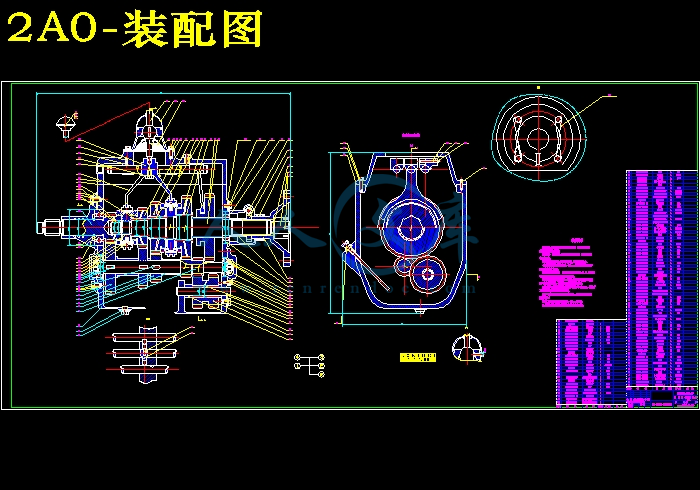

KD1060载货汽车变速器设计【说明书+CAD】

收藏

资源目录

压缩包内文档预览:(预览前15页/共30页)

编号:10049050

类型:共享资源

大小:904.42KB

格式:RAR

上传时间:2018-04-23

上传人:柒哥

认证信息

个人认证

杨**(实名认证)

湖南

IP属地:湖南

15

积分

- 关 键 词:

-

kd1060

载货

汽车

变速器

设计

说明书

仿单

cad

- 资源描述:

-

【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得,所见即所得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:12401814

- 内容简介:

-

附录BFULLER双中间轴变速器结构特点分析富勒(FULLER)双中间轴变速器是美国伊顿EATON公司六十年代的独创产品,于1965年申请专利,随即投入生产、供应市场。它是针对以下情况设计的当时美国已逐渐建成高速公路网,为了提高汽车货运经济效益,促使货车向着大型化、高速化、专用化的方向发展。在美国较为盛行的一种运输方式是由鞍式牵引车牵引的半挂车和汽车列车,此种牵引车是美国公路用重型汽车中的主要车型,其特征是轴距短,加之美国公路法规限定该类车的前悬不得大于800,因之使变速器轴向尺寸受到很大限制。面发展的需要却一再要求提高M汽车发动机功率,并相应加大变速器的承载能力,这对传统的单中间轴变速器来说,其轴向尺寸必然要加大因而产生了矛盾,双中间轴变速器即是在此种情况下应运面生的。它大大提高了变速器的扭矩容量(FULLER产品最大已达到2240),并减小了轴向尺寸。它供应市场以后,在美国的重型车上逐渐取N代了传统的单中间轴变速器。八十年代以来它几乎独占了美国重型车用变速器的市场(其中EATON公司产品约占75。七十年代中期以后,伊顿公司产品在降低噪音、提高寿命和可靠性方面又有显著提高。且在变速器基本结构不变的情况下,又研制成功细齿系列新一代变速器。同时,调整了原产品,重新编制了产品系列并实现标准化。八十年代初已经按新系列生产。本文是以原900系列(即新系列11600,二者基本结构相同)的RT915型组台式变速器的结构为例进行分折。附B1RT915型变速器的基本结构图B1所示为RT915型变速器结构简图,它由一个五档主箱与一个三档位的后置倍档副箱组合而成,它有15个前进档和三个倒档。主箱和副箱齿轮中心距均为14843它们各有两套中间轴总成,全部齿轮为直齿圆柱齿轮,常M啮合式传动,二者输出轴上齿轮均为浮动,主箱输出轴亦浮动。主箱各档无同步器,副箱高低档装有锁销式惯性同步器,超低档采用外齿接合套式换档装置。主箱各档为机械式手操纵,副箱各档采用全气动式操纵换档。当副箱同步器接合套与接合套均左移至接合位置时,组合式变速器分别处于高速区、低速区、超低速区,备有五种速比供选用。图B1FULLER双中间轴变速器主箱第一轴主箱第二轴主箱中间轴R主箱倒档轴副箱中间轴副箱输出轴换档接合套副箱高低档同步器接合套副箱超低档同步器接合套ZR2主箱倒档惰轮附B2结构特点分析附B21双中间轴功率分流图B1所示变速器主箱和副箱各有两套中间轴总成,输入的动力分两路传给二中间轴总成,再由输出轴总成将两路动力合流后输出。输入、输出轴上的齿轮同时有两个齿分别与二中间轴上的齿轮啮合,工作时每齿所受载荷相对单中间轴结构而言,理论上降低了1/2,实际上则由于齿形误差、齿厚误差、中心距误差等,使二中间轴上齿轮与相应啮合齿轮受载不均匀,使实际降低值少于1/2。此情况使双中间轴变速器较之单中间轴变速器具有明显的优势。附B211双中间轴变速器齿轮寿命鉴于齿轮的疲劳寿命约与其负荷的3次方成反比,关系式如下(常数)式B13PNC式中P齿轮轮齿负荷;N轮齿疲劳损坏的循环次数;由式B1可知,设单齿传力情况下,轮齿负荷,对应的疲劳损坏循环次1P数为。当双齿传力时,每一单齿负荷,较前者理论上降低了1/2,即12,此时对应的疲劳损坏循环次数,即传递相同扭矩,双齿传2/P31N力时,齿轮疲劳寿命可大幅度提高如果保持齿轮疲劳寿命不变,即,则,这说明了在齿轮疲劳寿命相等的情况下,双齿传力时,21N21P每一单齿的负荷可由提高到,即可提高一倍若按最差的实际情况,考/1虑,二齿载荷分布不均匀系数取为06,由计算知道此时扭矩容量仍可提高67。这也就是双中间轴变速器设计原理所根据的事实。附B212双中间轴变速器中心距双中间轴变速器的齿轮中心距按下列公式计算式B23MAX1AEGKBTIH式中B载荷分布不均匀系数取052060;由式B2可知,齿轮中心距可较单中间轴结构减小1520,这对改善变速器的经济性和轻量化有着重要的意义,我们知道齿轮中心距稍许减小,质量即可减轻许多。因此,齿轮中心距是齿轮传动设计中最基本的参数,它影响到变速器的很多重要性能指标,并直接和齿轮传动的结构设计及承载能力有密切关系。长期以来,国内外对减小传统变速器的齿轮中心距进行了不懈的努力,终因受到轴承、材料工艺水平及换档同步器成的设计制造技术水平的制约而进展不大。双中间轴结构的出现,由于功率分流大大改善了齿轮、轴、轴承和箱体的受载情况,并可降低加工精度要求,因而能做到既保证了变速器的使用性能,又减小了齿轮中心距。由于齿轮轮齿应力较传统变速器减小近一半,故可减小齿宽约40,既减小了变速器轴向尺寸,又保持了齿轮的承载能力,同对还改善了载荷沿齿面的分布状况,有利于提高齿轮寿命。附B22齿轮浮动主箱输出轴上的齿轮同时与对称布置的二中间轴上的齿轮啮合,它在二齿轮之间可沿径向浮动,靠啮合圆自动定心,副箱也是如此。这是FULLER双中间轴变速器结构的显著特点,其优点是(1)使输出轴上齿轮和二中间轴上齿轮正确啮合,并均匀分配载荷。(2)省去了传统变速器中输出轴上所有常啮合齿轮处的滚针轴承。此滚针轴承是传统变速器结构中的弱点,取消它,对提高变速器寿命和工作可靠性有明显作用。(3)对齿轮精度、轴的精度以及箱体轴承孔的位置精度可降低要求。(4)使齿形误差引起的动载荷影响减小。(5)试验表明,浮动啮合可减小强烈的谐振的噪音强度。附B23轴的布置与受力主箱第二轴为浮动结构,二轴后端与副箱驱动齿轮花键联接,通过轴承支承在箱体上;轴前端轴颈与含油轴承之径向间隙较大(陕西汽车轮厂测量为09,全轴以后端为支点,前端浮动。因此,第二轴上齿轮均是浮动的,换档M时,在第二轴上的外齿接合套随轴浮动,便于换档。图B1所示,二中间轴之中心连线与水平线之间夹角,FULLER为19,此A角若过小,将使箱体宽度尺寸加大,搅油损失增加,此损失是影响变速器效率的主要因素;如果过大,则箱体高度尺寸加大,且使上方轴承润滑条件变坏。对称布置的双中间轴使第一轴、第二轴上齿轮所受径向力相互平衡,使此二轴均不承受弯矩,而仅承受扭矩,放可使第一轴、第二轴直径减小。二中间轴亦因此所受弯矩减小1/2,可使轴保证足够刚度(这是设计中间轴应主要考虑的问题),以改善齿轮和轴承的工作条件,这对提高齿轮和轴承的寿命和降低噪音甚为有利。附B24解决了轴承使用寿命问题由上可知,输入轴与输出轴轴承所受径向力的合力为零,传动齿轮为直齿,无轴向力,轴承仅承受重力;中间轴的轴承所受径向力减小近1/2,无轴向力。所有轴承受载荷情况均获极大改善,这是造成此种变速器轴承寿命长的基本因素。另外,主副箱中间轴的一端仍采用了承载能力较强的滚柱轴承,既获容量大的好处,也是由于中间轴需采用游动式支承,且分离型轴承使装折方便。主箱其余轴承虽为常见类型,但与传统变速器比较,其寿命系数却高了许多。副箱输出轴是由两个反装的圆锥滚子轴承支承,按分析主要是为了增强悬臂式轴的支承刚度及稳定性,和增大轴承容量。在轴承负荷较小的情况下,尽可能增大轴承容量,既可提高轴承寿命,使之与变速器总寿命相适应;又可提高支承刚度,加强轴的运转刚性,保证齿轮正确啮合,提高齿轮寿命及降低噪音。新系列产品为降低噪音,又新设计了轴承,从而改进了轴承品质。实际使用结果FULLER双中轴变速器在48万公里内无需更换轴承,此寿命值在同等级变速器中居世界最佳水平。附B25主箱无同步器,采用拉型离合器配合换挡FULLER双中间轴变速器主箱没有采用同步器,而是采用外齿接合套式换档装置。按理,对于扭矩容量大的变速器而言,由于齿轮大,转动惯量大,换档时在将要进入啮合的转速差较大的轮齿之间产生的冲击力也大,造成换档困难。因此,应加装同步器好。但采用同步器,当前需解决其使用寿命问题。大扭矩容量的西德ZF单中间轴变速器是享誉世界的产品,仍然存在同步器早期损坏的问题,此问题在世界各生产厂家也均未获解决。FULLER双中间轴变速器主箱没有采用同步器,而是与拉型离台器配合,实现同步换档。它是在主箱第一轴上装设一摩擦制动盘,当换档分离离合器时,分离拨叉向后拉动分离轴承,将摩擦制动盘压向第一轴端盖,制动第一轴,以加速齿轮的同步过程,按此,它只能使第一轴作减速运动,故只可在原地起步及向上换挡时使用,而不能在向下换档时使用。在设计原理、结构及计算方面进行了探索性的实践,从原理和结构上可做到在向上和向下换档时均可使用。根据分析,这种装置在简化操作、缩短换档时间、实现同步换档上可起到与同步器相近的作用,但因这种结构不具有同步器所具有的锁止作用,要实现无冲击换档,还有赖于驾驶员操作的熟练程度。伊顿公司声言在换档机构中,外齿接合套的花键齿两端与相应的齿轮花键孔之间均设计有大倒角,它在换档过程中能起到一定的锁止作用。这种独特的换档机构,从美国重型汽车普遍使用的情况来看,是成功的,若经改善。可望完全取代同步器的功能,达到取消同步器的目的这样作的好处是明显的,它避开了同步器这个难题,以及变速器寿命中的弱点,提高了变速器的工作可靠性,简化了变速器结构,使其轴向尺寸减短,质量减轻,减少了对工艺和材料要求较高的零件,使变速器造价降低。附B26全直齿齿轮传动FULLER双中间轴变速器主箱和副箱的全部齿轮采用直齿齿轮常啮合传动,在国内外大扭矩容量变速器中实为少见。除副箱驱动齿轮副是采用单径节制齿轮外,余均是采用双径节制短齿齿轮,主箱和副箱之各档齿轮均各取一种经节,分别为6/7和5/7,换算成模数为432/363和508/363新系列产品的细齿齿轮,其模数小于127其齿形细长,易形成多齿啮合。主箱所有齿轮副的齿轮齿数为2223齿,全部齿轮采用小齿形角及正变位修正。为了达到新的交通法规对噪音的限制,伊顿公司对新系列产品采取了如下措施(1)改进齿形结构;(2)提高齿轮副重合系数;(3)提高齿轮精度(细齿系列齿轮精度比粗齿系列高一级,是使齿间负荷分布均匀);(4)改进轴承品质;(5)提高箱体刚性。取得了较好效果,新系列产品较老产品噪音强度降低了57。DB分析以上结构有如下特点(1)全部采用直齿齿轮,对整体式箱体的双中间轴结构,便于总成组装与解体(2)采用短齿制齿轮可增强轮齿的抗弯强度,但同时也加重了直齿齿轮重合系数小的缺陷,采用小齿形角和多齿啮合的办法可弥补此缺陷,新系列产品的重合系数可达到22(传统设计重合系数仅15左右)。瑞典SCANIA公司生产的GR860主变速器采用全斜齿轮常啮合传动,其重台系数为,145168。重合系数的提高可改善齿轮啮合性能,试验表明降低了噪音;使受表面疲劳影响的齿轮寿命有了明显提高(因齿面压力减小);较大重合度系数齿轮的抗冲击能力高于低重合系数齿轮(因前者负荷分配较均匀),此能力是重型汽车变速器所要求的。(3)因采用小齿形角会降低齿根强度,故采用正变位修正齿轮,以增强齿根强度。(4)为了保证主箱二中间轴上齿轮与第一轴、第二轴上齿轮能同时啮合,也使第二轴上齿轮能将负荷均匀地分配给二中间轴,故需保证第一轴、第二轴上齿轮的齿数均为偶数,中间轴上各齿轮均有一齿位于同一纵平面内,且所有齿轮的模数相同。(7)因齿轮外径较小,齿宽较窄,便于采用拉齿、剃齿等高效加工方式生产。道路试验结果表明平均运行64万公里的新系列产品,其可靠性系数为92,80万公里时为90。说明此种变速器不仅结构简单,工艺性好,而且工作可靠,寿命指标居世界先进水平,耐用容易制造,是一成功的实例。附B27主箱、副箱和箱体结构特点整个FULLER双中间轴变速器系列族是以两种中心距(135128与14843M)的五档主箱为基本型,采取主箱变型和按单元组合原理,与不同副箱组M合后,实现产品的系列化标准化多品种生产,图1所示主箱为此进行的结构设计是很有特色的,其变型是在保持齿轮中心距不变和除齿轮外的其余零件基本不变更的情况下,用18对齿轮进行不同的组合,从而获得8种不同速比组合的主箱。又如图B1所示,在全套零件不变更的情况下,仅将齿轮与,齿轮1Z3与装配位置互换后,又可获得具有超速档的主箱,从而使整个系列产品品2Z4种增加多种。对变型需要更换的零件采取花键联接的组合结构;第一轴、第二轴上所有齿轮的内孔为同一规格的花键孔,使齿轮可按需要换位安装;并因此采用外齿接合套式换档机构,且各档通用。使主箱易于实现变型,也可实现等强度。因为整个产品的零件通用化程度高达70以上,极大地方便了生产,获得很高的经济效益。副箱的二中间轴轴线与主箱二倒挡轴轴线共线,副箱与主箱的箱体为一整体,副箱内全部零体均安装在箱盖上,成为一个总成,二速和三速副箱均如此,二者箱盖通用,当变型时更换此总成即可,十分方便。整体式箱体省去了主箱与副箱之间的壳体与轴承,使整个结构紧凑、合理、缩短了轴向尺寸,减轻了质量,简化了加工。FULLER产品箱体的通用化程度高,同一齿轮中心距的单独主箱,它的各种变型产品可通用一种箱体;组合相同的整体式箱也可通用一种箱体;箱体齿轮中心距仅有两种却覆盖了整个系列族产品,这对大批量生产的变速器专业厂而言,意义是很大的。在变速器的生产中,箱体生产线个性最强,耗资最大,保持箱体生产线不变,不仅经济上十分合算,而且可迅速方便地适应市场竞争的需要,使工厂具有很强的应变能力。附B3结论由于FULLER变速器采取了一些独特的结构,极大地改善了内部结构的受力状况,它不仅具有性能指标先进、工作可靠、寿命长等突出优点,而且结构与加工工艺较简单,与国外目前较新的几种同级别单中间轴变速器相比较,如西德的ZF变速器、瑞典SCANIA的GR860和VOLVO的SR61、法国BERLLET的BRL3和NM9150、苏联的RM3201和日本尼桑的THM501等,它们性能指标不及FULLER双中间轴变速器,但精度要求、制造难度均超过后者。按我国当前的工艺水平,借鉴后者的设计与制造技术在品质上较易过关。此种变速器虽多一个中间轴总成,只不过增加了零件数量,质量并未增加,高效生产可弥补所增成本,更因它工作可靠性好、寿命长,在使用中可增效益、减损耗,使它所获总的经济效益是可取的。我国现引进了此种变速器的制造技术,对促进我国汽车变速器的设计、制造技术迅速达到世界先进水平将起到积极作用。此外,此种变速器设计构思周密、新巧,设计、试验方法严谨,有助于开拓思路,这是具有长远意义的。附录ATHEANALYSISOFFULLERTWINCOUNTERSHAFTSTRANSMISSIONSTRUCTURESHARACTERISTICSFULHAMFULLERBECAUSEAMERICANEATONISTWINCOUNTERSHAFTSTRANSMISSIONEATONCOMPANYOFTHE60SORIGINALPRODUCTS,IN1965PATENTAPPLICATION,ANDTHENPUTINTOPRODUCTION,SUPPLYMARKETITISAIMEDATTHECONDITIONOFDESIGNWHENTHEUSHASGRADUALLYBUILTHIGHWAYSYSTEM,INORDERTOIMPROVETHEECONOMICBENEFITTOFREIGHTCARS,TRUCKS,ANDFASTPACETOLARGE,SPECIALTYDIRECTIONINTHEUNITEDSTATESMOREPREVALENTMODEOFTRANSPORTATIONISBYTHESADDLETYPETRACTORTRAILERANDCARPULLEDTHETRACTORISTHETRAIN,THEMAINROADWITHHEAVYCARMODELS,ITSCHARACTERISTICISSHORTWHEELBASE,INADDITIONTOTHEUSHIGHWAYLAWCAPSTHECARBEFOREHANGINGMUSTNOTBEMORETHAN800,ANDCONSEQUENTLYMAKETWINCOUNTERSHAFTSTRANSMISSIONMSHAFTTOSIZEISVERYLIMITEDTHENEEDSOFTHEDEVELOPMENTOFSURFACEBUTREPEATEDREQUESTSTOIMPROVETHECARENGINEPOWER,ANDCORRESPONDINGENLARGESTHEBEARINGCAPACITYOFTHETRANSMISSION,THISTOTHETRADITIONALSINGLEAXISTWINCOUNTERSHAFTSTRANSMISSIONFOR,ITSAXIALDIMENSIONSMUSTINCREASETHUSHADACONTRADICTION,DOUBLETHEAXISISTHATTHETWINCOUNTERSHAFTSTRANSMISSIONINSUCHASITUATIONOFTHETIMESLOOKSUNFAMILIARITGREATLYIMPROVETHETWINCOUNTERSHAFTSTRANSMISSIONTORQUECAPACITYFULLERPRODUCTSHASREACHED2240,LARGESTANDDECREASESTHEAXIALNMDIMENSIONSITSUPPLYMARKETINTHEUNITEDSTATES,AFTERTHEHEAVYCARGRADUALLYREPLACEDTHETRADITIONALSINGLEAXISTRANSMISSIONEIGHTYSITALMOSTEXCLUSIVEAMERICANHEAVYVEHICLETWINCOUNTERSHAFTSTRANSMISSIONMARKETINCLUDINGEATONCOMPANYPRODUCTSACCOUNTEDFORABOUT75SINCETHEMIDSEVENTYS,EATONPRODUCTSINREDUCINGNOISEANDIMPROVELIFEANDRELIABILITYHAVEINCREASEDSIGNIFICANTLYANDINTHETWINCOUNTERSHAFTSTRANSMISSIONBASICSTRUCTUREUNDERTHECONDITIONOFINVARIABLE,ANDHASSUCCESSFULLYDEVELOPEDSERIESPRESENTATIONOFANEWGENERATIONTRANSMISSIONATTHESAMETIME,ADJUSTEDTHEORIGINAL,REDESIGNTHEPRODUCTSERIESANDREALIZESTANDARDIZATIONEIGHTYSHASTHENEWSERIESPRODUCTIONTHISPAPERISBASEDONTHEORIGINAL900SERIESNAMELYTHENEWSERIES11600,BOTHTHESAMEBASICSTRUCTUREOFRT915TYPEGROUPSTRUCTUREOFTHEDESKTOPTWINCOUNTERSHAFTSTRANSMISSIONFORANEXAMPLECENTFOLDFIGUREA1FULLERTWINCOUNTERSHAFTSTRANSMISSIONTHEFIRSTSHAFTLORDBOXBOXAXIALTHESECONDLORDBOXINTHEAXISRLORDBOXINREVERSETHAFTAXISVICEBOXVICEBOXOUTPUTSHAFTBHIFTJOINTSSETVICEBOXHIGHLOWSYNCHRONIZERJOINTSSETSVICEBOXSUPERCHEAPSYNCHRONIZERJOINTSSETOFZR2LORDBOXINREVERSEPRESENCEWHEELATTACHEDA1RT915TYPETHEBASICSTRUCTUREOFTRANSMISSIONFIGUREA1SHOWSISTHERT915TYPETWINCOUNTERSHAFTSTRANSMISSIONSTRUCTUREDIAGRAM,ITCONSISTSOFAMAINFIVEGEARBOXANDAREARTIMESOFTHREEGEARSHIFTCOMBINATIONTOVICEBOX,ITHAS15FORWARDGEARSANDTHREEINREVERSETHELORDBOXANDVICEGEARBOXWHICHIS14843CENTERDISTANCETHEYEACHHAVETWOSETSOFMINTERMEDIATEBEARINGASSEMBLY,ALLTHEGEARFORSPURGEAR,OFTENMESHINGTYPETRANSMISSION,BOTHONTHEOUTPUTSHAFTGEARAREFLOATING,LORDBOXOUTPUTSHAFTALSOFLOATTHEBOXWITHOUTTHEFILESYNCHRONIZER,VICEBOXWITHHIGHCHEAPLOCKINGPINTYPESYNCHRONIZER,ULTRALOWINERTIABYOUTERPROFILEOFMATINGTYPESHIFTDEVICETHEBOXFOREACHFILEMECHANICALHANDMANIPULATION,VICEBOXEVERYFILEADOPTEDTHEPNEUMATICCONTROLSHIFTWHENVICEBOXSYNCHRONIZERJOINTSSETWITHMATINGSETOFAREMOVEDTOTHEMATINGPOSITIONWHENTHELEFTANDTHETWINCOUNTERSHAFTSTRANSMISSIONWEREATHIGHSPEEDAREA,LOWSPEEDAREA,SUPERLOWSPEEDAREA,EQUIPPEDWITHFIVERATIOFORSELECTIONATTACHEDA2STRUCTUREANALYSISATTACHEDA21DUALAXISPOWERDIVERSIONFIGUREA1SHOWSTWINCOUNTERSHAFTSTRANSMISSIONBOXANDVICEBOXTHELORDHADTWOSETSOFTHEAXISASSEMBLY,INPUTPOWERPOINTSTOTWOROADAXISASSEMBLY,AGAINBYTHEOUTPUTSHAFTASSEMBLYWILLBETWOROADAFTERMIXINGPOWEROUTPUTINPUTANDOUTPUTSHAFTOFTHEGEARHASATTHESAMETIMETWOTEETHONTHEAXISOFTHETWORESPECTIVELYWITHGEAR,WORKBYLOADPERTOOTHSTRUCTUREISCONCERNED,BECAUSETHERELATIVESINGLEREDUCED1/2,INFACT,INTHEORY,THETOOTHSHAPEERROR,THETOOTHTHICKNESSERROR,THECENTERDISTANCE,THEERRORONTHEAXISGEARANDCORRESPONDINGMESHLOADINGNOTEVEN,MAKETHEACTUALREDUCETHEVALUEOFLESSTHAN1/2THISSITUATIONTHANSINGLEAXISTRANSMISSIONDOUBLETHEAXISHASOBVIOUSADVANTAGESATTACHEDA211DUALAXISGEARSLIFEINVIEWOFTHEFATIGUELIFEOFGEARWITHITSLOADOFTHREETIMESABOUTSQUAREOFINVERSERATIO,THEFORMULAISASFOLLOWSCONSTANTTYPEA13PNCTYPEPGEARLOADNFATIGUEDAMAGEOFGEARTOOTHCYCLESTHETYPETHATASINGLETOOTH,A1POWERTWINCOUNTERSHAFTSTRANSMISSIONCASES,GEARLOAD,THECORRESPONDINGFATIGUEDAMAGECYCLETIMESWHENDOUBLETEETH1P1NPOWERTRANSMISSION,EVERYSINGLETOOTHLOAD,AFORMERTHEORY,THATIS,THE2P21/PLOWERHALFOFTHECORRESPONDINGFATIGUEDAMAGEATTHISTIME,THATSAME32CYCLICNUMBERTRANSFERTORQUE,DOUBLETEETHPOWERTRANSMISSION,THEFATIGUELIFEOFGEARCANBEINCREASEDGREATLYIFKEEPGEARFATIGUELIFE,THATIS,THECONSTANT21N,THISSHOWSTHATTHEFATIGUELIFEOFGEAREQUAL,DOUBLETEETHPOWER21PTRANSMISSION,EVERYSINGLETOOTHCANBEINCREASEDBYTHELOADTO,CANIMPROVE1/P1PATIMESIFTHEWORSTOFTHEACTUALSITUATION,ACCORDINGTOCONSIDER,TWOTEETHLOADDISTRIBUTIONNONUNIFORMCOEFFICIENTFOR06,BYCALCULATINGKNOWTHATTHETORQUECAPACITYSTILLCANBEINCREASEDBY67THISISDOUBLETHEAXISONTHEBASISOFWHICHTHEDESIGNPRINCIPLEOFTHETWINCOUNTERSHAFTSTRANSMISSIONFACTSATTACHEDA212DOUBLETHEAXISCENTERDISTANCETRANSMISSIONTHEAXISOFGEARTWINCOUNTERSHAFTSTRANSMISSIONOFCENTERDISTANCETOTHEFOLLOWINGFORMULATYPEA23MAX1AEGKBTIHTYPEBTHELOADDISTRIBUTIONNONUNIFORMCOEFFICIENTFOR052060BYTYPEA2,ITISKNOWNTHATTHECENTERDISTANCEGEARISSINGLEAXISSTRUCTUREREDUCE15TO20,THISTOIMPROVETHETWINCOUNTERSHAFTSTRANSMISSIONEFFICIENCYANDLIGHTWEIGHTHASTHEIMPORTANTMEANING,WEKNOWTHATGEARCENTERDISTANCEISREDUCED,QUALITYCANREDUCEALOTTHEREFORE,THECENTERDISTANCEGEARISGEARTWINCOUNTERSHAFTSTRANSMISSIONINTHEDESIGNTHEMOSTBASICPARAMETERS,ITAFFECTSTHETWINCOUNTERSHAFTSTRANSMISSIONMANYOFTHEIMPORTANTPERFORMANCEINDEX,ANDDIRECTANDGEARTWINCOUNTERSHAFTSTRANSMISSIONANDSTRUCTUREDESIGNOFCARRYINGCAPACITYHASCLOSERELATIONSHIPFORALONGTIME,TOREDUCETHETWINCOUNTERSHAFTSTRANSMISSIONOFTHEDOMESTICANDFOREIGNTRADITIONALGEARFROMCENTERMADEUNREMITTINGEFFORTS,EVENTUALLYBECAUSEOFBEARING,MATERIALBYTECHNOLOGICALLEVELANDSHIFTTHEDESIGNANDMANUFACTUREOFSYNCHRONIZERINTOTHETECHNICALLEVELOFTHECHECKANDLITTLEPROGRESSTHEAXISOFTHESTRUCTUREOFTHEDOUBLEAPPEAR,BECAUSEPOWERDIVERSIONHASGREATLYIMPROVEDTHEGEARS,BEARINGSANDTHEAXIS,THELOADINGCONDITION,ANDMAYREDUCETHEPROCESSINGACCURACYREQUIREMENT,ANDCANTHEREFOREDONOTONLYENSURETHETWINCOUNTERSHAFTSTRANSMISSIONPERFORMANCE,ANDREDUCEDTHEGEARFROMTHECENTERDUETOTHESTRESSOFGEARTWINCOUNTERSHAFTSTRANSMISSIONGEARWITHAMORETRADITIONALNEARLYHALF,ITCANBEREDUCEDTOABOUT40OFTHEREDUCEDWIDTH,ALREADYREDUCEDTHETWINCOUNTERSHAFTSTRANSMISSIONSHAFTTOSIZE,ANDKEEPTHEBEARINGCAPACITYOFTHEGEAR,WITHIMPROVEDLOADOFTHETOOTH,ANDTOIMPROVETHEDISTRIBUTIONOFGEARLIFEATTACHEDA22GEARFLOATINGTHEBOXONTHEOUTPUTSHAFTGEARATTHESAMETIMEANDTHETWOSYMMETRICALLYARRANGEDONTHEAXISOFGEARENGAGEMENT,ITINTWOGEARSCANBEALONGRADIALDIRECTIONBETWEENFLOATING,RELYONMESHINGROUNDSELFCENTERING,VICEBOXALSOISSUCHTHISISBECAUSEOFTHESTRUCTUREOFTHEDOUBLEFULLERTWINCOUNTERSHAFTSTRANSMISSIONCHARACTERISTICS,ITSADVANTAGEIS1TOMAKETHEOUTPUTSHAFTGEARANDTWOONTHEAXISGEARMESHING,ANDCORRECTEVENLYDISTRIBUTEDLOAD2TELLTHETRADITIONALTWINCOUNTERSHAFTSTRANSMISSIONOUTPUTSHAFTINALLOFTENMESHINTHENEEDLEBEARINGTHENEEDLEBEARINGISTHEWEAKNESSESINTRADITIONALTWINCOUNTERSHAFTSTRANSMISSIONSTRUCTURE,CANCELIT,TOIMPROVETHETWINCOUNTERSHAFTSTRANSMISSIONOFLIFEANDTHEWORKINGRELIABILITYHAVEOBVIOUSFUNCTION3ONGEARPRECISION,ACCURACYANDTHESHAFTBEARINGHOLEPOSITIONPRECISIONCANREDUCEREQUIREMENTS4MAKETOOTHSHAPEBYTHEERROROFDYNAMICLOADLESSOFANEFFECT5TESTSHOWSTHATTHEMESHINGCANREDUCETHEFLOATINGSTRONGRESONANCENOISEINTENSITYATTACHEDA23THEARRANGEMENTOFTHESHAFTANDSTRESSTHESECONDSHAFTFORTHEBOXFLOATINGSTRUCTURE,TWOAXISBACKENDANDVICEBOXDRIVEGEARSPLINECONNECTION,ANDTHROUGHTHEBEARINGCANSUPPORTONTHEENCLOSURESHAFTFRONTSHAFTNECKANDOILBEARINGRADIALCLEARANCEOFTHEBIGSHAANXIAUTOMOBILEWHEELFACTORYMEASUREMENTFORTHE09,THESHAFTISTHEFULCRUM,FRONTAFTERMFLOATINGTHEREFORE,THESECONDSHAFTGEARAREFLOATING,SHIFT,INTHESECONDSHAFTOFTHEOUTERPROFILEOFENGAGEMENTWITHFLOATING,FACILITATECHANGEGEARSHAFTFIGUREA1SHOWS,THEAXISOFTHECENTREOFTHEATTACHMENTANDTHEANGLEABETWEENHORIZONTAL,FULLER19ANGLE,THISISTOOSMALL,IFWILLMAKETHEWIDTHDIMENSIONINCREASE,STIROILLOSSINCREASES,THELOSSISTHEMAINFACTORSOFINFLUENCETWINCOUNTERSHAFTSTRANSMISSIONEFFICIENCYIFTOOMUCH,ISTHESIZE,ANDINCREASETHEHEIGHTABOVEBEARINGBADLUBRICATIONCONDITIONSYMMETRICALARRANGEMENTOFTHEAXISMAKEFIRSTSHAFT,DOUBLETHESECONDSHAFTGEARBYRADIALFORCEBALANCEEACHOTHER,MAKETHISSECONDSHAFTUNDERBENDINGMOMENT,ANDARENOTONLYBEARTORQUE,PUTCANMAKETHEFIRSTAXIS,THESECONDSHAFTDIAMETER2THEAXISALSOTHISBYBENDINGMOMENT,CANMAKETHESHAFTDECREASE1/2ENSUREENOUGHTHISISINTERMEDIATEBEARINGSTIFFNESSDESIGNSHOULDBETHEMAINCONSIDERATIONQUESTION,TOIMPROVETHEWORKINGCONDITIONSOFTHEGEARANDBEARING,THISTORAISESGEARANDBEARINGLIFEANDREDUCETHENOISEISFAVORABLEATTACHEDA24SOLVETHEBEARINGSUSELIFEPROBLEMBYTHAT,INPUTSHAFTANDTHEOUTPUTSHAFTBEARINGSBYCOMPOSITIONOFRADIALFORCETOZERO,TWINCOUNTERSHAFTSTRANSMISSIONGEARSFORSTRAIGHTTEETH,NOAXIALFORCE,BEARINGUNDERGRAVITYONLYTHEAXISOFTHEBEARINGBYRADIALFORCENEARLY1/2,REDUCEWITHOUTAXIALFORCEALLBEARINGLOADCONDITIONSHAVEBEENGREATIMPROVEMENT,THISISCAUSEDSUCHTWINCOUNTERSHAFTSTRANSMISSIONBEARINGLIFELONGBASICFACTORSINADDITION,THEONEENDOFTHEINTERMEDIATEBEARINGVICEBOXSTILLUSEDBEARINGCAPACITYOFSTRONGROLLERBEARING,ALREADYWONTHEBENEFITSOFLARGECAPACITY,BUTALSOBECAUSEOFTHEAXISMUSTBEADOPTEDTOSUPPORT,ANDSEPARATESWIMMINGTYPETYPEBEARINGSWITHCONVENIENTFOLDTOTHEBOXISACOMMONTYPETHOUGHBEARINGTHEREST,BUTCOMPAREDWITHTHETRADITIONALTWINCOUNTERSHAFTSTRANSMISSIONCOEFFICIENTOFITSLIFE,BUTMANYHIGHDEPUTYBOXOUTPUTSHAFTISMADEUPOFTWOTHEOUTFITSCIRCULARCONEROLLERBEARINGS,ACCORDINGTOTHEANALYSISOFTHEMAINSUPPORTISTOENHANCETHECANTILEVEREDSHAFTSTIFFNESSANDSTABILITY,ANDINCREASETHEBEARINGCAPACITYINBEARINGLOADISSMALL,ASFARASPOSSIBLEINCREASEBEARINGCAPACITY,CANRISEALREADYBEARINGLIFE,TOTHATOFTHETWINCOUNTERSHAFTSTRANSMISSIONADAPTTOLIFEALWAYSANDENHANCETHESTIFFNESS,STRENGTHENTHEFUNCTIONINGOFTHESHAFTRIGIDITY,ENSUREGEARMESHING,IMPROVETHECORRECTLIFEANDREDUCENOISETHENEWSERIESOFPRODUCTSTOREDUCENOISE,ANDTHENEWDESIGN,SOASTOIMPROVETHEBEARINGTHEBEARINGQUALITYTHEACTUALAPPLICATIONRESULTFULLERDOUBLECENTRALAXISINTHETWINCOUNTERSHAFTSTRANSMISSIONWITHIN480000KILOMETERS,THELIFEWITHOUTCHANGINGBEARINGTHESAMELEVELINTHEVALUEOFTHEWORLDSBESTLEVELINTRANSMISSIONATTACHEDA25THELORDWITHOUTSYNCHRONIZERANDTHEBOX,TYPECLUTCHCOOPERATEWITHSHIFTEDGEARSFULLERDOUBLETHEAXISTWINCOUNTERSHAFTSTRANSMISSIONBOXHASNOTADOPTEDTHESYNCHRONIZER,BUTTHEOUTERPROFILEOFMATINGTYPESHIFTDEVICENORMALLY,FORLARGECAPACITYFORTHETWINCOUNTERSHAFTSTRANSMISSIONTORQUE,DUETOTHELARGEINERTIAGEAR,BIG,SHIFTINENTERINGWHENTHESPEEDOFTHEDIFFERENCEOFTHELARGERMESHINGBETWEENGEARFROMTHEIMPACTISBIGALSO,CAUSESHIFTDIFFICULTTHEREFORE,WESHOULDADDSYNCHRONIZERBUTTHESYNCHRONIZER,TOSOLVETHECURRENTPROBLEMOFITSSERVICELIFEBIGTORQUECAPACITYOFTHESINGLEAXISTWINCOUNTERSHAFTSTRANSMISSIONISWESTGERMANYGOVERNMENTISWORLDFAMOUSPRODUCTS,THEREARESTILLASYNCHRONIZEREARLYDAMAGE,THEPROBLEMINTHEWORLDEACHPRODUCTIONMANUFACTURERALSOHAVEBEENSOLVEDFULLERDOUBLETHEAXISTWINCOUNTERSHAFTSTRANSMISSIONBOXHASNOTADOPTEDTHESYNCHRONIZER,BUTFROMADEVICEWITHPULLMODEL,WITHASIMULTANEOUSSHIFTITISINTHEBOXONTHEFIRSTSHAFTINSTALLEDAFRICTIONBRAKEDISC,WHENSHIFTSEPARATIONCLUTCH,SEPARATEFORKPULLEDBACKBEARINGS,WILLFRICTIONBRAKEDISCPRESSURETOTHEFIRSTAXIS,BRAKEFIRSTSHAFTCOVER,TOSPEEDUPTHEPROCESS,ACCORDINGTOTHEGEARSYNCHRONOUSTHIS,ITCANONLYMAKETHEFIRSTSHAFTFOR,SOCANONLYSLOWMOVEMENTINPLACETHESTARTUPANDUSE,ANDCANTSHIFTINDOWNWARDSHIFTWHENUSEDINTHEDESIGNPRINCIPLE,STRUCTUREANDCALCULATIONONTHEPRACTICEOFEXPLORATORY,FROMTHEPRINCIPLEANDSTRUCTURECANBEDONEONTHEUPANDDOWNWHENSHIFTALLCANUSEACCORDINGTOTHEANALYSIS,THEDEVICEINTHESIMPLIFIEDOPERATION,SHORTENTHETIMESHIFT,ASIMULTANEOUSSHIFTONCANBEASEFFECTIVEASSYNCHRONIZERSIMILARROLE,BUTFORTHISSTRUCTUREDOESNOTHAVESYNCHRONIZERISTHELOCKFUNCTION,TOREALIZENOIMPACTSHIFT,BUTALSODEPENDSONTHEDRIVEROFTHEOPERATIONOFPROFICIENCYEATONCOMPANYCLAIMEDTHATTHESHIFTININSTITUTIONSOFTHEENGAGEMENTOFTHESET,THESPLINETOOTHENDSANDTHECORRESPONDINGSPLINEGEARSBETWEENABIGHOLEAREDESIGNANGLEPOURINGINSHIFT,ITCANPLAYACERTAINPROCESSLOCKUPTHEROLETHISKINDOFUNIQUESHIFTAGENCIESFROMTHEUNITEDSTATES,HEAVYDUTYTRUCKGENERALLYUSETHESITUATION,ISSUCCESSFUL,IFVIAIMPROVEDEXPECTEDTOCOMPLETELYREPLACETHESYNCHRONIZERFUNCTION,TOCANCELSYNCHRONIZERPURPOSESOTHEBENEFITSOFTHEOBVIOUS,ITAVOIDEDTHESYNCHRONIZERTHISDIFFICULTPROBLEM,ANDTRANSMISSION,IMPROVETHELIFETHEWEAKNESSESINTHEWORKOFTRANSMISSION,SIMPLIFYTHESTRUCTURERELIABILITYTRANSMISSION,MAKEITSAXIALDIMENSIONSCUTSHORT,QUALITY,REDUCETHEEASEOFTECHNOLOGYANDMATERIALSTODEMANDHIGHERPARTS,MAKETHETWINCOUNTERSHAFTSTRANSMISSIONCOSTREDUCEDATTACHEDA26THESTRAIGHTTEETHGEARTRANSMISSIONFULLERDOUBLETHEAXISTWINCOUNTERSHAFTSTRANSMISSIONBOXANDLORDOFALLGEARVICEBOXUSESTHESTRAIGHTTEETHGEARMESHINGTWINCOUNTERSHAFTSTRANSMISSIONATHOMEANDABROAD,OFTENTORQUECAPACITYISRAREINTRANSMISSIONINADDITIONTODEPUTYBOXDRIVEGEARISTHESINGLEDIAMETERTEMPERANCEGEAROUTSIDE,AREMORETHANDOUBLEDIAMETERTEMPERANCESHORTGEARS,LORDBOXANDVICEBOXOFEACHSHIFTGEARSAREONEFROMEACHKINDOFTHEFESTIVAL,6/7AND5/7RESPECTIVELY,CONVERTEDTO432/363AND508/363MODULENEWSERIESOFTHEPRODUCTS,THEMODULUSGEARPRESENTATIONISLESSTHAN127THETOOTHSHAPE,EASYTOFORMMORESLENDERGEARMESHINGTHELORDALLGEARPAIROFGEARBOXFOR22TO23OFGEARTEETH,ALLGEARTOOTHSHAPEBYSMALLANGLEANDDEFLECTIONISFIXEDINORDERTOACHIEVETHENEWTRAFFICREGULATIONSFORNOISELIMIT,EATONFORNEWPRODUCTSTOTAKETHEFOLLOWINGMEASURES1IMPROVETOOTHSHAPESTRUCTURE2IMPROVETHESUPERPOSITIONCOEFFICIENTVICE3IMPROVETHEPRECISIONPRESENTATIONTHANTHICKTOOTHGEARSERIESPRECISIONHIGHLEVEL,ISMAKESERIESLOADDISTRIBUTIONAMONGGEARTEETHUNIFORM4IMPROVEBEARINGQUALITY5IMPROVETHERIGIDITYGOODRESULTSHAVEBEENACHIEVED,NEWSERIESPRODUCTISOLDPRODUCTSTOREDUCENOISEINTENSITYBY57DBANALYSISTHECHARACTERISTICSOFSTRUCTUREABOVE1ALLADOPTTHESTRAIGHTTEETHGEAR,TOTHEDOUBLEINTEGRALOFTHEINTERMEDIATEBEARINGSTRUCTURE,EASYTOASSEMBLYASSEMBLYANDCOLLAPSE2USINGSHORTTEETHGEARSYSTEMCANENHANCETHEGEARBENDINGSTRENGTH,BUTATTHESAMETIME,THEYHAVEALSOMADETHESTRAIGHTTEETHGEARCOINCIDENCE,THEDEFECTSOFSMALLCOEFFICIENTBYSMALLTEETHSHAPEANGLEANDMORETOTHETEETHMESHAREAS,ITCANMAKEUPTHEDEFECTS,NEWSERIESOFPRODUCTSTOTHESUPERPOSITIONCOEFFICIENTREACHES22THETRADITIONALDESIGNSUPERPOSITIONCOEFFICIENTAROUND15ONLYSWEDENSCANIACOMPANYPRODUCESTHEGR860MAINTWINCOUNTERSHAFTSTRANSMISSIONADOPTSFULLINCLINEDGEARMESHINGTRANSMISSION,ITSOFTENHEAVYMACHINE,COEFFICIENTOF145TO168THEIMPROVEMENTOFSUPERPOSITIONCOEFFICIENTCANIMPROVETHEGEARINGMESHPERFORMANCE,TESTSHOWSTHAT1TOREDUCETHENOISE2MAKEISTHEINFLUENCEOFSURFACEFATIGUELIFEOFGEARWASOBVIOUSLYIMPROVEDFORTOOTHFACEPRESSUREDECREASE3THECOINCIDENCEDEGREECOEFFICIENTOFLARGEGEARIMPACTRESISTANTABILITYTHANSUPERPOSITIONCOEFFICIENTLOWGEARBYTHEFORMERLOADDISTRIBUTIONISMOREHOMOGENEOUS,THISABILITYISHEAVYAUTOTWINCOUNTERSHAFTSTRANSMISSIONISREQUIRED3WITHSMALLTEETHSHAPEANGLEWILLREDUCETHESTRENGTH,THEROOTISADOPTEDDEFLECTIONISMODIFIED,INORDERTOENHANCESTRENGTHOFTOOTHROOTGEAR4INORDERTOGUARANTEETHEBOXONTHEAXISWITHTHEFIRSTTWOGEARSHAFT,THESECONDSHAFTGEARCANATTHESAMETIME,ALSOMAKETHESECONDSHAFTMESHINGGEARSCANWILLLOADONEVENLYDISTRIBUTEDTOTWOAXIS,SOSHOULDGUARANTEETHEFIRSTAXIS,THESECONDSHAFTGEARTHENUMBEROFTEETHAREEVENONTHEGEARAXISALLHAVEATOOTHISLOCATEDINTHESAMELONGITUDINALPLANEINSIDE,ANDALLOFTHESAMEMODULUSGEAR7FORGEARTEETHSMALLERDIAMETER,WIDEISNARROWER,FACILITATETHEPULLTEETHANDSHAVINGTEETHANDOTHERHIGHEFFICIENTPROCESSINGMETHODPRODUCTIONTHEROADTESTRESULTSSHOWTHATTHEAVERAGEOPERATION640000KILOMETERSOFTHENEWSERIESPRODUCTS,THERELIABILITYCOEFFICIENTWAS92,90AT800000KMNOTONLYTHATSUCHTWINCOUNTERSHAFTSTRANSMISSIONOFSIMPLESTRUCTURE,GOODTECHNOLOGY,ANDRELIABLEWORK,LIFEINDEXINTHEADVANCEDWORLDLEVEL,DURABLE,EASYTOMAKEASUCCESSFULEXAMPLEATTACHEDA27THELORDBOX,VICEBOXANDTHESTRUCTURECHARACTERISTICSTHEFULLERDOUBLETHEAXISTWINCOUNTERSHAFTSTRANSMISSIONSERIESISTWOKINDSOFTHECENTERDISTANCE135128AND14843OFTHEFIVEGEARBOXFORBASIC,TAKEMTHELORDBOXANDCLICKUNITVARIANTCOMBINATIONPRINCIPLE,ANDDIFFERENTCOMBINATION,REALIZEAFTERVICEBOXSERIALIZATIONOFPRODUCTSSTANDARDIZATIONMANYVARIETIES,PRODUCTIONFIGURE1BOXINTHESTRUCTUREDESIGNISVERYDISTINCTIVE,THEVARIANTISTOKEEPAWAYFROMTHESAMECENTERINGEARANDTHERESTOFTHEPARTSINADDITIONTOTHEGEARBASICDONTCHANGEINTHE18TOGEARDIFFERENTCOMBINATIONS,TOGETEIGHTDIFFERENTRATIOOFCOMBINATIONOFLORDBOXANDASSHOWNINFIGUREA1SHOWS,INTHEFULLSETOFPARTSDOESNOTCHANGE,ONLYCHANGEGEARGEAR,GEARANDASSEMBLYANDPOSITION,1Z32Z4ANDALSOCANGETAFTEREXCHANGEWITHTHEOVERDRIVELORDBOX,SOTHATTHEENTIRESERIESPRODUCTSDUOZHONGINCREASEVARIANTNEEDTOREPLACEPARTSTOTAKETHECOMBINATIONOFTHESPLINECONNECTIONSTRUCTURETHEFIRSTAXIS,THESECONDSHAFTALLGEARHOLEFORTHESAMESPECIFICATIONSOFTHESPLINEHOLE,MAKEGEARACCORDINGTONEEDCONVERSIONINSTALLATIONANDSOTHETOOTHOFTHEENGAGEMENTOFSHIFTINSTITUTIONSANDEACHFILE,GENERALMAINBOXEASYTOREALIZETHEFORM,ALSOCANREALIZEFORSTRENGTHBECAUSETHEENTIREPRODUCTPARTSGENERALIZATIONDEGREEISASHIGHAS70ABOVE,GREATSHOW,WHEREPRODUCTIO

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号