MMW7660卧式双端面磨床改进设计【说明书+CAD】

收藏

资源目录

压缩包内文档预览:(预览前15页/共41页)

编号:10052887

类型:共享资源

大小:833.28KB

格式:RAR

上传时间:2018-04-24

上传人:柒哥

认证信息

个人认证

杨**(实名认证)

湖南

IP属地:湖南

33

积分

- 关 键 词:

-

mmw7660

卧式

端面

磨床

改进

改良

设计

说明书

仿单

cad

- 资源描述:

-

【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得,所见即所得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:12401814

- 内容简介:

-

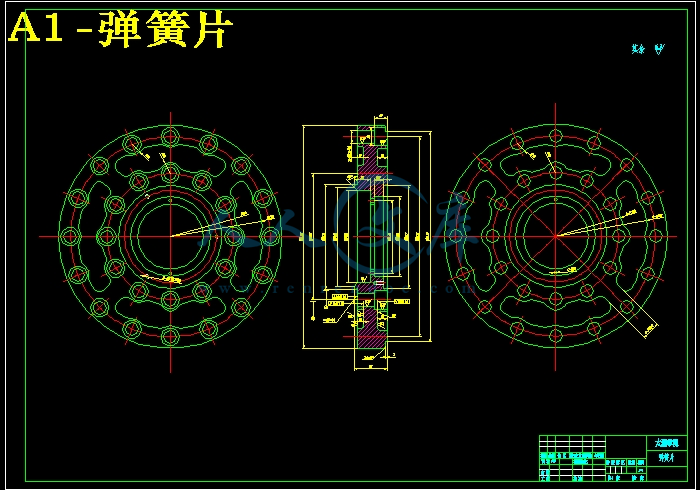

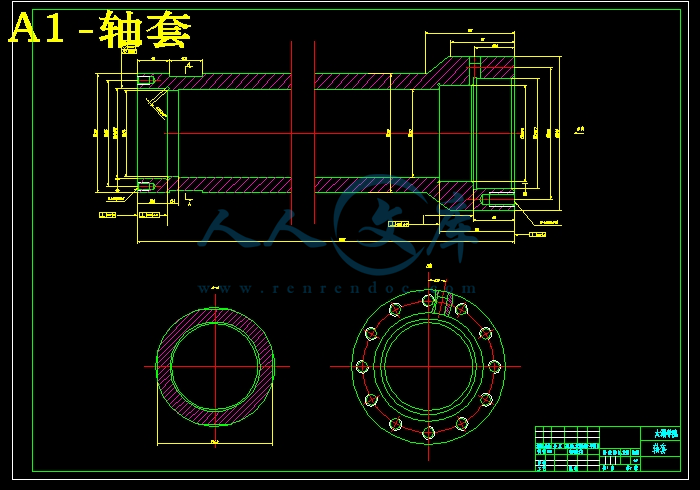

无锡太湖学院信机系机械工程及自动化专业毕业设计论文任务书一、题目及专题1、题目MMW7660卧式双端面磨床改进设计2、专题二、课题来源及选题依据本课题来源于无锡开源机床集团有限公司合作改造项目。对磨床进行数控改造提高加工精度。三、本设计(论文或其他)应达到的要求完成MMW7660卧式双端面磨床的改造方案设计,绘制左磨头装配图一份完成MMW7660卧式双端面磨床改进零件设计,绘制零件图各一份;完成设计说明书一份,有分析、比较和必要的计算。四、接受任务学生机械95班姓名赵原五、开始及完成日期自2012年11月12日至2013年5月25日六、设计(论文)指导(或顾问)指导教师签名签名签名教研室主任学科组组长研究所所长签名系主任签名2012年11月12日编号无锡太湖学院毕业设计(论文)相关资料题目MMW7660卧式双端面磨床改进设计信机系机械工程及自动化专业学号0923233学生姓名赵原指导教师许菊若(职称副教授)(职称)2013年5月25日目录一、毕业设计(论文)开题报告二、毕业设计(论文)外文资料翻译及原文三、学生“毕业论文(论文)计划、进度、检查及落实表”四、实习鉴定表无锡太湖学院毕业设计(论文)开题报告题目MMW7660卧式双端面磨床改进设计信机系机械工程及自动化专业学号0923233学生姓名赵原指导教师许菊若(职称副教授)(职称)2012年11月25日课题来源本课题来源于无锡开源机床集团有限公司合作改造项目。科学依据(包括课题的科学意义;国内外研究概况、水平和发展趋势;应用前景等)双端面磨床是一种在现代工业中应用非常广泛的高效加工设备,它是平面磨削加工机床的一个重要分支。双端面磨床的优点是磨削效率高、自动化程度高、不用吸盘夹持和加工精度高,在诸如汽车制造、轴承、工具、压缩机制造等行业有广泛的应用。据有关文献介绍,早在1894年美国的GARDNER与BESLY合伙制造了世界上第一台端面磨床,1912年由GARDNER公司制造出第一台双端面磨床。经过近百年的发展与演变,使双端面磨床成为许多行业中关键的高效加工设备。双端面磨床的工件两端面同时被连续磨削,加工时间与工件上下料等辅助时间重合,加工效率高,适合于大批量生产。磨削工件时,不必采用电磁吸盘夹持,这样可以避免工件有剩磁。特别是在用吸盘进行薄型工件磨削时,由于工件易翘曲变形,必须进行反复数次磨削。双端面磨床适合加工薄型工件。此外,还适合磨削非磁性材料与非金属材料。双端面磨床能连续磨削工件,可以在机床上配置自动测量、自动补偿、自动上下料等机构。因此,双端面磨床要比一般平面磨床自动化程度高,适宜在自动线上联机生产,是一种有前途的具有生命力的机床。研究内容1熟练掌握MMW7660卧式双端面磨床的工作原理与结构。2熟悉掌握MMW7660卧式双端面磨床进给运动过程中的结构设计与受力分析并对进给部分进行改进。3将滑动导轨改进为滚动导轨,采用伺服电机并对丝杆螺母部分进行改进。拟采取的研究方法、技术路线、实验方案及可行性分析总结本磨床的基本结构,工作方式与原理。然后根据考察的结果,再查阅相关书籍,确定基本的设计参数。交由指导老师检查,修改。完成后,再对主要载荷部件进行校核。最后出主要零件的零件图,编写设计说明书。研究方法首先是根据砂轮架主轴的要求进行轴的设计,然后再选取轴承,设计皮带和皮带轮等等。研究计划及预期成果研究计划2012年10月12日2012年12月31日按照任务书要求查阅论文相关参考资料,完成毕业设计开题报告书。2013年1月1日2013年1月27日学习并翻译一篇与毕业设计相关的英文材料。2013年1月28日2013年3月3日毕业实习。2013年3月4日2013年3月17日本磨床的的主要参数计算与确定。2013年3月18日2013年4月14日本磨床总体结构改造设计。2013年4月15日2013年4月28日零件图及二维画图设计。2013年4月29日2013年5月21日毕业论文撰写和修改工作。预期成果根据提供的主要构件参数而计算出的传动构件的参数,尺寸及机体等是合理的,并且通过对本磨床四杆螺母和进给部分的改进,最终提高本磨床的精度,效率及自动化程度。特色或创新之处本磨床在布置上有对称的两个模头,拖板进给机构,并采用定程系统,进给补偿和修正均采用机动,一般能自动卸料,实现全自动化,较方便,纳入自动线成本较低。通过对四杆螺母和进给部分的改造,使该机床从精度,效率自动化程度来看是一种有前途的具有生命力的机床。已具备的条件和尚需解决的问题1实验方案思路已经非常明确,已经具备使用CAD制图的能力和了解MMW7660双端面磨床的原理结构等知识。2使用CAD制图能力尚需加强。3准确的计算校核有待完成。指导教师意见指导教师签名年月日教研室(学科组、研究所)意见教研室主任签名年月日系意见主管领导签名年月日英文原文DIGITALSYSTEMINTHEHORIZONTALGRINDERAPPLICATIONOFTHESTATUSQUOANDDEVELOPMENTRAYMONDCOOPERMODERNINDUSTRIALPRODUCTION,SMALLANDLARGEPARTSFORTHEPRODUCTIONOFPRODUCTSOFTHEINCREASINGPROPORTIONOFPARTSCOMPLEXITYANDPRECISIONREQUIREMENTSRAPIDYINCREASE,THETRADITIONALGENERALMACHINETOOLSHASBECOMEINCREASINGLYDIFFICULTTOMETTHEREQUIREMENTSOFMODERNPRODUCTION,ANDAHIGHPRECISIONCNCMACHINETOOLS,HIGHEFFICIENCY,THEUSEOFAMANCHINECANCOMPLETECOMPLETYPEFACEPROCESSINGCHARACTERISTICS,INPARTICULARTHERAPIDDEVELOPMENTOFCOMPUTERTECHNOLOGYANDTHEWIDESPREADUSEOFDIGITALSYSTEMS,DIGITALDEVICESFROMALMOSTALLMAJORSOFTWAREFUNCTIONSTOACHIEVE,ALMOSTTOAHARDWARE,THEREBYMAKINGITMOREFLEXIBLEPROCESSING,FUNCTIONALSTRONGERMANUFACTURINGCOMPETITIONFROMLOWERLABOURCOSTSEARLY,PRODUCTCOSTANDIMPROVETHEIROVERALLEFFICIENCYANDQUALITIYOFCOMPETITION,TOMEETCUSTOMERDEMANDSCOMPREHENSIVE,ACTIVELYDEVELOPNEWPRODUCTSCOMPETITIVE,WILLFACEKNOWLEDGETECHNICALUPDATEDPRODUCTSHASBECOMESHORTERANDSHORTER,ANINCREASINGNUMBEROFSMALLPRODUCTS,ANDTHEQUALITY,PERFORMANCEREQUIREMENTSAREHIGHER,MEANWHILECOMMUNITYTOENVIRONMENTALPROTECTION,THEGROWINGAWARENESSOFGREENMANUFACTURINGTHEREFOREADVANCEDMANUFACTURINGTECHNOLOGYWILLBEQUICKLYWONTHECOMPETITIONANDSURVIVALOFTHEENTERPRISE,THEPRINCIPALMEANSOFDEVELOPMENTCOMPUTERINFORMATIONTECHNOLOGYANDMANUFACTURINGAUTOMATIONTASANIMPORTANTFOUNDATIONFORDIGITALMACHINEINTHEPRODUCTIONOFMACHINETOOLSTOSHAREMOREFIRSTDIGITALPINGFINDSTHESTATUSQUOANDDIGITALSYSTEMSPRIMARILFIRST,DIGITALPINGFINDSTHESTATUSQUOANDDIGITALSYSTEMSPRIMARILYHORIZONTALGRINDERCOMPAREDTOTHELATHE,MILLINGMACHINE,USINGDIGITALSYSTEMSLATER,THESPECIALREQUIREMENTSBECAUSEOFITSDIGITALSUSTEMSINTHEPASTDECADE,WITHTHETECHNICALFACILITY,GRINDER,THEGRINDINGWHEELFORREPAIR,AUTOMATICCOMPENSATION,AUTOMATICEXCHANGEGRINDINGWHEEL,ANDMOREWORKSTATIONS,SUCHASAUTOMATICTRANSMISSIONANDZHUANGJIAWORKINGINOPERABLEREALIZED,ANDDIGITALTECHNOLOGYINTHEHORIZONTALGRINDER,GRADUALLYSPREADINRECENTHANOVER,TOKYO,CHICAGO,ANDOTHERLARGEDOMESTICMACHINETOOLEXHIBITION,CNCGRINDERTHROUGHOUTTHEGRINDER,FORTHEMAJORITYOFTHEEXHIBITS,SUCHASGERMANYBLOHMCOMPANYELBCONPANIESSUCHFAMOUSGRINDERFACTORIESNOLONGERPROUDCEORDINARYGRINDERJAPANESEFORCES,JAPAN,LOWDIGITALPINGHIMSELFGERMANPRODUCTIONCOMPANYAFEWYEARSAGOELBBRILLIANTSERIESTWOCOORDINATESFACILITYSHAPEDGRINDER,THEVERTICALANDHORIZONTALAXISFORDIGITAL,VERTICALFORHYDRAULICCONTROL,GRINDINGWHEELREPAIRWORKPLATFORMINSTALLEDINAROLLERDIAMONDS,THEAPPLICATIONOFBRODADERSUPERBRILLIANTSERIESISONEDIMENSIONALANDSHAPEDGRINDERSSNZUOBIAOFACILITY,THEBEDSAREMANUFACTUREDUSINGNATURALGRANITE,HIGHGEOMETRICACCURACY,SLIDEAWAYFROMSTRAIGHTROLLINGGUIDE,DRIVINGWITHOUTRECOILINGMACHINERY,THUSENSURINGABETTERWORKINGSURFACESMOOTHNESSBRILIANTFUTURESERIESOFIMPROVEMENTSTOTHEABOVETWOPRODUCTS,USINGARTIFICIALGRANITEBEDWASPRODUCEDBYSTATICPRESSUREVERTICALGUIDE,CHIXINGBELTTRANSMISSION,VERTICALANDHORIZONTALGUIDEFORPREREINFORCEDSTRAIGHTROLLINGGUIDE,GUNZHUSIGANGTRANSMISSION,THREEAXISCNCCONTROLACSERVOELECTRICAL,MEASURING05M16UGIMAGEELBCOMPANYHASALSODEVELOPEDTHELATESTTECHNOLOGYGRINDERCONTEMPORARYPRODUCTS,ANDINTEGRATIONWITHCOMPUTERANDTECHNOLOGYBASEDSERIESOFSOFTSKILLSCAMMASTERPROCESSINGMODULESCADMASTERSERIESANDCOMPACTMASTERSERIESGRINDINGPROCESSINGCENTER,AMAXIMUMOFUPTO24AXISCONTROLAXIS,ASTHEFULLIMPLEMENTATIONOFMODULARDESIGNANDANUFACTUREOFDEDICATEDGRINDERCYCLESHORTENEDELBCOMPANYHASALSODEVELOPEDAVARIETYOFHIGHLYEFFICIENTDEDICATEDGRINDER,SUCHASSFVG100/2DEDICATEDGRINDER,WHICHWILLTILTMOTOU,CONTINUOUSIMPROVEMENTS,TOEASEINTO,PROCESSINGCENTERBRITISHANDAMRRICANCOMPANIESJONESINTERFACETOTHEWINDOWOPERATINGSYSTEMTOINCREASETHEMOUSEREMOTEOPERATIONOFVEHICLESFANUCMAJORCOMPANYTHISYEARLAUNCHED18,16I,20I,21ISYSTEMSIEMENSIS840D,810D,802DARETIGHTSTRUCTURETYPESYSTEMTHEREAREANUMBEROFMANUFACTURERSSUCHASTAIWANPRECISIONCNCCONTROLSONTHEUSEOFTHEWINDOWOPERATINGSYSTEMOFNC,ANDNTIMMEDIATEMULTIPROCESSINGCORE,SINGLESECTIONPROCEDURESFORPROCESSINGSPEED2000PIECES/S,SINGLESECTIONPRE1000TIMETODEALWITHAFEWPIECES,WITHAARTPREADAPTATIONTECHNOLOGIESANDTHEPARAMETERSOFTHEBESTLEARINGFUNCTIONWOULDFOLLOWERRORCONVERGENCETOZERO,THESOFTWAREPROCESSINGPATHFILTERTOREDUCEMACHINGPROCESSGENERATEDBYTHEACCELERATIONCHANGESEXCESSIVEMECHANICALRESONANCE,THEREBYIMPROVINGSURFACEROUGHNESSWITHTHEUSEOFSERVOFLEXIBLE,WITH,10VANALOGYSERVOINTERFACEITALSOPROVIDESINTERNATIONALSTANDARDSSERCOSDIGITALSERVOCOMMUNICATIONSINTERFACEDESIGNTIXINGTU;PLCPROCEDURES,STRUCTUREEXPRESSIONS,FUNCTIONALPIECES,INSTRUCTIONSCODE,FLOWCHARTS,FIVEFACILITATEDESIGN,COMMUNICATIONANDMAINTENANCELONGRANGECOMMUNICATIONSWITHTHECOMPUTER,INSTANTREMOTEMAINTENANCEFUNCTIONSCONTROLCANBEEXTENDEDTOAMAXIMUMAXLEANDSPINDLEAXIS64I/OPOINTSWHICHCANBEEXPANDEDTO792/528POINT,THEINTRODUCTIONOFPENTIUMPROCESSORS,HIGHSPEEDPLCPROCESSINGSPEEDTO25KAPARTFROMTHEWORLDFAMOUSSIEMENS,FANUCDIGITALSYSTEMS,SUCHASPROFESSIONALDEVELOPMENTANDPRODUCTIONOFTHEPLANTHASBEENAPPLIEDTOMANYHORIZONTALORSHAPEDGRINDINGSYSTEM,ANUMBEROFPRODUCTIONPLANTSPINGFINDSITSELFACTIVELYDEVELOPEDAPPLICATIONINTHEDIGITALGRINDERSYSTEMNOTABLYSIEMENSSINUMERIK840DOFTHESYSTEM,THESYSTEMHASMORETHAN20ROOTSSERVOAXIS,THECOORDINATESFORTHETRIPCONTROL,MANUALDATAENTRYORIMPORTEDTHROUGHEXTERNALCOMPUTER,REMOTEDIAGNOSISMAYREDUCETHEGRINDINGWHEELDIAMETERCHANGEITINERARY,GRINDINGWHEELREPAIROFAUTOMATICCOMPENSATIONGUNZHUSIGANGGAPERRORCOMPENSATION,SIEMENS3GSYSTEMISSPECIFICALLYFORGRINDINGANDPROCESSINGDEVELOPMENT,FORBOTHDIALOGUEWITHTHEPRESENTATIONDEVICESOPERATEINAXISTILT,CANALSOBESTRAIGHTANDARCWIDELYINGRINDING,RECURRINGOPERATIONALCYCLE,SUCHASTHEMAINAXISSWING,ANDUSEEXTERNALSIGNALINTERRUPTIONIMPLEMENTATIONPROCEDURES,GRINDINGWHEELCUT,GRINDINGWHEELREPAIR,ANDOTHERSPECIALFUNCTIONSFORTHEPREPARATIONOFAFIXEDCYCLEPROCEDURESNOTONLYCANUSEITSEXTERNALMEASUREMENTDEVICESSWITCHESSIGNAL,BUTWHENCONNECTEDTOASUITABLETIMETOFIRSTMEASUREMENTANDCONTROLDEVICESDIRECTLYTOTHEULTIMATESIZECOMPARISONAMERICANCOMPANIESALLEYBRANDLYPRODUCTION8400CNCDIGITALSERIESAPPLYLATHE,MILLINGMACHINEANDGRINDER,8400CNCUPTO6ROOTSSERVOAXISCONTROL,THESECTION2AXLEMAYDRAIN,THETHREEAXISMAYHELIXSPACED,SIXAXLESTRAIGHTDRAIN8600CNCSERIESOFCOORDINATESTOCONTROL17,INCLUDINGEIGHTINTHEDRAINAXLE,EIGHTSPACESCONTROLAXLEANDONEALLEGATIONTHATAGRAPHICSHOWNTHATTHEEXPANSIONOFBRANCHPROCEDURESTHATPROCESSINGTIME,HIGHSPEEDACCESSPROCEDURES,CUTLERYLIFEMONITORINGFUNCTIONJAPANESECOMPANIESDEVELOPEDFANUCOGHIGHSPEEDHIGHPERFORMANCEDIGITALSYSTEM,WHICH0GSGAPPLICABLETOHORIZONTALGRINDER,THEGRINDINGPARTSUNDERDIFFERENTSHAPES,FOURDIFFERENTMETHODSOFGRINDING,AGRINDINGWHEELAXLEANGLECYCLEOFGRINDINGWHEELFLOWPOSITIONAFTERFINISHINGCOMPENSATIONFUNCTIONCOMPAREDTOREPAIRVEHICLESWEREREPAIREDROUNDNOEMALLINEDIRECTIONCONTROLFUNCTIONALGRINDINGWHEELSHAPEGRAPHICSANDGRINDINGPARAMETERSSHOWTHATTHEFUNCTIONAL,SYSTEMSMALLESTUNITSET0116UGM,A“TIGHT”TYPEDIGITALSYSTEMS,LOWERPRICESTHEREAREALSOCOMPANIESSUCHASGERMANYANDUNIVERSITYJOINTLYDEVELOPEDBYELBUNICONSYSTEMJAPANESEBIGCOVEIRONWORKEROSP5000GG,OSP30NFSUCHASSELFDEVELOPMENTANDSHAPEDGRINDINGDIGITALPRINTSYSTEM,THEMAXIMUMCONTROLOSP5000GGNINECOORDINATES,WHICHCANBELINKEDSIXCOORDINATESA12INCHHALL,INTRACTIVEPROGRAMMING,AUTOMATICIDENTIFICATIONOFCUTTINGFACTORUSEDDIKRTTESIMPORTED,INTOAUTOMATEDSYSTEMSTHESMALLESTPULSEEQUIVALENT,THEMOBILEEQUIVALENTANDTESTINGEQUIVALENT16UGARE01M,PINGHIMSELFALSOUSEDSIMULTANEOUSLYBYTHEENTIRELOOPDETECTORSALTHOUGHTHEREISTHEPINGHIMSELFFACTORYUSINGDIGITALZHUJICHANGSYSTEM,BUTSELFDEVELOPMENTOFSOFTWARE,USEITMORESUITABLEFORHORIZONTALANDSHAPEDGRINDING,SUCHASGERMANCOMPANYSIEMENSSINUMERIK810JUNGBASED,THECOMPANYSPECIALIZEDSOFTWAREUSEDBYJUNGKONTURPROGRAMMINGLANGUAGEFORASHAPEDGRINDINGWHEELREPAIR,ANDGRAPHICSSUPPORTINGOPERATIONALFUNCTIONSJAPANSINCERELYCOMPANIESINFANUCDIGITALSYSTEMSHARDWARECOMPANIES,THEOPLDEVELOPMENTLANGUAGEFORGRINDINGPROCESSING,ANDSOONTHELINERELECTRICAL,BALANCE,TECHNOLOGY,THEGROWINGDUEPROCESS,ANDGREATLTENHANCETHEEFFICACYOFACHINETOOLS,THEAPPLICATIONOFAPPROPRIATEMEASUREMENTTECHNIQUESFORTHEDEVELOPMENTSINCETHESTARTOFPRODUCTIONDIGITALHORIZONTALGRINDER1980S,THEDEVELOPMENTOFMANUFACTURESHAVEDEVELOPEDSEPARATELY,THEDEVELOPMENTOFCOOPERATIONWITHUNIVERSITIESANDRESEARCHUNITSDIRECTTOINTRODUCEMATUREDIGITALSYSTEMSDEVELOPMENTFOREXAMPLEHANGZHOUMACHINETOOLPLANTISAHISTORYOF50YEARSOFPROFESSIONALGRAPHICGRINDEROFFACTORYPRODUCTION,WHICHBEGANPRODUCTIONINTHEMID1980SFROMDIGITALPINGHISSELF,HASDEVELOPEDAPRODUCTIONMGK7132STRAIGHTAXLERULETAIWANHIGHPRECISIONPINGHIMSELFINTO,MGK7120,MK7163,MK7150STRAIGHTAXLERULETAIWANDIGITALPINGHIMSELF,MKY7760VERTICALSHAFTDIGITALHZK2010,HZ050CNC,HZKD2010,HZK3015,HZK3020,SUCHASDEDICATEDDIGITALDRAGONGATETYPEHZK4020HORIZONTALGRINDERANDGUIDETHEDEVELOPMENTANDAPPLICATIONOFSYSTEMS,DEVELOPEDINCOOPERATIONWITHUNIVERSITIESANDSCIENTFICRESEARCHUNITSINSHANBANJISYSTEM,BUTALSOFORSELFDEVELOPMENTTOTHEMAINFRAMECHANPIANJITHESIMPLECONTROLSYSTEM,ANDTHEUSEOFDIGITALZHUJICHANGMATUREDIGITALPRODUCTIONSYSTEMPINGFIDNSITSPRODUCTIONMGK7120HIGHPRECISION,THECOMPANYINTRODUCEDJAPANFANUCMATEDPURCHASEDDIGITALRECORDINGSYSTEMTOCONTROLMOTOUCHIN,CHINTOTHESMALLESTVOLUME0116UGM,ACOMPLETEAUTOMATICGRINDINGCYCLEFUNCTIONSMKY7650/0101CARRYNOODLESGRINDERISFULLYAUTOMATICDIGITALDOUBLETECHNICALCOOPERATIONWITHIRALIANCOMPANYVIOTTOPRODUCTSUSINGSINMENSSIMATICS5115UPROGRAMMABLECONTROLLERCONTROLCRTDISPLAY,MACHINETOOLSLEFTRIGHTMOTOUDRIVENBYTHETWOAXISDCSERVOELECTRICAL,MACHINETOOLSCAPABLEOFMANUALANDAUTOMATICGRINDINGCYCLEOFADJUSTMENTOPTIONSEQUIPPEDWITHITALIANMAERBOSIE9MEASUREMENTSYSTEMS,THEFIRSTTWOMEASUREMENTS,AMEASUREMENTGRINDINGWHEEL,GRINDINGWHEELWEARANDTEAROFFEEDBACKTOTHECONTROLSYSTEM,ABRASIVEWHEELSCOMPENSATIONANOTHERMEASUREAFTERHERFIRSTMEASUREMRNTSGRINGING,ANDMEASUREMENTSGRINDING,SANDMEASUTEMENTSOFTHECONTROLSYSTEMINTOTHESERVOCOMPENSATIONFORELECTRICALLEFTANDRIGHTMOTOUUSEDFORPOSITIONMEASUREMENTVIOTTORASTERCONTROL,HAVINGACHIEVEDAWHOLESETSFROMTHEEXPECTEDCOMPLETIONOFTHEENTIRELOOPGRINGDINGANDFULLYAUTOMATICPROCESSINGHZ050CNCDIGITALLINEARROLLINGGUIDEDEDICATEDGRINDERISTHESHANGHAISCIENCEANDTECHNOLOGYFORTHEPRODUCTIONOFKEYINDUSTRIALPROJECTSINTHETHIRDRESEARCHANDDEVELOPMENTPROJECTDEDICATEDGRINDERBOTHFUCTIONALANDSHAPEDGRINDINGFLATGRINDINGFUCTION,ANDITHASADOPTEDTHEUSCOMPANYAB8400MPDIGITALPRODUCTIONSYSTEM,ASEVENKANDIGITALAXISMACHINETOOLS,X,Y,ZINTOTHREEROOTSMOTOUTOAXLEANDU,V,W3ROOTGRINDINGWHEELREPAIRAXLEDIRECTCONTROLBYTHESYSTEM,ANOTHERQFORTHEHORIZONTALGRINDINGWHEELHORIZONTALAXISINTOTHEONEDIMENSIONALWITHGRINDINGTHROUGHSLCPROGRAMMABLECONTROLLERPLUSWIFEPOSITIONINGMODULE,THEMAINFRAMESYSTEMI/OIMPORTED8400MPCONTROLITSPOSITION,WITHCONTINUOUSIMPROVEMENTSINTHEGRINDINGGRINGDING,GRINDINGWHEELORGAPTYPEGRINDINGWHEELTOREPAIRSUCHAUTOMATICPROCESSINGINTCOMPENSATIONHZKD2010SISAXLEDOUBLEMOTOUDRAGONGATEDIGITALGRAPHICGRINDER,USINGFANUCOMCDIGITALSYSTEMS,USINGFOURROOTSCNCAXISCONTROLTWOSEPARATEHORIZONTALANDVERTICALINTOMOTOUTOUSEAPMCPERIPHERALMOUTOUCONTROLOFTHEGRINDINGWHEELAXLEREPAIRVEHICLESLORDSCHINTOTHEOTHERROOTSPMCAXISCONTROLALMIGHTYMOTOUSUBDEGREEROTATIONTAKEFULLADVANTAGEOFTHESYSTEMPERFORMANCE,REDUCEPRODUCTIONCOSTSANDENHANCETHEXINGJIABIOFMACHINESTOOLTHISPAPERPRESENTSANALTERNATIVECENTERLESSGRINDINGMACHINETECHNOLOGY,THATIS,THROUGHFEEDSURFACEGRINDERCENTERLESSGRINDERINTHENEWMETHOD,ACOMPACTCENTERLESSGRINDERUNITS,GUIDES,ULTRASONICCRAWLER,ABLADEOFTHEIRRESPECTIVEHOLDERS,MOUNTEDINASURFACEGRINDERTABLEATTHEWORKPIECEISFEDINTOANDTHROUGHFEEDCENTERLESSGRINDINGMACHINEOPERATIONISPERFORMEDGUIDESTHESPACEBETWEENTHEGRINDINGWHEELANDTHEULTRASONICCRAWLERULTRASONICCRAWLER,THEMETALELASTICBODYISBONDEDTOTHEPIEZOELECTRICCERAMICPRODUCTION,INCLINEDATASMALLANGLEINORDERTOPROVIDESUFFICIENTSTRENGTHTOCONTROLTHEROTATIONALMOVEMENTOFTHEWORKPIECE,ANDFEEDTHEULTRASONICELLIPTICALVIBRATIONOFTHEWORKPIECEALONGITSAXISINTHISARTICLE,THEMOVEMENTOFTHEWORKPIECECONTROLWEMUSTFIRSTENSURETHATTHEWORKPIECESPEEDANDFEEDRATECANCOMPLETELYCONTROLTHEULTRASONICCRAWLER,WHICHISAHIGHPRECISIONGRINDINGOPERATIONISESSENTIALTHEN,THEMAINPROCESSPARAMETERS,SUCHASTHEECCENTRICANGLEOFTHEWORKPIECE,THECUTTING,THEULTRASONICCRAWLERINCLINATIONANGLEOFTHEMACHININGACCURACYOFTHEAPPLIEDVOLTAGEAMPLITUDEIE,THEROUNDNESSOFTHECYLINDRICALWORKPIECEANDTHEWORKPIECEWERECLARIFIEDEXPERIMENTTHERESULTSOBTAINEDSHOWTHAT1THEWORKPIECEROTATIONALSPEEDCANBEADJUSTEDBYCHANGINGTHEAMPLITUDEOFTHEAPPLIEDVOLTAGE,BYFEEDRATECANBECHANGEDBYAPPLYINGAVOLTAGEMAGNITUDEANDTHEULTRASONICCRAWLERINCLINATIONANGLEOFADJUSTMENT2THETOPOFTHEECCENTRICANGLEOF6,ALARGERCUTTINGASMALLERINCLINATIONANGLE,ORTHEHIGHERTHEAPPLIEDVOLTAGEISBETTERFORHIGHERMACHININGACCURACY3ANDROUNDNESSOFCYLINDRICALWORKPIECEFROMTHEINITIALVALUE1663M1486MIMPROVEMENTFINALLY,THEOPTIMUMGRINDINGCONDITIONSUNDER149MICRONSAND074MICRONSKEYWORDSCENTERLESSGRINDINGSURFACEGRINDINGMACHINEULTRASONICVIBRATIONTRACKRUNSTHROUGHTHEFEEDROUNDNESS1INTRODUCTIONCENTERLESSGRINDINGMACHINE,HIGHEFFICIENCYOFTHEMANUFACTURINGPROCESS,HASBEENWIDELYUSEDINHIGHPRECISION,HIGHPRODUCTIVITYMACHININGCYLINDRICALPARTS,SUCHASBEARINGRACEWAYS,INGOTS,ACUPUNCTUREDEVICEANDCATHETERINTHEMANUFACTURINGINDUSTRY,THETWOTYPESOFCENTERLESSGRINDINGMACHINECANBEPURCHASEDONEISTOADJUSTTHEROLLERSANDTRACKTHEYAREDIFFERENTFROMONEANOTHERWORKPIECEISHOWTOSUPPORTANDHOWTOCONTROLTHEWORKPIECESPEEDGRINDINGSELFADJUSTINGWHEELTYPECENTERLESSGRINDINGMACHINEOFTHEINVENTIONBYTHE1915ANAHEIMYONETSU,1966,ALOTOFRESEARCHHASBEENCOMMITTEDTOIMPROVETHEPRECISIONANDEFFICIENCYROWEANDBARASH1964PROPOSEDACOMPUTERSURVEYMETHODOLOGYINHERENTTHECENTERLESSGRINDERACCURACY,TAKINGINTOACCOUNTTHEGEOMETRICFACTORSANDELASTICDEFLECTIONMACHINEROWEETAL1965THEPROCESSINGOFTHEEXPERIMENTALELASTICPARAMETERSROWEANDKOENIGSBERGER1965,DESCRIBEACHARTANDDISCUSSIONOFTHEMETHODOFANALYSISOFADERIVEDSTABLETHRESHOLDWORKINGRECYCLEDCORRUGATEDWORKPIECEINCENTERLESSGRINDINGENCOUNTEREDDYNAMICMACHINECHARACTERISTICSANDGEOMETRICEFFECTSINTHETHEABRASIVEOPERATINGSYSTEMCONFIGURATIONMIYASHITADEFORMATIONOFTHECONTACTAREAANDTHEESTABLISHMENTOFCONDITIONSOFFREEDOMOFCHOICEOFTHEDYNAMICMODELCHATTER,EXPERIMENTALSTUDYOFHIGHREMOVALRATEGRINDINGPROCESSANDOPTIMIZETHEGRINDINGCONDITIONSWUETAL1996TOCLARIFYTHEEFFECTSOFGRINDINGPARAMETERSBYCOMPUTERSIMULATIONMETHODSROUNDNESSERRORSTUDYTHEGEOMETRYOFTHECENTERROUNDEDBELOWTHECENTERCENTERLESSGRINDINGMACHINE,INORDERTOASSISTINTHECHOICEOFSETTINGCONDITIONSGOLD2003DESCRIBESA3DGRINDERMODELTAKESINTOACCOUNTTHECONTACTLINEBETWEENTHEGRINDINGWHEELANDTHEWORKPIECESURVEYTHROUGHFEEDCENTERLESSCYLINDRICALFORMATIONMECHANISMOFTHEGRINDINGPROCESSKRAJNIKETAL2008DEVELOPEDANANALYTICALMODELTOASSISTINEFFICIENTCENTERLESSGRINDERSYSTEMSETTINGSHIGHERPROCESSINGFLEXIBILITYANDPRODUCTIVITYDRAZUMERICETAL2010DISCUSSEDANDADOPTEDBYTHEFEEDCENTERLESSGRINDINGPROCESSSIMULATIONINAVIRTUALENVIRONMENT,ITISBASEDONTHEANALYSISOFTHEGRINDINGGAPMODELGRINDINGGAPMACROGEOMETRYANDWORKPIECEDYNAMICSANDAVOIDCONTACTWITHISSUESRELATEDTOTHENORMALOPERATIONOFTHECONTROLWHEELANDTHEWORKPIECEBETWEENLOSSONTHEOTHERHAND,CRAWLERTYPECENTERLESSGRINDERALSOATTRACTEDTHEATTENTIONFROMINDUSTRYANDACADEMIADESIGNEDTHEVACUUMOFHYDROSTATICCRAWLERINCREASELOADCAPACITYANDSTIFFNESSOFTHETRACKCENTERLESSGRINDINGMACHINEFORHIGHPRECISIONAPPLICATIONSINAPLANEPROPOSEDTHEEFFECTIVENESSOFTHEDYNAMICMODELDISPLAYHYDROSTATICCRAWLERIMPROVESTABILITYSURVEYTRACKEDTHEBASISOFCENTERLESSGRINDERFIXTUREMECHANISMSYSTEM,ANDPRESENTSATHEORETICALMODELTOPREDICTDRIVINGGRINDINGSYSTEMTHEABILITYTORESOLVETHEFIXTURESTABLEINADDITION,DEVELOPEDA2DGEOMETRICMODELFORECASTTRACKCENTERLESSGRINDERLOBEGENERATIONANDMODELANALYSISOFTHEGRINDINGPROCESSFROMTHEPRODUCTIONCOSTPOINTOFVIEW,THETWOTYPESOFTHECENTERLESSGRINDINGMACHINEISVERYSUITABLEFORTHEPRODUCTIONOFSMALLSPECIESANDLARGEVOLUMETHELOADING/UNLOADINGOFTHEWORKPIECEISVERYEASYANDFASTHOWEVER,THECENTERLESSGRINDINGMACHINEASPECIALPURPOSEMACHINESANDMOREEXPENSIVE,ITDISADVANTAGESALARGEVARIETYANDSMALLBATCHPRODUCTION,INRECENTYEARS,THERAPIDINCREASEINDEMANDASASOLUTIONTOTHISPROBLEM,THEAUTHORSPROPOSEANEWCENTERLESSGRINDINGMACHINETECHNOLOGY,YOUCANPERFORMSURFACEGRINDERBEFORETHISMETHODISBASEDONTHECONCEPTOFULTRASONICCRAWLERCENTERLESSGRINDINGMACHINEDEVELOPEDBYWUETAL2003,2004METHOD,ACOMPACTUNITBASEDULTRASONICELLIPTICALVIBRATIONCRAWLER,ABLADEOFTHEIRRESPECTIVEHOLDERSINSTALLEDONASURFACEGRINDERTABLETHISFUNCTIONULTRASONICCRAWLERCYLINDRICALWORKPIECEISHELDINCONJUNCTIONWITHTHEBLADEANDCONTROLTHEWORKPIECESPEEDONTHEENDFACEOFTHEELLIPTICALMOTIONACCORDINGTOTHERELATIVEMOVEMENTOFTHEWORKPIECEGRINDINGWHEEL,THREETYPESOFCENTERLESSGRINDINGOPERATIONISPERFORMEDINTHEPROPOSEDMETHODTYPETANGENTFEEDTYPE,FEEDTYPE,ANDTHROUGHTHEFEEDTHETANGENTIALFEEDTYPE,XU2010CREATED,TAKINGINTOACCOUNTTHEMODEL2DGRINDINGMACHINE,INORDERTOCLARIFYTHEELASTICDEFORMATIONOFTHEWORKPIECEROUNDINGPROCESSANDPROCESSPARAMETERSWORKPIECEROUNDNESS,SIMULATIONEXPERIMENTSCONFIRMTHERESULTSFURTHER,WUANDXU2010PROPOSEDANACTUALINCREASEINTHEMATERIALREMOVALRATE,ANDTH

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号