摘要

全自动V带分拣机是一种昂贵的高效能设备,所以在广大厂家中需要一种价格低廉又能够进行分拣工作的设备。本文介绍既能达到维修,调试,使用方便,又能达到高效能的一种半自动只能V带长度分拣机。主要研究内容有,设计了用于V带分拣,融PLC现代传感器技术机械气动于一体的机电一体化设备,利用现代传感技术,实现位移量于检测脉冲数之间的转换,通过对检测脉冲数分组,简介实现北侧带长的分组:组别标记号对应的打印脉冲次数,实现自动打印组别号标记。以PLC为控制核心部分实现智能化控制。根据V带日生产量大的特点,通过自动检测于打印一体化,实现了高效率检测。半自动智能的设计思想,使高科技于丰富人力资源实现了有机结合,适合国情。

关键词:分拣,PLC, 打印脉冲

Abstract

The sort of V-belt is a wide-used product. It is difficult to accomplish it by hand and the Auto-Sorter is effective but too expensive. So most of the sorts are done by selective exams.in this case,an efficient convenient and cheap V-belt sorter is in bad need。In this dissertation, the semi-auto V-belt sorter is developed to meet this need. It is typical mechatronic equipment。Auto-mask is realized by using sensor, PLC is used as a main controlling section. The technique of auto-sort and auto-mark can meet the need of the rapid massive production .the semi-auto design can take advantage of the rich human resources, which is more adoptable in China.

Key words: sort PLC exam pulse

目录

Abstract 2

第1章 绪 论 4

1.1引言 4

1.2分组分拣技术与分组销售 5

1.2.1分组分拣技术与分组销售的问题描述及解决方案特点 5

2、分拣技术 5

1.2.2半自动智能v带长度分拣机技术分析 7

1.3现代控制技术、检测技术现状分析 8

1.3.1可编程控制器(PLC)国内应用现状 9

2.1 引言 10

2.2总体设计的主要内容 10

2.2.1 V带分组性能指标 11

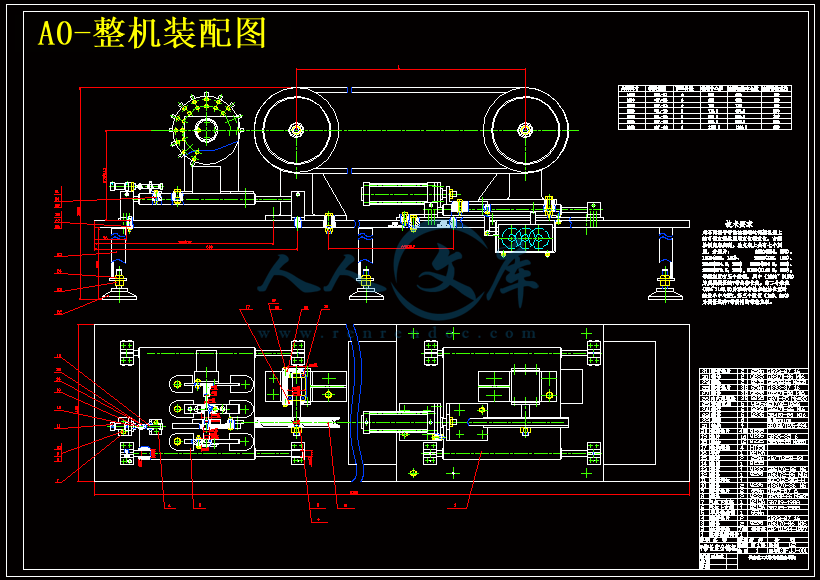

2.2.2总体方案 12

(Ld=1400 mm) 单位:mm 13

3.1引言 14

3.2位移检测 15

3.2.2.根据本机精度确定被测V带组段范围 16

3.2.3 分辨率提高器结构尺寸的设计 17

3.3自动打印标记 21

3.3.1 字头转动电机的选择 24

3.3.2 字头转动轴的设计 25

3.3.3 联轴器的选择 25

3.4设备各工作过程的控制 26

3.4.1 PLC控制特点及所选型号 27

4.1引言 28

4.2气动技术的主要特点 28

4.3气动装置设计 29

5.1引言 31

5.2检测带轮直径及结构设计 31

5.2.1固定式检测带轮 32

5.2.2夹紧式检测带轮 34

5.3初始中心距及基准中心距的确定、总自支架上的刻度 36

5.4检测带轮轴系以及机架设计 37

5.4.1 检测带轮轴的设计 37

(1).对导轨进行弯曲应力校核 41

5.6本章小节 43

参考文献 45

致 谢 46

第一章 绪 论

1.1引言

带传动是一种应用很广的机械传动,其中V带产生的摩擦力要比普通平带大得多,因此v带的传动能力比普通平带高,目前V带在机械中获得广泛的应用。V带已标准化,根据国家标准的规定,普通V带按剖面尺寸不同,分为Y, Z, A, B, C,D, E七种型号,V带是无接头的环形带,每种型号都有几种不同的周长。标准中将内周长度定为公称长度,长度从400-1600mm不等[1]。由于受单根V带所能传递功率之限制,在传递较大功率时,往往设置多根V带成组使用。但一般要求,为避免载荷在各根带上分布不均匀,带的根数不宜过多,一般不应超过9根。

V带的伸张层与压缩层由橡胶制成,强力层可由几层帘布或线绳制成。其公称尺寸受生产工艺、原材料等因素影响较大。事实上,目前各类规模生产厂家生产的同一型号、同一公称尺寸V带的长度误差值均较大(可达几十毫米,这在金属制品中是不可想象的)。由此造成在成组使用多根V带的传动中,尽管选用了某生产厂家的同一型号、同一公称尺寸的V带,但由于存在较大的长度误差,每根V带的张紧力相差很大。相对而言,张紧力较大的V带会过早的发生疲劳失效,如脱层,撕裂或拉断等;与此相反,张紧力较小的V带,承载能力没有完全发挥,甚至会出现打滑现象,整体传动效率降低,极大降低了带的预期寿命,难以达到设计的传动效果。只有减小一组带传动中带长的误差,方可提高传动能力。可采用如下两种途径加以解决:

1.从V带生产的制造工艺、原材料、生产过程控制等方面考虑提高单根带的公称尺寸精度。

川公网安备: 51019002004831号

川公网安备: 51019002004831号