锁壳冷冲压模具的设计【优秀】【word+15张CAD图纸全套】【冲裁压复合模具类】【毕业设计】

【带任务书+开题报告+评阅评语表+答辩资格审查表+工作中期检查表+指导教师评阅表+外文翻译】【35页@正文12800字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】

A0总装配.DWG

A1上模座.DWG

A1下模座.DWG

A3凸凹模.DWG

A3凹模.DWG

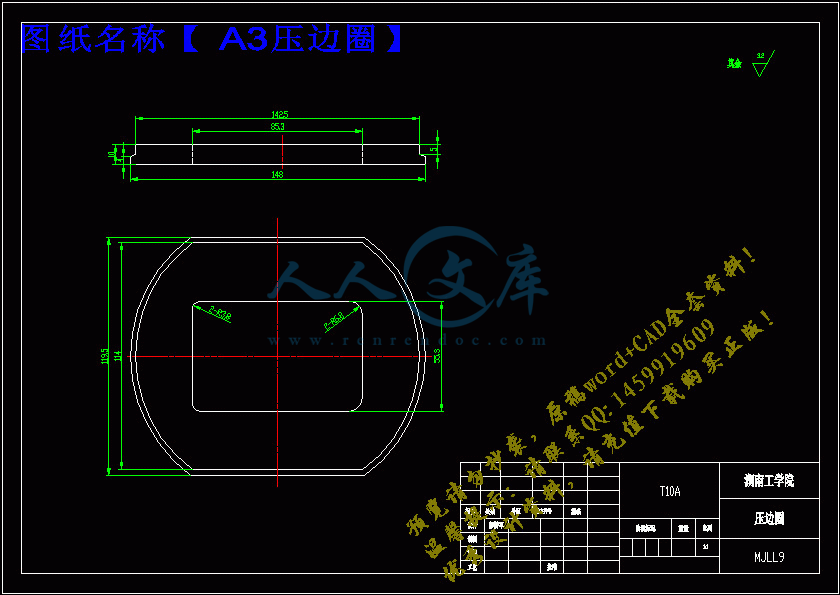

A3压边圈.DWG

A3固定卸料板.DWG

A3垫块.DWG

A3垫板.DWG

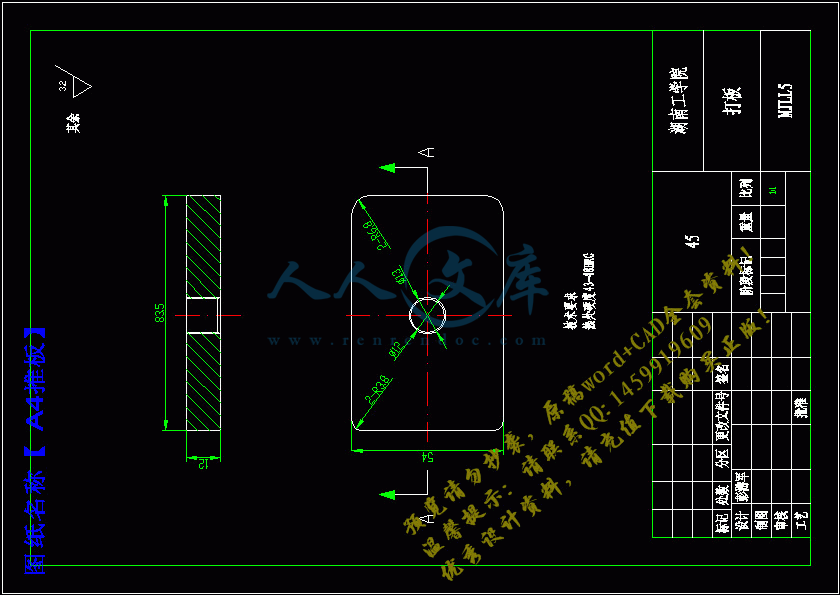

A4凸模.DWG

A4导套.DWG

A4导柱.DWG

A4推板.DWG

A4模柄.DWG

THE STRENGTHENING EFFECT OF ICOSAHEDRAL PHASE ON.PDF

任务书.doc

工作中期检查表.doc

开题报告.doc

指导教师评阅表.doc

正文.DOC

答辩资格审查表.doc

评阅评语表.doc

译文.DOC

零件图.dwg

任务书

课题名称锁壳冷冲压模具设计

内容及任务

根据所给定的冲压零件产品(如右图所示),设计出冲压模具。主要内容如下:

1、绘制产品零件图。

2、绘制模具装配图。

3、绘制整套模具零件图,标准件除外。

4、编写设计说明书。

5、自选一个重要模具零件编制加工工艺路线,进行相关的计算,并编制加工工艺卡和工序卡。

1绘制产品零件图。

拟达到的要求或技术指标按照“湖南工学院毕业设计(论文)工作管理规定”,本课题设计要求及技术指标如下:

(一)模具

1、保证规定的生产率和高质量产品的同时,力求成本低、寿命长。

2、模具结构设计合理,工艺性好,具有一定的创新性。

3、操作安全、方便,易于维修,便于管理。

4、在保证模具强度前提下,注意外形美观,各部分比例协调。

(二)设计图纸

1、模具绘图布局合理,视图完整、清晰,各项内容符合标准要求。

2、设计图纸应符合学校的要求,不少于3张零号图纸的结构设计图、装配图和零件图,其中应包含一张以上用计算机绘制的具有中等难度的1号图纸,同时至少有折合1号图幅以上的图纸用手工绘制。

(三)设计说明书

1、资料数据充分,并标明数据出处。

2、计算过程详细、完全。

3、公式的字母含义应标明,有时还应标注公式的出处。

4、内容条理清楚,按步骤书写。

5、说明书按照学校的有关规定,编写不少于12000字的设计说明书,同时上交电子文档。

(四)其他要求

1、查阅到10篇以上与题目相关的文献

2、翻译一篇本专业外文文献(10000个以上印刷符号),并附译文。

进度安排起止日期工作内容备注

2011年2月~ 5月

1周(2、21—2、28)

4周(2、28—3、25)

2周(3、28—4、10)

2周(4、11—4、24)

1周(4、25—5、1)

5周(5、2—6、3)

1周(6、6—6、10)

完成毕业设计的选题和开题报告;

进行毕业实习及调研;

进行工艺及结构设计;

绘制装配图和零件图;

对整个设计进行合理性检查;

撰写设计说明书及毕业答辩的准备;

毕业设计答辩。

主要参考资料[1] 中国标准出版社. 中国机械工业标准汇编冲压模具卷[M].北京:中国标准出版社,1998,12.

[2] 王立人,张辉.冲压模设计指导[M]. 北京:北京理工大学出版社, 2009,8.

[3] 牟林、魏峥.冷冲压工艺及模具设计(第2版)[M].北京:清华大学出版社,2009,7.

[4] 肖景容,姜奎华.冲压工艺学[M].北京:机械工业出版社,2006,3.

[5] 王芳.冷冲压模具设计指导[M].北京:机械工业出版社,2009,1。

[6] 模具实用技术丛书编委会.冲模设计应用实例[M].北京:机械工业出版社,2005,1。

[7] 冯炳尧?,韩泰荣,?蒋文森.?模具设计与制造简明手册[M].上海:上海出版社。2008,6

[8] 郑家贤.冲压工艺模具设计实用技术[M].北京:机械工业出版社,2005,1.

[9] 梁炳文.实用板金冲压工艺图集[M].北京:机械工业出版社,2003,8.

[10] 冲模设计手册编写组.冲模设计手册[M].北京:机械工业版社,2007,3.

摘 要

近年来,我国家电工业的高速发展对模具工业,尤其是冷冲模具提出了越来越高的要求,近些年,冷冲模具在整个模具行业中所占比例已上升到50%左右,据有关专家预测,在未来几年中,中国冷冲模具工业还将持续保持年均增长速度达到10%以上的较高速度的发展。国内冷冲模具市场以冷冲模具需求量最大,其中发展重点为工程冷冲模具。

冲裁成型是冷冲成型的一种重要方法,它主要适用于金属材料的成型,可以一次成型形状复杂的精密零件。本课题就是将锁壳冷冲压模作为设计模型,将冲裁模具的相关知识作为依据,阐述冷冲压模具的设计过程。

本设计对锁壳冷冲压模进行的冷冲压模的设计,对工件结构进行了工艺分析。明确了设计思路,确定了冲压成型工艺过程并对各个具体部分进行了详细的计算和校核。如此设计出的结构可确保模具工作运用可靠,保证了与其他部件的配合。最后用autoCAD绘制了一套模具装配图和零件图。

本课题通过对锁壳冷冲压模的冷冲压模具设计,巩固和深化了所学知识,取得了比较满意的效果,达到了预期的设计意图。

关键词:冲压模具;冲裁成型;模具设计

Abstract

In recent years, China's household electrical appliance industry in the development of high-speed tooling industry, in particular, have raised Die growing demands in recent years, the entire Die in a proportion of trade has risen to around 50 percent, according to the relevant Experts predict that in the next few years, China will continue to Die with industry to maintain an average annual growth rate reached over 10 percent of high speed development. Die with the domestic market to Die with the greatest demand, which focus on the development of a project Die.

Blanking is forming a cold-forming an important method, which apply mainly to the forming of metal materials, forming a complex shape of the precision components. The issue is to lock shell cold stamping die as a design model, will be punching die of related knowledge as the basis on cold stamping die design process.

The design of the lock shell of the cold stamping die of cold stamping die design, the structure of the workpiece Technology Analysis. Defined the design, determine the process of stamping and forming part of the specific details of the calculation and verification. So the structure can be designed to ensure that the use of reliable mold work to ensure that the co-ordination with other components. Finally, autoCAD drawing a mold assembly and parts plans.

The subject of the lock through the shell cold stamping die of cold stamping die design, consolidated and deepened by knowledge, has been relatively satisfied with the results, achieved the expected design intent.

Keywords :stamping die; blanking molding; die design

目 录

前 言15

1 工艺分析工艺方案的确定19

1.1 冲裁件的工艺性分析19

1.2 综合技术经济效益观念19

1.3 零件材料性能分析及工件工艺性分析19

1.4零件工艺性的分析21

1.5重视模具材料和结构的选择,保证有一定的模具寿命。21

1.6 确定工艺方案及模具结构形式22

2 工艺计算及排样方案24

2.1尺寸的确定24

2.2确定排样方式和计算材料利用率27

2.3搭边值的确定28

2.4冲压设备的选择29

3 工作零件设计31

3.1凹模的设计31

3.2凸模的设计33

3.3凸凹模具的设计34

3.4卸料板的设计35

3.5打杆的长度35

3.6压边装置的设计36

3.7顶杆的长度36

3.8根据国标选用导向机构36

3.9导柱加工工艺过程卡38

3.10橡皮垫的设计39

3.11模具的选择40

4 工作原理及装配图41

参考文献42

致谢44

前 言

模具在现代生产中,是生产各种工业产品的重要工艺装备,它以其特定的形状通过一定的方式使原材料成形。例如,冲压件和锻件是通过冲压和锻造方式使金属材料在模具内发生塑性变形而获得的;金属压铸件、粉末冶金零件以及塑件、陶瓷、橡胶、玻璃等非金属制件,绝大多数也是通过模具成形的。由于模具成形具有优质、高产、省料、低成本等特点,现已在国民经济各部门,特别是汽车、拖拉机、航空航天、仪器仪表、机械制造、家用电器、石油化工、轻工日用品等工业部门得到极其广泛的应用。

现在,模具技术已成为衡量一个国家产品制造水平的重要标志之一,研究和发展模具技术,对于促进国民经济的发展有着特别重要的意义。模具工业能促进工业产品生产的发展和质量的提高,并能获得极大的经济效益,因此引起各个国家的高度重视和赞赏。在日本,模具被誉为“进入富裕社会的原动力”,在德国则冠以“金属加工业中的帝王”,在罗马尼亚视为“模具就是黄金”。因此可以断言,随着工业生产的迅速发展,模具工业在国民经济中的地位将日益提高,模具技术也会不断发展,并在国民经济发展过程中发挥越来越重要的作用。

模具是高科技含量的产品,是专门为工业生产服务,并用于特定产品生产而被特殊制作的工艺装备,随着工业产品向多样化发展,模具生产从形状、尺寸、数量、材料、结构、精度、使用条件及寿命等方面,向着多样化发展的倾向也日趋明显。模具基本上是按订货合同单件生产,因此,模具产品的多样性及单件生产的技术特点十分突出。所以,工厂的设计、工艺、工艺装备和管理等,都要适应这个技术特点。大部分精密复杂模具都需要高精度机床加工,检测设备要求精密度更高。模具加工技术集中了机械、电子乃至化学和光学等工业技术的精华。同时,模具对熟练技工的依赖程度远比其他加工业要大。因此,技术的先进性及对熟练技巧的依靠性也是模具产品的技术特点。随着技术的快速发展,特别是信息技术等高新技术在模具设计制造上的应用日渐广泛和高新技术对模具提出的要求越来越高,模具的高新技术特点将日益明显,而对熟练技巧的依靠性将逐步淡化。

作为工业生产基础工艺装备,模具在国民经济中占有重要的地位,模具技术也已成为衡量一个国家产品制造水平的重要标志之一。80年代以来,我国模具工业发展十分迅速。国民经济的高速发展对模具工业提出了越来越高的要求,也为其发展提供了巨大的动力。这些年来,中国模具工业一直以15%左右的增长速度快速发展。目前,中国17000多个模具生产厂点,从业人数约50多万。1999年中国模具工业总产值已达245亿元人民币。工业总产值中企业自产自用的约占三分之二,作为商品销售的约占三分之一。

在模具工业的总产值中,冲压模具约占50%,塑料模具约占33%,压铸模具约占6%,其它各类模具约占11%。改革开放以来,中国模具工业企业的所有制成分也发生了巨大变化。除了国有专业模具厂外,其他所有制形式的模具厂家,包括集体企业、合资企业、独资企业和私营企业,都得到了快速发展,集体

和私营的模具企业在广东和浙江等省发展得最为迅速。例如,浙江宁波和黄岩地区,从事模具制造的集体企业和私营企业多达数千家,成为国内知名的“模具之乡”和最具发展活力的地区之一。在广东,一些大集团公司和迅速崛起的乡镇企业,为了提高其产品的市场竞争能力,纷纷加入了对模具制造的投入,例如科龙、美的、康佳和威力等集团都建立了自己的模具制造中心。中外合资和外商独资的模具企业多集中于沿海工业发达地区,现已有几千家。例如,江苏无锡的微研有限公司为一日本独资企业,员工有200余人,拥有精密数控模具加工设备60余台,1998年其模具产值超过2亿元。

中国模具工业的技术水平近年来也取得了长足的进步。目前,国内已能生产精度达2微米的精密多工位级进模,工位数最多已达160个,寿命1~2亿次。在大型塑料模具方面,现在已能生产48英寸电视的塑壳模具、6.5Kg大容量洗衣机的塑料模具,以及汽车保险杠、整体仪表板等模具。在精密塑料模具方面,国内已能生产照相机塑料模具、多型腔小模数齿轮模具及塑封模具等。在大型精密复杂压铸模方面,国内已能生产自动扶梯整体踏板压铸模及汽车后桥齿轮箱压铸模。在汽车模具方面,现已能制造新轿车的部分覆盖件模具。其他类型的模具,例如子午线轮胎活络模具、铝合金和塑料门窗异型材挤出模等,也都达到了较高的水平,并可替代进口模具。

虽然中国模具工业在过去十多年中取得了令人瞩目的发展,但许多方面与工业发达国家相比仍有较大的差距。例如,精密加工设备在模具加工设备中的 比重还比较低,CAD/CAE/CAM技术的普及率不高,许多先进的模具技术应用还不够广泛等等。特别在大型、精密、复杂和长寿命模具技术上存在明显差距,这些类型模具的生产能力也不能满足国内需求,因而需要大量从国外进口。

但是,由于我国的模具行业起步较晚,与国外相比,仍存在不小的差距,主要体现在:

产需矛盾:随着工业发展水平的不断提高,工业产品更新速度的加快,对模具的需求越来越大。无论是数量还是质量都无法满足国内市场的需要,只达到70%左右。造成矛盾突出的原因是模具企业的专业化、标准化程度低,生产周期长。另外,设计和制造工艺水平还不能完全适应发展的需要。

企业结构不合理:我国很多模具生产能力集中在各主机厂的模具分厂或车间内,模具的商品化程度低,而国外70%以上都是专业模具厂,且走的是“小而精”的道路,因此生产效率和经济效益俱佳。

产品水平 :衡量模具的产品水平,主要有模具加工的制造精度和表面粗糙度,加工模具的复杂程度,以及模具的制造周期和使用寿命。而这几项指标与国外相比的差距都十分明显。

此外,模具工业的整体装备水平也存在相对落后,利用率低的现象。高素质的模具技术人才缺乏,产品的综合开发能力还急需加强。

针对不足和模具市场巨大的潜力,根据我国模具工业的现状,并联系国际先进水平,中国模具工业协会协助政府制定了我国模具行业“十五”发展规划,确定模具工业重点发展领域有三方面:一是对整个模具行业发展有重要影响的主要模具标准件;二是技术含量高,反映模具制造水平和发展方向的模具;三是目前大量进口的中高档模具。重点发展的模具产品主要有:模架,包括冷冲模架、塑料模架和压铸模架等;模具导向件,包括导柱、导套、导板及无油润滑

导向件等;推杆、推管,包括塑料模用及压铸模用的异型推杆等;热流道元件,包括内热式、外热式、阀式和管式等;弹性元件,包括矩形弹簧、聚氨酯弹性体和氮气缸等;小型标准件,包括标准凸凹模、浇口套、定位圈和拉钩等;汽车覆盖件模具,特别是轿车所需的覆盖件模;精密冲压模,包括多工位级进模、厚板精冲模和硬质合金多功能复合模等;大型塑料模,包括汽车饰件模和家电塑壳模等;精密塑料模,包括塑封模和多层多腔、多材质、多色精密塑料模;大型薄壁精密复杂压铸模,包括用于铝、镁、锌、铜及其合金压铸的模具;大型、精密锻模;子午线轮胎橡胶模;长寿命玻璃、陶瓷模;快速经济模具;多工位冷镦模及挤压模;塑料型材及塑料管路模具。希望在模具企业的整体实力有进一步提升,重点、骨干企业可以达到50%。2003年是“十五”关键的一年,如果做不到60%任务的完成,那么计划就会失败,而模具失败了,对整个工业都会有影响。

近年来,外企进入中国, 加剧了竞争,也出现一些价格方面的恶性竞争。为了避免因为暂时的利益而损失长远和整体的发展,未来一年中,行业协会也将加强模具企业间的组织和协调,制定合理的价格水平。同时,研究国际模具价格水平,以对行业进行指导和信息沟通。

在中国,人们已经越来越认识到模具在制造中的重要基础地位,认识到模具技术水平的高低,已成为衡量一个国家制造业水平高低的重要标志,并在很大程度上决定着产品质量、效益和新产品的开发能力。

许多模具企业十分重视技术发展,加大了用于技术进步的投资力度,将技术进步视为企业发展的重要动力。此外,许多研究机构和大专院校开展模具技术的研究和开发。目前,从事模具技术研究的机构和院校已达30余家,从事模具技术教育的培训的院校已超过50余家。其中,获得国家重点资助建设的有华中理工大学模具技术国家重点实验室,上海交通大学CAD国家工程研究中心、北京机电研究所精冲技术国家工程研究中心和郑州工业大学橡塑模具国家工程。

在现代工业发展的进程中,模具的地位及其重要性日益被人们所认识。模具工业作为进入富裕社会的原动力之一,正推动着整个工业技术向前迈进!模具就是“高效益”,模具就是“现代化”之深刻含意,也正在为人们所理解和掌握。当塑料品种入其成型加工设备被确定之后,塑料制品质量的优劣及生产效率的高低,模具因素约占80%。由此可知,推动模具技术的进步应刻不容缓!培养了我综合运用多学科理论、知识和技能,以解决较复杂的工程实际问题的能力,主要包括设计、实验研究方案的分析论证,原理综述,方案方法的拟定及依据材料的确定等。它培养了我树立正确的设计思想,勇于实践、勇于探索和开拓创新的精神,掌握现代设计方法,适应社会对人才培养的需要。

此次毕业设计除了对知识和能力培养的收获感受外,还得到思想道德方面的锻炼。通过这次毕业设计,让我感受到了作为一名工程技术人员应该具备的基本精神,需要强化的工程实践意识,以及对设计工作的质量要负责,具有高度的责任感,树立实事求是的科学作风,并严格遵守规章制度。

1 工艺分析工艺方案的确定

1.1 冲裁件的工艺性分析

冲裁件的工艺性是指从冲压工艺方面来衡量其设计是否合理。一般的讲,在满足使用的要求的条件下,能以最简单最经济的方法将工件冲制出来,就说明该件的冲压工艺性好,否则,该件的工艺性就差。工艺性的好坏是相对的,它直接受到工厂的冲压技术的水平和设备条件等因素的影响。

1.2 综合技术经济效益观念

改革开放以前,我国企业,特别是在军工生产中,只要产品,不讲经济效益是很普通的。那时,模具技术工作者在确定工艺方案,设计模具时,主要考虑的是满足产品质量和数量的要求,很少考虑经济效益。今天,在现代工业生产与市场经济的条件下,常常需要他们参与对生产的预测与决策。因此,必须具有现代技术经济效益观念。在工艺设计过程中,还应考虑节省能源、减少材料消耗、降低生产成本,实施安全生产,保证获得利润等等。在保证产品质量的条件下,充分发挥企业技术与设备的优势,争取获得最佳技术经济效益。

1.3 零件材料性能分析及工件工艺性分析

该产品的基本工序为落料、冲孔。它对零件尺寸公差特殊要求,采用IT12级,利用普通加工方式可达到图样要求。

参考文献

[1]肖景容,姜奎华编的《冲压工艺学》北京:机械加工出版社会性, 1999。

XiaoJingRong, JiangKuiHua compiled the stamping technology of Beijing: mechanical processing publishing sociality 1999.

[2]王孝培.主编《冲压手册》第二版 北京 机械工业出版社。2004

WangXiaoPei. (Ed.), the stamping manual "second edition Beijing machinery industry press 2004

[3]王芳.主编《冷冲压模具设计手册》 北京 机械工业出版社。1999

Wang fang. (Ed.), the cold stamping mould design manual "Beijing machinery industry press 1999

[4]黄毅宏、李明辉。主编模具制造工艺.北京:机械工业出版社,1999.6。

HuangYiHong, LiMingHui. Editor mould manufacturing process. Beijing: machinery industry press 1999

[5]李绍林,马长福。主编.实用模具技术手册.上海:上海科学技术文献出版社,2000.6。

LiShaoLin, MaChangFu. Editor. Practical mould technology handbook. Shanghai: Shanghai science and technology literature press 2000

[6] 华北航天工业学院,钟 斌主编《冲压工艺与模具设计》。北京:机械工业出版社,2000.5。

North China aerospace industry institute, clock, ".bin stamping process and mold design ". Beijing: machinery industry press 2000

[7]模具实用技术丛书编委会.冲模设计应用实例[M].北京:机械工业出版社,2005,1。

Mould practical technology series. Die design application examples editorial [M].beijing: machinery industry press, 2005,1.

[8]郑家贤.冲压工艺模具设计实用技术[M].北京:机械工业出版社,2005,1.

ZhengjiaXian. Stamping process mold design and practical technology [M].beijing: machinery industry press, 2005,1.

[9]梁炳文.实用板金冲压工艺图集[M].北京:机械工业出版社,2003,8.

LiangBingWen. Practical sheet metal stamping process atlas [M].beijing: machinery industry press, lei. 2003,8.

[10]冲模设计手册编写组.冲模设计手册[M].北京:机械工业版社,2007,3.

Editorial stamping die design manual design manual. [M].beijing: machinery industry edition clubs,.res social admi pharm. 2007,3.

[11]王立人,张辉.冲压模设计指导[M]. 北京:北京理工大学出版社, 2009,8.

WangLiRen, zhang hui punch mould design guidelines. [M].beijing: Beijing university of science and technology press, 2009,8.

川公网安备: 51019002004831号

川公网安备: 51019002004831号