锻件的结构设计与工艺性分析

59页 19000字数+说明书+开题报告+论文+答辩稿+外文翻译+3张CAD图纸【详情如下】

内封皮.doc

外文翻译--金刚石刀具磨损的评价.doc

封皮.doc

答辩成绩评定.doc

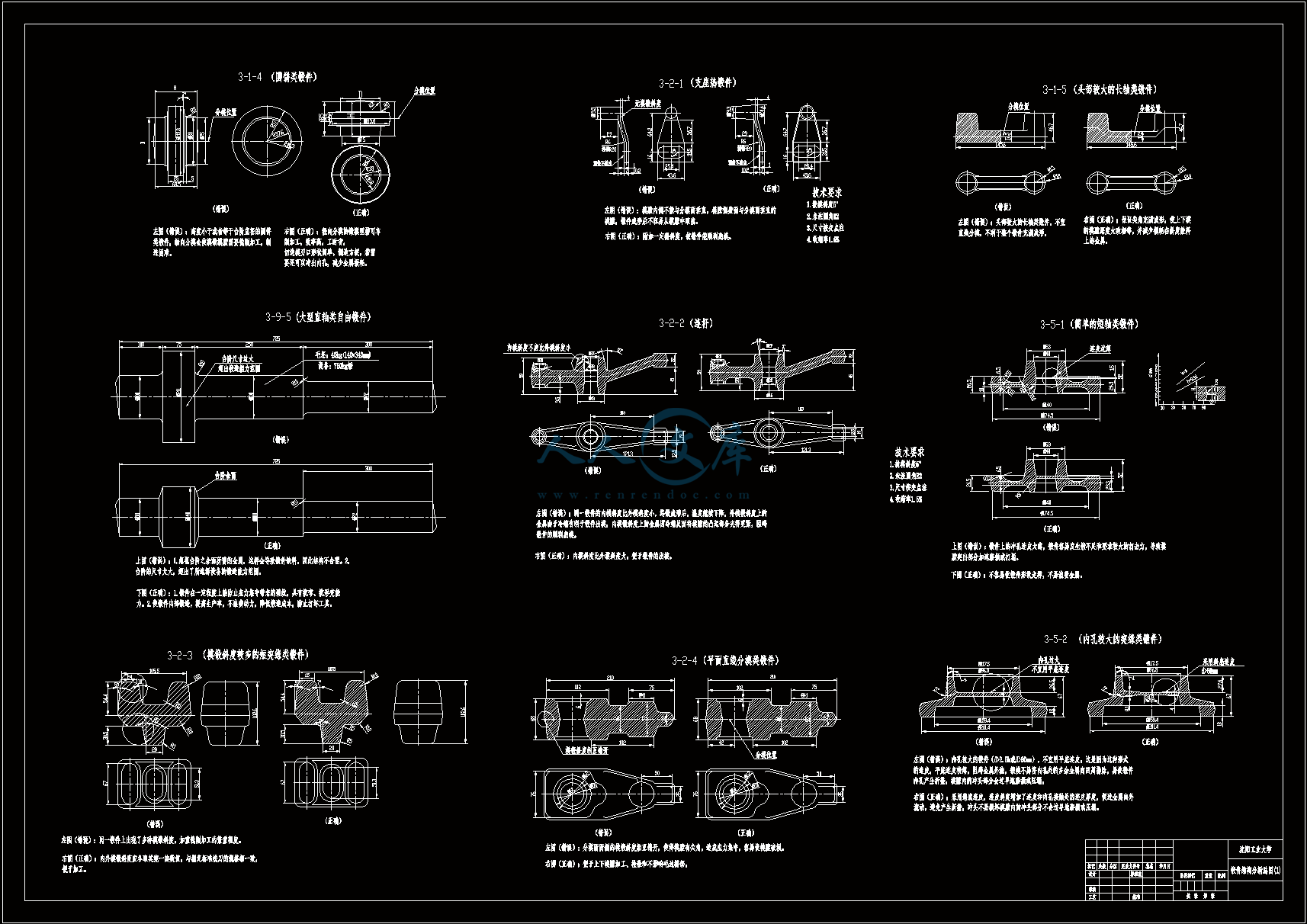

结构分析图(1).dwg

结构分析图(2).dwg

结构分析图(补充2).dwg

锻件的结构设计与工艺性分析开题报告.doc

锻件的结构设计与工艺性分析答辩稿.ppt

锻件的结构设计与工艺性分析论文.doc

目 录

摘 要I

AbstractII

前 言1

第1章 绪论3

1.1 目前锻件的应用3

1.2 目前国内外发展概况和发展趋势4

第2章 锻件的结构设计及工艺性分析5

2.1 对锻造零件结构工艺性的要求5

2.2 锻件组织特点5

2.3 锻件的结构工艺性5

2.3.1自由锻件的结构工艺性5

2.3.2 模锻件的结构工艺性9

第3章 锻件的结构设计错误示例及其改进12

3.1 模锻件的分模位置问题12

3.1.1 上下对称锻件的分模位置不应选在上平面或下平面12

3.1.2 倾斜锻件不宜采用折线分模13

3.1.3 左右对称的锻件,分模面不宜选在过度截面上14

3.1.4 高度小于或者等于台阶直径的圆饼类锻件,不宜轴向分模15

3.1.5 头部较大的轴类锻件不宜直线分模16

3.2 模锻件的模锻斜度问题17

3.2.1 模膛内侧不能与分模面垂直17

3.2.2 同一锻件的内模斜度不应比外模斜度小18

3.2.3 同一锻件上不宜出现多种模锻斜度20

3.2.4 分模面两侧的模锻斜度不能相互错开21

3.3 零件上过于复杂的部分不要锻出,应合理设计余块21

3.3.1 对于有凸缘的锻件22

3.3.2对于有难成形的复杂形状的锻件23

3.3.3 对于零件相邻台阶直径相差不大的锻件25

3.4 需增设定位块的锤上模锻件26

3.5 模锻件连皮的问题27

3.5.1 冲孔连皮不能太薄,也不宜太厚27

3.5.2 锻件内孔较大时,不宜用平底连皮28

3.5.3 锻件上的小孔不宜锻出连皮, 只进行压凹29

3.6 对于法兰较薄的锻件,在锻件两侧各增加一块工艺凸台敷料31

3.7 合理确定锻件的分合32

3.7.1 单拐曲线两件合锻32

3.7.2 轴套类零件两件合锻33

3.7.3 复杂模锻件的分锻34

3.7.4 有骤变横截面模锻件的分锻35

3.8 合理确定锻件的凸肩36

3.8.1 凸肩与锻件直径相差不大时不宜锻出凸肩36

3.8.2 高度过小的凸肩不要锻出37

3.9 自由锻件结构应力求简单38

3.9.1 自由锻件应尽量避免有锥形和斜度平面38

3.9.2 自由锻件应避免两曲面或曲面与棱柱面交接40

3.9.3 自由锻件应避免加强筋41

3.9.4 自由锻件不允许在基体上或在叉件内侧有凸台42

3.9.5 大型锻件台阶余面的重量不能忽视,锻造设备不能选择过大,也不能选择太小43

3.10 孔径小于30mm的孔,不宜锻出45

3.11 模锻件应尽可能直接模锻成形46

3.12 加大连接板的厚度47

3.13 复杂锻件应成对称形状,可使模具和夹具通用48

3.14 合理选择锻件上的倒圆半径49

3.15 不能忽视预锻成型50

3.16 平锻机上终锻成形时的冲孔芯料不能太薄51

3.17 合理安排毛刺、飞边的位置52

第4章 结论54

参 考 文 献55

致 谢56

摘 要

目前国内外的锻造方法主要的仍然是自由锻和模锻,工业发达国家的模锻大大超过自由锻。因为模锻生产率高,锻件尺寸精度高,材料利用率高,纤维组织沿锻件轮廓分布,故力学性能好,故强度高,耐冲击抗疲劳。如果能结合胎膜锻、型砧锻,其经济效益会显著提高,“锻压”是人类发明的最古老的生产技术之一,也是机械制造业中重要的技术之一。它包含了锻造和冲压技术,以及与之相关的塑性变形技术。锻造作为金属加工的主要方法和手段,因此锻造工艺是发展趋势,锻造加工能保证金属纤维组织的连续性,使锻件的纤维组织与锻件外形保持一致,金属流线完整,可保证零件具有良好的力学性能与长的使用寿命,锻件是机器中负重载荷的零件,特别适合结构尺寸小而载荷大或受疲劳载荷的零件。不懂锻件设计就有可能违反锻造原理和锻造结构工艺性,轻则延长零件的生产周期锻造加工能保证金属纤维组织的连续性,使锻件的纤维组织与锻件的外形保持一致,金属流线完整,可保证零件具有良好的力学性能与长的使用寿命,增加制造困难,增加成本;重则可能无法把您设计的零件锻造出来。本设计将通过对各种锻件的具体案例的结构设计及其工艺性进行分析,把握锻件的结构设计及其工艺性的制造规律,并通过其规律的把握,达到灵活运用制造技术,合理设计零件结构及其工艺的目的。

关键词:自由锻;模锻;锻造工艺;胎膜锻;结构

Abstract

Currently,forging method at home and abroad,mainly remains Free forging and Roll forging,Model Forging of Industrial developed countries easily outnumbered Free forging. Beca mechanical property. High strength, impact fatigue resistance. "Forge" is one of the oldest use of high production rate of Roll forging,high dimension precision of forging,high utilization ratio of material and fibrous tissue distributes the outlines of forging,so it has good production technology of human invention, is one of the important technology in mechanical manufacturing industry. It includes the forging and stamping technology, and the plastic deformation associated with technology. Forging as main methods and means of metal processing . Forging ps histiocytomarocess can ensure the continuity of metallic fibrou , consistent with appearance of fibrous tissue and forgings forging, metal flow line complete, guaranteed parts with good mechanical properties and long service life, Forging is the weight-bearing loads in the machine parts, particularly suited to the structure of small size and loading large or subject to fatigue loading parts,If we can combine The fetal membrane hammers and the swage block hammers,the Economic efficiency will obviously enhances,so Forging craft is the trend of development, we will disobey Forging principle and Forging structure technology capability if we can not understand Forging design, the result range from not forging the components to protracting the production cycle, increasing manufacturing difficulties and costing this Graduation Project, we can grasp the law of the manufacture of structural design and forging structure technology capability by analysising the structural design of a wide range of forging and the technology capability, also nimbly use the technique of manufacture, reasonably design the structural and the craft by grasping the law. Keywords:Free forging;Roll forging;Forging craft;The fetal membrane hammers;structural

川公网安备: 51019002004831号

川公网安备: 51019002004831号