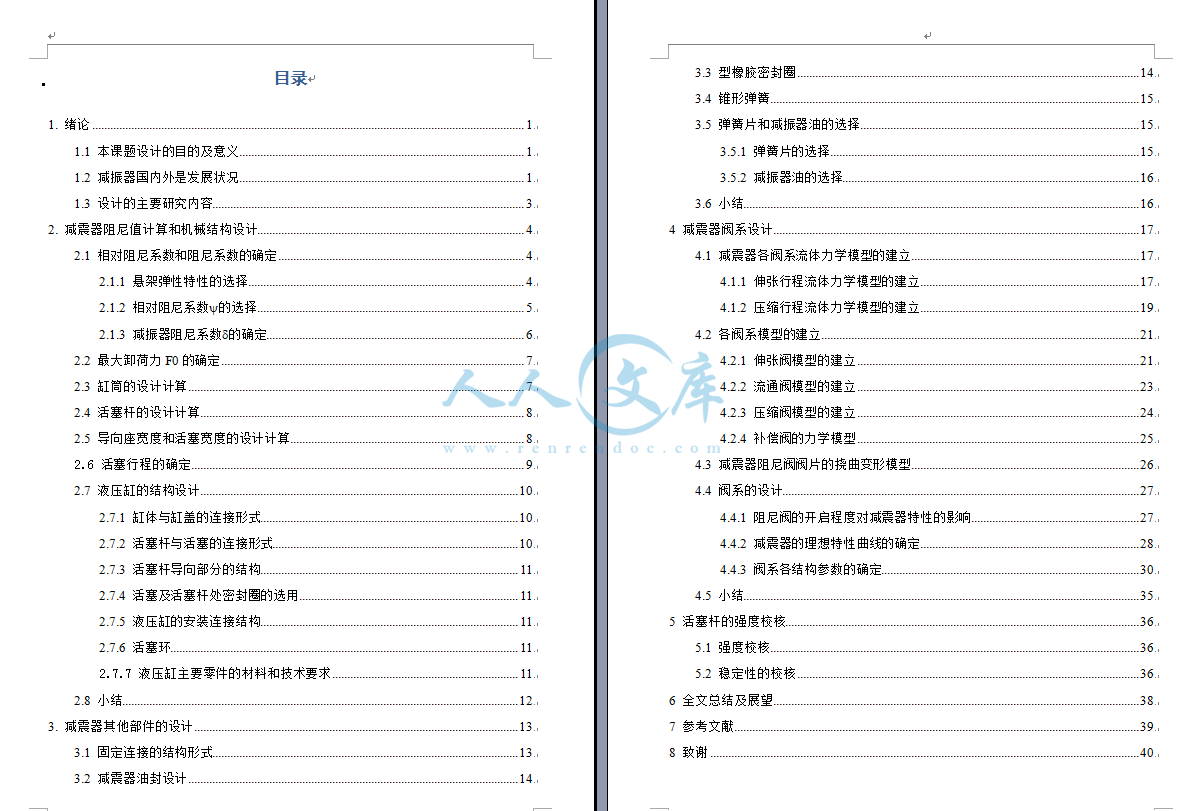

车用双向作用筒式减震器设计【含CAD图纸、UG三维模型、说明书文档、开题报告】

收藏

资源目录

压缩包内文档预览:

编号:29812654

类型:共享资源

大小:9.45MB

格式:ZIP

上传时间:2019-12-08

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

含CAD图纸、UG三维模型、说明书文档、开题报告

双向

作用

减震器

设计

CAD

图纸

UG

三维

模型

说明书

文档

开题

报告

- 资源描述:

-

- 内容简介:

-

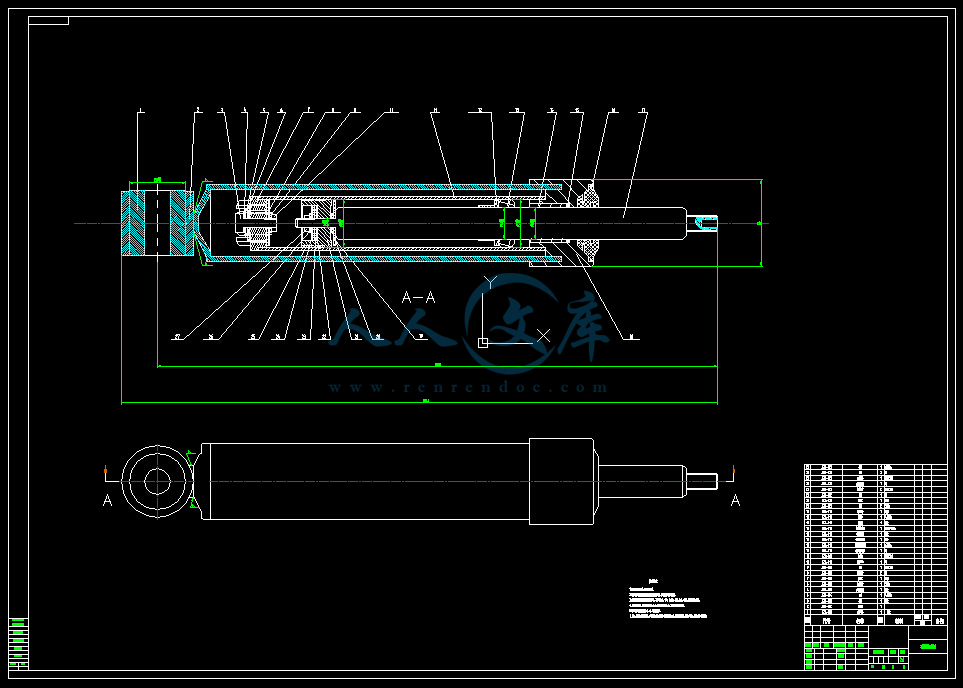

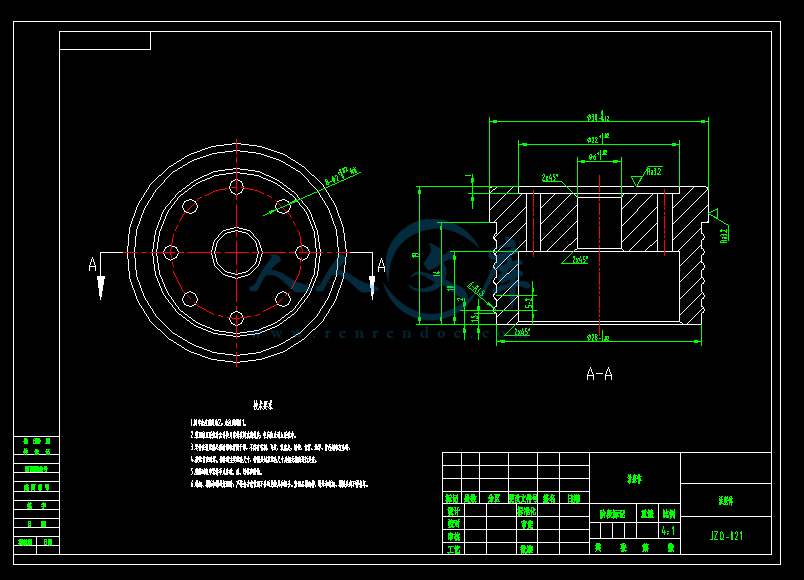

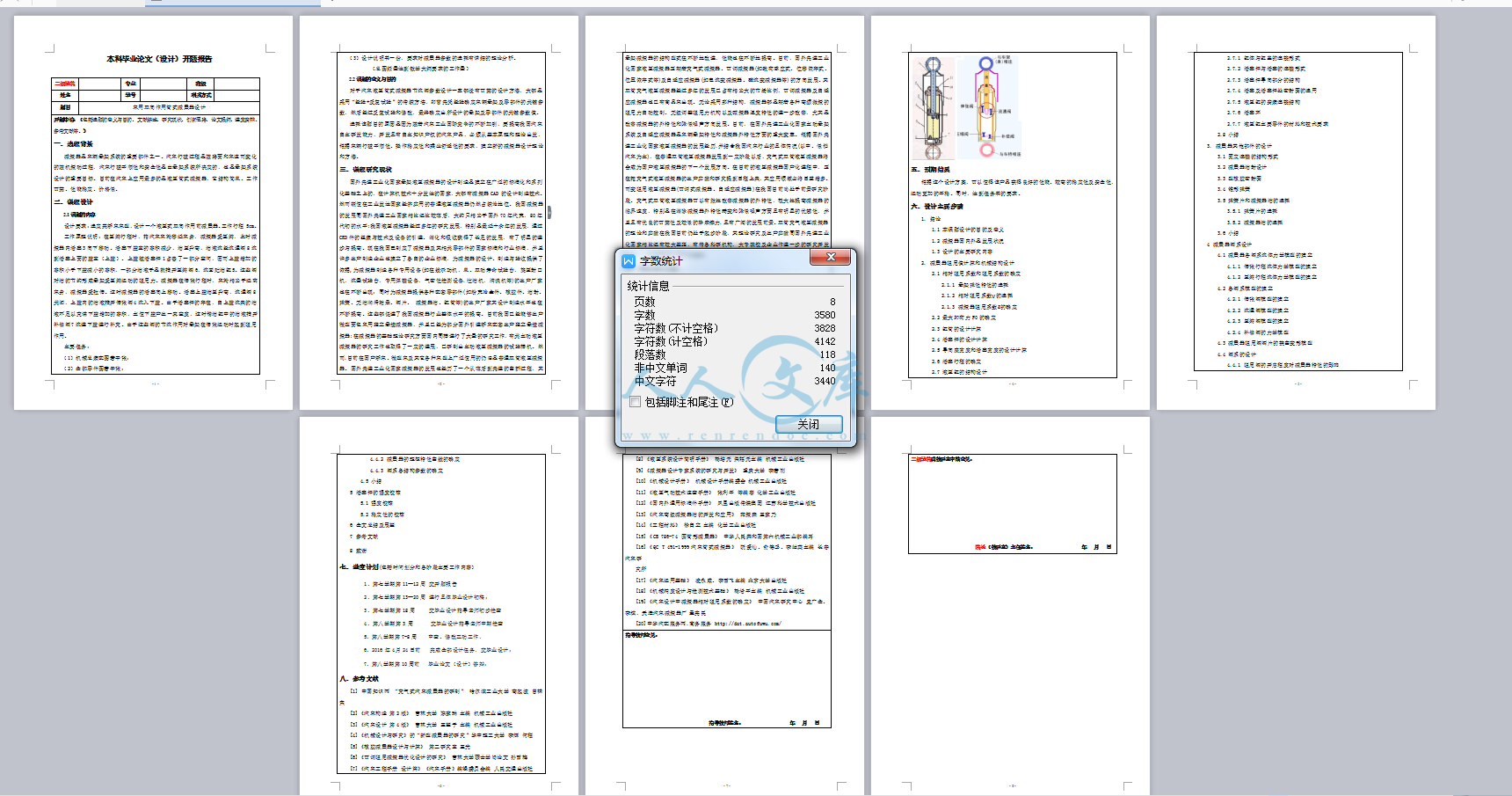

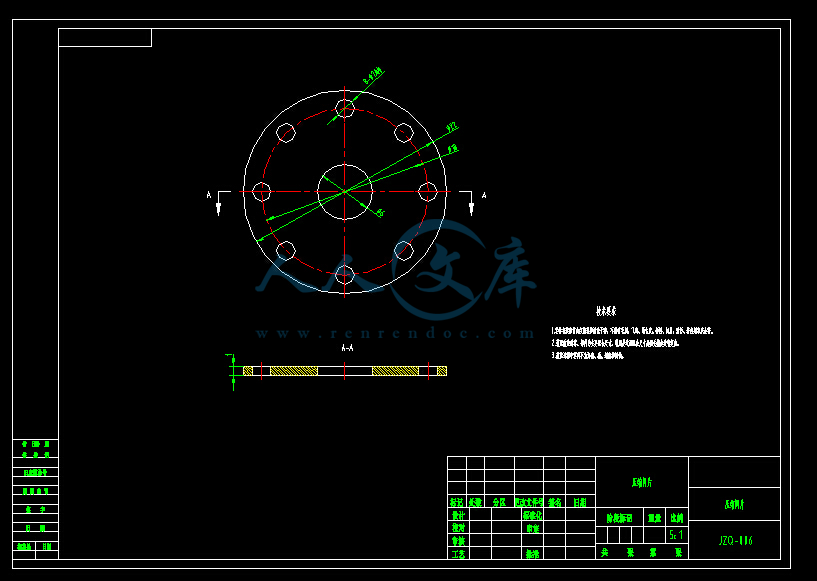

外文翻译减震器减震器(Absorber) ,减震器主要用来抑制弹簧吸震后反弹时的震荡及来自路面的冲击。在经过不平路面时,虽然吸震弹簧可以过滤路面的震动,但弹簧自身还会有往复运动,而减震器就是用来抑制这种弹簧跳跃的。减震器太软,车身就会上下跳跃,减震器太硬就会带来太大的阻力,妨碍弹簧正常工作。在关于悬挂系统的改装过程中,硬的减震器要与硬的弹簧相搭配,而弹簧的硬度又与车重息息相关,因此较重的车一般采用较硬的减震器。与引震曲轴相接的装置,用来抗衡曲轴的扭转震动(即曲轴受汽缸点火的冲击力而扭动的现象)。减震器的名词解释减震器(Absorber) ,减震器主要用来抑制弹簧吸震后反弹时的震荡及来自路面的冲击。减震器的工作原理悬架系统中由于弹性元件受冲击产生震动,为改善汽车行驶平顺性,悬架中与弹性元件并联安装减震器,为衰减震动,汽车悬架系统中采用减震器多是液力减震器,其工作原理是当车架(或车身)和车桥间震动而出现相对运动时,减震器内的活塞上下移动,减震器腔内的油液便反复地从一个腔经过不同的孔隙流入另一个腔内。此时孔壁与油液间的摩擦和油液分子间的内摩擦对震动形成阻尼力,使汽车震动能量转化为油液热能,再由减震器吸收散发到大气中。在油液通道截面和等因素不变时,阻尼力随车架与车桥(或车轮)之间的相对运动速度增减,并与油液粘度有关。减震器与弹性元件承担着缓冲击和减震的任务,阻尼力过大,将使悬架弹性变坏,甚至使减震器连接件损坏。因面要调节弹性元件和减震器这一矛盾。(1) 在压缩行程(车桥和车架相互靠近),减震器阻尼力较小,以便充分发挥弹性元件的弹性作用,缓和冲击。这时,弹性元件起主要作用。(2) 在悬架伸张行程中(车桥和车架相互远离),减震器阻尼力应大,迅速减震。(3) 当车桥(或车轮)与车桥间的相对速度过大时,要求减震器能自动加大液流量,使阻尼力始终保持在一定限度之内,以避免承受过大的冲击载荷。在汽车悬架系统中广泛采用的是筒式减震器,且在压缩和伸张行程中均能起减震作用叫双向作用式减震器,还有采用新式减震器,它包括充气式减震器和阻力可调式减震器。双向作用筒式减震器工作原理说明:在压缩行程时,指汽车车轮移近车身,减震器受压缩,此时减震器内活塞3向下移动。活塞下腔室的容积减少,油压升高,油液流经流通阀8流到活塞上面的腔室(上腔)。上腔被活塞杆1占去了一部分空间,因而上腔增加的容积小于下腔减小的容积,一部分油液于是就推开压缩阀6,流回贮油缸5。这些阀对油的节约形成悬架受压缩运动的阻尼力。减震器在伸张行程时,车轮相当于远离车身,减震器受拉伸。这时减震器的活塞向上移动。活塞上腔油压升高,流通阀8关闭,上腔内的油液推开伸张阀4流入下腔。由于活塞杆的存在,自上腔流来的油液不足以充满下腔增加的容积,主使下腔产生一真空度,这时储油缸中的油液推开补偿阀7流进下腔进行补充。由于这些阀的节流作用对悬架在伸张运动时起到阻尼作用。由于伸张阀弹簧的刚度和预紧力设计的大于压缩阀,在同样压力作用下,伸张阀及相应的常通缝隙的通道载面积总和小于压缩阀及相应常通缝隙通道截面积总和。这使得减震器的伸张行程产生的阻尼力大于压缩行程的阻尼力,达到迅速减震的要求。减震器的分类材料角度划分从产生阻尼材料的角度划分,减震器主要有液压和充气两种,还有一种可变阻尼的减震器。(1)液压式汽车悬架系统中广泛采用液力减震器。其原理是,当车架与车桥做往复相对运动儿活塞在减震器的缸筒内往复移动时,减震器壳体内的油液便反复地从内腔通过一些窄小的孔隙流入另一内腔。此时,液体与内壁的摩擦及液体分子的内摩擦便形成对振动的阻尼力。(2)充气式充气式减震器是60年代以来发展起来的一种新型减震器。其结构特点是在缸筒的下部装有一个浮动活塞,在浮动活塞与缸筒一端形成的一个密闭气室种充有高压氮气。在浮动活塞上装有大断面的O型密封圈,它把油和气完全分开。工作活塞上装有随其运动速度大小而改变通道截面积的压缩阀和伸张阀。当车轮上下跳动时,减震器的工作活塞在油液种做往复运动,使工作活塞的上腔和下腔之间产生油压差,压力油便推开压缩阀和伸张阀而来回流动。由于阀对压力油产生较大的阻尼力,使振动衰减。结构角度划分减震器的结构是带有活塞的活塞杆插入筒内,在筒中充满油。活塞上有节流孔,使得被活塞分隔出来的两部分空间中的油可以互相补充。阻尼就是在具有粘性的油通过节流孔时产生的,节流孔越小,阻尼力越大,油的黏度越大,阻尼力越大。如果节流孔大小不变,当减震器工作速度快时,阻尼过大会影响对冲击的吸收。因此,在节流孔的出口处设置一个圆盘状的板簧阀门,当压力变大时,阀门被顶开,节流孔开度变大,阻尼变小。由于活塞是双向运动的,所以在活塞的两侧都装有板簧阀门,分别叫做压缩阀和伸张阀。减震器按其结构,则分为单筒和双筒两种。可以进一步分为:单筒气压减震器、双筒油压减震器、双筒油气减震器。(1)双筒式指减震器有内外两个筒,活塞在内筒中运动,由于活塞杆的进入与抽出,内筒中油的体积随之增大与收缩,因此要通过与外筒进行交换来维持内筒中油的平衡。所以双筒减震器中要有四个阀,即除了上面提到的活塞上的两个节流阀外,还有装在内外筒之间的完成交换作用的流通阀和补偿阀。(2)单筒式与双筒式相比,单筒式减震器结构简单,减少了一套阀门系统。它在缸筒的下部装有一个浮动活塞,(所谓浮动即指没有活塞杆控制其运动),在浮动活塞的下面形成一个密闭的气室,充有高压氮气。上面提到的由于活塞杆进出油液而造成的液面高度变化就通过浮动活塞的浮动来自动适应之。除了上面所述两种减震器外,还有阻力可调式减震器。它可通过外部操作来改变节流孔的大小。最近的汽车将电子控制式减震器作为标准装备,通过传感器检测行驶状态,由计算机计算出最佳阻尼力,使减震器上的阻尼力调整机构自动工作。筒式减震器的基本介绍该减震器广泛应用在汽车悬架系统之中,且在压缩和伸张行程中都能起到减震作用,因此它又叫做双向作用式减震器。组件包括:活塞杆、工作缸筒、活塞、伸张阀、储油缸筒、压缩阀、补偿阀、流通阀、导向座、防尘罩、油封。在汽车车轮移近车身,减震器受压缩时,此时减震器内活塞向下移动。活塞下腔室的容积减少,油压升高,油液流经流通阀流到活塞上面的腔室(上腔)。上腔被活塞杆占去了一部分空间,因而上腔增加的容积小于下腔减小的容积,一部分油液于是就推开压缩阀,流回储油缸。这些阀对油的节约形成悬架受压缩运动的阻尼力。减震器在车轮远离车身,减震器受拉伸,这时减震器的活塞向上移动。活塞上腔油压升高,流通阀关闭,上腔内的油液推开伸张阀流入下腔。由于活塞杆的存在,自上腔流来的油液不足以充满下腔增加的容积,主使下腔产生一真空度,这时储油缸中的油液推开补偿阀流进下腔进行补充。由于这些阀的节流作用,因此对悬架在做伸张运动时起到阻尼作用。由于伸张阀弹簧的刚度和预紧力设计的大于压缩阀,在同样压力作用下,伸张阀及相应的常通缝隙和通道截面积总和小于压缩阀及相应常通缝隙通道截面积总和。这使得减震器的伸张行程产生的阻尼力大于压缩行程的阻尼力,达到迅速减震的要求。English translationShock AbsorberShock Absorber (Absorber), after the shock absorber is mainly used to suppress spring shock absorbers and rebound when the impact from the road surface. When after a rough road, while the shock-absorbing spring can filter road vibration, but the spring itself there will be reciprocated and the shock absorber is used to inhibit this spring jump. Shock absorber is too soft, the body will be jumping up and down, shock absorbers too hard will bring too much resistance, hinder the normal spring work. About the suspension of the conversion process, the hard shock absorber to be matched with the stiffer springs and the spring stiffness and is closely related to vehicle weight and thus heavier vehicles generally use a harder shock absorbers. Cited in contact with the crankshaft shock means for counter crankshaft torsional vibration (ie, crank the ignition cylinder by twisting and impact of the phenomenon).Damper GlossaryShock Absorber (Absorber), after the shock absorber is mainly used to suppress spring shock absorbers and rebound when the impact from the road surface.Shock absorber worksThe suspension system due to the elastic element by the impact of any shock to improve vehicle ride comfort, suspension shock absorbers mounted in parallel with the elastic member for damping vibrations, shock absorbers used in automobile suspension systems are mostly hydraulic damping device, its working principle is that when the frame (or body) and inter-axle vibration occurs relative motion, up and down movement of the piston within the shock absorber, the shock absorber fluid chamber will pass repeatedly from a different chamber pore into the other chamber. In this case internal friction and fluid friction and oil molecules between the cell walls between the damping force of the shock formation, making the car vibration energy into heat oil, then absorbed by the shock absorber circulated into the atmosphere. When oil passage section and other factors constant, the relative velocity damping force with frame and axle (or wheel) between the increase and decrease, and with the oil viscosity is related.Shock absorbers and elastic elements bear the impact and ease the task of damping, the damping force is too large, the elastic suspension will deteriorate, and even the shock absorber connector damage. To adjust the surface due to the elastic element and the damper this contradiction.(1) during the compression stroke (axle and frame close to each other), the smaller the shock absorber damping force, in order to give full play to the elasticity of the elastic element, easing the impact. At this time, the elastic member play a major role.(2) uphold the suspension stroke (axle and frame away from each other), the shock absorber damping force should be large, rapid damping.(3) when the axle (or wheel) and the relative speed between the axle is too large, it is required to automatically increase the shock absorber fluid flow, so that the damping force is always kept within certain limits in order to avoid excessive impact withstand load.In the automotive suspension system is widely used telescopic shock absorber, and is done in the compression stroke and can play a cushioning effect called double-acting shock absorbers, as well as the use of new shock absorbers, which includes inflatable Save shock resistance and adjustable shock absorbers.Double-acting telescopic shock absorber works Description: When the compression stroke, an automobile wheel closer to the body, the shock absorber is compressed, then move down into the damper piston 3. Volume of the piston lower chamber is reduced, oil temperature, oil flow through the circulation flow valve 8 above the piston chamber (upper chamber). The chamber is a piston rod 1 takes up part of the space, thus increasing the chamber volume is less than the lower chamber to reduce the volume, part of the oil so he opened the compression valve 6, back into the storage tank 5. These valves on oil savings formed by compression damping force of the suspension movement. When done damper stroke, the equivalent of the wheel away from the body, shock absorbers under tension. In this case the shock absorber piston moves upward. Piston hydraulic chamber increases, the circulation valve 8 is closed, the upper chamber of the oil valve 4 open stretch into the next chamber. Due to the presence of the piston rod, since the upper chamber to the fluid flow is not sufficient to increase the volume of the lower chamber is filled, dictates the lower chamber to generate a vacuum, then pushed the oil storage tanks in compensating valve 7 flows into the lower cavity supplement. Because these valves throttling the suspension damping to play a role in stretching exercise.Since stretching valve spring stiffness and preload is greater than the compression valve design, under the same pressure, stretching the sum channel load area and the corresponding valve normally-compression valve gap is less than the sum of the cross-sectional area and the corresponding normally-slot channel. This allows the shock absorber damping force is greater than the elongation stroke damping force of the compression stroke, to achieve rapid damping requirements.Damper classification Materials division angleFrom the perspective of damping material division, hydraulic and pneumatic shock absorbers are mainly two types, there is a variable damping shock absorbers.(1) hydraulicAutomobile suspension system is widely used in hydraulic shock absorbers. The principle is that when the frame and axle reciprocating piston relative movement of children in the cylinder when the shock absorber reciprocating, oil within the damper housing will be repeated from the other inflow lumen through some narrow pores a lumen. At this time, friction and friction within the liquid molecules of the liquid and the inner wall is formed on the vibration damping force.(2) inflatableInflatable shock absorbers since the 1960s, developed a new type of shock absorber. The structure is characterized in the lower portion of the cylinder is provided with a floating piston, a sealed chamber in the floating piston and cylinder formed at one end is filled with high-pressure nitrogen species. With large cross-section of the O-ring on the floating piston that is completely separate from the oil and gas. Equipped with its velocity on the size of the working piston and change the channel cross-sectional area of the compression valve and valve done. When the wheel up and down, the shock absorber in the working piston reciprocates seed oil, so oil pressure difference generated between the upper chamber and a lower chamber of the working piston, oil pressure will open the valve and compression valve and elongation flow back and forth. Since the valve of the oil pressure have a greater damping force, the vibration damping. angle division structureShock absorber piston rod structure is inserted into the cylinder with a piston in the cylinder filled with oil. Piston orifice, such that the two parts are separated out of the piston space of the oil can complement each other. Damping oil is viscous when produced through the orifice, the orifice the smaller the damping force, the greater the viscosity of the oil, the greater the damping force. If you change the size of the orifice, when the shock absorber to work fast, too much effect on the absorption of damping shocks. Therefore, provided at the outlet of the orifice of a disk-shaped leaf spring valve when the pressure increases, the valve top is open, the orifice opening degree becomes larger, the damping becomes small. Since the piston is a two-way movement, so both sides of the piston valves are equipped with leaf springs, they are called compression valves and valve done.Shock absorber according to their structure, monocular and binocular is divided into two kinds. Can be further divided into: single cylinder gas pressure shock absorbers, hydraulic shock absorbers binoculars, binoculars and gas shock absorbers.(1) binoculars formulaIt refers to both internal and external shock absorber cylinder, a piston moving the inner cylinder, the piston rod and drawn into the inner tube of oil volume increases and contraction, and therefore with the outer cylinder exchange to maintain the inner tube of oil balance. So binoculars shock absorber have four valves, which in addition to two throttle piston mentioned above, there are mounted on the completion of the exchange interaction flow valve and compensation valve between the inner and outer cylinders.(2) single cylinderCompared with the binocular-type, single tube shock absorbers simple structure, reducing a valve system. It is in the lower part of the cylinder containing a floating piston (referring to the so-called floating piston does not control its movements), the floating piston is formed below a closed chamber, filled with high-pressure nitrogen. Changes in the liquid level of oil out of the piston rod caused by the above-mentioned floating piston will automatically adapt themselves to float. In addition to the above said two damper, there is resistance adjustable shock absorbers. It may be to change the size of the orifice by an external operation. Recent automotive electronic damper control as standard equipment, with state detection by the sensor, the computer calculates the optimal damping force shock absorber damping force adjustment mechanism on the work automatically.Basic introduction of telescopic shock absorberThe shock absorber is widely used among automotive suspension systems, and can play a role in damping the compression stroke and done, so it is called double-acting shock absorbers.Assembly comprising: a piston rod, a cylinder barrel, piston, done valves, storage tanks cylinder compression valves, compensation valve, circulation valve, pilot seat, dust cover, oil seal.In the car wheels closer to the body, when the shock absorber is compressed, then moves within the damper piston downward. Volume of the piston lower chamber is reduced, oil temperature, oil flow through the circulation flow valve above the piston chamber (upper chamber). The chamber is a piston

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号