摘 要

模具作为一种成型工具,其设计、制造水平的高低,直接关系到产品的质量与更新换代,是衡量一个国家产品制造水平的重要标志。

本文主要介绍的是晾衣叉注塑模具的设计方法。首先分析了晾衣叉制件的工艺特点,包括材料性能、成型特性与条件、结构工艺性等,并选择了成型设备。接着系统介绍了晾衣叉注塑模的分型面的选择、型腔数目的确定及布置,重点介绍了浇注系统、成型零件、侧向抽芯机构、合模导向机构、脱模机构、定距分型机构以及冷却系统的设计。然后选择标准模架和模具材料,并对注射机的工艺参数进行相关校核。最后对模具的工作原理进行阐述,以及在安装调试过程中可能出现的问题进行总结、分析,并给出了相应的解决方法。本文论述的晾衣叉注塑模具采用两板式结构,采用一模二腔的型腔布置,最后利用推杆将制件推出。

关键词:晾衣叉;注塑模;二板模;浇注系统

Abstract

Die as a tool for molding, its design, manufacture level are of direct bearing on the quality of products and replacement, an important indicator to measure a country's level of manufacturing.

The designing methods of injection mould of clothes fork are mainly introduced in this paper. First, the technological characteristics are analyzed, including material properties, forming characteristics and conditions, the process of the structure, the forming equipment is selected. Then the parting line is selected, the number of cavities is determined. The specific introduction are made on gating system, cooling system, Molding parts, Steering mechanism, moulding mechanism, and spacer parting institutions. Then the standard mould bases and mould materials are selected, and the technological parameters of the forming equipment is checked. Finally, problems that may emerge during the mold installation process are analyzed and the appropriate solutions are provided.Two pence mould is used on the design of charger shell. there are two cavities in this mould, finally a stripper plate is used to push off the clothes fork.

Keyword: Clothes fork; Injection mould; Two pence mould; Gating system;

目 录

引言 1

1 塑件结构及尺寸 3

1.1 本塑件的材料分析 3

1.2 本塑件的工艺参数 4

1.3 本塑件的产品结构 4

1.4 塑件的公差 5

1.5 塑件的壁厚 5

1.6 塑件的脱模斜度 6

2 模具结构的设计 7

2.1 确定型腔数目的方法 7

2.2 型腔排列方式的确定 8

3 注射机型号的确定 8

3.1 注塑机定义 8

3.2 注塑机的类型 9

3.3 注塑机的结构 9

3.4 注塑机的选择 10

3.4.1所需注射量的计算、塑件质量、体积计算 10

3.4.2浇注系统凝料体积的初步估算 11

3.5 注塑机的校核 11

3.5.注射压力校核 11

3.5.2锁模力校核 12

3.5.3开模行程和模板安装尺寸校核 12

4 成型零件的设计 13

4.1 分型面的设计 13

4.2 成型零部件的结构设计 14

4.2.1型芯和型腔的结构设计 14

4.2.2注射模强度要求 15

4.3 型芯型腔的确定 16

5 侧向分型与抽芯机构 16

5.1 侧向抽芯机构的分类及组成 16

5.2 确定抽芯距 18

5.3 抽芯力的计算 18

5.4 斜导柱设计 20

6 浇注系统的设计 21

6.1 浇注系统的组成 21

6.2 浇注系统的作用 21

6.3 浇注系统设计影响因素 21

6.4 主流道的设计 22

6.4.1主流道的材料 23

6.4.2主流道的表面精度 23

6.5 分流道设计 23

6.6 浇口设计 25

6.6.1浇口的选用 26

6.6.2浇口位置的选用 26

6.6.3浇注系统的平衡 28

6.6.4排气的设计 28

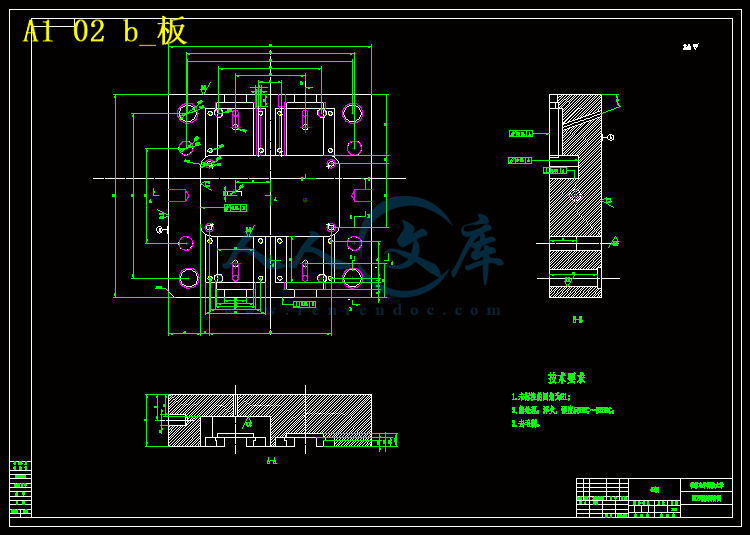

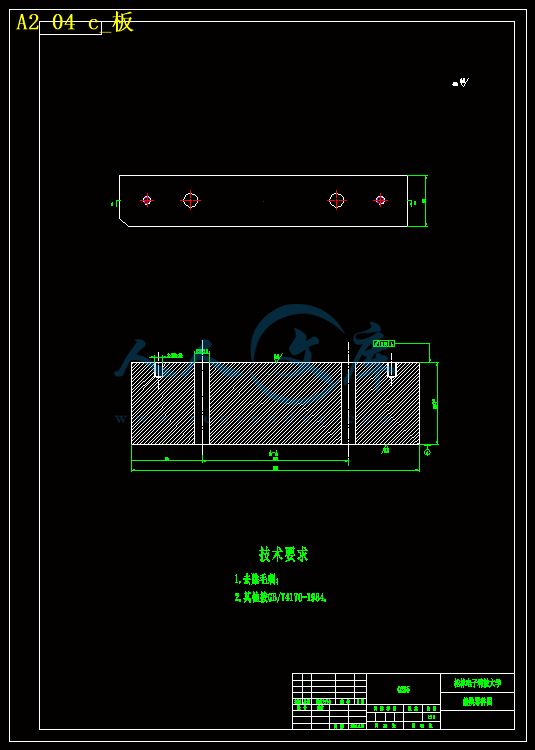

7 标准模架的选取 28

8 合模导向机构的设计 30

8.1 导柱导向机构设计要点 30

9 脱模机构的设计 32

9.1 脱模机构设计的总原则 32

9.2 推杆设计 32

9.2.1推杆的形状 32

9.2.2推杆的位置和布局 33

9.3 推件板设计的要点 33

10 冷却系统的设计 34

10.1 冷却系统的计算 34

10.2 冷却系统的设计准则 34

11 典型零件的制造工艺 35

11.1 浇口套加工 35

11.2 定模座板加工 36

11.3 动模模套加工 37

11.4 导柱的加工 38

12 结语 39

谢 辞 40

参考文献 41

引言

作为工业生产基础工艺装备的模具,在国民经济中占有重要的地位,模具技术也已成为衡量一个国家产品制造水平的重要标志之一。

第十一五规划中指出,模具是工业生产的基础工艺装备,国民经济的五大支柱产业——机械、电子、汽车、石化、建筑都要求模具工业发展与之相适应。模具因其生产效率高、产品质量好、材料消耗低、生产成本低而获得广泛应用,与其他加工制造业所无法比拟的。从工业产品生产行业看,模具是现代工业,特别是汽车、摩托车、航空、仪表、仪器、医疗器械、电子通讯、兵器、家用电器、五金工具、日用品等工业必不可少的工艺装备。据资料统计,利用模具制造的零件数量,在飞机、汽车、摩托车、拖拉机、电机、电器、仪器仪表等机电产品中占80%以上;在电脑、电视机、摄像机、照相机、录像机、传真机、电话及手机等电子产品中占85%以上;在电冰箱、洗衣机、空调、微波炉、吸尘器、电风扇、自行车、手表等轻工业产品中占90%以上;在子弹、枪支等兵器产品中占95%以上。

川公网安备: 51019002004831号

川公网安备: 51019002004831号