新能源汽车副仪表板设计与建模课题申报表、任务书、开题报告.doc

新能源汽车副仪表盘设计与建模【原创含9张CAD图带开题报告+外文翻译】

收藏

资源目录

压缩包内文档预览:

编号:10235072

类型:共享资源

大小:6.26MB

格式:ZIP

上传时间:2018-06-25

上传人:QQ14****9609

认证信息

个人认证

郭**(实名认证)

陕西

IP属地:陕西

100

积分

- 关 键 词:

-

新能源

汽车

仪表盘

设计

建模

原创

cad

开题

报告

讲演

呈文

外文

翻译

- 资源描述:

-

新能源汽车副仪表盘设计与建模【含9张CAD图带开题报告+外文翻译】

【需要咨询购买全套设计请加QQ1459919609】图纸预览详情如下:

- 内容简介:

-

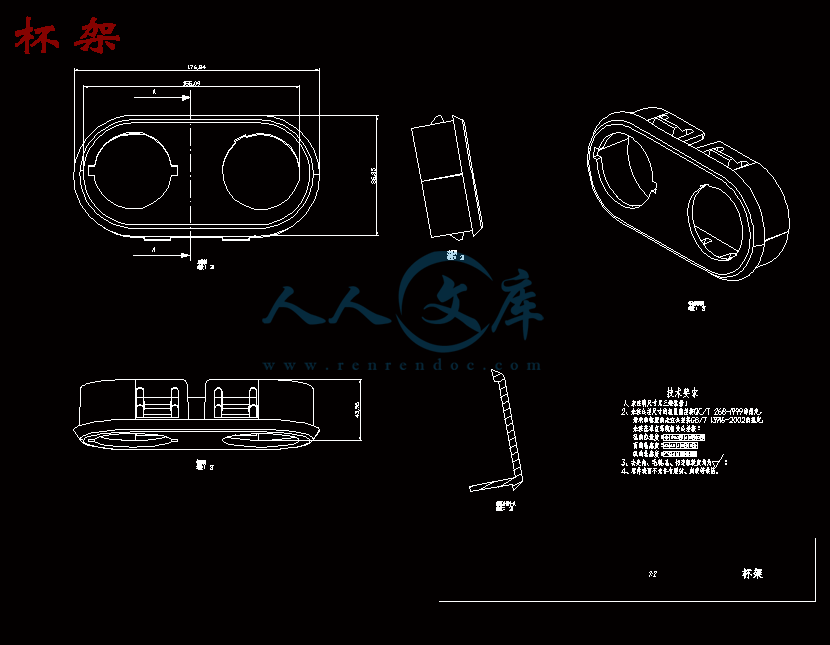

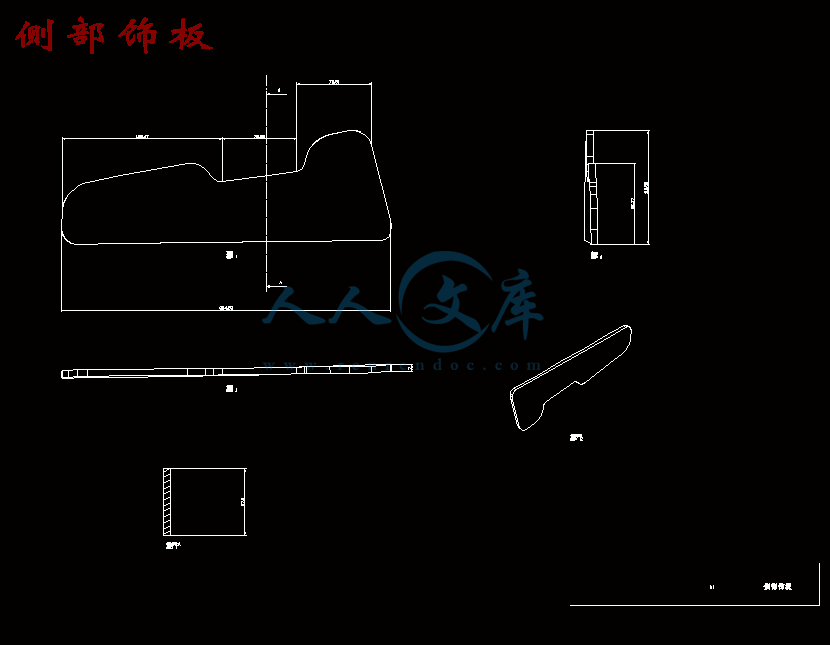

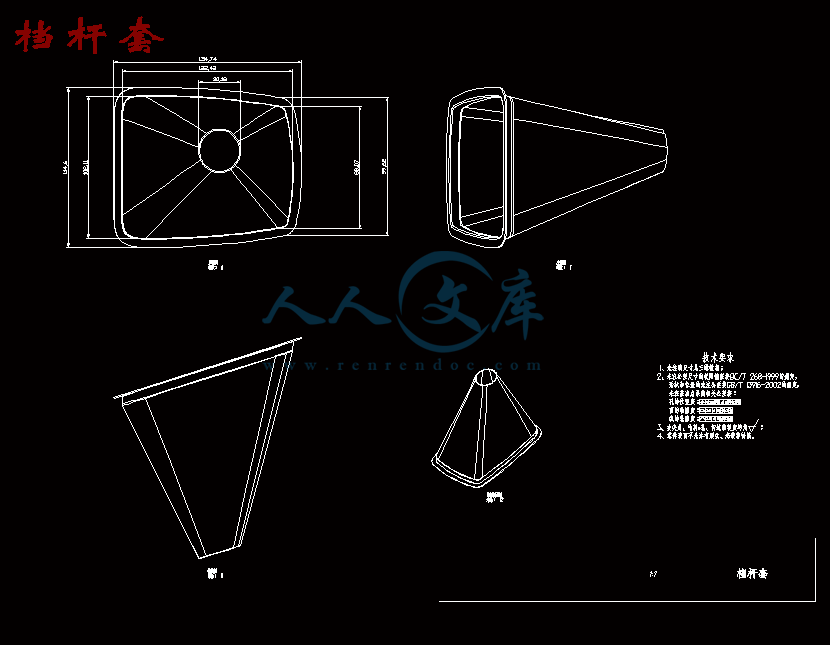

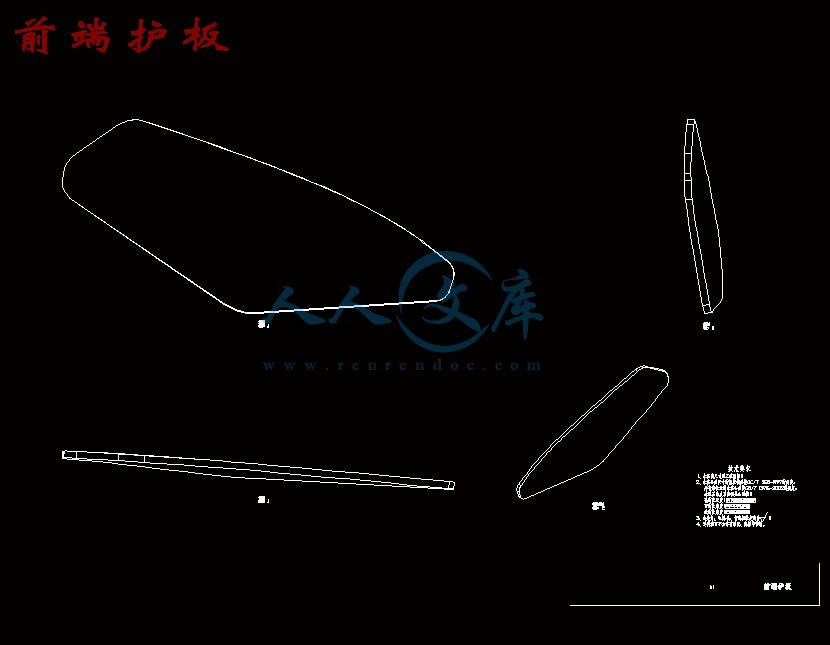

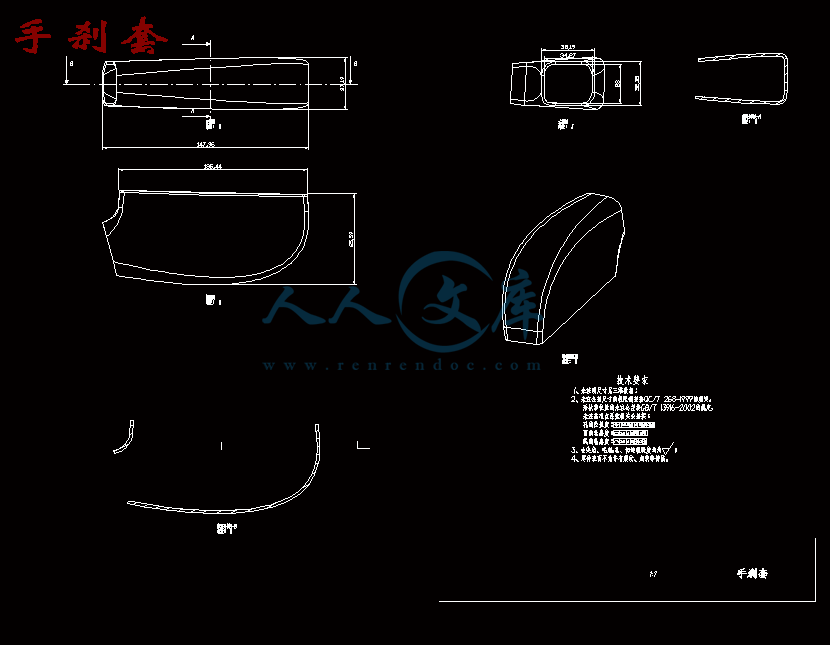

充值后即可下载预览所包含的全套带图纸源文件压缩包,需要其他课题加 Q-1459919609I新能源汽车副仪表盘设计与建模DESIGN AND MODELING OF NEW ENERGY VEHICLE AUXILIARY DASHBOARD摘要在国内经济快速发展的当下,制造业特别是汽车制造业也迎来了发展的春天。目前能源和环境问题日益严重,发展新能源汽车是解决能源环境问题的有效途径,因此,对其进行设计和研究非常有意义。本文结合了我国已有车型的结构布置方案,以及国内外典型车型的副仪表板内部结构设计,以 CATIA 软件为基础,对轿车的副仪表板进行工程可行性分析、空间布置、结构设计以及 3D 数据设计,最终完成 3D 数模。轿车副仪表板的设计是否合理与轿车后期的使用性能,该产品的可靠性以及人机舒适性等重要因素密切相关。关键词 内饰设计; 轿车副仪表板; 结构设计; 可行性分析充值后即可下载预览所包含的全套带图纸源文件压缩包,需要其他课题加 Q-1459919609IIAbstractWith the rapid development of the domestic economy, the manufacturing industry, especially the automobile industry, has also ushered in the spring of development. At present, energy and environmental problems are becoming more and more serious. Developing new energy vehicles is an effective way to solve the energy and environmental problems. Therefore, it is of great significance to design and study them.This paper combines the structure of the existing models of our country, as well as the appearance and interior design of the typical sub-panel of the car at home and abroad. The space layout, structural designing and 3D data designing of the sub-panel of the car is obtained by using CATIA softwareThe reasonability of the sub-panel designing is related to the performance of the car,the reliability of the product and the man-machine comfortability.Keywords new energy vehicles interior designing car console structural designing feasibility analysis充值后即可下载预览所包含的全套带图纸源文件压缩包,需要其他课题加 Q-1459919609III目 录摘要 .IAbstract .II1 绪论 .11.1 本课题研究的背景 .11.2 新能源汽车的概述及分类 .11.3 新能源汽车的产生背景及其发展现状 .21.3.1 新能源汽车的发展历程 .21.3.2 新能源汽车的发展现状 .32 设计说明 .42.1 新能源汽车副仪表盘组件简介 .42.1.1 副仪表盘组件概述 .42.1.2 各总成的组成 .42.1.3 各零部件的作用 .52.2 新能源汽车副仪表盘组件简介 .62.2.1 副仪表盘的工艺选择 .62.2.2 副仪表盘的材料选择 .72.3 副仪表盘总成的工程可行性分析 .82.3.1 新能源汽车副仪表盘设计的技术要求 .82.3.2 CAS 面的可行性分析 .92.3.3 工艺可行性分析 .112.4 副仪表盘组件的方案设计 .122.4.1 确立副仪表盘的设计构思 .122.4.2 安装点的布置 .132.5 新能源汽车副仪表盘的典型断面设计 .142.5.1 截面的定义 .142.5.2 副仪表盘典型断面的分布 .142.6 副仪表盘结构设计 .162.6.1 结构设计原则 .162.6.2 副仪表板总成结构设计 .172.7 副仪表盘三维模型建立 .24结论 .25致谢 .26参考文献 .27附录 .28充值后即可下载预览所包含的全套带图纸源文件压缩包,需要其他课题加 Q-145991960911 绪论1.1 本课题研究的背景汽车是工业文明的代表作之一,也是一个国家的产业支柱,在国民经济和社会发展中发挥着重要作用。多年来,人民的生活水平随着汽车的进化时刻提高,然而,许多问题也随之而来。首先,随着国民经济日益提高,家家户户都买了汽车,汽车尾气已然成为了环境污染的重要组成部分,世界各国和城市对于汽车尾气排放的标准越来越严格,许多汽车制造厂商也把新能源汽车作为第一目标。其次,家用汽车越来越多,世界各国石油供给率也越来越满足不了各国的需求,随之而来石油的价钱也愈来愈高,因此,新能源汽车的发展需收到各方面的支持,汽车工业的发展也要以新能源汽车为重中之重。随着汽车工业的极速发展,人们对于汽车的需求也越来越具有个性化,多元化。人们在享受汽车带给他们出行便利的同时,也不断地在追求汽车的性能,外观以及使用方便性。这也就导致了汽车多种不同风格的呈现。汽车的副仪表板是汽车内饰中非常重要的一部分,是汽车内饰设计风格最直观的表现,是重要、典型的汽车内装饰件集成模块。因此,对汽车副仪表板的研究与设计也是相当的重要。本课题对新能源汽车副仪表盘进行了研究,设计与建模,着重研究新能源汽车副仪表盘的设计流程、材料的选择、结构特征、作用、建模过程。1.2 新能源汽车的概述及分类新能源汽车具有先进的原理、技术和新式结构。采用非规燃料或者使用了新型的更加科学的动力装置,整体考虑了车辆动力及其驱动技术。(1)纯电动汽车车辆仅靠单一蓄电池提供电能,使电动机转动,进而达到行驶的目的(2)混合动力汽车驱动系统主要用热动力源与电动力源,可以同时运作,也可单个驱动车辆。而这两个驱动系统会根据实际情况进行单独或者同时驱动。(3)燃料电池电动汽车在催化剂作用下,氢气和空气中氧在燃料电池中经电化学反应,产生电能从而驱动汽车行驶。(4)氢发动机汽车充值后即可下载预览所包含的全套带图纸源文件压缩包,需要其他课题加 Q-14599196092氢气发动汽车是一种真正意义上实现零排放的汽车,因为氢气发动机利用氢气,为汽车提供动力,在使用过程中,所排放的唯一产物,就是纯净水。无污染、零排放而且氢气储备量极为丰富。(5)插电式混合动力汽车插电式的装了一台燃油发动机,但驱动原理和驱动装置和电动汽车是一样的。(6)其他新能源汽车除了以上提及的几种新能源汽车外,还用许多其他形式的新能源车。纯电动和混合动力汽车是人们经常提起的新能源汽车,此外还有被淘汰的增程式电动汽车,科技含量较大以及推广较为困难的燃料电池电动汽车、氢发动机汽车,还有日渐兴起表现突出的插电式混合动力汽车(属于混合动力一种)。1.3 新能源汽车的产生背景及其发展现状1.3.1 新能源汽车的发展历程18 世纪:蒸汽机和电动汽车兴起18 世纪末-1925:蒸汽机汽车、电动汽车、燃油汽车并驾齐驱1925-1960:燃油汽车一枝独秀1960-现今:电动汽车逐步复兴,其它新能源技术涌现,以及后来的新能源汽车迅猛发展,开始影响燃油汽车地位,但燃油汽车仍然处于霸主地位。(1)18 世纪:蒸汽机和电动汽车兴起1800 年前后世界第一台蒸汽汽车横空出世;1873 年世界上第一台上路的电动汽车被发明,此时用的铁锌电池无法进行充电;1881 年,第一台可以充电的电动三轮汽车被发明。随着各国都开发电动汽车,现代汽车雏形开始逐渐呈现。(2)18 世纪末-1925 :蒸汽机汽车、电动汽车、燃油汽车并驾齐驱三足鼎立的时代:蒸汽机汽车、电动汽车、燃油汽车在 18 世纪末到 19 世纪初期几乎同时有了进步与改进。卡尔本茨研制了世界上第一辆用汽油发动机来驱动的三轮汽车。众所周知,石油等化石燃料能量密度高,因此能带来更持久的续航(这也是当今电动汽车一直被诟病的核心原因) ,1920 年后蒸汽汽车由于能源转换效率低下,而电动汽充值后即可下载预览所包含的全套带图纸源文件压缩包,需要其他课题加 Q-14599196093车技术没有什么提升,而燃油汽车,价格也相对便宜。所以在逐渐进入了燃油汽车一枝独秀的局面。(3)1925-1960 :燃油汽车一枝独秀蒸汽机汽车和电动汽车几乎完全暗淡消逝,并退出舞台。而燃油汽车由于技术逐步成熟、性能越发出色。(4)1960- 现今:电动汽车逐步复兴,其它新能源技术涌现,以及后来的新能源汽车迅猛发展,开始影响燃油汽车地位,但燃油汽车仍然处于霸主地位。1.3.2 新能源汽车的发展现状首先,我们看一下国内新能源汽车的发展情况,可以说一场新能源汽车大战已经在中国打响,在新能源汽车推广方面,我国一直大力支持加以政策补贴,我国的新能源汽车发展形势一片大好 。再观全球,2016 年全球的新能源汽车增长速率高达了惊人的 40%,虽然我国新能源汽车形式大好,这个数据却是我国的 20 倍,可见国内外都对新能源汽车的高度关注和支持,所以说,在全球形势下,新能源汽车的发展潜力和发展的趋势都是不可限量的。随着新能源汽车的发展形式一片大好,整个全球的新能源汽车发展主要围绕着三大区域发展,第一个国家便是日本,日本在新能源开发上一直起着领头羊的作用,一直以混合动力汽车为主的新能源汽车推向市场,面向全国,节能一直是他们的招牌特点,的确他们以这一特点打入了多国汽车市场,增强了自身竞争力,让他们的新能源汽车在各国汽车市场都有一席之地。其次便是美国了,美国主打车便是以纯电动车为主的电动新能源汽车,再接受日本的混合动力后汽车后,新能源汽车技术能力也得到了提升,其中最为突出的便是特斯拉汽车。第三区域便是欧洲,欧洲作为发达国家聚集地,过早的工业化和现代化,环境污染问题非常严峻,在这一形式下,不得不将汽车市场重新投向新能源汽车上。纵观世界形势,可见新能源汽车在大的形势下发展前景还是一片大好的。充值后即可下载预览所包含的全套带图纸源文件压缩包,需要其他课题加 Q-145991960942 设计说明2.1 新能源汽车副仪表盘组件简介2.1.1 副仪表盘组件概述新能源汽车副仪表盘位于汽车主驾驶员座椅和副驾驶员座椅的中间,是轿车的重要组成部分,它用于控制齿轮换挡,电气开关,放置水杯等物件。整个副仪表盘是由副仪表盘主体总成,副仪表盘前端防护组件和中央控制面板组件组成,其中副仪表盘主体组件囊括副仪表木匡架,副仪表盘左侧,右侧盖板,扶手和后盖板,副仪表盘前端防护组件包括副仪表盘左前防护板和右前防护板。中央控制面板组件包括中央控制面板,换挡面板,杯架,电器开关和装饰环等。副仪表板总成如图 2-1 所示图 2-1 副仪表板总成2.1.2 各总成的组成每一个小的组件都是由许许多多的零件和部件所组成,详情如图 2-2 所示。充值后即可下载预览所包含的全套带图纸源文件压缩包,需要其他课题加 Q-14599196095图 2-2 各总成的组成2.1.3 各零部件的作用(1)副仪表盘框架:副仪表盘木匡架是主要是用来放置仪表盘的组件和副仪表盘的有关的配件,左侧盖板和右侧盖板以及后盖板和扶手都有自己的机构来安置装配和确定位置。副仪表盘骨架还有其他很多的作用,比如储存硬币,钥匙等等。副仪表板骨架的结构如图 2-3 所示。图 2-3 副仪表板骨架(2)副仪表板盘侧饰板:副仪表盘两边装饰板安置在子仪表盘配件的左边和右边,即左侧装饰板与右侧装饰板。左右侧装饰板的功用是遮盖住骨架,不暴漏出里面的零件,不能够影响驾驶员和乘坐人员对于它的外观的印象,她还有的作用就是用来是保护内部结构,不露出内部让人看着不舒服的赤裸的组件。与此同时还要安装前端护板,中央控制面板和扶手组件并且放置好它的位置。(3)副仪表盘前端防护组件:前端防护组件安装在左侧盖板和右侧盖板上,位于子仪表盘的左前侧和右前侧,就是左前护板和右前护板。左前端防护板和右前端防护板的作用是阻止线路暴露,不让驾乘人员一不小心触碰到从而保证驾乘人员的生命安全,并且使驾乘人员看到之后不觉得丑陋。充值后即可下载预览所包含的全套带图纸源文件压缩包,需要其他课题加 Q-14599196096(4)中央控制面板:中央控制面板是用来安放变速换挡机构、前翻盖以及电气开关的。同时,杯架与中央控制面板的设计是不断开的,节省了分开设计所带来的不必要的材质,使之没有造成没有必要的浪费,一旦节省了材质,就可以减少开支,降低了一部分的人力,物力和财力:还有便于工人更加方便的装配。(5)扶手:扶手箱被安置在驾驶员座椅和副驾驶座椅的中间部分,在驾驶人员驾驶汽车的时候让驾驶人员的手臂与手肘部分能够烤房,让驾驶人员更加方便的驾驶,而且手臂也不会感到劳累。同时,它还能偶遮挡住骨架上的存储盒,不让存储的东西在路途颠簸的时候翻出来 ,而且还能保证汽车内饰的美观。(6)后盖板:后端面板能够起到美观的作用,使得驾驶人员看到不会感觉到生硬,保护副仪表盘骨架的内部结构,并且能够方便存储箱的装配。(7)亮条:用于装饰新能源汽车副仪表盘的表面,还能够遮挡住新能源汽车副仪表盘的骨架内部的东西,不让内部的零件结构暴漏在外面。(8)前翻转盒 :具有存储功能,可以存放小物件,比如硬币,笔和钥匙。2.2 副仪表盘组件的工艺与材料选择2.2.1 副仪表盘的工艺选择(1)成型工艺在研究这个课题时,选择注塑成型作为副仪表盘本体的成型技术。优点是生产效率高、速度快、自动化较高且生产尺寸精度高。适用于形状复杂零件的批量生产。(2)表面处理副仪表盘的用来装扮木不架亮条以及装扮变速换挡面板的亮条在一定温度下,被搅拌至完全熔融之后,再用高压摄入模腔,冷却就能够注塑成型,塑料部分就需要通过电镀处理从而防止亮条金属不被锈蚀。这不仅使得装饰部件不被锈蚀还能提高不见得耐磨性,导电性和反光性,还提高了抗腐蚀性,提高了档次,还能够提高副仪表盘表面的美感,而且还可以减轻零件的重量。(3)脱模角度为了从模具腔中成功的取出塑料部件或者从塑料部件中取出芯材,设计了塑料部件的充分释放角。较脆、硬的材料脱模角度越大。同时,在设计时应注意释放角的选择:1 当塑料部件的尺寸相对比较大的时候,为了不让塑料部件的厚度太大或太小的情况发生,我们应该采用比较小的拔模斜度。2 对于观测值与真值接近程度高的塑料零部件,我们应该采用较小的拔模角度。充值后即可下载预览所包含的全套带图纸源文件压缩包,需要其他课题加 Q-145991960973 对于奇形怪状,凹凸不一、脱模步骤复杂的塑料部件,应采用较大的拔模角度。4 塑料部件的内表面可以具有比外表面更小的拔模角度,一旦塑料部件在脱模后需要保留在芯部的一侧。2.2.2 副仪表盘的材料选择轿车副仪表盘组件经常被选用的材料:翻译部分英文原文Additive Manufacturing: Polymers applicable for Laser Sintering (LS)AbstractAdditive Manufacturing (AM) is close to become a production technique changing the way of part fabrication in future. Enhanced complexity and personalized features are aimed. The expectations in AM for the future are enormous and betimes it is considered as kind of the next industrial revolution. Laser Sintering (LS) of polymer powders is one component of the AM production techniques. However materials successfully applicable to Laser Sintering (LS) are very limited today. The presentation picks up this topic and gives a short introduction on the material available today. Important factors of polymer powders, their significance for effective LS processing and analytical approaches to access those values are presented in the main part. Concurrently the exceptional position of polyamide 12 powders is this connection is outlined.1.IntroductionTechniques capable to transfer CAD data directly into physical objects are specified today as Additive Manufacturing (AM) 1. AM is opposite to subtractive technologies, where material is removed by drilling, milling or grinding to achieve a desired geometry. In a recently published ASTM standard (ASTM F2792-12a) the following definition of AM is established: “Additive manufacturing (AM), Processes of joining materials to make objects from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing fabrication methodologies.” One element of the layer upon layer based additive production techniques is Laser Sintering (LS) of polymers 2. Space-resolved consolidation of polymer powders by means of laser energy opens innumerable options to yield custom-built parts with freedom of complexity 3. Amongst all presently existing AM-techniques LS is considered as the most promising approach to become a sincere production technique for plastic parts appropriate for industry.1.1. LS Basic PolymersA problem obstructing LS in a wider prospect is the limited variety of applicable polymers. Whilst traditional polymer processing techniques e.g. injection molding or extrusion have access to thousands of different formulas composed of several dozen basic polymers 4, for LS treatment just a handful different formulations are provided so far. Moreover, almost all of them are based on two basic polymers: polyamide 12 (PA12) and its near relative polyamide 11 (PA11) 5. Fig. 1 presents the chemical formula of the two basic polymer structures. There similarity is obvious.Fig. 1. Chemical formula of the two basic polymers for LS powders: PA 12 and PA 111.2. Commercial situationFig. 2 illustrates the situation for the global and the LS market today regarding consumption, price and market share. It can clearly be seen, that LS-market with a share of approximately 1900 t/year is less than a niche market compared to total consumption of about 290 Mio-t/y; a relation of about 1: 200000! This means in words, as 1 kg LS-powder is sold about 200 t other polymeric material is sold in the same time. Even when the relation with the total amount of only PAs is used a consumption of 1.5 t to 1 kg LS-material exists. So, the market of LS needs further development and new materials urgently to develop more weight.Fig. 2. Market overview and comparison between global and LS marketTable 1 provides additionally an outline of the main commercially available LS materials based on PA12 and PA 11. The differences between the global polymer market and the LS market are obvious. An application rate of around 900 tons/year the LS share is not even a fraction related to 260 million tons of worldwide plastic use. However the price of LS polymers is around factor 10 and more higher compared to their respective plastics in the standard pyramid. Table 1. Commercial LS Polymers based on PA12 and PA 11 (most important ones in bold letters).In addition noticeable is the lack of standard polymers of the bottom of the pyramid for LS. Almost no materials from these so-called commodity plastics: PE, PP, PVC and others are available so far for LS processing. What are the reasons for thesesignificant differences in polymer distribution for “standard” use and LS adoption? Besides some business and consumption arguments the main reason is the very sophisticated combination of polymer properties necessary for successful application.2. Polymer Properties for LS-ProcessingFig. 3 summarizes the most important factors to transfer a polymer into a LS powder and distinguish between extrinsic and intrinsic properties. Accepting Fig. 3 it is obvious that a complex system of interconnected powder features exists. The different properties can be divided into intrinsic (thermal, optical and rheological) and extrinsic properties (particle and powder). Intrinsic properties are typically determined form the molecular structure of the polymer itself and cant be influenced easily, whereas production of powder controls extrinsic properties. This mandatory property combination is not easy to achieve from new powders and will be discussed following.Fig. 3. Combination of important properties of LS-powders (intrinsic and extrinsic);2.1. Extrinsic Properties - ParticleShape and surface of single particles regulate the behavior of the resulting powder to a great extent. In case of LS powders the particles should be at least as feasible formed spherical. This is in order to induce an almost free flowing behavior and is necessary as LS powders are distributed on the part bed of an LS machine by roller or blade systems and will not be compacted additionally. A simple approach to access the flowability of powders is the determination of bulk and tap density. Determination of bulk and tap density gives a good indication on the one hand regarding powder density which is correlated with the final part density and on the other hand regarding the flowability by calculation of the so called Hausner ratio H R . Regarding literature a H R 1.4 means fluidization problems (cohesive properties): H R = tap / bulk ( loose = bulk density; tap = tapped density) The LS part density achieved during processing is openly linked to powder density in part bed and is thus coupled to the shape of particles and their free flowing behavior. Fig. 4 illustrates some particle forms attained from different powder generation processes. Spherical particles are usually received from co-extrusion processes with soluble/non-soluble material mixtures, like oil droplets in water. Potato-shaped particles are typical for the today available commercial PA12 powder from precipitation process. Particles obtained from cryogenic milling are inadequate in the majority of cases and fail for LS processing. The poorer powder flowability generates poor part bed surface in LS machine and a reduced powder density as well. Thus, cryogenic milled powders finally end in weak, less condensed LS parts with low density and poor properties usually.Fig. 4. Particle shapes attainable by different production technologies;2.2. Exrinsic Properties - PowderFor LS powders a certain particle size distribution (PSD) is necessary to be processable on LS equipment. This distribution is favorably between 20 m and 80 m for commercial system. The PSD is usually measured by laser diffraction systems.However, with this measurement the fraction of small particles is frequently neglected. But particularly the amount of small units is often responsible if a powder depicts a reasonable LS processing behavior or not.Fig. 5 illustrates such a case. Both, Powder 1 and Powder 2 have some good and acceptable PSD looking at volume distribution (Fig. 5, middle column). From that point of view both powder should be processable on LS equipment. However, in reality, the trial to do so with Powder 2 failed. The reason can be recognized form number distribution (Fig. 5, right column).Powder 2 consists of an extreme high portion of small particles which may induce stickiness in powders. The enhancedadhesion between particles reduces the free flowing powder behavior and prevents LS processing. As especially milled powder represents often a high amount of fine particles this is another reason why these powders are frequently unsuccessful in LS processing.Fig. 5. Distribution of powders with similar volume distribution and dissimilarnumber distributionIt is also interesting to recognize, that even for the most often used commercial powders for LS-processing: PA 2200 (Company EOS) and Duraform PA (company 3D-systems) the powder distribution is not equal. Fig. 6 indicates the distribution. It can be clearly identified, that PA 2200 exhibits an almost mono-modal distribution in contrast to Duraform PA, where the distribution consists of several powder fractions. Even form the particle photos in the right side of Fig. 6 it can be identified that Duraform PA powder has a much broader distribution with a higher amount of fine particles. If the fine particles dont influence the flowability too much in a negative sense, the smaller particles can help to enlarge the powder density and consequently the part density as well.Fig. 6. Powder distribution of commercial LS-Powders (PA12)2.3. Intrinsic Properties Thermal BehaviorIdentifying the challenging aspects of the desired thermal properties it is necessary to understand the course of action during LS processing. In a LS system essentially a CO 2 laser beam is used to selectively fuse or melt the polymer particles deposited in a thin layer. Locally full coalescence of polymer particles in the top powder layer is necessary as well as an adhesion with previous sintered layers. For semi crystalline polymers usually used in LS processing this implies that crystallization (T c ) should be inhibited during processing as long as possible, at least for several sintered layers. Thus, processing temperature must be precisely controlled in-between melting (T m , red line, Fig. 7) and crystallization (T c , blue line, Fig. 7) of the given polymer. This meta-stable thermodynamic region of undercooled polymer melt is called sintering window of LS processing for a given polymer. Fig. 7 shows a DSC run (DSC = Differential Scanning Calorimetry) for commercial PA 12 LS-powder. The nature of sintering window between onset points of T c and T m is obvious.Fig. 7. Typical DSC-Thermogram with nature of sintering window as LS process temperatureHowever it must be indicated, that the scheme in Fig. 7 is just an idealized representation of thermal reality as it is received with fixed heating and cooling rates (10C/min) never existing during LS processing. In fact there are undefined and hardly controllable temperature change rates and especially the sintering temperature (T s = process temperature during sintering) close to crystallization onset means that stimulation of crystallization shifts to higher temperatures for LS processing. Fig. 8 indicates what can occur usually for polymer powders with a too small sintering window. If T s is too close to crystallization (left side in Fig. 8) curling due to premature crystallization is induced and parts are distorted after releasing fromsurrounding powder bed. If temperature is just slightly higher during processing (right side of Fig. 3) an early crystallization can be avoided but in this case the temperature is too close to melting and leads to a loss of exact definition of part features. Powderparticles in the direct neighborhood of the laser trace stick on the molten surfaces (lateral growth) and prevent desired resolution of part topography.Fig. 8. LS Processing problems for too small sintering window: curling or lateral growth;Additionally to the very critical point of suitable thermal transitions (T m , T c ) there are farther intrinsic factors like optical properties, melt viscosity and surface tension that needs to be very specific for successful application of polymer powders toSelective Laser Sintering.2.4. Intrinsic Properties Viscosity and Surface TensionA low zero viscosity ( 0 ) and a low surfaces tension () of polymer melt are necessary for successful LS processing. This is indispensable to generate an adequate coalescence of polymer particles. Especially a low melt viscosity without shear stress is of high importance, as, unlike injection molding, LS cannot provide an additional compacting during part generation (holding pressure). Fig. 9 indicates the effect of inferior melt viscosity clearly visible. The right side image (Fig. 9) depicts a lot ofimperfections in the part morphology and a poor surface quality as well. The required low zero viscosity is also the reason why attempts to process amorphous polymers with LS usually ends with brittle and instable parts. Due to the fact that viscosity ofthose polymers above glass transition (T g ) is still very high in general a proper coalescence does not take place usually.Fig. 9. Cross section of PA 12 parts made from PA 12 polymers with different melt viscosity2.5. Intrinsic Properties Optical PropertiesFig. 10 depicts a scheme of the optical circumstances during LS processing. When a laser beam hits a polymer material three effects can occur in principle. Besides the absorption of the energy also (diffuse) reflexion and transmission is possible (Fig. 10a). In case of energy absorption it is obvious that a sufficient capability of the material to absorb radiation of present laser wavelength (CO 2 -Laser: 10.6 m) is necessary. This is apparent for most polymers as they consist of aliphatic compounds (C-H). Those polymers have, in the majority of cases, some group vibrations in the fingerprint infrared (IR) region, sufficient to absorb relevant portions of 10.6 m CO 2 -laser radiation.Fig. 10. Optical circumstances for LS processingHowever during the LS processing the effects of reflexion and transmission become relevant as well (see Fig. 10 b). Transmission is desired to direct a sufficient portion of the radiation energy into deeper regions of the powder bed in order to induce an adequate layer adhesion. Only when the current powder layer is connected with the previous sintered layer in a satisfactory amount a LS part can be generated without layer delamination. In case of a poor absorption and transmission capability, an increase of laser energy power can compensate to a certain amount the effect. However an augmentation of laser power must be limited in order not to destroy the polymer by too high energy.3. ConclusionAdditive Manufacturing (AM) is close to become a production technique with the potential to change the way of producing parts in future. High complex parts in small series are targeted. Selective Laser Sintering (LS) of polymer powders is onecomponent of the additive production techniques, which is regarded as one of the most promising ones for functional end products in the AM-area. However an analysis of the commercial situation reveals, that there is a problem with the small number of applicable polymer powders for this technology today.To understand this limitation, the paper summarizes the most important key factors materials which have to b

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

|

2:不支持迅雷下载,请使用浏览器下载

3:不支持QQ浏览器下载,请用其他浏览器

4:下载后的文档和图纸-无水印

5:文档经过压缩,下载后原文更清晰

|

川公网安备: 51019002004831号

川公网安备: 51019002004831号