汽车前灯罩的冲压模具设计【全套含CAD图纸、说明书】

收藏

资源目录

压缩包内文档预览:(预览前20页/共35页)

编号:14951781

类型:共享资源

大小:891.01KB

格式:ZIP

上传时间:2019-02-19

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

20

积分

- 关 键 词:

-

全套含CAD图纸、说明书

汽车

灯罩

冲压

模具设计

全套

cad

图纸

说明书

仿单

- 资源描述:

-

- 内容简介:

-

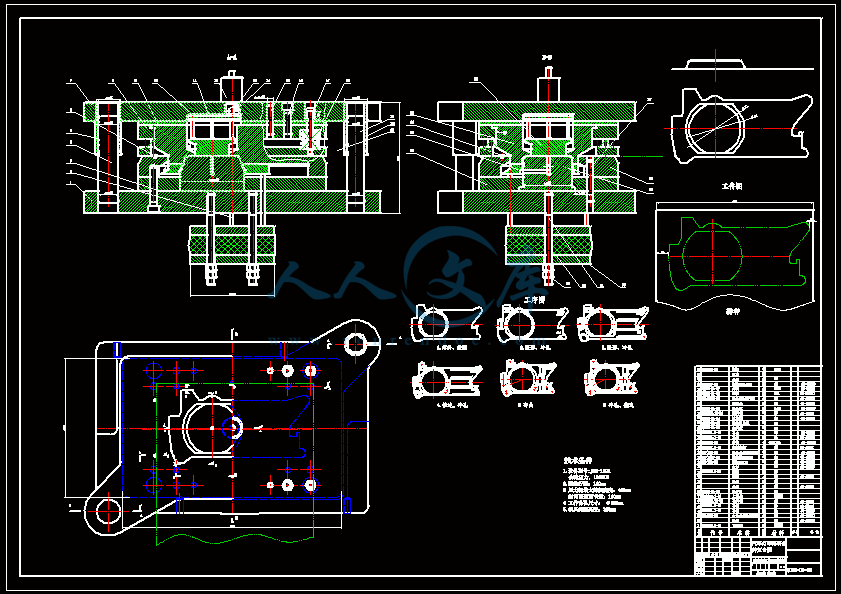

毕业设计(论文)题目: 汽车前灯罩的冲压模具设计 系 别 专业名称 班级学号 学生姓名 指导教师 二O* 年 五 月 毕业设计(论文)任务书I、毕业设计(论文)题目:汽车前灯罩的冲压模具设计II、毕 业设计(论文)使用的原始资料(数据)及设计技术要求:1. 灯罩零件图2.生产纲领:中等批量3.要求完成零件的冲压工艺分析和冲压工艺规程的编制。1) 分析冲件成形工艺及坯料展开 2)编制灯罩零件冲压工艺 3)完成灯罩模具设计III、毕 业设计(论文)工作内容及完成时间:1. 查阅相关资料,外文资料翻译(6000字符以上),撰写开题报告。第1周第2周3.绘制灯罩板冲件图,分析冲件成形工艺及坯料展开 第3周第6周4.编制灯罩冲压成形工艺规程; 第7周第8周5.绘制灯罩模具总装图及零件图; 第9周第13周6.撰写毕业设计说明书(论文) 第14周第16周7.毕业设计审查,毕业答辩。 第17周 、主 要参考资料:1.冲模设计手册编写组.冲模设计手册.北京:冲模设计手册,19952. 陈为国.带缺口筒形件冲压工艺及模具设计.金属成形工艺,1998.23.王新华,袁联富编.冲模结构图册.北京:机械工业出版社,20034.罗益旋.冲压新工艺新技术及模具设计实用手册. 银声音像出版社,20045. GB28512875冷冲模国家标准 汽车前灯罩的冲压模具设计 摘要: 本文介绍了汽车前灯罩的冲压模具设计。设计内容包括产品零件工艺分析、模具设计以及主要零件制造工艺的确定等。此零件结构复杂,需要多道工序完成,基本工序包括落料、拉深、冲孔、弯曲、翻边等。针对此产品件,应明确设计路线,确定设计方案,构思模具结构。首先对产品进行结构和尺寸分析,利用AUTOCAD绘出零件的三向视图,确定尺寸;之后确定优选的工艺方案(落料、拉深胀形、冲孔胀形、冲孔修边、冲孔弯曲冲孔、翻边);然后再进行必要的工艺计算和尺寸计算,利用AUTOCAD完成第一道工序落料拉深复合模装配图,并绘出各非标零件;然后同样用AUTOCAD完成第二道工序胀形冲孔复合模;对其它工序进行分析,确定每道工序的细节工作;最后完成设计。关键词:灯罩 冲压 模具 工艺 设计指导老师签名:Automotive Stamping Die Design front lamp shadesAbstract: This paper describes the car before the shade of the stamping die design. Includes part of the product design process analysis, mold design and manufacturing process to determine the main parts and so on. This part is complex, requires multiple procedures done, the basic processes include blanking, drawing, punching, bending, flanging and so on. Parts for this product, the design should be clear lines to determine the design, the idea of the mold structure. First, the product structure and size analysis, the use of AUTOCAD to draw part of the three views to determine the size; then determine the optimal process plan (Blanking, Drawing - bulging, punching - bulging, punching - trimming, Punching - Bending - piercing and flanging); and then make the necessary calculation and dimensioning techniques, the use of AUTOCAD to complete the first process - drawing composite blanking die assembly drawing, and draw the non-standard part; then the same with AUTOCAD completion of the second procedure - bulging punching compound die; of other processes were analyzed to determine the details of each process of work; the last to complete the design.Keywords: stamping die process design lampshade Signature of Supervisor:朗读显示对应的拉丁字符的拼音字典目录前 言31 绪论41.1我国冲压模具业发展现状41.2 我国冲压模具制造技术发展趋势42 汽车前灯罩成形工艺分析72.1 分析制件的冲压工艺性72.1.1 材料72.1.2 结构分析72.1.3 尺寸精度与表面粗糙度72.2 确定冲压工艺方案72.3 模具形式82.4 毛坯展开计算82.4.1 拉深部分82.4.2 弯曲部分92.4.3 其它部分 (直接由CAD得出)93 落料拉深复合模设计103.1 排样103.2 确定冲压方向和冲压中心103.2.1 确定冲压方向103.2.2 确定压力中心113.3 确定拉深次数123.4 确定冲裁力和拉深力133.4.1 冲裁力133.4.2 压边力133.4.3 拉深力的计算133.5 选择压力机143.6 选用标准模架153.7 工作部分尺寸计算153.7.1 拉深工作部分尺寸153.7.2 落料工作刃口部分尺寸计算163.8 模具总体设计183.8.1 工作零件183.8.2 其它主要零件203.9 模具结构尺寸验算244 胀形冲孔复合模设计254.1 成形部分254.2 变形力与冲裁力的计算264.2.1 胀形变形力264.2.2 冲裁力274.3 确定压力中心274.4 选择压力机284.5 选用标准模架294.6 工作部分刃口尺寸计算294.6.1 对冲裁刃口尺寸进行计算294.6.2 胀形刃口尺寸的说明及确定294.7 模具结构设计304.7.1 主要工作零件304.7.2 其它零件设计31结 论33参考文献34致谢35毕业设计(论文)任务书I、毕业设计(论文)题目:汽车前灯罩的冲压模具设计II、毕 业设计(论文)使用的原始资料(数据)及设计技术要求:1. 灯罩零件图2.生产纲领:中等批量3.要求完成零件的冲压工艺分析和冲压工艺规程的编制。1) 分析冲件成形工艺及坯料展开 2)编制灯罩零件冲压工艺 3)完成灯罩模具设计III、毕 业设计(论文)工作内容及完成时间:1. 查阅相关资料,外文资料翻译(6000字符以上),撰写开题报告。第1周第2周3.绘制灯罩板冲件图,分析冲件成形工艺及坯料展开 第3周第6周4.编制灯罩冲压成形工艺规程; 第7周第8周5.绘制灯罩模具总装图及零件图; 第9周第13周6.撰写毕业设计说明书(论文) 第14周第16周7.毕业设计审查,毕业答辩。 第17周 、主 要参考资料:1.冲模设计手册编写组.冲模设计手册.北京:冲模设计手册,19952. 陈为国.带缺口筒形件冲压工艺及模具设计.金属成形工艺,1998.23.王新华,袁联富编.冲模结构图册.北京:机械工业出版社,20034.罗益旋.冲压新工艺新技术及模具设计实用手册. 银声音像出版社,20045. GB28512875冷冲模国家标准 系 专业类 班学生(签名): 填写日期: 20XX 年 01 月 03 日指导教师(签名): 助理指导教师(并指出所负责的部分):机械设计制造及其自动化 系主任(签名):附注:任务书应该附在已完成的毕业设计说明书首页。附录:灯罩零件图毕业设计(论文)外文文献翻译题目 汽车前灯罩的冲压模具设计专 业 名 称 班 级 学 号 学 生 姓 名 指 导 教 师 填 表 日 期 20XX 年 05 月 20 日Mould type of numerical control process computer assist the cutter choose and studyForewordNumerical control include cutter production and cutter of orbit choose two key problems process ,. The first problem has been got and studied extensivly and deeply over the past 20 years, a lot of algorithms developed have already got application in commercial CAD/ CAM system. Most CAM systems can produce the cutter orbit automatically after users input relevant parameters at present. Comparatively speaking , it is still not ripe to regard quality , efficiency as the research of choosing the problem of cutter of optimizing the goal correctly, do not have commercial CAM system that can offer the preferred decision support tool of cutter at present, therefore it is difficult to realize the integrating automatically and organically of CAD/ CAM. The cutter is chosen to usually include cutter type and cutter size. Generally speaking , suitable for one processing cutter of target for much kind , one cutter can finish different processing tasks, so it is easier to only consider meeting the cutter that basically processes the requirement and choose, especially to geometirc characteristics of model such as the hole , trough ,etc. But in fact, it is common for cutter to choose and sure optimization goal interrelate, for instance most heavy to cut efficiency , process time , minimum process cost , longest service life ,etc. at least, so the cutter is chosen it is a complicated optimization question. Such as mould type one of parts, because the geometirc form is complicated (usually include curved surface of freedom and island), influence geometry that cutter choose it restrains from to be can explicit to say among CAD model, need to design the corresponding algorithm to draw, therefore choose the cutter specification suitable and cutter association , it is not easy things by improving efficiency and quality processed in numerical control.Mould type generally with preparation method that numerical control mill, usually including rough machining, half finish machining , precise process of processing etc. The principle of rough machining is to spare no effort to remove the surplus metal with high efficiency, therefore hope to choose the larger cutter, but the cutter is oversized, may cause the increase of the crude volume ; Half finish machining of tasks to remove rough machining leave over step that get off mainly; Finish machining mainly guarantees size of the part and surface quality. Consider , go on , select exist , sure by computer difficult automatically totally up till now, therefore assist the cutter to choose in the computer that we developed (Computer Aided Tool Selection , CATS) among the system, base on , provide one aid decision tool for user, rough machining , half finish machining , precise to process etc., the real policy-making power is still left to users, in order to give full play to the advantages of computer and people.1 Basic structure of the system CATS system is CAD model, output for cutter type , cutter specification , mill depth of sharpening , enter the giving amount , rotational speed of main shaft (cut the pace ) and process six parameters such as time (such as Fig. 1), including choosing the aid decision tool in cutter type, rough machining cutter choose aid decision tool, half finish machining cutter choose aid decision tool and finish machining cutter choose aid decision tool ,etc.Given the rough machining in Xingqiang processing of the important position (usually rely time 510 times), rough machining, the system automatically optimize portfolio with cutlery functions to enhance overall processing efficiency. In addition to the decision-making tools, the system also has a detailed look cutlery norms, based on the type and size cutlery recommended processing parameters and assess the function of processing time, the last generation of the overall results of choice cutlery statements (figure 2). All the data and knowledge systems cutlery done by the background database support.2 Key technologies and algorithms2.1 Cutlery type choiceAccording to Assistant Xingqiang digital processing practice, Xingqiang Xi state general processing cutlery into milling cutter, milling cutter radius milling cutter and the first three balls. D based cutlery diameter, radius radius r when r=0 for milling cutter, 0RCutlery can be divided into the overall style and embed films ceremony. For inlay film style, the key is to select the materials razor blades, razor blades materials choice depends on three elements : the processing of working materials, machine tools and cutlery jig stability of the state structures. Processing system will be translated into material steel, stainless steel, cast iron, nonferrous metals, materials and hard to cut materials six groups. Machine tool jig stability into good, better and less than three levels. Cutlery investigation into the short and long cantilever structures two, the system automatically reasoning on the basis of the specific circumstances of razor blades materials, decision-making knowledge from Walter cutlery manual system by the users first choice cutlery type in the world. To embed film style cutlery, a rules-based automated reasoning suitable razor blades materials. For example, if the final processing of materials for the steel, machine tool jig for good stability, cutlery cantilever structures for short, razor blades materials for WAP25.Rough machining cutlery portfolio optimizationXingqiang rough machining the aim is to maximize the removal of excess metal normally used milling cutter, take-cutting approach. Thus, 3D mould Xingqiang the rough machining process, is actually a series of 2.5D components Xingqiang processing. Cutlery optimization is to find a group of cutlery portfolio, allowing for maximum efficiency removal of most metals. Cutlery portfolio optimized basic methods as follows :A. To do some long step into knife in the direction of a group of vertical and horizontal search Xingqiang another entity to form a search layer.B. Derive closed to the contours.C. Calculated between Central and outside the island or islands and the distance between the key that affect cutlery choice geometric constraints algorithm flow As shown in figure 3D. According to the principle of the merger (adjacent to the critical distance will be smaller than the difference between the threshold) to search layer merger, graphic processing and identifying viable cutlery sets, a processing layer.E. Determine the use of each processing layer cutlery, cutlery Xingqiang processing portfolio. F. According cutlery recommended processing parameters (cutting speed, depth and into Xianxiao to speed), the calculation of material removal. G. According to the actual removal of the volume processing layer, the processing time for each processing layer. H. Xingqiang calculating the total processing time and residual volume.I. The overall portfolio of the Group cutlery processing efficiency assessment. J . Repeat ai until derive optimal mix of cutlery. If time is the goal, called for the entire processing time t Xingqiang shortest portfolio to optimize cutlery.2.2 Semi-finished cutlery choiceThe main purpose is to remove semi-finished rough machining residual contours of the new warrants. To completely remove height, depth must be greater than Xianxiao parts of each level to the surface distance x. Its algorithm steps are as follows :Step 1:entity models from parts of two adjacent to the cross section of the surface contours and the corresponding length;Step 2: The average length of contours;Step 3:calculate its width;Step 4 : calculating height floor to the surface of parts to the law distance x;Step 5 : steps 1 repeat steps 4, each level of decision Xianxiao depth;Step 6 : calculate cutlery diameter D, by or under cutlery experience D=x/0.6 manual recommended;steps7 : choose Xianxiao x depth than the smallest cutlery.2.3 fine cutlery choice Fine cutlery choice is the basic principle : cutlery parts surface radius smaller than the smallest size R curve radius r, the general admission R= (0.80.9) r. Its algorithm steps are as follows :Step 1 : from the smallest curve radius calculation model parts entities; Step 2 : From cutlery database search radius of less than a cutlery calculated radius of the curve all cutlery; Step 3 : select the best cutlery meet the above requirements; Step 4 : If all cutlery than the smallest curve radius, the smallest chosen as a recommended cutlery.3 summary and discussionMould type of craft of processing plan , need high technology and experience very usually, prepare NC time of data nearly and process time to be large. So person who produce of craft of processing plan and NC process demand of the order right away seem further more urgent automatically.This text system research mould type of craft cutter plan , choose problem, put forward mould of rough machining , half finish machining , finish machining principle and method that cutter chooses, the realization algorithm with corresponding structure , and has carried on the realization of preliminary programming under the environment of UG/OPEN API, have developed CATS prototype system. In cutter type and on the foundation that the specification is fixed, system also can recommend parameter of processing according to cutter manual (cut pace , mill , sharpen depth , enter person who give ,etc.), evaluate corresponding processing time. Final purpose its to realize integration of CAD/CAM really , produce through aftertreatment numerical control process the order.Need to point out , should improve the mould type totality of and process efficiency, need it from the rough machining , half finish machining , consideration on the whole of finish machining , make up and optimize many targets, this will be work that we want to carry on next .模具型腔数控加工计算机辅助刀具选择和研究引言 数控加工中包括刀具轨迹的产生和刀具选择两个关键问题。前一问题在过去的20 年里得到了广泛而深入地研究, 发展的许多算法已在商用CAD/ CAM 系统中得到应用。目前大多数CAM 系统能够在用户输入相关参数后自动产生刀具轨迹。比较而言,对以质量、效率为优化目标的刀具选择问题的研究还远未成熟,当前还没有商用CAM 系统能够提供刀具优选的决策支持工具,因而难以实现CAD/ CAM 的自动有机集成。刀具选择通常包括刀具类型和刀具尺寸。一般来说,适合一个加工对象的刀具通常有多种,一种刀具又可完成不同的加工任务,所以仅考虑满足基本加工要求的刀具选择是较容易的,尤其对孔、槽等典型几何特征。但实际上,刀具选择通常和一定的优化目标相联系,如最大切削效率、最少加工时间、最低加工成本、最长使用寿命等,因此刀具选择又是一个复杂的优化问题。比如模具型腔类零件,由于几何形状复杂(通常包含自由曲面及岛) ,影响刀具选择的几何约束在CAD 模型中不能显式表示,需要设计相应的算法进行提取,因而选择合适的刀具规格及其刀具组合,以提高数控加工的效率与质量并非易事。 模具型腔一般用数控铣的加工方法,通常包括粗加工、半精加工、精加工等工序。粗加工的原则就是尽最大可能高效率地去除多余的金属,因而希望选择大尺寸的刀具,但刀具尺寸过大,可能导致未加工体积的增多;半精加工的任务主要是去除粗加工遗留下来的台阶;精加工则主要保证零件的尺寸及表面质量。考虑到目前完全由计算机进行自动选刀还存在一定困难,因而在我们开发的计算机辅助刀具选择(Computer Aided Tool Selection ,CATS)系统中,立足于给用户提供一个辅助决策工具,即粗加工、半精加工、精加工等,真正的决策权仍留给用户,以充分发挥计算机和人的优势。 1 系统基本结构 CATS系统的输入为CAD模型,输出为刀具类型、刀具规格、铣削深度、进给量、主轴转速(切削速度) 和加工时间等六个参数(如图1) ,包括刀具类型选择辅助决策工具、粗加工刀具选择辅助决策工具、半精加工刀具选择辅助决策工具及精加工刀具选择辅助决策工具等鉴于粗加工在型腔加工中的重要地位(通常为精加工时间的510 倍) ,粗加工时系统具有刀具自动优化组合的功能,以提高整体加工的效率。除了上述决策工具外,系统还具有查看刀具详细规范、根据刀具类型和尺寸推荐加工参数及评估加工时间等功能,最后生成总的刀具选择结果报表。系统所有的刀具数据及知识均由后台数据库做支持。 2 关键技术及算法 2.1 刀具类型选择 根据模具型腔数控加工实践,型腔铣加工的刀具一般分为平头铣刀、圆角铣刀及球头铣刀三种。设刀

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号