摘 要

随着社会的不断发展和进步,消费者对于水果的需求量日益增加,并且中国还是水果种植和出产大国,水果贸易十分发达,目前的水果套袋包装工业则远远达不到要求,每年都会有一笔不小的经济损失是出自水果损伤方面的,而水果损伤的原因主要在于水果在运输过程中会受到多种因素的影响而受到的破坏,大大的增加了供货商的经济损失。为了减少水果贸易的损失需要有一种能给水果表面进行套袋包装的水果套袋设备。

本次主要对水果套袋机的总体布局和包装工艺进行了分析,对水果套袋机的工作过程进行了规划,并在此基础上对水果套袋机的工作装置和传动装置进行了详细设计,然后对水果套袋机的电动机和主要零部件的性能参数进行计算和整理,最后对水果套袋机中的转轴、运输带、支架以及间歇机构进行了设计。

水果套袋机不仅是在一定程度上解决了水果从采摘到最终流通到市场的过程中的水果受损问题,而且真正意义上实现了水果套袋包装工业的自动化。尽管水果套袋机的市场前景十分光明,但中国的水果套袋机种类比较少,功能上也有所欠缺,缺乏高精度高性能的优质产品。所以,还需要进行不断的改进和创新,使得水果套袋机可以为中国水果套袋包装工业创造更多的效益。

关键词 水果套袋机;转轴;间歇机构

Fruit bagging machine design

Abstract

Along with the continuous development and progress of society, consumer demand for fruit growing, and China or fruit growers and producers, fruit trade is highly developed, the fruit bag packaging industry is far not up to the requirements every year a sum of no small economic loss is from fruit injury, and fruit damage reason mainly lies in fruit in the transport process will be subject to the influence of many factors have been destroyed, greatly increase the supplier's economic losses. In order to reduce the loss of fruit trade, it is needed to have a fruit bagging device that can be carried out on the surface of the fruit.

The mainly on fruit bagging machine overall layout and packaging technology are analyzed, to planning of fruit bagging machine working process, and on the basis of fruit bagging machine work device and a driving device were detailed design, then the performance parameters of fruit bagging machine motor and main components of the calculation and arrangement, the fruit bagging machine shaft, transportation belt and a bracket and intermittent mechanism is designed.

Fruit bagging machine is not only to a certain extent, to a certain extent, to solve the problem of fruit damage from picking to the final flow to the market, but also to achieve the true sense of fruit bagging packaging industry automation. Although the fruit bagging machine market prospects are very bright, but China's fruit bagging machine types are relatively small, also has a lack of functionality, the lack of high precision and high performance quality products. Therefore, the need for continuous improvement and innovation, so that fruit bagging machine can be used to create more benefits for China's fruit bag packaging industry.

Key words Fruit bagging machine; shaft ; Intermittent mechanism

目 录

摘要 I

Abstract II

第1章 绪论 1

1.1 本设计研究的目的及意义 1

1.2 国内外同类研究及设计的现况 1

1.3 本设计的主要研究思路 2

1.4 本章小结 3

第2章 整体方案设计 4

2.1 总体工艺分析 4

2.2 总体布局分析 4

2.3 工作过程分析 5

2.4 本章小结 7

第3章 水果套袋机工作装置的设计 8

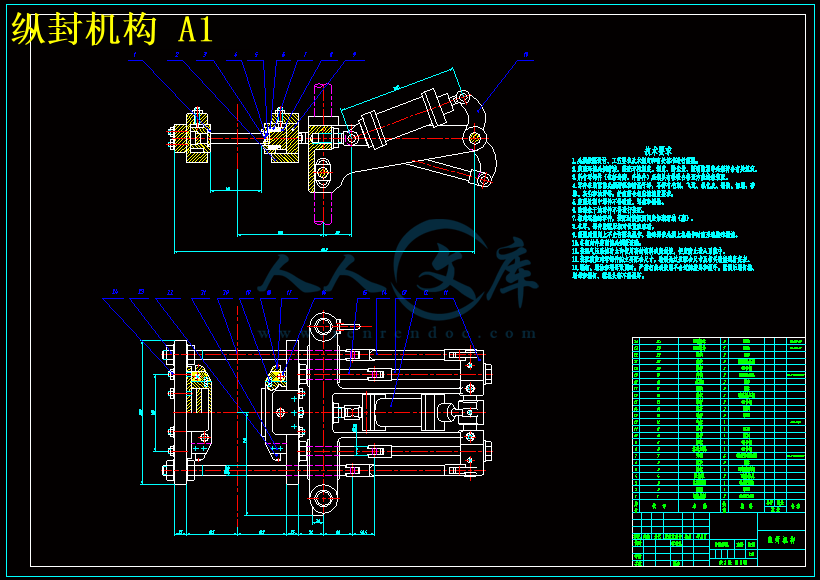

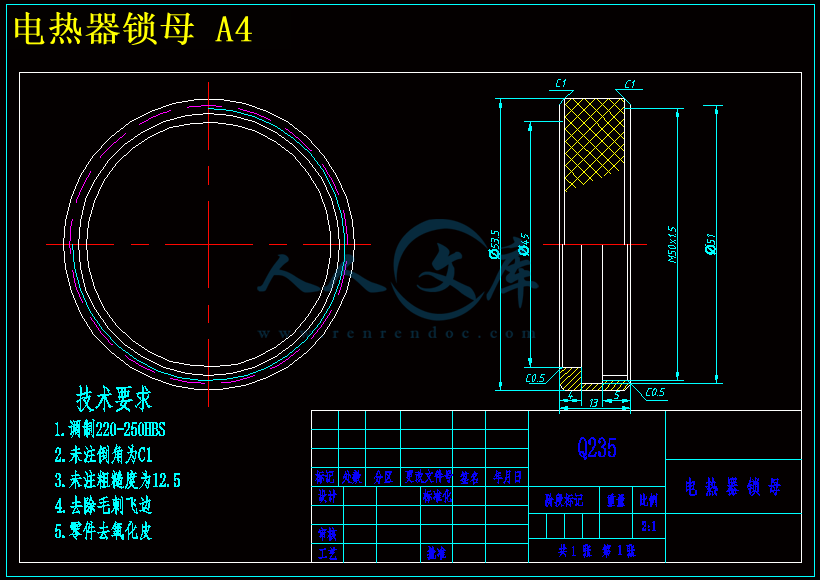

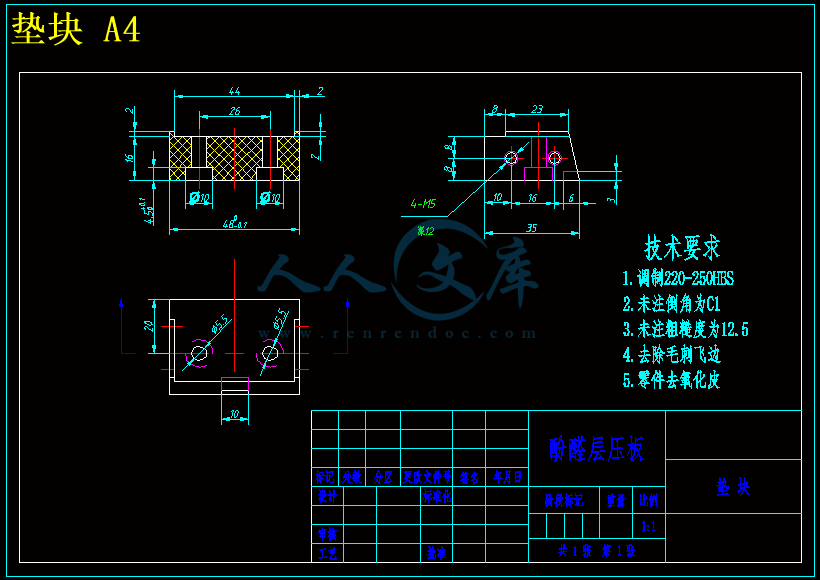

3.1 封口装置设计 8

3.2 退网装置的设计 11

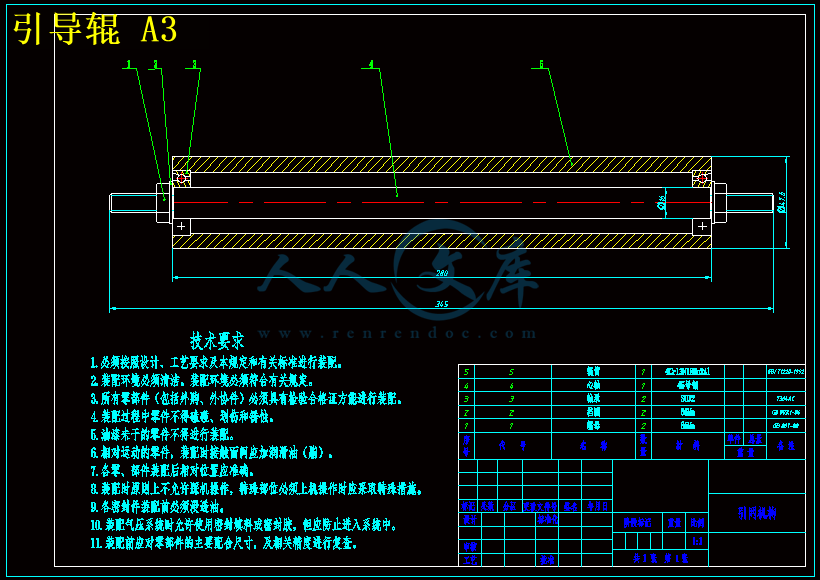

3.3 引导装置设置 11

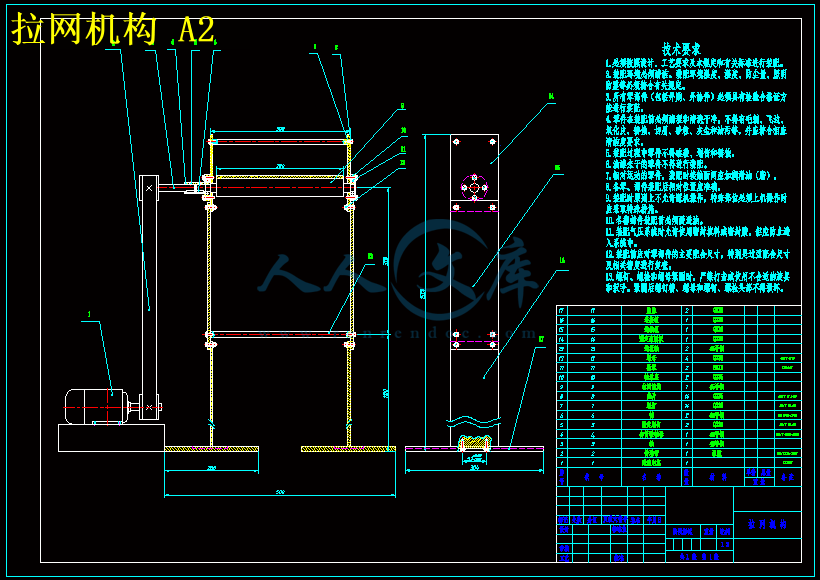

3.4 拉网装置的设置 12

3.5 本章小结 13

第4章 水果套袋机传动装置的设计 14

4.1 电动机的选择 14

4.2 传动比分配 16

4.3 支架的设计 18

4.4 运输带的设计 19

4.5 转轴的设计 23

4.6 间歇机构的设计 25

4.7 本章小结 26

结论 27

致谢 28

参考文献 29

第1章绪论

1.1本设计研究的目的及意义

水果套袋是水果在市场中是不可或缺的一个方面,水果套袋的好处主要有三个:优点一是可以起到保障水果品质,防止水果在途中造成不必要的损失,从而可以有效的降低破坏水果质量的程度;优点二是可以使得水果的样貌上看上去更加漂亮;优点三是运送途径多样[1]。

水果从摘取到最后流通于市场的过程当中会因为各种原因导致水果的品质降低,这样就会给供货商和销售商造成了不小的损失,究其原因不外乎水果运输过程中受到的损害。为了使水果在摘取下来以后,避免在交通运输和正常的存放中受到不同角度的碰撞,从而对水果造成更多的伤害,这就需要一种可以保护水果的产品出现,水果套袋机便应运而生。给水果进行一次套袋的包装就可以起到显著的效果,让水果受到更少的损伤。

目前而言,我国进行水果套袋包装还停留在人工手动操作的阶段,这样套袋的效率十分低下而且还耗费大量的劳动力,并且还提高了供应商的经济投入[2]。所以,水果套袋机的设计是极其符合现状的,而且水果套袋机的市场前景也是十分广阔的。水果套袋机的优点在于它是机器自动进行套袋包装,大大减少了劳动力,降低了成本,也提高了水果在市场上的最终品质。水果套袋机设计中的机器操作简单,容易上手,并且安全性能高没有任何安全隐患。

水果套袋机一旦在市场流通起来便会引起新的潮流。据统计表明,中国沿海地区和内陆地区的水果贸易非常发达,使得许多农民将水果种植业大力发展起来。最近的几年里,中国的水果市场非常发达,这也必将导致水果种植业的飞速发展。时下,中国内陆地区的水果种植和出产量都是世界第一的,各种水果的贸易数量早就突破了6000万吨,大约占到了世界的15%的比重。在我国消费者对水果的需求量巨大,目前的水果套袋包装工业则远远达不到要求。每年都会有一笔不小的经济损失是出自水果损伤方面的,消费者梦想能有一种机器来处理目前的这个现状。水果套袋机不仅能够提高水果套袋包装的效率,降低劳动力的投入,而且水果套袋机必将有光明的市场前景,并且水果套袋机还能满足中国水果包装工业的严格要求,可以为我国的水果套袋工业创造不可估量的效益[3]。

1.2国内外同类研究及设计的现况

目前,中国的水果套袋机是最近几年设计出来的,并且它的种类也比较少,功能上也有所欠缺,缺少高精度高性能的优质产品,并且现在设计出的水果套袋机安全性上也有一定的缺陷,一些主要零件的质量太差,用不了多长时间就不能继续使用,这也间接的决定了水果套袋机的性能。尽管水果套袋机的市场前景特别光明,而且我国也是水果生产和贸易大国;然而,我国水果套袋机根本程度上还停留在中国制造的阶段,设计和创新的部分太差[4]。

川公网安备: 51019002004831号

川公网安备: 51019002004831号