【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

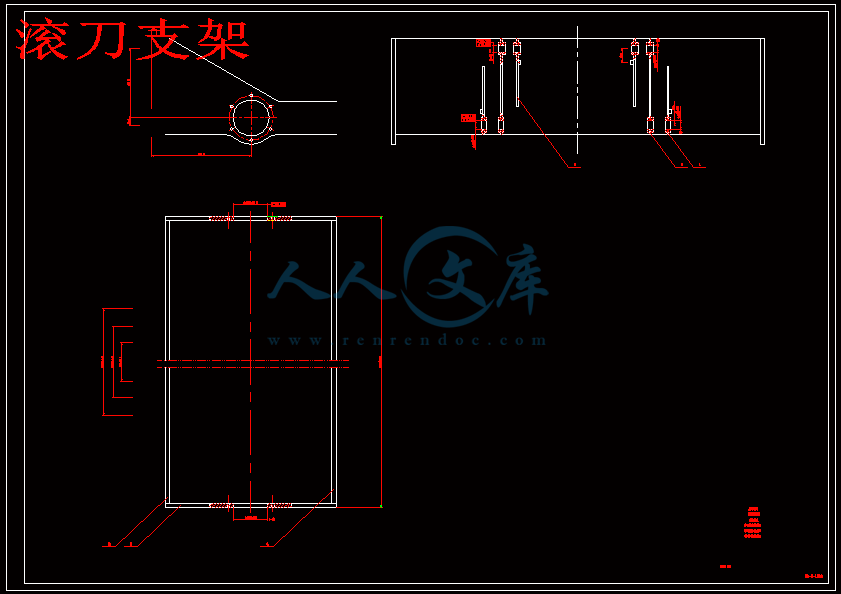

滚圈图纸如下

目 录

绪论 ……………………………………………………………………… 1

1.1本次设计来源、目的、意义、国内外概况………………………………1

1.1.1 本次设计的来源…………………………………………………… 1

1.1.2 本次设计研究目的………………………………………………… 1

1.1.3 本次设计研究的意义…………………………………………………1

1.1.4 有关清雪机国内外研究概况…………………………………………2

1.2 本设计预期达到的目标……………………………………………………4

1.3 本设计研究内容、研究方法及技术路线…………………………………5

1.3.1 斜刃螺栓连接式厚冰雪磙压除雪机的整体方案构想………………5

1.3.2 结构原理和计算要点…………………………………………………5

1.4 本课题实现的现有条件……………………………………………………6

1.5 研究的主要内容和方法……………………………………………………6

1.5.1冰雪切削挤压破碎技术、总体方案………………………………… 6

1.5.2 碾压滚型式和结构……………………………………………………6

1.5.3 滚齿排列方式及刀刃几何参数………………………………………6

1.5.4 各主要零件的校核验算………………………………………………6

第2章 路面冰雪清除机机理研究……………………………………………… 8

2.1 冰雪的物理机械性质………………………………………………………8

2.2 路面冰雪清除机基本方案、原理…………………………………………9

2.3 整机分析及装置重量的确定…………………………………………… 13

2.3.1整机的组成………………………………………………………… 13

2.3.2清除冰雪装置重量………………………………………………… 14

第3章 碾压滚结构及参数………………………………………………………15

3.1 碾压滚结构形式………………………………………………………… 15

3.2 碾压滚参数……………………………………………………………… 15

3.3 工作阻力的计算………………………………………………………… 15

第4章 齿刀的研究……………………………………………………………… 17

4.1 齿刀在碾压滚上的排列﹑数量﹑间距………………………………… 17

4.2 齿刀几何参数…………………………………………………………… 17

4.3 切削力计算……………………………………………………………… 18

第5章 主要零件校核计算……………………………………………………… 19

5.1 轴承的校核计算…………………………………………………………19

5.1.1 当量动载荷的校核…………………………………………………19

5.1.2 滚动轴承寿命的计算………………………………………………30

5.2 齿刀强度的校核分析…………………………………………………… 21

5.3 销轴的校核计算………………………………………………………… 26

5.4 轴的校核计算…………………………………………………………… 29

5.4.1 按扭转强度条件计算………………………………………………30

5.4.2 按弯扭合成强度条件计算…………………………………………30

第6章 电器系统………………………………………………………………… 33

6.1 电源电路………………………………………………………………… 33

6.2 启动系统………………………………………………………………… 33

6.3 照明和信号系统………………………………………………………… 33

6.4 仪表系统………………………………………………………………… 33

6.5 预热器…………………………………………………………………… 34

第7章 电算部分…………………………………………………………………35

第8章 结 论……………………………………………………………………43

致谢…………………………………………………………………………………45

参考文献……………………………………………………………………………46

1 课题来源、目的、意义、国内外概况

1.1 本课题的来源

本课题属于吉林大学机械科学与工程学院2000级本科生的毕业设计指导教师的科研项目(国家经贸委“国家重点技术改造项目[2003]86”)。是根据国际和国内的最新形势和市场需求而确定的研究课题。对实际的生产和生活有很大的实际意义。是隶属于国家攻关课题-----多功能铲雪车研制的一部分。

1.2 本课题研究目的

中国北方大部分地区,每年有3~5个月的降雪期,道路积雪给交通运输及人民日常生活带来许多困难,有时甚至阻断交通。近几年来高等级公路里程不断增加,及时有效地清除路面积雪已成为亟待解决、刻不容缓的问题,这对于提高车辆的运输效率、避免重大交通事故的发生,具有很大的社会经济效益。目前,国内除雪作业多由人工或其它代用机械完成,其劳动强度大,作业效率低。进口外国先进的除雪设备,造价高且不适合中国国情;而用其它的代用机械如平地机进行除雪作业,则又浪费实用设备且对路面具有破坏性。所以,尽快开发出适合中国国情的低成本、高效率、且宜大面积推广应用的除雪设备,是一项艰巨而紧迫的任务。

1.3 本课题研究的意义

我国北方大部分地区,每年有很长的降雪期,道路积雪给交通运输及人民日常生活带来许多不便。尤其冻结在道路上的积雪与薄冰,采用传统除雪机用推刮的办法无法清除,为此不得不耗费大量人力物力进行人工铲除。采用机械方法清除是一项急需解决的难题。就目前国内除雪机械来看,大多数功能单一,或只能清除积雪、或只能破除积冰[1]。国外的除雪机功能较全,但结构复杂,造价昂贵,且大多不适合国内的道路状况。因此开发研制适合我国道路情况的集破冰除雪于一机的设备,具有十分重大的意义。国外的除雪机功能较全,但结构复杂,造价昂贵,且大多不适合国内的道路状况。因此开发研制适合我国道路情况的集破冰除雪于一机的设备,同样具有十分重大的意义。

1.4 本课题国内外研究概况

1.4.1 本课题国内外研究概况

目前,世界各个国家除冰雪的方法中,应用最普遍的是溶解法和机械法。溶解法是依靠热作用或撒部化学药剂使冰雪融化。其优点是除净率高,但是它的成本很高。而且容易造成环境污染。虽然环保型融雪药剂已经问世,对环境和植被的影响减少了,但是并未彻底根除。因此使用范围受到一定限制。

机械法是通过机械作用直接作用解除冰雪危害。虽然除净率较低,但是对环境和植被无任何影响。能实现冰雪的异地转移。应用范围比较广。因此,笔者认为:清除冰雪必须以机械法为主,以溶解法为辅助,才能达到快速和环保的除雪效果。

我国对除雪机械的开发、生产都比较晚,因此还处于起步阶段。目前,我国的城市道路和公路冬季除雪大部分仍沿用传统的养护方式,即人工作业和小型的除雪机械相结合的方式。高速公路和一级公路开始使用大型专用除雪机械,进行冬季养护。但是,除雪机械在数量和品种规格上还很少,所以除雪设备大部分依赖进口。机械化程度和总体水平远远落后于发达国家。只是最近几年国内的厂家才参照国外的先进技术研制了适合我国国情的除雪机械。

综观国内外的除雪机械,其类型总的来说有三种类型:

(1) 犁式除雪机

犁式除雪机的工作装置一般安装在主机的前端,是所有除雪机中应用最为广泛、起源最早的除雪设备。主要使用于未被压实的新降集雪,其厚度为300mm以下。犁板有整体式和分段式,有V型犁和U型犁之分。其特点是:多数采用了双摇杆机构,避让效果明显,越障高度较大,环境适应性强,可以在硬质雪区工作。有的还增加了滑靴和滚轮等装置,用来减少或消除铲刃对地面的作用力,保护了地面,减少了刀刃的磨损。

具体类型有:

1) 向犁-----除雪犁以固定角度装在除雪车前部。

2) V型犁-----主要结构和工作原理与单向犁相同,只是结构呈左右对称,形成V形。

3)变角度犁------指犁的排雪方向和行进角度可以改变的除雪机械

4)复合犁------又叫铰接雪犁,采用两翼结构,中间垂直铰链可以自由改变形状,形成单向犁、V型犁、变角度犁等犁形。

比较典型的产品有:徐州装载机长的专利产品------调压自动越障式除雪装置。郑工、柳工和沈阳山河等厂家生产的ZL50型除雪机。由于该类除雪机械拥有结构简单、性能可靠、价格低廉等特性,因此受到广大用户的认可,得以广泛的使用。

(2) 旋切式除雪机械

旋切式除雪机械工作方式为自行式和悬挂式两种。主要有离心式物料风机、风道、抛雪筒、护板和螺旋型集雪器等部分组成。结构相对比较复杂。工作时借助主机或者专用底盘的动力,驱动风机做高速旋转运动,将集雪器聚拢的雪由风道、抛雪筒抛出去。抛出距离和角度可以根据需要自己调整。在清除雪障时旋切式除雪机械有明显的优势。但是无法清除压实的积雪。

具体类型有:

1) 螺旋式-----螺旋轴鼓上的叶片呈左右旋向,左右旋向的叶片在轴线中部结合形成U形抛雪槽,U形抛雪槽低部稍微向后倾斜,内侧光滑,工作时轴鼓上的叶片刀刃切削破碎积雪,并将积雪集中送到中部U形槽内抛出。

2) 转子式-----主要以清除新雪为主要作业对象。转子叶片可以完成切雪、扒雪和抛雪。

3) 单螺旋转子式-------有转子和一根螺旋组成。螺旋水平布置在转子前,螺旋 叶片作成左右旋向,当螺旋周转动时,把两边的积雪送到中间,再由转子抛出。

4) 双螺旋转子式-------双螺旋转子式的工作装置的两螺旋上、下平行地置于转子前面。

5) 立轴螺旋转子式-------该工作装置将螺旋竖放在转子两侧,螺旋叶片为左右旋向,工作时雪的移动方向为上下运动。

主要机型有:哈尔滨开达公司生产的抛雪式除雪机和吉林大学研制的CX-30型除雪机。

(3) 扫滚式除雪机械

扫滚式除雪机械工作方式为自行式和悬挂式两种。在主机或者专用底盘的动力作用下,驱动扫雪滚和扫雪盘做高速旋转运动,扫雪滚和扫雪盘上的柔性强力扫雪刷,将路面积雪卷起使之脱离地面,在高压空气的作用下吹向路边。该式除雪机械主要适合于较薄的或者是犁式除雪机械工作后的残留积雪。即使路面凸凹不平也可以获得无残雪的除雪效果。主要生产厂家有:哈尔滨开达公司和哈尔滨重型机械厂等。

国内的除雪机械虽然有了很大的发展,但其总体水平与发达国家相比,产品品种及性能都还有很大差距。适应不了我国高速公路的发展的需求,主要体现在以下几个方面:

1)技术水平低,除雪机械在结构设计、制造工艺、零部件供应和使用管理等方面都存在技术水平低的问题。致使除雪机械可靠性差、故障多、寿命短。

2)功能单一。除雪机械具有明显的季节性,如果功能单一,只能用做除雪和除冰专用,那么,机械一年中大部分时间处于闲置状态,大大增加了除雪 的成本。加重了公路养护部门的负担。

3)品种类型不全。与国外相比,现在有不少除冰雪机械在国内还是一片空白。现有的除冰雪机械无法满足公路和大型机场的除冰雪的要求。

1.4.2 国内外在这个方面的发展方向:

(1) 加强对雪质、雪性的基础研究。

为了提高除冰雪机械的设计水平,需要对冰雪的力学性质和物理特性进行深入研究。特别是对压实冰雪的理论研究。据有关资料研究:东北地区压实冰雪占总的除雪任务的80%以上。

(2) 向一机多能和机电液一体化方向发展。

在现有的条件下,可以对汽车、拖拉机、装载机和推土机等设备进行改装,冬季降雪时用来除冰雪作业,其余时间可用来进行公路养护和其他作业。可以提高设备的利用率。采用机械、电子、液压等技术提高除雪机械的科技含量,减轻工人的劳动强度。

(3) 向大型、小型和高速方向发展。

我国的地理环境复杂,各个城市道路建设布局各异,冬季降雪情况不同,在除雪设备的选取上也不尽相同,因此要开发出大型、小型的各种除冰雪机械,以满足不同地区和工况的除冰雪要求。同时要开发出效率高的机械,避免除雪作业造成路面交通拥挤。例如,东北有些城市规定:对于市区内主干道,雪停止24H后需运出城市外。

(4) 加强行业间的技术交流与合作。走共同研发之路。

各个厂家根据自己的实际情况开发出的产品各有优缺点,为了加快除冰雪机械的开发和应用,应加强企业间的合作,集中财力、物力和人力走共同发展之路,实现除冰雪的机械化。

2 本课题预期达到的目标

在ZL40型装载机的前端安装除雪装置-----斜刃螺栓连接式压磙除厚冰雪装置。

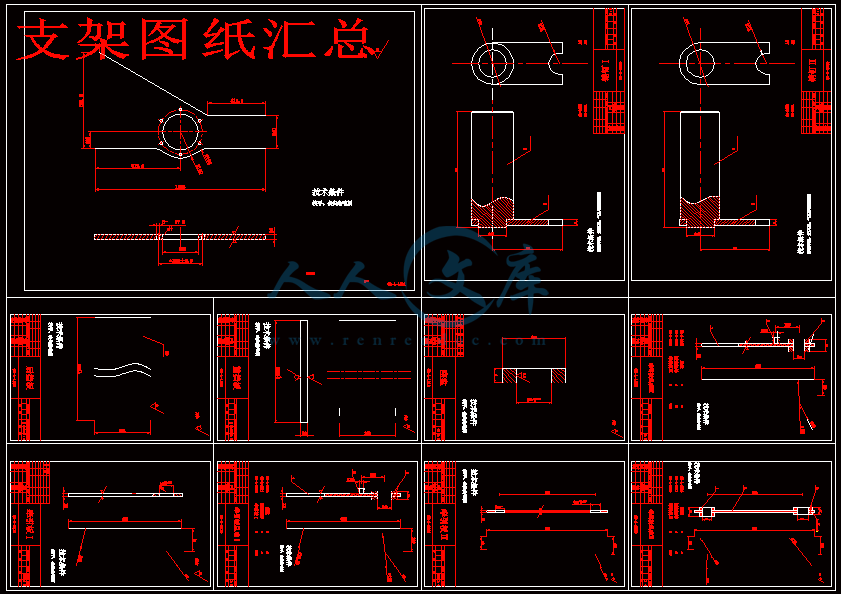

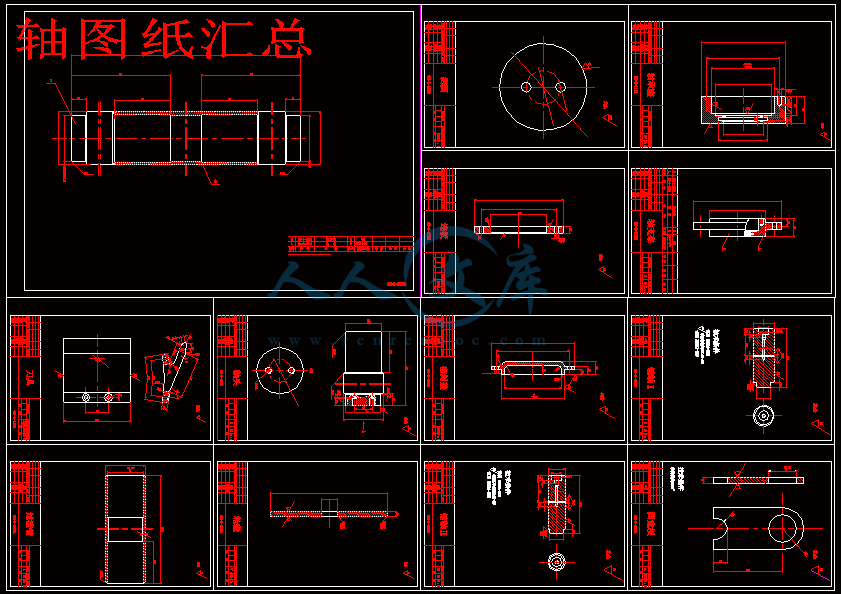

采用斜刃式除雪装置,使冰雪在破冰刀刃的作用下破碎。压磙与ZL40型装载机大臂相连。设计出包括铲及其连接机构。画出全部图纸:装配图、部件图、零件图、总明细表。

设计时要保证相应构件的可靠性,所以要进行相应的力学分析、设计计算 、方针模拟等。并要求用计算机软件对重要部件进行详细的运动学和动力学分析。设计相关的软件。

通过这次设计,要不仅温习好大学四年所学的大不分的理论知识,还要培养工程实际应用的能力,锻炼实际的动手和全局的驾御能力。对装载机和除雪机械有更深的认识,加强在此方面的设计能力。

3 本课题研究内容、研究方法及技术路线

3.1 斜刃螺栓连接式厚冰雪磙压除雪机的整体方案构想

斜刃螺栓连接式厚冰雪磙压除雪机是针对我国道路情况设计的破冰清雪除雪设备。该设备主要起破冰作用的碾压辊构成。

该设备的主机架可与ZL40装载机直接联接。该设备碾压辊固定在联架臂上,联架臂通过大臂与主机架铲接。碾压辊上装有刀板,刀板上的刀条直接作用在冰面上,利用自身的重力和空气锤的振动的冲击力达到破冰目的。

3.2 结构原理和计算要点

斜刃螺栓连接式厚冰雪磙压除雪机是利用前部安装的碾压辊上装有的刀板对雪进行切削,利用自身的重力和空气锤的振动的冲击力达到破冰目的。

(1) 叶片结构:

采用斜刃螺栓连接式,材料用耐磨仿形材料。按与地面平行布置在压磙上,前后两排叶片位置错开。

(2) 除雪机功率的计算:

除雪机所消耗的功率包括两大部分:行走装置和工作装置所消耗的功率。行走装置所消耗的功率可以参照一般自行式车辆的计算办法。下面对除雪工作装置的所消耗的功率Na做一分析:

Na=Ne+Nf+Nr+Nd

其中: Ne-----推雪板切削所需功率。KW

Nf-----克服雪与板面的摩察力所需的功率。KW

Nr----推雪板前雪堆移动所需的功率,KW

Nd----板刃与存雪地面间的摩察力所需的功率。KW

3.3 拟采用的研究方法

采用新旧技术相结合的方法。因为有关装载机和除雪机构的研究在我国已经有了一定的进展------即使和发达国家相比还很落后-----在很多领域。但近几年我们引进了很多先进的技术,特别是除雪机械方面的,加上我们的有关装载机和其他工程机械的研究知识,将这两方面的知识有机地结合起来,实现新的突破,研制出适合我国国情的公路养护机械-----集工程作业和除雪能力于一体的多功能机械产品。

3.4 拟采用的技术路线

4研究冰雪的物理和力学特性------查阅国内外有关装载机和除雪机械、机构的设计资料和最新进展------消化、吸收个方面的技术资料,并加以整理和创新------技术设计和整机设计。

4 本课题实现的现有条件

国内外关于ZL40装载机的数据和文献资料的搜集较为便利。在理论上和方法上具有很强的借鉴意义。指导老师李萌老师对我国这方面的情况很了解,是这方面的专家。有很深的理论和实践知识,为本课题的研究奠定了很好的理论和实证基础。本人对于装载机和除雪机械也有一定的认识,相信一定能在李老师的指导下顺利完成课题的研究。并取得优异的毕业设计成绩!同时为我国在此领域的研究作出自己应有的贡献!

川公网安备: 51019002004831号

川公网安备: 51019002004831号