汽车轴盖冲压模设计

48页 13000字数+说明书+外文翻译+开题报告+11张CAD图纸【详情如下】

中期报告.doc

冲孔凸模A3.dwg

凸凹模固定板A2.dwg

凸模固定板A2.dwg

压边圈A2.dwg

垫板A2.dwg

外文翻译-快速原型技术及在模具制造中的应用.doc

弹压卸料板A2.dwg

拉深凸模A2.dwg

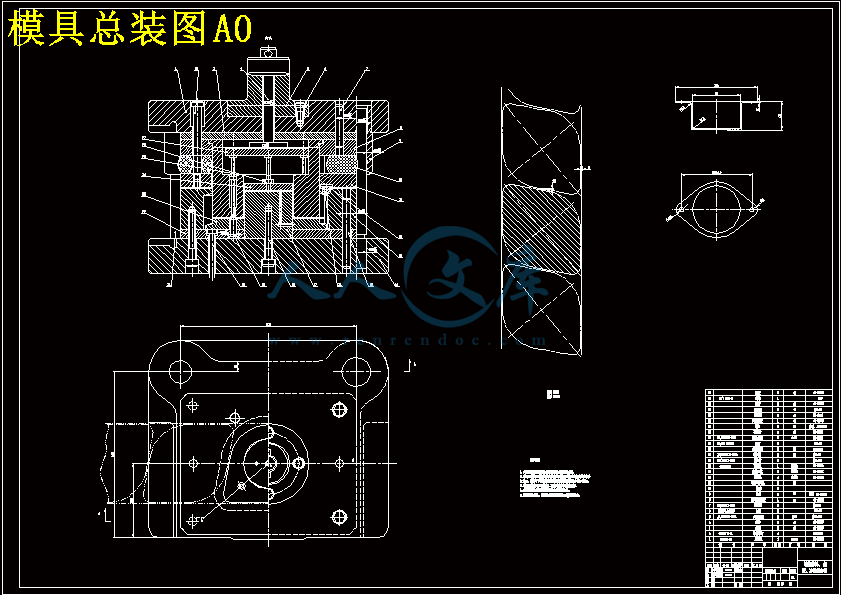

模具总装图A0.dwg

汽车轴盖.dwg

汽车轴盖冲压模设计开题报告.doc

汽车轴盖冲压模设计论文.doc

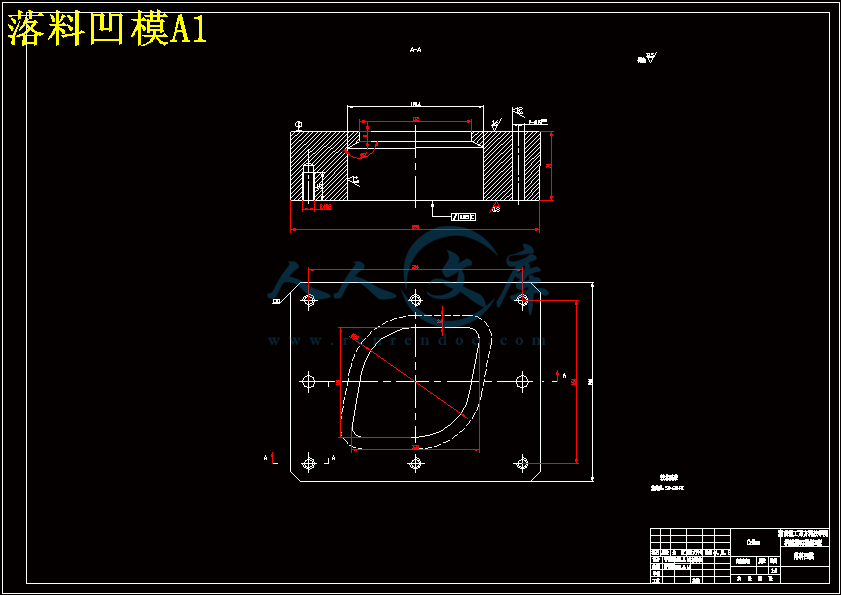

落料凹模A1.dwg

落料拉深凸凹模.dwg

摘 要

随着中国工业不断地发展,模具行业也显得越来越重要。本文针对端盖的冲裁工艺性和拉深工艺性,分析比较了成形过程的三种不同冲压工艺(单工序、复合工序和连续工序),确定用一幅复合模完成落料、拉深和冲孔的工序过程。介绍了端盖冷冲压成形过程,经过对端盖的批量生产、零件质量、零件结构以及使用要求的分析、研究,按照不降低使用性能为前提,将其确定为冲压件,用冲压方法完成零件的加工,且简要分析了坯料形状、尺寸,排样、裁板方案,拉深次数,冲压工序性质、数目和顺序的确定。进行了工艺力、压力中心、模具工作部分尺寸及公差的计算,并设计出模具。还具体分析了模具的主要零部件(如凸凹模、卸料装置、拉深凸模、垫板、凸模固定板等)的设计与制造,冲压设备的选用,凸凹模间隙调整和编制一个重要零件的加工工艺过程。列出了模具所需零件的详细清单,并给出了合理的装配图。通过充分利用现代模具制造技术对传统机械零件进行结构改进、优化设计、优化工艺方法能大幅度提高生产效率,这种方法对类似产品具有一定的借鉴作用。

关键词:端盖;模具设计;复合模;拉深冲孔

ABSTRACT

With China's industries continue to develop and die industry is also becoming increasingly important. Based on the Cover of the stamping process and the deep drawing process, Comparative analysis of the process of forming three different stamping process (single processes, complex processes and continuous processes) confirm completion of a composite model blanking, drawing processes and punching process. On the cover of the cold stamping process, right after the Cover of the mass production, quality components, and the use of structural components of the analysis, research, in line with lower performance prerequisite to the identification of stampings, Stamping method used to complete the processing components, and a brief analysis of the blank shape, size, layout, the Conference Board, the number of Drawing, stamping processes in nature, number and sequence determination. For the process, the center of pressure, the die size and the tolerance of the calculation, design mold. Also analyzes the mold of the main components (such as punch and die and dump devices, drawing punch, slates, Punch plate, etc.) design and manufacturing, stamping equipment selection, punch-gap adjustment and establishment of a vital parts machining process. Die requirements set out a detailed list of parts, and gives a reasonable assembly. By fully utilizing modern manufacturing technology to mold traditional mechanical parts for structural improvements, design optimization, Process optimization methods can greatly enhance production efficiency, the method of similar products have some reference.

Keywords: Cover; Mold design; Composite molding; Drawing Punc

目 录

1 分析零件的工艺性 …………………………………………………1

2 工艺方案的拟定 ……………………………………………………3

2.1 计算毛坯尺寸…………………………………………………3

2.2 确定是否要压边圈……………………………………………4

2.3 计算拉深次数…………………………………………………5

2.4 确定工艺方案…………………………………………………6

3 主要工艺参数的计算 ………………………………………………8

3.1 确定排样、裁板方案…………………………………………8

3.2 计算工艺力、初选设备………………………………………10

3.2.1 计算工艺力………………………………………………10

3.2.2 拉深功的计算……………………………………………14

3.2.3 初选压力机………………………………………………15

3.2.4 计算压力中心……………………………………………16

3.2.5 计算凸、凹模刃口尺寸及公差 …………………………16

4 模具的结构设计 ……………………………………………………20

4.1 模具结构形式的选择…………………………………………20

4.1.1 模架的选用………………………………………………20

4.1.2 模具的闭合高度…………………………………………20

4.2 模具工作部分尺寸计算………………………………………21

4.2.1 落料凹模…………………………………………………21

4.2.2 拉深凸模…………………………………………………23

4.2.3 凸凹模……………………………………………………24

4.2.4 弹压御料板………………………………………………26

4.2.5 上垫板……………………………………………………28

4.2.6 压边圈……………………………………………………29

5 模具的整体安装 ……………………………………………………31

5.1 模具的总装配…………………………………………………31

5.2 模具零件………………………………………………………32

6 选定冲压设备 ………………………………………………………34

7 模具的装配 …………………………………………………………35

7.1 复合模的装配…………………………………………………35

7.2 凸、凹模间隙的调整…………………………………………35

8 重要零件的加工工艺过程编制 ……………………………………37

结论………………………………………………………………………41

参考文献…………………………………………………………………42

致谢………………………………………………………………………43

分析零件的工艺性

冲压件工艺性是指冲压零件在冲压加工过程中加工的难易程度。虽然冲压加工工艺过程包括备料—冲压加工工序—必要的辅助工序—质量检验—组合、包装的全过程,但分析工艺性的重点要在冲压加工工序这一过程里。而冲压加工工序很多,各种工序中的工艺性又不尽相同。即使同一个零件,由于生产单位的生产条件、工艺装备情况及生产的传统习惯等不同,其工艺性的涵义也不完全一样。这里我们重点分析零件的结构工艺性。

该零件是端盖,如图1.1,该零件可看成带凸缘的筒形件,料厚t=2mm,拉深后厚度不变;零件底部圆角半径r=1.5mm凸缘处的圆角半径也为R=1.5mm;尺寸公差都为自由公差,满足拉深工艺对精度等级的要求。 工艺性对精度的要求是一般情况下,拉深件的尺寸精度应在IT13级以下,不宜高于IT11级;对于精度要求高的拉深件,应在拉深后增加整形工序,以提高其精度,由于材料各向异性的影响,拉深件的口部或凸缘外缘一般是不整齐的,出现“突耳”现象,需要增加切边工序。

影响拉深件工艺性的因素主要有拉深件的结构与尺寸、精度和材料。拉深工艺性对结构与尺寸的要求是拉深件因尽量简单、对称,并能一次拉深成形;拉深件的壁厚公差或变薄量一般不应超出拉深工艺壁厚变化规律;当零件一次拉深的变形程度过大时,为避免拉裂,需采用多次拉深,这时在保证必要的表面质量前提下,应允许内、外表面存在拉深过程中可能产生的痕迹;在保证装配要求下,应允许拉深件侧壁有一定的斜度;拉深件的径向尺寸应只标注外形尺寸或内形尺寸,而不能同时标注内、外形尺寸。

工艺性要求材料具有良好的塑性,屈强比值越小,一次拉深允许的极限变形程度越大,拉深的性能越好;板厚方向性系数r和板平面方向性系数反映了材料的各向异性性能,当r较大或较小时,材料宽度的变形比厚度方向的变形容易,板平面方向性能差异较小,拉深过程中材料不易变薄或拉裂,因而有利于拉深成形。

该零件结构较简单、形状对称,完全由圆弧和直线组成,没有长的悬臂和狭槽。零件尺寸除中心孔和两中心孔的距离尺寸接近IT11级外,其余尺寸均为自由尺寸且无其他特殊要求,利用普通冲裁方法可以达到零件图样要求。零件材料为20号钢,退火抗拉强度为400Mpa,屈服强度为206Mpa.此材料具有良好的结构强度和塑性,其冲裁加工性较好。该零件的冲裁性较好,可以冲裁加工,适于大批大量。2.1 计算毛坯尺寸

由于板料在扎压或退火时所产生的聚合组织而使材料引起残存的方向性,反映到拉深过程中,就使桶形拉深件的口部形成明显的突耳。此外,如果板料本身的金属结构组织不均匀、模具间隙不均匀、润滑的不均匀等等,也都会引起冲件口高低不齐的现象,因此就必需在拉深厚的零件口部和外缘进行修边处理。这样在计算毛坯尺寸的时候就必需加上修边余量然后再进行毛坯的展开尺寸计算。

根据零件的尺寸取修边余量的值为3.6mm。

在拉深时,虽然拉深件的各部分厚度要求发生一些变化,但如果采用适当的工艺措施,则其厚度的变化量还是并不太大。在设计工艺过程时,可以不考虑毛坯厚度的变化。同时由于金属在塑性变形过程中保持体积不变,因而,在计算拉深件的的毛坯展开尺寸时,可以认为在变形前后的毛坯和拉深间的表面积相等。2.4 确定工艺方案

根据以上分析和计算,可以进一步明确该零件的冲压加工需要包括以下基本工序:落料、拉深、冲孔和修边。

根据这些基本工序,可以拟出如下几种工艺方案:

方案一

先进行落料,再拉深,修边,最后冲孔,以上工序过程都采用单工序模加工。用此方案,模具的结构都比较简单,制造很容易,成本低廉,但由于结构简单定位误差很大,而且单工序模一般无导向装置,安装和调整不方便,费

方案二

落料与拉深、修边在复合模中加工成半成品,再在单工序模上进行冲孔。采用了落料与拉深、修边的复合模,提高了生产率。对落料以及拉深的精度也有很大的提高。由于最后一道冲孔工序是在单工序模中完成,使得最后一步冲孔工序的精度降低,影响了整个零件的精度,而且中间过程序要取件,生产效率不高。

方案三

落料、拉深、冲孔和修边全都在同一个复合模中一次加工成型。此方案把三个工序集中在一副复合模中完成,使得生产率有了很大的提升。没有中间的取放件过程,一次冲压成型,而且精度也比较高,能保证加工要求,在冲裁时材料处于受压状态,零件表面平整。模具的结构也非常的紧凑,外廓尺寸比较小,但模具的结构和装配复杂。

方案四

采用带料级进多工位自动压力机冲压,可以获得较高的生产效率,而且操作安全,但这一方案需要专用的压力机或自动的送料装置。模具的结构比较复杂,制造周期长,生产成本高。

根据设计需要和生产批量,综合考虑以上方案,方案三最适合。即落料、拉深、冲孔和修边在同一复合模中完成,这样既能保证大批量生产的高效率又能保证加工精度,而且成本不高,经济合理。 3.1 确定排样、裁板方案

加工此零件为大批大量生产,冲压件的材料费用约占总成本的60%~80%之多。因此,材料利用率每提高1%,则可以使冲件的成本降低0.4%~0.5%。在冲压工作中,节约金属和减少废料具有非常重要的意义,特别是在大批量的生产中,较好的确定冲件的形状尺寸和合理的排样的降低成本的有效措施之一。

由于材料的经济利用直接决定于冲压件的制造方法和排样方式,所以在冲压生产中,可以按工件在板料上排样的合理程度即冲制某一工件的有用面积与所用板料的总面积的百分比来作为衡量排样合理性的指标。

同时属于工艺废料的搭边对冲压工艺也有很大的作用。通常,搭边的作用是为了补充送料是的定位误差,防止由于条料的宽度误差、送料时的步距误差以及送料歪斜误差等原因而冲出残缺的废品,从而确保冲件的切口表面质量,冲制出合格的工件。同时,搭边还使条料保持有一定的刚度,保证条料的顺利行进,提高了生产率。搭边值得大小要合理选取。根据此零件的尺寸通过查表取:

参考文献

[1]刘心冶. 冷冲压工艺及模具设计[M]. 重庆:重庆大学出版社,1998

[2]卢险峰. 冲压工艺模具学[M]. 北京:机械工业出版社,2000

[3]梁柄文. 实用板金冲压工艺图集[M]. 北京:机械工业出版社,1999

[4]模具实用技术丛书编委会. 冲模设计应用实例[M]. 北京:机械工业出版社,2002

[5]杜东福. 冷冲压工艺及模具设计[M]. 长沙:湖南科学技术出版社,1990

[6]成虹. 冲压工艺与模具设计[M]. 成都:电子科技大学出版社,2000

[7]冯柄尧. 模具设计与制造简明手册[M]. 上海:上海科学技术出版社,1998

[8]王树勋,高广升. 冷冲压模具结构图册大全[M]. 广州:华南理工大学出版社,1988

[9]郑家贤. 冲压工艺模具设计实用技术[M]. 北京:机械工业出版社,1999

川公网安备: 51019002004831号

川公网安备: 51019002004831号