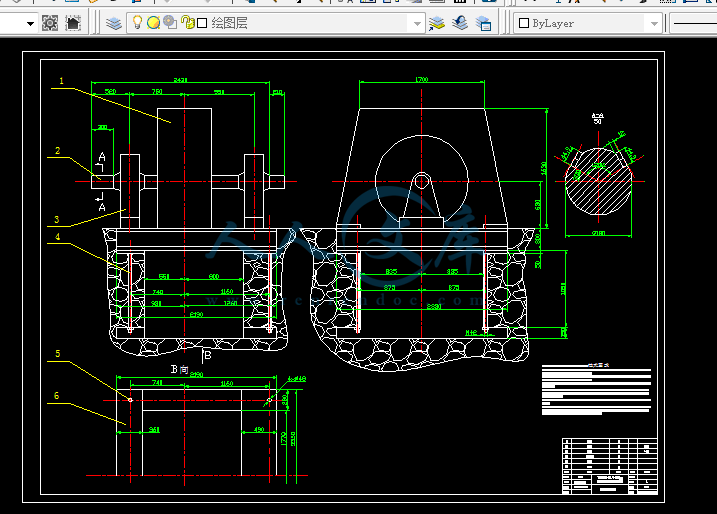

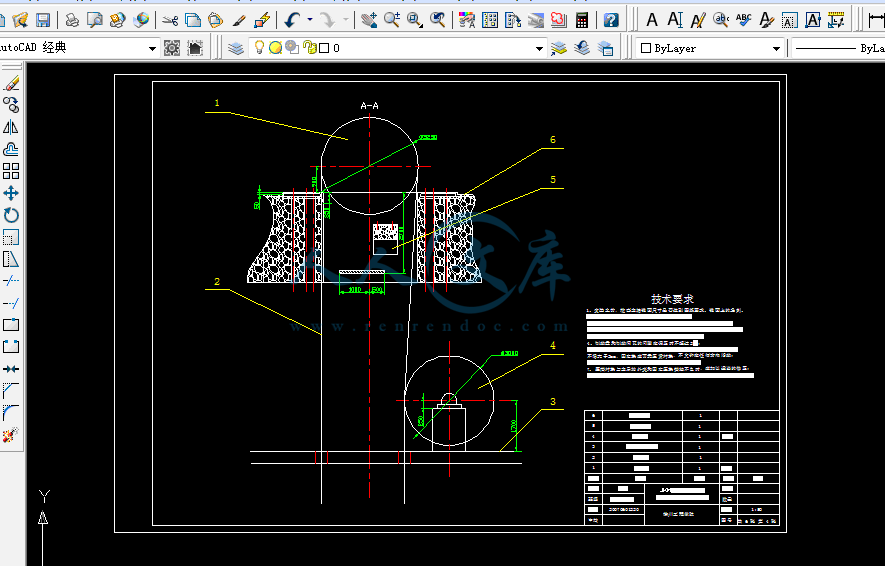

多绳摩擦式提升机的设计

目录

摘要I

AbstractII

1 绪论1

2主井提升机的选型设计3

2.1 计算原始数据3

2.2 箕斗的选型3

2.3 提升钢丝绳的选择7

2.3.1钢丝绳的最大悬垂长度7

2.3.2 估算钢丝绳每米重力7

2.3.3 钢丝绳安全系数校核8

2.3.4 提升钢丝绳的维护和试验9

2.4 选择提升机10

2.5 提升机的维护与检修12

2.5.1 提升机设备的日常维护12

2.5.2 提升机设备的定期检查12

2.5.3 提升机设备的计划维修13

2.5.4 提升机的润滑14

2.5.5 主提升机操作工自检自修的具体内容15

2.6 提升系统的确定16

2.7 提升容器的最小自重17

2.8 预选电动机18

2.8.1 电动机转数18

2.8.2 提升机的最大速度18

2.8.3 预选电动机功率18

2.9 提升系统总变位质量19

2.9.1 变位重量19

2.9.2 变位质量19

3 提升设备的运动学和动力学20

3.1 提升速度图20

3.1.1 六阶段速度图20

3.1.2 加速度的确定21

3.2 提升能力校核25

3.3 电动机等效功率计算25

3.3.1 运动力计算25

3.3.2 等效力计算27

3.3.3 等效功率28

3.3.4 校核电动机过负载系数28

3.4 电耗计算28

4 提升机的防滑验算30

4.1 提升机的防滑验算30

4.1.1 静防滑安全系数31

4.1.2动防滑安全系数31

4.1.3 制动力矩的验算32

5 最终的确定方案33

结论34

致谢35

参考文献36

1 绪论

矿山提升机是矿山大型固定机械之一,矿山提升机从最初的蒸汽机拖动的单绳缠绕式提升机发展到今天的交——交变频直接拖动的多绳摩擦式提升机和双绳缠绕式提升机已经历了170多年的发展历史,它是矿山井下生产系统和地面工业广场相连接的枢纽,被喻为矿山运输的咽喉。因此矿山提升设备在矿山生产的全过程占有重要的地位。

我国早在公元前1100年左右就发明和使用了辘轳提水和提升重物,这就是现在提升机的始祖。1953年抚顺重型机器厂制造了我国第一台缠绕式提升机;1958年洛阳矿山机器厂制造了第一台多绳摩擦提升机。国外矿井提升机的发展有几个代表性的时期:1827年出现第一台蒸汽提升机;1877年制造了第一台单绳摩擦提升机;1905年使用了第一台电动提升机;1938年创造了第一台多绳摩擦提升机;1957年发明了多绳缠绕式提升机。

一个现代化的矿井在提升设备的选型上尤为重要。因为提升设备选型的合理与否,直接关系到矿井的安全和经济性,因此确定合理的提升系统时,必须经过多方面的技术经济比较,结合矿井的具体条件选择合适的设备。目前我国可以成批生产各种现代化大型矿井提升机以及各种配套设备,无论从设计、制造、自动控制等各方面,我国生产的矿井提升设备都正在跨入世界先进的行列。

根据矿井提升机工作原理和结构的不同,可分为缠绕式提升机和摩擦式提升机。单绳缠绕式提升机是较早出现的一种,它工作可靠,结构简单,但是仅适用于浅井及中等深度的矿井,而对于井深超过300米的矿井,宜选用多绳摩擦式提升机。在国内外,多绳摩擦式提升机飞跃发展,其发展速度远远超过单绳缠绕式提升机,这是因为它有着许多单绳缠绕式提升机无法比拟的优点,其优点如下:

提升容器及静荷载由多根钢丝绳共同承担,提升钢丝绳直径较小,主导轮直径及整个机器尺寸都相应缩小,设备重量也减轻了。

由于提升容器是同时悬吊在多根钢丝绳上,这些钢丝绳一般不会同时拉断,故可以不设置防坠器。

主导轮直径的缩小,系统的惯量和主轴上的扭力矩也随之减小,因而可以使用高速电动机和重量较轻的减速器,电动机功率和电能消耗都相应降低。

提升钢丝绳的根数是偶数,且由左向捻和右向捻各占一半组成,可以互相抵消钢丝绳运行中松捻的扭力,减轻了提升容器对罐道的运行阻力,因而延长了罐道及罐耳的使用寿命。

当多绳摩擦轮提升机安装在井塔上时,减少了工业广场的占地面积,并为地面生产系统的布置创造了有利条件。

下面是我针对不同的矿井的地质、煤层等情况,进行综合计算分析后,本着安全、经济等原则对提升设备系统进行的选型设计。

本设计充分贯彻以下设计原则:根据国家现有的设备生产状况,结合某些使用中的具体情况,以及经济角度出发尽量选用国产设备并力求在条件基本相当的情况下进行技术的方案比较,选择即经济又合理的设备。

由于本人水平有限,设计中难免出现错误和不足之处,敬请各位老师指正。

川公网安备: 51019002004831号

川公网安备: 51019002004831号