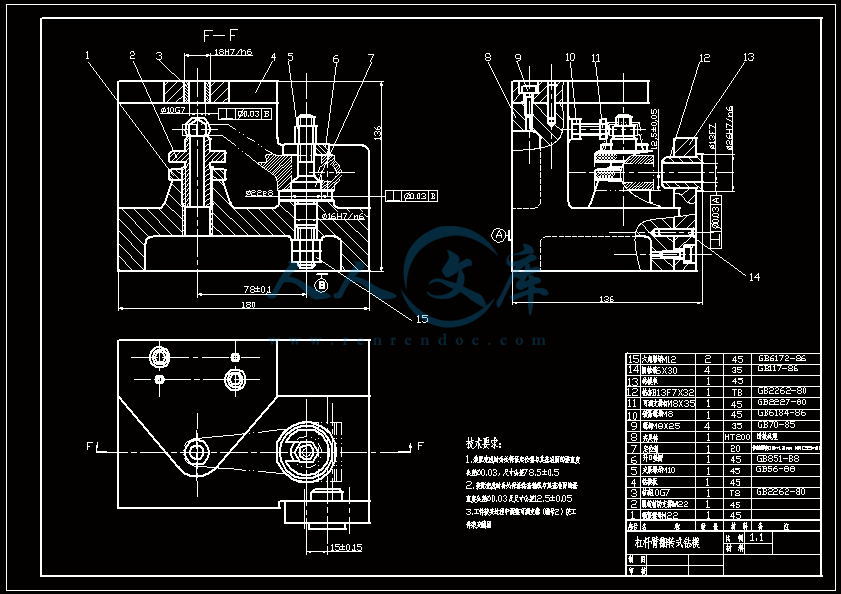

K13-杠杆臂的钻模夹具设计(全套含CAD图纸)

收藏

资源目录

压缩包内文档预览:

编号:9921139

类型:共享资源

大小:983.44KB

格式:ZIP

上传时间:2018-04-04

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

k13

杠杆

夹具

设计

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

下载后包含有CAD图纸和说明书,咨询Q197216396或11970985任务书题目杠杆臂的钻模夹具设计原始数据图纸及手册一、目的要求1、培养学生综合运用所学理论和专业知识分析和解决本专业的工程技术问题的能力。2、培养学生正确使用技术资料,国家标准,有关手册的方法。3、掌握中等复杂零件的夹具设计的方法步骤。二、原始资料1、杠杆臂零件图纸一张2、生产纲领小批量生产3、有关工具书、手册三设计内容设计杠杆臂钻模。1、必须设计的图纸(1)、绘制工件零件图一张(A4)(2)、绘制钻模装配图一张(A2)2、设计说明书内容(1)、夹具方案的论证(2)、夹具结构及特点(3)、定位(4)、夹紧(5)、导向(6)、主要尺寸及尺寸公差、配合公差及形位公差的确定(7)、定位误差的计算下载后包含有CAD图纸和说明书,咨询Q197216396或11970985(8)、夹具的使用(9)、参考资料四、日期1、接受设计任务日期20年月日2、完成设计任务日期20年月日备记注本设计任务书一式三份。分别交毕业设计委员会,指导教师和学生。学生需将任务书附入毕业设计说明书内。下载后包含有CAD图纸和说明书,咨询Q197216396或11970985杠杆臂零件图以及题目的文字说明杠杆臂钻模设计题目的文字说明杠杆臂属小批量生产。控制杠杆臂22以及它的两端面已加工完毕控制杠杆臂10的两端面已加工完毕控制杠杆臂13的两端面尺寸42已加工完毕本工序要加工以及13。任务设计钻以及13的钻模下载后包含有CAD图纸和说明书,咨询Q197216396或11970985摘要这是杠杆臂钻模的设计,为了保证加工精度和提高生产效率,特设计此钻模,以满足本工件的加工要求首先对夹具方案进行了论证,由于杠杆臂是小批量生产,夹具应简单,易于制造,操作方便。本说明书对夹具的结构及特点,夹具的定位和夹紧等等问题进行了深入的分析和确定,以满足本次设计的根本要求,对于夹具体的设计和制造方法等问题,也都进行了分析和确定。而主要尺寸则由所加工工件的具体尺寸要求进行了分析确定。还对本夹具的定位误差进行计算,以证明能否保证零件的加工精度。最后是夹具的使用说明本设计还附有一张工件零件图,和一张杠杆臂钻模的装配图下载后包含有CAD图纸和说明书,咨询Q197216396或11970985下载后包含有CAD图纸和说明书,咨询Q197216396或11970985下载后包含有CAD图纸和说明书,咨询Q197216396或11970985目录绪论1夹具方案的论证2夹具的结构及特点3定位4夹紧5导向6夹具体的设计7主要尺寸的确定8定位误差的计算9夹具的使用下载后包含有CAD图纸和说明书,咨询Q197216396或1197098510参考资料11附件图纸绪论夹具设计的分类机床夹具按其使用范围可分为通用夹具、专用夹具、可调夹具、组合夹具及随行夹具五种基本类型按机床可分为车床夹具、铣床夹具、镗床夹具钻床夹具等等。本夹具是钻床夹具也叫钻模夹具设计说明书的简要内容本夹具因为要加工两个相互垂直方向的孔,故采用翻转钻模,且钻模不与钻床安装在一起根据所加工零件的具体情况,定位采用完全定位,由一面一销加防转销组成为了结构简单,夹紧采用螺纹夹紧装置,导向装置采用固定钻套与快换钻套,安装在上模板和钻模体上下载后包含有CAD图纸和说明书,咨询Q197216396或11970985其钻模体的设计本着廉价工艺性好的原则,采用灰铸铁铸造件上模板与钻模体的联接用圆锥销定位,用螺钉固定连接主要尺寸根据控制臂要求,应尽量使结构简化其中的配合和精度都由查表确定再通过对定位误差的计算,可以确定所设计的夹具符合工件的要求,适合小批量生产,操作简单,方便最后对夹具的使用方法加以说明夹具设计说明书1夹具方案的论证本专用钻模用于钻杠杆臂的10钻削以及另一垂直方向13孔的钻加工。由于加工精度不高,属于单工步工序应采用固定钻套。由于10与13分布在不同表面且相互垂直,加工时由手工操作连同工件一起翻转,所以应采用翻转式钻模。此种钻模在设计制造时应注意安装位置的平稳性及切屑的排出等问题本工序(8孔的钻、扩、铰)之前已加工完各平面且30内孔,提供了本工序的加工定位基准。为此根据加工要求确定定位方案为完全定位夹紧机构采用螺旋夹紧机构,简单可靠本工序采用立钻Z5025机床,刀具为标准麻花钻。机床与刀具均为通用型号,故夹具设计应使其适应机床与刀具,由于是小批量生产,夹具的结构力求简单,易于制造,操作方便。2夹具的结构及特点21夹具的结构本钻模属翻转钻模(适合重不大于10小件)加工时翻转使用,在工作台上不安装,本夹具主要由钻模体、上模板、定位轴、辅助支撑等组成。22夹具的特点铸造钻模体钻模板还可分为固定式钻模板、铰链式钻模板、可卸式钻模板和悬挂式钻模板。下载后包含有CAD图纸和说明书,咨询Q197216396或11970985本夹具根据结构特点,10以及13加工皆采用固定模板。这样可以保证较高的中心距精度,用两对角线布置的定位锥销来定位,再由两对角线布置的螺钉紧本夹具有辅助支撑3定位31定位与定位原理本夹具在钻模中采用完全定位,即六点定位,用适当分布的六个约束点限制工件的六个自由度。32定位方式本钻模定位属于组合定位22圆柱孔用于短销定位,限制两个自由度,端平面(4222环形面)定位,限制三个自由度,形成了短销加宽环形平面组合,共限制五个自由度。另用一个防转定位销定位,限制一个定位度。防转定位销定在工件的另一端厚10MM,10的侧面(见左视图)位置,可防止工件转动。对于一孔一端面的定位基准我们设计了定位柱。定位柱的结构分三段安装部分42下端面往下16安装柱,安装螺纹M12。(加垫圈、锁紧螺母)是用来定位柱安装在钻模体上的。定位部分42上端面加上往上22定位颈。(长度较短,与22长25通孔是间隙配合,作定位时属短销定位。)形成短销加宽环形面的组合定位夹紧部分定位部分再往上的一段螺纹M10、(加外六角夹紧螺母M10和开口垫圈10)用来夹紧工件。辅助支承辅助支撑采用的是螺旋辅助支承,本夹具夹紧力作用点远离切削力,为了提高工件装夹刚性和稳定性,宜在工件定位后,在10下方增设螺旋辅助支撑(用M22螺纹拧在夹具体上)。他不起定位作用,是在定位夹紧后,调高与工件接触,为了让开钻头,并有利排削。支撑制成中空通孔11,(比10大)。下载后包含有CAD图纸和说明书,咨询Q197216396或11970985高度调好后由M22锁紧螺母锁紧。一般情况下同一批零件辅助支承不进行调整。零件换批后要进行调整。4夹紧夹紧机构的任务是在夹紧过程中不破坏工件的正确定位,且在加工过程中不因为受到切削力、离心力、惯性力以及重力等外力的作用,而破坏工件的正确定位定。41对加紧装置的基本要求夹具上实现夹紧的夹紧机构是否正确合理,对于保证加工质量提高生产率、减轻工人的劳动强度有很大影响。411夹紧时不破坏工件的正确位置,并使工件在加工过程中不因振动而变形、错位。412夹紧作用准确、安全、可靠,夹紧机构要要有自锁作用。413夹紧动作迅速,操作方便省力。414夹紧机构的自动化程度应与工件的生产批量及工厂的生产条件相适应。415结构简单、紧凑、有足够刚性,尽量使用标准件。42夹具夹紧力分析421夹紧力方向的选择4211夹紧力的方向应有利于工件的定位,而不能破坏定位。为此一般要求主夹紧力应垂直指向第一定位基准面。4212夹紧力的方向应尽量与工件刚度大的方向一致,以减少工件变形。4213夹紧力的方向应尽可能与切削力,工件重力方向一致,以较小所下载后包含有CAD图纸和说明书,咨询Q197216396或11970985需的夹紧力。422夹紧力作用点的选择4221夹紧力作用点应正对支撑元件或位于支撑元件所形成的稳定受力区内,以保证工件已获得的定位不变。4222夹紧力作用点应处在工件刚性较好的位置,以减小工件的夹紧变形。4223夹紧力作用点和支撑点应尽量靠近切削部位,以提高工件切削部位的刚度和抗震性。4224夹紧力作用点应尽量使各支撑处的接触变形均匀,以减小加工误差。43夹紧力大小夹紧力大小应保证定位稳定可靠,夹紧力过小,在加工过程中会发生位移或偏转,夹紧力过大会使工件变形,因此夹紧力大小应适当。本控制臂钻模具有结构简单,夹紧方便,自锁性好,安全省力的特点。其夹紧装置由定位柱上端的外螺纹M10、外六角夹紧螺母M10和开口垫圈10组成。符合夹具的基本要求,也符合夹紧力三要素的选择原则。很适合小批量生产,手动夹紧。5导向51本钻模的钻模板钻模板可分为固定式钻模板、铰链式钻模板、可卸式钻模板和悬挂式钻模板。本夹具根据结构特点,钻10以及13孔,皆采用固定模板。这样可以保证较高的中心距精度,用两对角线布置的定位锥销来定位,再由两对角线布置的螺钉紧固下载后包含有CAD图纸和说明书,咨询Q197216396或11970985钻模板的材料4552钻套的选择按结构和使用情况有固定钻套、快换钻套、可换钻套和特殊钻套四种。本钻模属小批量生产,钻10以及13孔,精度要求较低,用单独一个钻头一次钻成,是单工步工序故使用固定钻套。固定钻套以过盈配合直接压入夹具体钻套板孔内,固定钻套位置精度高,但磨损后不易更换。钻套材料及热处理方法的选择T10A淬火5560HRC优质碳素工具钢(高级)淬火加低温回火而耐磨6夹具体的设计夹具体是整个夹具的基体和骨架,要服从所有元件、机构和装置的安装要求来精心设计,夹具体需要正确的安装在机床上,故夹具体的形状和尺寸,主要取决于夹具上各组成体的分布、工件形状、尺寸、加工性质等。61设计夹具体的基本要求611要有足够的强度和刚性。夹具体在夹紧力、切削力的作用下,应不变形、不震动,保证加工质量612结构应简单,工件装卸方便。在保证夹具体强度和刚度的前提下,尽可能的体积小,重量轻,以便操作613要有良好的机械加工工艺性和使用性。夹具体上有三个主要部分即夹具体与机床表面的安装基面安装导向装置的表面安装定位元件的表面614尺寸要稳定。下载后包含有CAD图纸和说明书,咨询Q197216396或11970985铸造件夹具体要进行时效处理,壁厚变化要缓和、均匀,以免产生过大的内应力615排除切屑要方便。为了防止加工中切削积留在定位元件工作表面或其他装置而影响工件的正常定位和夹具的正常工作,在设计夹具时要考虑切屑的排泄问题616夹具体在机床上的安装要稳定、可靠、安全。本钻模体采用中空式,每边厚10MM,其中与B基准面相平行的两个面上分别开两个3020MM的孔,从而使钻模体减轻重量。使工人操作方便,快捷。62夹具体的毛坯制造方法本夹具属于铸造夹具体,它的优点是工艺性好,可铸造各种外形,而且抗压强度、刚度和吸震性能比较好,经过时效处理后尺寸稳定成。本夹具体材料采用HT150成本低。63夹具体支脚的设计应减少夹具体底面与机床工作台的接触面积,使夹具体放置平稳。支脚的设计应满足下面的要求631支脚必须是四个632支脚断面尺寸必须大于机床工作台T形槽的宽633夹具的重心、钻削压力必须落在支脚形成的支撑面上634支脚必须与钻床主轴轴线垂直或平行,保证加工质量本钻模体有两个基准面,(彼此互相垂直)以保证两基准面分别与加工时的钻头方向垂直。7主要尺寸的确定71轮廓尺寸为180X143X140下载后包含有CAD图纸和说明书,咨询Q197216396或1197098572有关尺寸的确定。711定位柱中心线到10钻套的中心距由杠杆臂上的尺寸来确定,零件图上中心距为780。5夹具定位柱中心线到10钻套的中心距的基本尺寸为78,公差为零件公差的1/31/5取0。15定位柱中心线到10钻套的中心距为780。15712在另外一个垂直方向上,定位柱中心线到13钻套的中心距由杠杆臂上的尺寸来确定,定位柱中心线到13钻套的中心在左右方向的中心距零件图上为150。5,夹具定位柱中心线到13钻套的中心距的基本尺寸为15,公差为零件公差的1/31/5取0。15定位柱中心线到13钻套的中心距为150。15713定位柱中心线到13钻套的中心在上下方向的中心距零件图上为125,是未注公差我们取12500572几处配合的确定。定位柱与体孔配合16H7/N6定位柱与工件配合10钻套22H8/E810钻套与模板低孔是配合18H7/N613钻套与模板低孔是配合22H7/N68定位误差的计算一批工件分别在夹具中定位时,各工件所占据的位置并不完全一致。由于工件在夹具中定位不准确所引起的加工误差,称为定位误差。定位误差的计算公式DBW下载后包含有CAD图纸和说明书,咨询Q197216396或11970985其中D定位误差B基准不重合误差W基准位移误差81钻10孔时的定位误差基准不重合误差BB0(设计基准与定位基准重合)W由于不能保证单边接触基准位移误差等于定位柱配合的最大间隙WXMAX定位误差DBWXMAX8钻13孔时的定位误差基准不重合误差BB0(设计基准与定位基准重合)W(定位环形面和基准环形面经过加工而接触)定位误差的DBW09夹具的使用91工件在夹具上的安装下载后包含有CAD图纸和说明书,咨询Q197216396或11970985工件以22孔套入夹具定位柱上,以端面与定位基准面(环形面)接触,且转动工件使另一端厚10,以R12D侧向中心线与防转销接触,定位完毕。初步拧紧件夹紧螺母,工件另一端与调高后的辅助支撑接触良好后,宁紧锁紧螺母,再将夹紧螺母完全拧紧。其夹紧力的大小由工人凭经验自行掌握(用标准呆扳手)92工件的加工过程921以夹具基准面AF平放在立钻工作台上,让钻头与钻套处于正确位置,引导钻头钻10孔,操作完毕后,夹具翻转90度,以基准面E平放在工作台上,对好基准钻13孔93松开夹紧螺纹,侧向抽出开口垫圈,取出工件,加工完毕。10参考资料机械制造工艺学(清华大学王先逵主编)机械设计师手册机床夹具设计(哈尔滨工业大学)机加工工艺手册高级钳工技能训练机械制造装备(黄鹤汀主编)下载后包含有CAD图纸和说明书,咨询Q197216396或11970985致谢尊敬的各位领导我作为XX级机电学院的毕业生,非常感谢学院对我们的关心和照顾,在校的三年里我不但学习了很多专业知识还参加了一些学院的活动,让我的学习生活多姿多彩,更重要的是让我学到了很多为人处事的道理,给我们的就业铺平了道路,在此我感谢学校能给我这么多学习的机会,在此毕业之际,我用心作好我的最后一门课程,以表示对学院对我们多年的培养表示感谢。特别值得提出的是,感谢我的毕业设计辅导老师XXX。ROBOTICSANDCOMPUTERINTEGRATEDMANUFACTURING212005368378KEYWORDSFIXTUREDESIGNGEOMETRYCONSTRAINTDETERMINISTICLOCATINGUNDERCONSTRAINEDOVERCONSTRAINEDCONSTRAINTSTATUS,AWORKPIECEUNDERANYLOCATINGSCHEMEFALLSINTOONEOFTHEFOLLOWINGTHREECATEGORIESLOCATINGPROBLEMUSINGSCREWTHEORYIN1989ITISCONCLUDEDTHATTHELOCATINGWRENCHESMATRIXNEEDSTOBEFULLRANKTOACHIEVEDETERMINISTICLOCATIONTHISMETHODHASBEENADOPTEDBYNUMEROUSSTUDIESASWELLWANGETAL3CONSIDEREDARTICLEINPRESS07365845/SEEFRONTMATTERR2005ELSEVIERLTDALLRIGHTSRESERVEDDOI101016/JRCIM200411012C3CORRESPONDINGAUTHORTEL15088316092FAX15088316412EMAILADDRESSHSONGWPIEDUHSONG1WELLCONSTRAINEDDETERMINISTICTHEWORKPIECEISMATEDATAUNIQUEPOSITIONWHENSIXLOCATORSAREMADETOCONTACTTHEWORKPIECESURFACE2UNDERCONSTRAINEDTHESIXDEGREESOFFREEDOMOFWORKPIECEARENOTFULLYCONSTRAINED3OVERCONSTRAINEDTHESIXDEGREESOFFREEDOMOFWORKPIECEARECONSTRAINEDBYMORETHANSIXLOCATORSIN1985,ASADAANDBY1PROPOSEDFULLRANKJACOBIANMATRIXOFCONSTRAINTEQUATIONSASACRITERIONANDFORMEDTHEBASISOFANALYTICALINVESTIGATIONSFORDETERMINISTICLOCATINGTHATFOLLOWEDCHOUETAL2FORMULATEDTHEDETERMINISTIC1INTRODUCTIONAXTUREISAMECHANISMUSEDINMANUFACTURINGOPERATIONSTOHOLDAWORKPIECERMLYINPOSITIONBEINGACRUCIALSTEPINPROCESSPLANNINGFORMACHININGPARTS,XTUREDESIGNNEEDSTOENSURETHEPOSITIONALACCURACYANDDIMENSIONALACCURACYOFAWORKPIECEINGENERAL,321PRINCIPLEISTHEMOSTWIDELYUSEDGUIDINGPRINCIPLEFORDEVELOPINGALOCATIONSCHEMEVBLOCKANDPINHOLELOCATINGPRINCIPLESAREALSOCOMMONLYUSEDALOCATIONSCHEMEFORAMACHININGXTUREMUSTSATISFYANUMBEROFREQUIREMENTSTHEMOSTBASICREQUIREMENTISTHATITMUSTPROVIDEDETERMINISTICLOCATIONFORTHEWORKPIECE1THISNOTIONSTATESTHATALOCATORSCHEMEPRODUCESDETERMINISTICLOCATIONWHENTHEWORKPIECECANNOTMOVEWITHOUTLOSINGCONTACTWITHATLEASTONELOCATORTHISHASBEENONEOFTHEMOSTFUNDAMENTALGUIDELINESFORXTUREDESIGNANDSTUDIEDBYMANYRESEARCHERSCONCERNINGGEOMETRYABSTRACTGEOMETRYCONSTRAINTISONEOFTHEMOSTIMPORTANTCONSIDERATIONSINXTUREDESIGNANALYTICALFORMULATIONOFDETERMINISTICLOCATIONHASBEENWELLDEVELOPEDHOWEVER,HOWTOANALYZEANDREVISEANONDETERMINISTICLOCATINGSCHEMEDURINGTHEPROCESSOFACTUALXTUREDESIGNPRACTICEHASNOTBEENTHOROUGHLYSTUDIEDINTHISPAPER,AMETHODOLOGYTOCHARACTERIZEXTURINGSYSTEMSGEOMETRYCONSTRAINTSTATUSWITHFOCUSONUNDERCONSTRAINTISPROPOSEDANUNDERCONSTRAINTSTATUS,IFITEXISTS,CANBERECOGNIZEDWITHGIVENLOCATINGSCHEMEALLUNCONSTRAINEDMOTIONSOFAWORKPIECEINANUNDERCONSTRAINTSTATUSCANBEAUTOMATICALLYIDENTIEDTHISASSISTSTHEDESIGNERTOIMPROVEDECITLOCATINGSCHEMEANDPROVIDESGUIDELINESFORREVISIONTOEVENTUALLYACHIEVEDETERMINISTICLOCATINGR2005ELSEVIERLTDALLRIGHTSRESERVEDCAMLAB,DEPARTMENTOFMECHANICALENGINEERING,WORCESTERPOLYTECHNICINSTITUTE,100INSTITUTERD,WORCESTER,MA01609,USARECEIVED14SEPTEMBER2004RECEIVEDINREVISEDFORM9NOVEMBER2004ACCEPTED10NOVEMBER2004LOCATINGCOMPLETENESSEVALUATIONANDREVISIONINXTUREPLANHSONGC3,YRONGWWWELSEVIERCOM/LOCATE/RCIMLOCATORWORKPIECECONTACTAREAEFFECTSINSTEADOFAPPLYINGPOINTCONTACTTHEYINTRODUCEDACONTACTMATRIXANDPOINTEDOUTTHATTWOCONTACTBODIESSHOULDNOTHAVEEQUALBUTOPPOSITECURVATUREATCONTACTINGPOINTCARLSON4SUGGESTEDTHATALINEARAPPROXIMATIONMAYNOTBESUFCIENTFORSOMEAPPLICATIONSSUCHASNONPRISMATICSURFACESORNONSMALLRELATIVEERRORSHEPROPOSEDASECONDORDERTAYLOREXPANSIONWHICHALSOTAKESLOCATORERRORINTERACTIONINTOACCOUNTMARINANDFERREIRA5APPLIEDCHOUSFORMULATIONON321LOCATIONANDFORMULATEDSEVERALEASYTOFOLLOWPLANNINGRULESDESPITETHENUMEROUSANALYTICALSTUDIESONDETERMINISTICLOCATION,LESSATTENTIONWASPAIDTOANALYZENONDETERMINISTICLOCATIONINTHEASADAANDBYSFORMULATION,THEYASSUMEDFRICTIONLESSANDPOINTCONTACTBETWEENXTURINGELEMENTSANDWORKPIECETHEDESIREDLOCATIONISQ,ATWHICHAWORKPIECEISTOBEPOSITIONEDANDPIECEWISELYDIFFERENTIABLESURFACEFUNCTIONISGIASSHOWNINFIG1THESURFACEFUNCTIONISDENEDASGIQC30TOBEDETERMINISTIC,THERESHOULDBEAUNIQUESOLUTIONFORTHEFOLLOWINGEQUATIONSETFORALLLOCATORSGIQ0I12N,1WHERENISTHENUMBEROFLOCATORSANDQX0Y0Z0Y0F0C0C138REPRESENTSTHEPOSITIONANDORIENTATIONOFTHEWORKPIECEONLYCONSIDERINGTHEVICINITYOFDESIREDLOCATIONQC3WHEREQQC3DQASADAANDBYSHOWEDTHATARTICLEINPRESSHSONG,YRONG/ROBOTICSANDCOMPUTERINTEGRATEDMANUFACTURING212005368378369GIQGIQC3HIDQ,2WHEREHIISTHEJACOBIANMATRIXOFGEOMETRYFUNCTIONS,ASSHOWNBYTHEMATRIXINEQ3THEDETERMINISTICLOCATINGREQUIREMENTCANBESATISEDIFTHEJACOBIANMATRIXHASFULLRANK,WHICHMAKESTHEEQ2TOHAVEONLYONESOLUTIONQQC3RANKQG1QX0QG1QY0QG1QZ0QG1QY0QG1QF0QG1QC0QGIQX0QGIQY0QGIQZ0QGIQY0QGIQF0QGIQC0QGNQX0QGNQY0QGNQZ0QGNQY0QGNQF0QGNQC026666666664377777777758963UPONGIVENA321LOCATINGSCHEME,THERANKOFAJACOBIANMATRIXFORCONSTRAINTEQUATIONSTELLSTHECONSTRAINTSTATUSASSHOWNINTABLE1IFTHERANKISLESSTHANSIX,THEWORKPIECEISUNDERCONSTRAINED,IE,THEREEXISTSATLEASTONEFREEMOTIONOFTHEWORKPIECETHATISNOTCONSTRAINEDBYLOCATORSIFTHEMATRIXHASFULLRANKBUTTHELOCATINGSCHEMEHASMORETHANSIXLOCATORS,THEWORKPIECEISOVERCONSTRAINED,WHICHINDICATESTHEREEXISTSATLEASTONELOCATORSUCHTHATITCANBEREMOVEDWITHOUTAFFECTINGTHEGEOMETRYCONSTRAINSTATUSOFTHEWORKPIECEFORLOCATINGAMODELOTHERTHAN321,DATUMFRAMECANBEESTABLISHEDTOEXTRACTEQUIVALENTLOCATINGPOINTSHU6HASDEVELOPEDASYSTEMATICAPPROACHFORTHISPURPOSEHENCE,THISCRITERIONCANBEAPPLIEDTOALLLOCATINGSCHEMESXYZOXYZOX0,Y0,Z0GIUCSWCSWORKPIECEFIG1FIXTURINGSYSTEMMODELTHEYFURTHERINTRODUCEDSEVERALINDEXESDERIVEDFROMTHOSEMATRIXESTOEVALUATELOCATORCONGURATIONS,FOLLOWEDBYOPTIMIZATIONTHROUGHCONSTRAINEDNONLINEARPROGRAMMINGTHEIRANALYTICALSTUDY,HOWEVER,DOESNOTCONCERNTHEARTICLEINPRESSREVISIONOFNONDETERMINISTICLOCATINGCURRENTLY,THEREISNOSYSTEMATICSTUDYONHOWTODEALWITHAXTUREDESIGNTHATFAILEDTOPROVIDEDETERMINISTICLOCATION2LOCATINGCOMPLETENESSEVALUATIONIFDETERMINISTICLOCATIONISNOTACHIEVEDBYDESIGNEDXTURINGSYSTEM,ITISASIMPORTANTFORDESIGNERSTOKNOWWHATTHECONSTRAINTSTATUSISANDHOWTOIMPROVETHEDESIGNIFTHEXTURINGSYSTEMISOVERCONSTRAINED,INFORMATIONABOUTTHEUNNECESSARYLOCATORSISDESIREDWHILEUNDERCONSTRAINEDOCCURS,THEKNOWLEDGEABOUTALLTHEUNCONSTRAINEDMOTIONSOFAWORKPIECEMAYGUIDEDESIGNERSTOSELECTADDITIONALLOCATORSAND/ORREVISETHELOCATINGSCHEMEMOREEFCIENTLYAGENERALSTRATEGYTOCHARACTERIZEGEOMETRYCONSTRAINTSTATUSOFALOCATINGSCHEMEISDESCRIBEDINFIG2INTHISPAPER,THERANKOFLOCATINGMATRIXISEXERTEDTOEVALUATEGEOMETRYCONSTRAINTSTATUSSEEAPPENDIXFORDERIVATIONOFLOCATINGMATRIXTHEDETERMINISTICLOCATINGREQUIRESSIXLOCATORSTHATPROVIDEFULLRANKLOCATINGMATRIXWLASSHOWNINFIG3,FORGIVENLOCATORNUMBERNLOCATINGNORMALVECTORAIBICIC138ANDLOCATINGPOSITIONXIYIZIC138FOREACHLOCATOR,I12NTHENC26LOCATINGMATRIXCANBEDETERMINEDASFOLLOWSA1B1C1C1Y1C0B1Z1A1Z1C0C1X1B1X1C0A1Y12637KANGETAL7FOLLOWEDTHESEMETHODSANDIMPLEMENTEDTHEMTODEVELOPAGEOMETRYCONSTRAINTANALYSISMODULEINTHEIRAUTOMATEDCOMPUTERAIDEDXTUREDESIGNVERICATIONSYSTEMTHEIRCAFDVSYSTEMCANCALCULATETHEJACOBIANMATRIXANDITSRANKTODETERMINELOCATINGCOMPLETENESSITCANALSOANALYZETHEWORKPIECEDISPLACEMENTANDSENSITIVITYTOLOCATINGERRORXIONGETAL8PRESENTEDANAPPROACHTOCHECKTHERANKOFLOCATINGMATRIXWLSEEAPPENDIXTHEYALSOINTRODUCEDLEFT/RIGHTGENERALIZEDINVERSEOFTHELOCATINGMATRIXTOANALYZETHEGEOMETRICERRORSOFWORKPIECEITHASBEENSHOWNTHATTHEPOSITIONANDORIENTATIONERRORSDXOFTHEWORKPIECEANDTHEPOSITIONERRORSDROFLOCATORSARERELATEDASFOLLOWSWELLCONSTRAINEDDXWLDR,4OVERCONSTRAINEDDXWTLWLC01WTLDR,5UNDERCONSTRAINEDDXWTLWLWTLC01DRI6C26C0WTLWLWTLC01WLL,6WHERELISANARBITRARYVECTORTABLE1RANKNUMBEROFLOCATORSSTATUSO6UNDERCONSTRAINED66WELLCONSTRAINED646OVERCONSTRAINEDHSONG,YRONG/ROBOTICSANDCOMPUTERINTEGRATEDMANUFACTURING212005368378370WLAIBICICIYIC0BIZIAIZIC0CIXIBIXIC0AIYIANBNCNCNYNC0BNZNANZNC0CNXNBNXNC0ANYN6666647777757WHENRANKWL6ANDN6THEWORKPIECEISWELLCONSTRAINEDWHENRANKWL6ANDN46THEWORKPIECEISOVERCONSTRAINEDTHISMEANSTHEREARENC06UNNECESSARYLOCATORSINTHELOCATINGSCHEMETHEWORKPIECEWILLBEWELLCONSTRAINEDWITHOUTTHEPRESENCEOFTHOSENC06LOCATORSTHEMATHEMATICALREPRESENTATIONFORTHISSTATUSISTHATTHEREARENC06ROWVECTORSINLOCATINGMATRIXTHATCANBEEXPRESSEDASLINEARCOMBINATIONSOFTHEOTHERSIXROWVECTORSTHELOCATORSCORRESPONDINGTOTHATSIXROWVECTORSCONSISTONEARTICLEINPRESSLOCATDETERM1234BE3WORKPIHSONG,YRONG/ROBOTICSANDCOMPUTERINTEGRATEDMANUFACTURING212005368378371INGSCHEMETHATPROVIDESDETERMINISTICLOCATIONTHEDEVELOPEDALGORITHMUSESTHEFOLLOWINGAPPROACHTOINETHEUNNECESSARYLOCATORSFINDALLTHECOMBINATIONOFNC06LOCATORSFOREACHCOMBINATION,REMOVETHATNC06LOCATORSFROMLOCATINGSCHEMERECALCULATETHERANKOFLOCATINGMATRIXFORTHELEFTSIXLOCATORSIFTHERANKREMAINSUNCHANGED,THEREMOVEDNC06LOCATORSARERESPONSIBLEFOROVERCONSTRAINEDSTATUSTHISMETHODMAYYIELDMULTISOLUTIONSANDREQUIREDESIGNERTODETERMINEWHICHSETOFUNNECESSARYLOCATORSSHOULDREMOVEDFORTHEBESTLOCATINGPERFORMANCEWHENRANKWLO6THEWORKPIECEISUNDERCONSTRAINEDALGORITHMDEVELOPMENTANDIMPLEMENTATIONTHEALGORITHMTOBEDEVELOPEDHEREWILLDEDICATETOPROVIDEINFORMATIONONUNCONSTRAINEDMOTIONSOFTHEECEINUNDERCONSTRAINEDSTATUSSUPPOSETHEREARENLOCATORS,THERELATIONSHIPBETWEENAWORKPIECESPOSITION/FIG2GEOMETRYCONSTRAINTSTATUSCHARACTERIZATIONXZYA1,B1,C12,B2,C2X1,Y1,Z1X2,Y2,Z2AI,BI,CIXI,YI,ZIAFIG3ASIMPLIEDLOCATINGSCHEMEORIENTIJLLLARTICLEINPRESS3725TOIDENTIFYALLTHEUNCONSTRAINEDMOTIONSOFTHEWORKPIECE,VDXIDYIDZIDAXIDAYIDAZIC138ISINTRODUCEDSUCHTHATVDX09SINCERANKDXO6THEREMUSTEXISTNONZEROVTHATSATISESEQ9EACHNONZEROSOLUTIONOFVREPRESENTSANUNCONSTRAINEDMOTIONEACHTERMOFVREPRESENTSACOMPONENTOFTHATMOTIONFOREXAMPLE,000300C138SAYSTHATTHEROTATIONABOUTXAXISISNOTCONSTRAINED011000C138MEANSTHATTHEWORKPIECECANMOVEALONGTHEDIRECTIONGIVENBYVECTOR011C138THERECOULDBEINNITESOLUTIONSTHESOLUTIONSPACE,HOWEVER,CANBECONSTRUCTEDBY6C0RANKWLBASICSOLUTIONSFOLLOWINGANALYSISISDEDICATEDTONDOUTTHEBASICSOLUTIONSFROMEQS8AND9VXDXDXDYDYDZDZDAXDAXDAYDAYDAZDAZDXXNI1W1IDRIDYXNI1W2IDRIDZXNI1W3IDRIDAXXNI1W4IDRIDAYXNI1W5IDRIDAZXNI1W6IDRIXNI1VW1IW2IW3IW4IW5IW6IC138TDRI010EQ10HOLDSFOR8DRIIFANDONLYIFEQ11ISTRUEFOR8I1PIPNVW1IW2IW3IW4IW5IW6IC138T011EQ11ILLUSTRATESTHEDEPENDENCYRELATIONSHIPSAMONGROWVECTORSOFWRINSPECIALCASES,SAY,ALLW1JEQUALTOZERO,VHASANOBVIOUSSOLUTION1,0,0,0,0,0,INDICATINGDISPLACEMENTALONGTHEXAXISISNOTCONSTRAINEDTHISISEASYTOUNDERSTANDBECAUSEDX0INTHISCASE,IMPLYINGTHATTHECORRESPONDINGPOSITIONERROROFTHEWORKPIECEISNOTDEPENDENTOFANYLOCATORERRORSHENCE,THEASSOCIATEDMOTIONISNOTCONSTRAINEDBYLOCATORSMOREOVER,ACOMBINEDMOTIONISNOTCONSTRAINEDIFONEOFTHEELEMENTSINDXCANBEEXPRESSEDASLINEARCOMBINATIONOFOTHERELEMENTSFORINSTANCE,9W1JA0W2JA0W1JC0W2JFOR8JINTHISSCENARIO,THEWORKPIECECANNOTMOVEALONGXORYAXISHOWEVER,ITCANMOVEALONGTHEDIAGONALLINEBETWEENXANDYAXISDENEDBYVECTOR1,1,0TONDSOLUTIONSFORGENERALCASES,THEFOLLOWINGSTRATEGYWASDEVELOPED1ELIMINATEDEPENDENTROWSFROMLOCATINGMATRIXLETRRANKWLNNUMBEROFLOCATORIFRONCREATEAVECTORINNC0RDIMENSIONSPACEUU1UJUNC0RHI1PJPNC0R1PUJPNSELECTUJINTHEWAYTHATRANKWLRSTILLHOLDSAFTERSETTINGALLTHETERMSOFALLTHEUJTHROWSEQUALTOZEROSETRC26MODIEDLOCATINGMATRIXWLMA1B1C1C1Y1C0B1Z1A1Z1C0C1X1B1X1C0A1Y1AIBICICIYIC0BIZIAIZIC0CIXIBIXIC0AIYIANBNCNCNYNC0BNZNANZNC0CNXNBNXNC0ANYN2666666437777775RC26,WHERGEOMETATIONERRORSANDLOCATORERRORSCANBEEXPRESSEDASFOLLOWSDXDXDYDZAXAYAZ2666666666437777777775W11W1IW1NW21W2IW2NW31W3IW3NW41W4IW4NW51W5IW5NW61W6IW6N2666666666437777777775C1DR1DRIDRN2666666437777775,8EDXDYDZAXAYAZAREDISPLACEMENTALONGX,Y,ZAXISANDROTATIONABOUTX,Y,ZAXIS,RESPECTIVELYDRIISRICERROROFTHEITHLOCATORWISDENEDBYRIGHTGENERALIZEDINVERSEOFTHELOCATINGMATRIXWRWTWWTC01HSONG,YRONG/ROBOTICSANDCOMPUTERINTEGRATEDMANUFACTURING212005368378WHEREI12NIAUJ46CONSTREXAMPLVECTORARTICLEINPRESSL30,0,10,2,1,00,L40,1,00,3,0,20,L50,1,00,1,0,20CONSEQUENTLY,THELOCATINGMATRIXISDETERMINEDWL0013C0100013C0300011C020010C02032666666437777775LLVSV666647775WQKIWQKR66647775C1WL1WLIWLRW61W6IW6R66647775,WHERES126SAQJSAQKL126LAQJREPEATSTEP4SELECTANOTHERTERMFROMQANDSTEP5UNTILALL6C0RBASICSOLUTIONSHAVEBEENDETERMINEDBASEDONTHISALGORITHM,ACPROGRAMWASDEVELOPEDTOIDENTIFYTHEUNDERCONSTRAINEDSTATUSANDUNAINEDMOTIONSE1INASURFACEGRINDINGOPERATION,AWORKPIECEISLOCATEDONAXTURESYSTEMASSHOWNINFIG4THENORMALANDPOSITIONOFEACHLOCATORAREASFOLLOWS10,0,10,1,3,00,20,0,10,3,3,00,CALCULATEDUNDETERMINEDTERMSOFVVISALSOASOLUTIONOFEQ11THERUNDETERMINEDTERMSCANBEFOUNDASFOLLOWSV126663777WQK126663777W11W1IW1R26663777C015WRMWL1WLIWLRW61W6IW6R666477756C26,WHEREL126LAQJNORMALIZETHEFREEMOTIONSPACESUPPOSEVV1V2V3V4V5V6C138ISONEOFTHEBASICSOLUTIONSOFEQ10WITHALLSIXTERMSUNDETERMINEDSELECTATERMQKFROMVECTORQ1PKP6C0RSETVQKC01VQJ0J126C0RJAK2COMPUTETHE6C2NRIGHTGENERALIZEDINVERSEOFTHEMODIEDLOCATINGMATRIXWRWTLMWLMWTLMC01W11W1IW1RW21W2IW2RW31W3IW3RW41W4IW4RW51W5IW5RW61W6IW6R26666666664377777777756C2R3TRIMWRDOWNTOARC2RFULLRANKMATRIXWRMRRANKWLO6CONSTRUCTA6C0RDIMENSIONVECTORQQ1QJQ6C0RHI1PJP6C0R1PQJPNSELECTQJINTHEWAYTHATRANKWRRSTILLHOLDSAFTERSETTINGALLTHETERMSOFALLTHEQJTHROWSEQUALTOZEROSETRC2RMODIEDINVERSEMATRIXW11W1IW1R26663777HSONG,YRONG/ROBOTICSANDCOMPUTERINTEGRATEDMANUFACTURING212005368378373010C0201ARTICLEINPRESSTHISLOCATINGSYSTEMPROVIDESUNDERCONSTRAINEDPOSITIONINGSINCERANKWL5O6THEPROGRAMTHENCALCULATESTHERIGHTGENERALIZEDINVERSEOFTHELOCATINGMATRIXWR000000505C01C00515075C01251500025025C0050005C00500000005C00526666666643777777775THERSTROWISRECOGNIZEDASADEPENDENTROWBECAUSEREMOVALOFTHISROWDOESNOTAFFECTRANKOFTHEMATRIXTHEOTHERVEROWSAREINDEPENDENTROWSALINEARCOMBINATIONOFTHEINDEPENDENTROWSISFOUNDACCORDINGTHEREQUIREMENTINSTEP5OFTHEPROCEDUREFORUNDERCONSTRAINEDSTATUSTHESOLUTIONFORTHISSPECIALCASEISOBVIOUSTHATALLTHECOEFCIENTSAREZEROHENCE,THEUNCONSTRAINEDMOTIONOFWORKPIECECANBEDETERMINEDASVC0100000C138THISINDICATESTHATTHEWORKPIECECANMOVEALONGXDIRECTIONBASEDONTHISRESULT,ANADDITIONALLOCATORSHOULDBEEMPLOYEDTOCONSTRAINTDISPLACEMENTOFWORKPIECEALONGXAXISXZYL3L4L5L2L1FIG4UNDERCONSTRAINEDLOCATINGSCHEMEHSONG,YRONG/ROBOTICSANDCOMPUTERINTEGRATEDMANUFACTURING212005368378374EXAMPLE2FIG5SHOWSAKNUCKLEWITH321LOCATINGSYSTEMTHENORMALVECTORANDPOSITIONOFEACHLOCATORINTHISINITIALDESIGNAREASFOLLOWSL10,1,00,896,C0877,C05150,L20,1,00,1060,C0875,C03780,L30,1,00,1010,C0959,C06120,L409955,C000349,00880,977,C0902,C06240,L509955,C000349,00880,977,C0866,C06240,L60088,0017,C009960,1034,C0864,C03590THELOCATINGMATRIXOFTHISCONGURATIONISWL01051500089600103781060001061200010009955C00034900880C01012445C070726640863809955C00034900880C0980728C07072664082800088000170C009960866625799824660093626666666643777777775,RANKWL5O6REVEALSTHATTHEWORKPIECEISUNDERCONSTRAINEDITISFOUNDTHATONEOFTHERSTVEROWSCANBEREMOVEDWITHOUTVARYINGTHERANKOFLOCATINGMATRIXSUPPOSETHERSTROW,IE,LOCATORL1ISREMOVEDFROMWLTHEARTICLEINPRESSMODIEDLOCATINGMATRIXTURNSINTOWLM0103780010600010612010009955C00034900880C01012445C070726640863809955C00034900880C0980728C07072664082800088000170C0099686662579982466009362666666437777775THERIGHTGENERALIZEDINVERSEOFTHEMODIEDLOCATINGMATRIXISWR18768C018607C02066652137160499530551C020551C03244483244480C01095610862120648C0124764C002916C0000440004400061C000061000025C00002500065C00006900007C0000040000400284C000284026666666643777777775THEPROGRAMCHECKEDTHEDEPENDENTROWANDFOUNDEVERYROWISDEPENDENTONOTHERVEROWSWITHOUTLOSINGGENERALITY,THERSTROWISREGARDEDASDEPENDENTROWTHE5C25MODIEDINVERSEMATRIXIS23FIG5KNUCKLE610MODIEDFROMREALDESIGNHSONG,YRONG/ROBOTICSANDCOMPUTERINTEGRATEDMANUFACTURING212005368378375WRM30551C020551C03244483244480C01095610862120648C0124764C002916C0000440004400061C000061000025C00002500065C00006900007C0000040000400284C000284066666647777775THEUNDETERMINEDSOLUTIONISVC01V2V3V4V5V6C138TOCALCULATETHEVEUNDETERMINEDTERMSOFVACCORDINGTOSTEP5,18768C018607C02066652137160499526666666643777777775TC130551C020551C03244483244480C01095610862120648C0124764C002916C0000440004400061C000061000025C00002500065C00006900007C0000040000400284C000284026666666643777777775C010C01713C000432C000706004C138SUBSTITUTINGTHISRESULTINTOTHEUNDETERMINEDSOLUTIONYIELDSVC010C01713C000432C000706004C138THISVECTORREPRESENTSAFREEMOTIONDENEDBYTHECOMBINATIONOFADISPLACEMENTALONGC01,0,C01713DIRECTIONCOMBINEDANDAROTATIONABOUTC000432,C000706,004TOREVISETHISLOCATINGCONGURATION,ANOTHERLOCATORSHOULDBEADDEDTOCONSTRAINTHISFREEMOTIONOFTHEWORKPIECE,ASSUMINGLOCATORL1WASREMOVEDINSTEP1THEPROGRAMCANALSOCALCULATETHEFREEMOTIONSOFTHEWORKPIECEIFALOCATOROTHERTHANL1WASREMOVEDINSTEP1THISPROVIDESMOREREVISIONOPTIONSFORDESIGNER4SUMMARYDETERMINISTICLOCATIONISANIMPORTANTREQUIREMENTFORXTURELOCATINGSCHEMEDESIGNANALYTICALCRITERIONFORDETERMINISTICSTATUSHASBEENWELLESTABLISHEDTOFURTHERSTUDYNONDETERMINISTICSTATUS,ANALGORITHMFORCHECKINGTHEGEOMETRYCONSTRAINTSTATUSHASBEENDEVELOPEDTHISALGORITHMCANIDENTIFYANUNDERCONSTRAINEDSTATUSANDINDICATEQFIQFIQFIARTICLEINPRESSWXHSONG,YRONG/ROBOTICSANDCOMPUTERINTEGRATEDMANUFACTURING212005368378376ITHLOCATORINILILRGILXFIXLIHLIRLIQXLIDXLIQHLIDHLIQRLIDRLI,14WORKPIECEWIWRWXWTHEUNCONSTRAINEDMOTIONSOFWORKPIECEITCANALSORECOGNIZEANOVERCONSTRAINEDSTATUSANDUNNECESSARYLOCATORSTHEOUTPUTINFORMATIONCANASSISTDESIGNERTOANALYZEANDIMPROVEANEXISTINGLOCATINGSCHEMEAPPENDIXLOCATINGMATRIXCONSIDERAGENERALWORKPIECEASSHOWNINFIG6CHOOSEREFERENCEFRAMEFWGXEDTOTHEWORKPIECELETFGGANDFLIGBETHEGLOBALFRAMEANDTHEITHLOCATORFRAMEXEDRELATIVETOITWEHAVEFIXWHWRWIFIXLIHLIRLI,12WHEREXW23C21ANDHW23C21XLI23C21ANDHLI23C21ARETHEPOSITIONANDORIENTATIONOFTHEWORKPIECETHEITHLOCATORINTHEGLOBALFRAMEFGGRWI23C21RLI23C21ISTHEPOSITIONOFTHEITHCONTACTPOINTBETWEENTHEWORKPIECEANDTHEITHLOCATORINTHEWORKPIECEFRAMEFWGTHEITHLOCATORFRAMEFLIGASSUMETHATDXW23C21DHW23C21ANDDRWI23C21ARETHEDEVIATIONSOFTHEPOSITIONXW23C21ORIENTATIONHW23C21OFTHEWORKPIECEANDTHEPOSITIONOFTHEITHCONTACTPOINTRWI23C21RESPECTIVELYTHENWEHAVETHEACTUALCONTACTONTHEWORKPIECE,FIXWDXWHWDHWRWIDRWIFIXWHWRWIQFIQXWDXWQFIQHWDHWQFIQRWIDRWI,13WHERETHESECONDTERMINTHERIGHTSIDEOFEQ13ISTHEPOSITIONERROROFTHEITHCONTACTPOINTRESULTINGFROMTHEPOSITIONERRORDXWOFTHEWORKPIECE,THETHIRDTERMISTHEPOSITIONERROROFTHEI

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号