SY5430JBC28搅拌泵车液压系统设计

液压系统全套课程毕业设计

SY5430JBC28搅拌泵车液压系统设计【优秀液压系统设计含11张CAD图纸】

【带任务书+开题报告+外文翻译】【62页@正文19400字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】

任务书双面.doc

内容提要.rtf

图纸目录.doc

封面 .doc

开题报告.doc

开题报告封面.doc

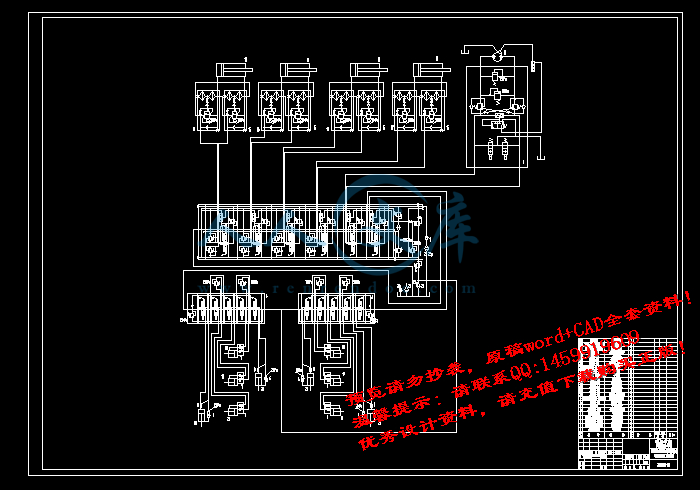

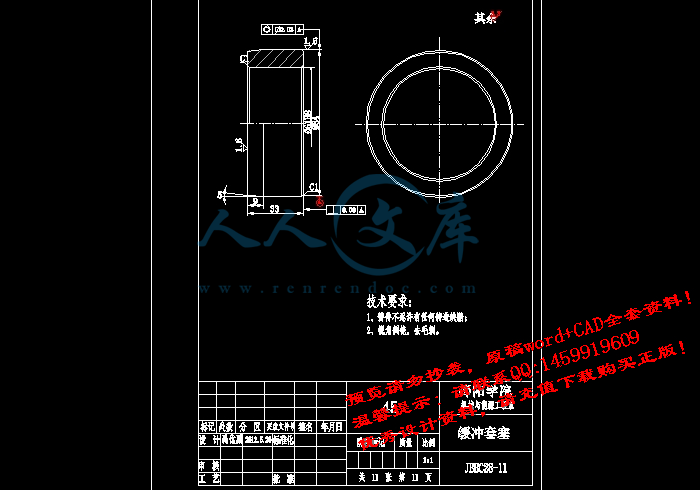

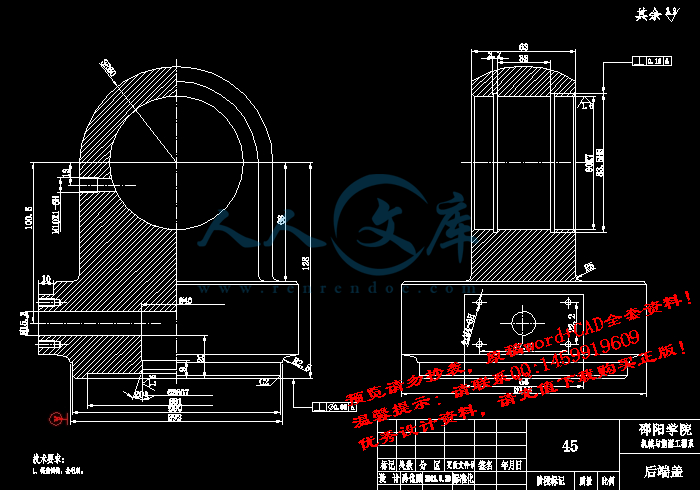

总图合计11张.dwg

正文.rtf

目录.doc

翻译中文译文.doc

英文摘要.doc

评阅表双面.doc

译文.doc

进度考核表.doc

任务书

课题名称SY5430JBC28搅拌泵车液压系统设计

一、课题研究的目的与主要内容

研究目的:

1.通过该课题的研究和设计巩固所学的有关专业理论知识,掌握液压系统设计一般的过程;

2. 本设计将基于自已所学的专业,对搅拌泵车液压系统进行的设计,在这过程中可以用到专业领域各科知识,如液压传动,机械设计等,这将是多自己大学四年以来所学的知识进行一次大的总结。

3.可以通本次设计提高自己查找和查阅资料的能力,提高自己的设计水平,提高动手能力,这样有利于自己以后的工作。

研究的主要内容:

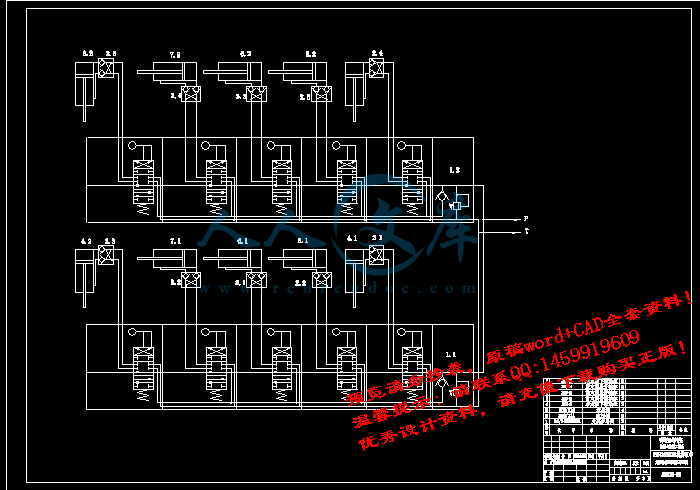

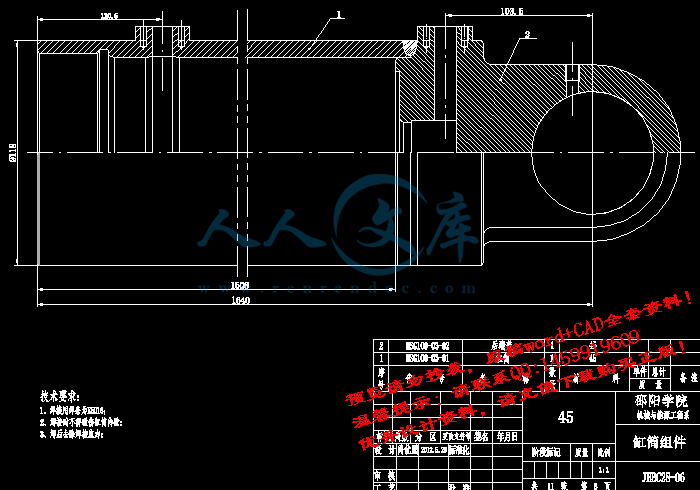

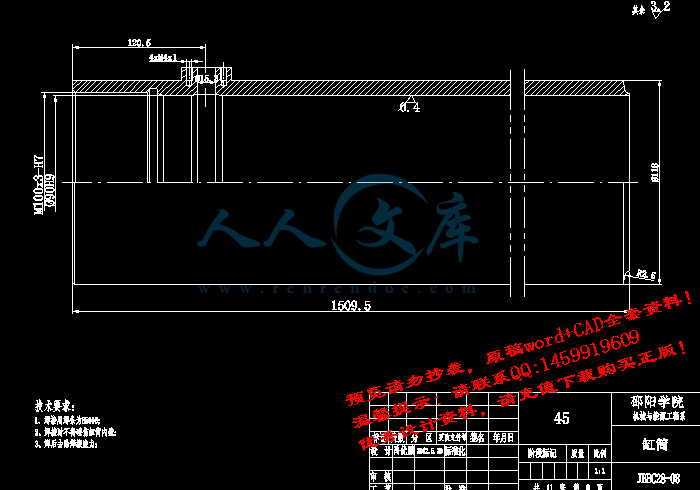

在这个设计中主的要设计内容为:液压系统的工作要求、液压系统方案的确定、液压站的设计、最后绘制出全部的图纸和编写出设计说明书。

二、基本要求

(1)认真分析前面初步确定的搅拌泵车液压系统设计方案,并查找相关设计手册确定主要技术参数。

(2)查找征对设计有用的文献资料,通过自己实习的体会并查相关的标准,然后使用CAD设计软件,绘制出重要零部件图并完成装配图的绘制,最后按照指导老师的要求,正确完成说明书和图纸 。

(3)整理资料,撰写设计、计算说明书,整理译文。

内容提要

混凝土搅拌泵车是一机多用的一种工程机械,它集混泥土运输、泵送、布料功能于一身。其紧凑的结构和高效的灵活特点,更加适合在狭小的工地甚至居民区进行施工。搅拌泵车自带混凝土可以满足小方量泵送作业的需求,在大方量泵送工作时,它可以补充搅拌车运输过程中缺料的弊端,实现不断地泵送,省时又经济。泵车的核心技术就是液压系统的设计,由于泵车的工作条件恶劣,要求实现的动作较复杂,于是对液压系统的设计提出了较高要求,其液压系统也是工程机械液压系统中较为复杂的。因此,对泵车液压系统的分析设计对推动我国泵车发展具有十分重要的意义。

本次设计的课题是SY5430JBC28混凝土搅拌泵车液压系统设计,内容首先陈述了课题提出的背景,分析了泵车的发展趋势及市场需求,再对泵车的基本构造进行确定。通过对泵车液压系统总体分析设计了开式回路,制定了液压系统工作原理图和各回路液压系统工作原理图。最后完成对泵送机构进行设计与计算和配套件选型。

此设计在整体上结构布局合理,液压元件的选择和使用具有较好的经济性和实用性,并且性能方面得到了最好的发挥。

Content summary

Concrete pump truck is a machine with an engineering machinery, it sets concrete transport pump, cloth, in a function. Its compact structure and efficient and flexible characteristics, is more suitable for small sites even residential area construction. Mixing pump carrying concrete can meet the demand of small-size pumping operation in large quantity, pump work, it can complement the mixer transportation process in short of material defects, to achieve continuous pumping, time-saving and economic. Pump the core technology is the design of the hydraulic system, the pump 's working conditions, the demands of the movement is complex, and the hydraulic system design put forward higher requirements, the hydraulic system of engineering machinery hydraulic system is more complex. Therefore, the pump hydraulic system analysis of the design on the promotion of China's pump development has very important significance.

This design is the subject of SY5430JBC28concrete pump hydraulic system design, content is first stated the background, analysis of the pump and the development trend of the market demand, the basic structure of pump. The pump hydraulic system overall analysis of the design of open loop, developed hydraulic system principle diagram and the circuit hydraulic system principle diagram. The final completion of the pumping mechanism design and calculation and matching pieces of selection.

The design on the whole structure of reasonable layout, the choice of hydraulic components and use with good economical and practical performance, and has been the best play.

目录

内容提要Ⅰ

Content summaryⅡ

1 绪论1

1.1 前言1

1.2 课题提出的背景1

2 泵车结构4

2.1 底盘部分4

2.2 臂架系统8

2.3 泵送系统14

3 液压系统的设计21

3.1 液压系统动作说明21

3.2 泵送回路22

3.3 泵送的高低压切换23

3.4 泵车臂架部分液压系统的设计26

总 结46

参考文献47

附录48

致谢49

1 绪论

1.1 前言

搅拌泵车集混凝土运输、泵送、布料功能于一身,具有结构紧凑和高效灵活的特点,其自带混凝土可以满足小方量泵送作业的需求;在大方量泵送工作时,它可以补充搅拌车运输过程中缺料的弊端,实现不间断地泵送,省时又经济,从而提供一个全新的混凝土作业方案。[1]在作业中,搅拌泵车的动力装置的动力驱动拌筒的正反转以及转速的变化,来完成进料、搅拌、搅动、出料,再驱动泵送机构、搅拌机构、分配机构和臂架机构等工作装置。而液压系统作为泵车最重要组成部分,随着施工要求的提高,人们对液压系统的要求越来越高。[2]

1.2 课题提出的背景

1.2.1 课题提出的宏观背景

我国搅拌泵车起步较晚,当时靠从国外引进搅拌泵车到国内进行施工。随着我国建筑业的发展,泵车生产厂家逐渐增多,但臂架部分开始大都是进口,如中联中科、辽宁海若从意大利引进臂架,安徽星马从日本极东引进臂架,徐州工程机械厂从普茨迈斯特引进臂架等等,现在逐步改为自制为主和进口为辅生产配套模式。

参考文献

[1]/supply/90333900.html,2012-09-11

[2]三一重工混凝土机械公司培训部.三一重工混凝土机械基础知识教材[M].2008:13-62.

[3]三一重工混凝机械公司培训部.三一重工混凝土机械底盘基础知识教材[M].2006:8-10.

[4]中联重科混凝土机械公司培训部.中联重科混凝土机械基础知识教材[M].2008:5-6.

[5]三一重工搅拌运输车公司培训部.三一重工搅拌运输车基础知识教材[M].2008:128.

[6]张利平主编.液压传动系统及设计[M]. 北京:化学工业出版社,2005.175-247.

[7] 马俊.张增峰.张宝群主编.液压基础[M].长沙:三一集团有限公司,2006:12-112

[8]雷天觉主编.新编液压工程手册[M].北京:理工大学出版社,1998:173-180.

[9]徐灏主编.机械设计手册(第5卷) [M].北京:机械工业出版社,1992:256-358.

[10]王三民.诸文俊主编.机械原理与设计[M].北京:机械工业出版社,2000:87-93.

[11] 姜继海.宋锦春,高常识主编.液压与气压传动[M].北京:高等教育出版社,2002:120-123.

[12]王广怀.液压技术应用[M].哈尔滨:哈尔滨工业大学出版社,2001.23-45.

[13] 许福玲.陈尧明主编.液压与气压传动(4版)[M].北京:机械工业出版社,2007:141-169.

川公网安备: 51019002004831号

川公网安备: 51019002004831号