摘要

随着社会的发展,不同品种和功能的塑料的出现,塑料产品与我们的日常生活越来越密切。塑料模具设计对生产与生活也越来越重要。

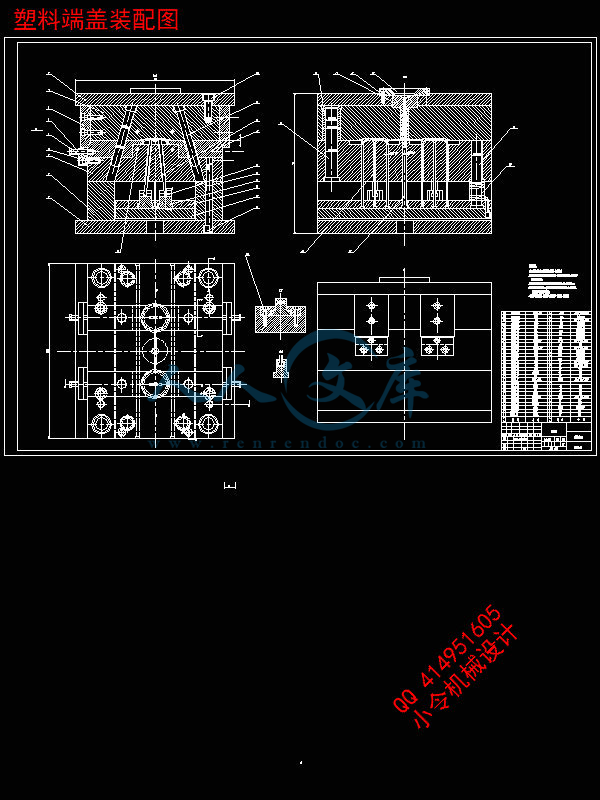

本次毕业设计的课题为塑料端盖注塑模具设计,主要在对塑件从材料上进行工艺分析,确定分型面及型腔数;完成浇注系统的设计,浇口采用侧浇口;抽芯机构采用斜导柱实现塑件的侧孔成型;脱模机构采用顶杆推出。同时通过合理地选择注射机并对注塑压力、最大注塑量、锁模力、开模行程等相关方面进行校核,进一步保证设计的合理型,并设计温度调节系统和阐述模具装配等方面。

本次设计完成了塑料端盖的生产,此次设计不仅结构简单,生产效率高,而且运动可靠生产成本低。最重要的是适用于人们的生活中。

关键词:端盖注塑模具;分型面;注塑模具;注射机

Plastic end cap injection mold design

Abstract

With the development of society different varieties and function plastic appearance in our lives, plastic productions have closer to our daily lives. Plastic mold design is more and more important to the production and life.

The topic of this graduation design for the plastic end cover injection mold design, mainly in based on the analysis of the molding for plastic parts are made from the raw material analysis, forming characteristics, parting surface selection, the design of the gating system, cooling system design, the core and cavity structure design, launch reset structure design, design of side core-pulling mechanism and the design of steering mechanism and other aspects detailed in this paper, the design of the end cover injection mold process. At the same time, through the rational selection of the injection machine and check the injection pressure, the maximum injection quantity, clamping force, mold opening stroke and other related aspects, further ensuring reasonable design, and design the temperature control system and elaborated the mold assembly.

This design completed the production of plastic end cover, it not only has simple structure, but also has high production efficiency and the movement is reliable low production cost.The most important it is suitable for people's life.

Key Words:cover injection mold;lateral core-pulling;parting surface;injection mold;injection machine

目 录

摘要I

AbstractII

主要符号表III

1 绪论1

1.1塑料的发展1

1.2塑料模具发展1

1.2.1国内外注塑模具的发展现状1

1.2.2国内外注塑模具的发展趋势2

1.3本文主要设计内容2

2 塑件材料及工艺的分析4

2.1PA1010基本特性4

2.2PA1010成型工艺分析4

2.3塑件结构分析4

2.4塑件尺寸及精度分析5

2.5塑件表面质量分析5

2.6塑件厚度分析5

2.7塑件的体积和质量6

3 塑件在模具中的布局7

3.1型腔数目的确定7

3.2型腔的分布7

3.3分型面设计7

3.3.1分型面的分类7

3.3.2分型面的选择原则7

4 浇注系统的设计9

4.1浇注系统设计的组成及要求9

4.2主流道设计9

4.3分流道设计10

4.3.1分流道设计要点10

4.3.2分流道的形状和尺寸11

4.3.3分流道的表面粗糙度11

4.4浇口设计11

4.4.1浇口的作用12

4.4.2浇口的截面形状和尺寸12

4.4.3浇口位置的选择13

4.5冷料穴的设计14

4.6拉料杆的设计14

5 成型零件的结构设计15

5.1成型零件的结构形式及设计15

5.1.1凹模结构设计15

5.1.2型芯结构设计16

5.2成型零件工作尺寸的计算16

5.2.1影响塑件尺寸精度的因素16

5.2.2模具成型零件的工作尺寸计算17

6 结构零部件设计18

6.1注射模架的选取20

6.2垫块的设计20

6.3合模导向机构的设计20

6.3.1导柱的设计20

6.3.2导套设计21

7 侧向分型与抽芯机构的设计22

7.1斜导柱的设计22

7.1.1斜导柱的形状及技术要求22

7.1.2斜导柱的倾斜角22

7.1.3斜导柱的长度22

7.1.4斜导柱的受力分析与直径计算23

7.2滑块的设计24

7.3导滑槽的设计24

7.4滑块定位装置25

7.4.1滑块定位装置的作用25

7.4.2结构形式25

7.5楔紧块25

7.6成型斜顶杆的设计26

8 推出机构设计27

8.1推出方式的选取27

8.2推出力计算27

8.3推出机构设计28

8.3.1推杆推出机构设计28

8.3.2推出机构导向与复位29

9 注射机的型号和规格选择及校核31

9.1初选注射机规格31

9.2注射机工艺参数校核31

9.2.1最大注射量的校核31

9.2.2注射压力的校核32

9.2.3锁模力的校核32

9.3注射机安装部分与模具相关尺寸校核32

9.3.1喷嘴尺寸校核32

9.3.2定位圈尺寸校核33

9.3.3最大最小模厚校核33

9.3.4开模行程校核33

10 冷却系统的设计34

10.1冷却装置设计要点34

10.2冷却回路布置34

11 模具的分析及保养35

11.1模具的经济效益分析35

11.2模具的保养35

12 结论36

参考文献37

致谢38

毕业设计(论文)知识产权声明39

毕业设计(论文)独创性声明40

1 绪论

1.1塑料的发展

现代工业的飞速发展为素有“工业之母”美誉的模具工业带来前所未有的发展机遇,而模具材料的应用在模具制造中起举足轻重的作用。塑料,作为重要的模具材料之一,随着家电、汽车、电子、电器、通讯产品的迅猛发展而得到更为广泛的应用。塑料模具,成为时下模具品种之“关键词”。在此背景下,如何更深入地认识塑料模具的发展状况并把握其市场走向,成为重要课题。

随着中国汽车、家电、电子通讯、各种建材的迅速发展与国民经济的快速增长,在未来的模具市场中,塑料模具在模具总量中的比例将进一步提高,其发展速度将快于其他模具种类,塑料模具的加工与生产将形成遍地开花之势。

模具是汽车、电子、电器、航空、仪表、轻工、塑料、日用品等工业生产的重要工艺装备,模具工业是国民经济的基础工业。没有模具,就没有高质量的产品。用模具加工的零件,具有生产率高、质量好、节约材料、成本低等一系列优点。因此已经成为现代工业生产的重要手段和工艺发展方向。因此,模具技术,特别是制造精密、复杂、大型模具的技术,已成为衡量一个国家机械制造水平的重要标志之一。

1.2塑料模具发展

1.2.1国内外注塑模具的发展现状

目前,国内生产的小模数塑料齿轮等精密塑料模具已达到国外同类产品水平。在齿轮模具设计中采用最新的齿轮设计软件,纠正了由于成型压缩造成的齿形误差,达到了标准渐开线造型要求。显示管隔离器注塑模、高效多色注射塑料模、纯平彩电塑壳注塑模等精密、复杂、大型模具的设计制造水平也已达到或接近国际水平。使用CAD三维设计、计算机模拟注塑成形、抽芯脱模机构设计新颖等对精密、复杂模具的制造水平提高起到了很大作用。20吨以上的大型塑料模具的设计制造也已达到相当高的水平。34英寸彩电塑壳和48英寸背投电视机壳模具,汽车保险杠和仪表盘的注塑模等大型模具,国内都已可生产。国内最大的塑料模具已达50吨。

虽然在这十多年中注塑模具工业取得了令人瞩目的发展,但许多方面与工业发达国家相比仍有较大的差距。精密加工设备在模具加工设备中的比重还比较低,CAD/CAE按术的普及率不高,许多先进的模具技术应用还不够广泛等。特

别在大型、精密、复杂和长寿命模具技术上存在明显差距,这些类型模具的生产能力也不能满足国内需求,因而需要大量从国外进口。

国外注塑模具制造行业的最基本特征是高度集成化、智能化、柔性化和网络化。追求的目标是提高产品质量及生产效率。国外发达国家模具标准化程度达到较高水平,实现部分资源共享,大大缩短设计周期及制造周期,降低生产成本。最大限度地提高模具制造业的应变能力 满足用户需求。

模具企业在技术上实现了专业化,在模具企业的生产管理方面,也有越来越多的采用以设计为龙头、按工艺流程安排加工的专业化生产方式,降低了对模具工人技术全面性的要求,强调专业化。

1.2.2国内外注塑模具的发展趋势

由于塑料模具工业快速发展及上述各方面差距的存在,因此我国今后塑料模具的发展必将大于模具工业总体发展速度。塑料模具生产企业在向着规模化和现代化发展的同时,“小而专”、“小而精”仍旧是一个必然的发展趋势。从技术上来说,为了满足用户对模具制造的“交货期短”、“精度高”、“质量好”、“价格低”的要求,以下的发展趋势也较为明显。

未来我国的模具将呈现十大发展趋势:一是模具日趋大型化。二是模具的精度越来越高。三是多功能复合模具将进一步发展。新型多功能复合模具除了冲压成型零件外还担负叠压、攻丝、铆接和锁紧等组装任务对钢材的性能要求也越来越高。四是热流道模具在塑料模具中的比重逐渐提高。五是随着塑料成型工艺的不断改进与发展气辅模具及适应高压注射成型等工艺的模具将随之发展。六是标准件的应用将日渐广泛。七是快速经济模具的前景十分广阔。八是随着车辆和电机等产品向轻量化发展压铸模的比例将不断提高,同时对压铸模的寿命和复杂程度也将提出越来越高的要求。九是以塑代钢、以塑代木的进程进一步加快塑料模具的比例将不断增大。十是模具技术含量将不断提高中、高档模具比例将不断增大,这也是产品结构调整所导致模具市场走势的变化。

国外注塑成型技术在也向多工位、高效率、自动化、连续化、低成本方向发展。因此,模具向高精度复杂、多功能的方向发展。例如:组合模、即钣金和注塑一体注塑铰链一体注塑、活动周转箱一体注塑;多色注塑等;向高效率、高自动化和节约能源,降低成本的方向发展。例如:叠模的大量制造和应用,水路设计的复杂化、装夹的自动化、取件全部自动化。

1.3本文主要设计内容

本次毕业设计的课题是塑料端盖注射模设计,也就是设计一副注塑模具来生产端盖塑件产品,基于此,必须实现大批量的生产、提高生产效率,降低生产周期,才能降低成本。注射模具的使用是实现高效率生产的一个非常好的途径,在本次设计中就是要对塑料端盖塑件的特性进行分析,对成型工艺性的可行性进行分析,完成其生产模具的设计。模具的设计过程综合性很强,需要考虑的因素很多,需要一个整体的思维模式去考虑问题,才能设计出一个合格的作品。本此设计的目标,就是通过确定成型零件、推出机构等的合理结构并进行计算校验,设计出一个结构合理、操作简单、动作可靠、使用寿命长的模具。

川公网安备: 51019002004831号

川公网安备: 51019002004831号