履带机器人驱动机构及关节机构设计【救灾机器人】【含CAD图纸、说明书】

履带机器人驱动机构及关节机构设计【救灾机器人】【含CAD图纸、说明书】

收藏

资源目录

压缩包内文档预览:

资源预览需要最新版本的Flash Player支持。

您尚未安装或版本过低,建议您

编号:17668362

类型:共享资源

大小:1.19MB

格式:ZIP

上传时间:2019-04-13

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

救灾机器人

含CAD图纸、说明书

CAD图纸和

含CAD图纸

CAD图纸和说明书

驱动机构设计

CAD图纸和说明书

CAD 图纸和说明书

CAD图纸

履带驱动机构

机器人驱动及

- 资源描述:

-

- 内容简介:

-

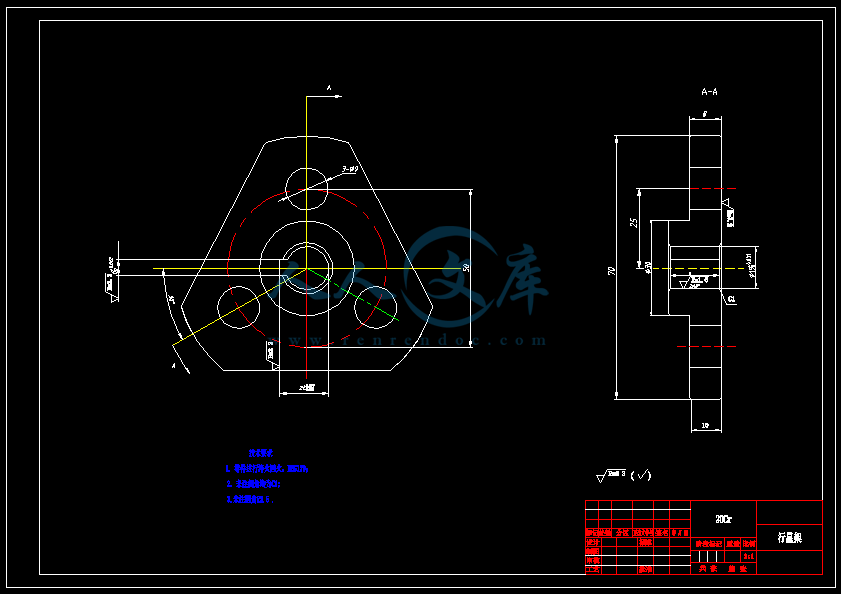

英文文献翻译学 生 姓 名:学 院:专业及班级:学 号:指 导 教 师:Simple structure pipe inspection robotThis article describes the architecture of the original pipe inspection robot. The robot contains two universal joints by the hinge portion. Part of the parallel movement along the pipeline axis wheel drive, while the other part is forced to follow the axis of rotation of the wheel and the inclined pipe spiral motion related. A single motor is placed between the two institutions motion generated. All wheels mounted on the suspension, in order to adapt to changing curve pipe. The robot has its own battery and a wireless link. Four different diameters respectively of 170,70 and 40 mm. For smaller diameters, battery, radio receiver can be placed in any extra bodies. This architecture is very simple, its rotational motion can be used to scrub or inspection tasks.Keywords: autonomous mobile robot in pipeline inspection, spiral motionPipeline inspection robot has been studied for a long time, many of the original motion ideas have been proposed to solve the many technical difficulties in pipe diameter, curve and change-related energy supply. Although an exhaustive review of the literature is impossible, according to the limited space available, several major categories can be identified several broad categories:1 For a small number of projects to follow the earthworm principles: the central part axial movement, and both ends of the connected equipment with barrier pipes. This concept has been proposed pneumatic version,But they need the power cord. For smaller diameter (10 mm or less), according to the principle of inchworm, or driven by a sawtooth voltage based on inertial motion, or in combination with the differential coefficient of friction vibration fin, the piezoelectric drive.2 For a variety of medium-sized pipes, depending on the diameter of adaptability and cornering ability classical electromechanical systems have been proposed various structures involved in the wheel tracks and kinematics.3 For large pipes, pipe crawling walk has also been proposed.Four mobile robot proposed in this paper belongs to the second category, the liquidity of their tube diameter from 40 to 170mm, the design attempts to use a single drive to reduce the complexity of the realization of the machine along the tube, even though our research efforts can be seen as an independent to result. But this spiral theory seems to have been studied.The robot is divided into two parts, the stator and rotor, including a DC connection, motor and gearhead, universal joints. The stator is equipped with a set of wheels to help movement parallel; in this case, the constraint along the tube axis of the stator, the rotor wheel only along the helical path, the axial velocity and the relationship between the rotational speed of the robotWherein R is the pipe radius, a is the inclination angle of the wheel. Stator and rotor must ensure stability, to ensure that the pipeline and sufficient contact force between the robot to adapt to changes and obstacles pipe diameter and allows travel in a curved pipe. For larger robot (D -170), the robot is rigidly connected to the motor shaft to ensure stability. For smaller diameter, bend the need for greater freedom, requires twice the number of wheels.Diameter of 70 mm or more robots provide nine cells, located in the stator. Tests showed that the smaller diameter, this configuration is not possible. First by the rotor, and the second one includes a motor and gear, and the third is the stator wheel to the axle, energy supply and telecommunications networks. Two schemes were investigated 70mm diameter. In the first, a motor and a battery mounted on the stator, but can not be used in the second scenario, if the robot using a power cable.中文翻译:简单结构管道检测机器人本文介绍了管道检测机器人的原始架构。该机器人由包含两个万向节铰接部分。一部分是沿管道平行移动的轴车轮盘,而另一部分则是被迫遵循与螺旋运动有关的轴线旋转的车轮倾斜管。单台电动机被放置在两个机构之间产生的运动。所有车轮安装在悬架上,以适应不断变化的曲线管道。该机器人有其自己的电池和无线链路。四种不同管径分别为的170,70和40毫米。对于较小的直径,电池,无线电接收器,可放置在其他额外的机构中。这种架构非常简单,其旋转运动可以被利用来进行擦洗或检验任务。关键词:自主移动机器人,在管道检测,螺旋运动管道检测机器人已经被研究了很长一段时间,许多原来的运动观念被提出来解决在管道直径,曲线和能源供应变化中有关的许多技术困难。虽然一个详尽的文献回顾是不可能的,根据有限的可用空间,几大类别,可确定几大类别:1对于小规模,许多项目遵循蚯蚓原则:中央部分组成轴向移动,而两端连接的设备具有阻隔管道。这一概念已经提出气动版本,但他们需要电力脐带。对于较小的直径(10毫米或更小),根据尺蠖的原则,或根据惯性运动由锯齿波电压驱动,或使用与微分摩擦系数振动鳍,则采用压电驱动。2对于各种中型管道,根据直径的适应性和转弯能力古典机电系统已提出各种涉及车轮和轨道运动学结构。3对于大型管道,管道爬行走路也已提出。文中提出的四个移动机器人属于第二类,他们的管直径从40到170mm,该设计尝试使用单一驱动器减少机器的复杂性实现沿管的的流动性,即使我们的研究可看作一个独立努力地结果。但此螺旋论似乎已经被研究过。该机器人主要分为两部分,定子和转子,包括一个DC连接,马达与减速机,万向节。定子配备了一套轮子,有助于运动平行; 在这种情形下,定子约束沿着管轴,而转子的车轮只能沿着螺旋轨迹,该机器人之间的轴向速度和旋转速度的关系 。其中R为管道半径, a是车轮倾斜角度。定子和转子必须保证稳定性,以保证机器人之间的管道和足够的接触力,以适应管道直径的变化和障碍,并允许在弯曲的管道中行驶。对于更大型的机器人(D -170),机器人是硬性连接到电机轴上来确保稳定性。对于规模较小的直径,弯管需要更大程度的自由,需要两倍的数量的轮子。直径70毫米以上的机器人提供了9个电池,分布在电机定子上。试验表明,对于规模较小的直径,这个配置是不可能的。第一个由转子组成,第二个包括电机和减速器,第三个是定子车轮与轴,能源供应和电信网络。两个方案进行了70mm直径的调查。在第一个中,马达和电池安装在定子上,但却无法用在第二个方案中,如果机器人使用缆索电源。毕业设计开题报告学 生 姓 名:学 院:专业及班级:学 号:指导教师4毕业设计开题报告题 目 履带机器人驱动机构及关节机构设计作者姓名学号所学专业机械设计制造及其自动化1、 研究的意义,同类研究工作国内外现状、存在问题从20年代80年代起,国内外就对小型履带式机器人进行了研究。目前,在救灾机器人研究方面,美国走在了世界的前列,美国在微小型机器人研制方面投入了大量的人力和物力,特别是新型、高机动、高可靠性移动载体研究方面。如美国移动机器人(TMR)计划中的便携式机器人系统(MPRS),Inuktun公司推出的UGTV机器人具有独特履带可变形功能,可以辅助攀爬和扩大机器人视野,曾在“911”事件的搜救任务中大显身手;加拿大Sherbrook大学研制的AZIMUT机器人,该机器人采用轮、履、腿复合移动机构,具有四个履腿模块,每个履腿模块与本体相连接时有3个自由度,机器人运动功能多样,越障能力强,上下台阶方便;但结构极为复杂,仅电机就有12个,运动控制困难,该机器入主要用于室内环境执行反恐、排爆任务。国内,中国矿业大学可靠性工程与救灾机器人研究所研制的CUMT - 1 型矿井搜救机器人,是我国第1 台针对煤矿救援的机器人。该机器人装备有低照度摄像机、气体传感器和温度计等设备。能够探测灾害环境,实时传回灾区的瓦斯、一氧化碳、粉尘浓度和温度,以及现场图像等信息。煤矿救灾机器人技术总体来说尚未成熟,仍处于技术研究阶段,明确机器人在煤矿救灾中的作用以及煤矿救灾对机器人的要求,有利于机器人技术的完善。由于煤矿灾害尤其是瓦斯煤尘爆炸事故发生后,矿井环境十分复杂,井下因灾受伤人员面临极其危险的状况,需尽快地转移与救护;而救援工作异常困难和危险,往往在救援工作中造成救护人员的伤亡。研发代替或部分代替救护人员及时、快速深入矿井灾区进行环境探测和搜救工作的救灾机器人具有极其重要的意义。将机器人技术、营救行动技术、灾害学等多学科知识有机融合,研制与开发用于搜救与营救的救援机器人,将有效地提高救援的效率和减少救援人员的伤亡。2、 研究目标、内容和拟解决的关键问题在我国虽然煤炭资源丰富,但考虑到矿井自然条件差,加上技术和管理等诸多方面不到位,以及近年来国家对煤炭资源需求量的不断增长,使得我国煤矿矿井灾害事故频繁发生,人员伤亡十分惨重,灾害后的救援工作又是极为困难和危险,因此研发具有环境探测和搜救功能的煤矿救灾机器人十分必要。在救援初期,主要使用灾后救灾机器人,其主要作用是代替矿山救护人员进入灾区,进行环境探测,并将采集的数据发送至救援指挥中心,这些环境信息主要包括瓦斯、CO、氧气的浓度、环境温度、湿度与粉尘情况,以及灾区的通风状况的参数,还应包括生命和图像等信息,为救灾决策提供重要参考。3、 特色与创新之处 1在发生倒塌后,机器人可以立即展开对幸存者的搜索,进入结构不稳定的建筑物,降低救援队员的风险,为搜救工作节约时间。 2可以进入狭窄空间,扩展搜救专家的工作范围。建筑物倒塌会形成各种各样的空间,这些空间可能就会有幸存者,但搜救人员难以进入,而机器人却可以一展身手。 3可以携带多种传感器,探测幸存者空间状况,在机器人软件的帮助下对搜索区域实行完整的三维搜索,绘制结构图,提升工作效率和可靠性。搜救机器人可以携带温度探测器、一氧化碳探测器、爆炸界限探测器、氧气、PH探测器、辐射探测器和杀伤性武器探测器,从而测定空气读数,探测有害物质,分析后向救援人员提出警告。4、 拟采取的研究方法、步骤、技术路线 1在图书馆借阅相关书籍 2在学校数据库查找相关资料 3通过老师的指导 4通过浏览因特网上的相关资料5对相关资料和数据进行整理并对救机器人的外形、动力、结构、工作原理等进行分 析和研究 6设计参考有关设计样板,完善设计方法,进一步完善设计结果 7通过与同学探讨得出有关结论8 自己总结资料得出结论5、 拟使用的主要设计、分析软件及仪器设备1 类比设计、优化设计,经验设计以及数据计算法。2在绘图过程中使用电脑运用AutoCAD绘图和Pro/E等绘图方法。6、参考文献1 蔡自兴、机器人学M、北京、清华大学出版社、20002 濮良贵、机械设计第八版、北京、高等教育出版社、20063 徐元吕、工业机器人、北京、中国轻工业出版社、20064 李科杰、危险作业机器人发展战略研究J、机器人技术及应用2003(5)5 李东晓、机器人技术在煤矿自动化中的应用、煤炭科学技术、20076 钱善华、王勇等、机器人研究的现状及煤矿搜救的应用、2006(5)摘 要煤矿灾害尤其是瓦斯煤尘爆炸事故发生后,矿井环境十分复杂,井下因灾受伤人员面临极其危险的状况,需尽快地转移与救护;而救援工作异常困难和危险,往往在救援工作中造成救护人员的伤亡。研发代替或部分代替救护人员及时、快速深入矿井灾区进行环境探测和搜救工作的救灾机器人具有极其重要的意义。本论文研究工作的目的是设计结构新颖、具有独创性的可携带、抗一定冲击的履带移动机器人,以能够适应在恶劣环境和复杂路况下工作。通过在移动系统上加载不同的模块,能够实现搜救机器人不同的使用功能。本研究所设计的搜救机器人移动方案是履带式驱动结构。该方案采用模块化设计,便于拆卸维修,可以分段自适应复杂路面,并可主动控制两侧翼板模块的转动来调节机器人姿态变化,辅助爬坡、越障和跨沟;机器人经过合理的结构布局和设计后具有良好的环境适应能力、机动能力并能抵抗一定高度的掉落冲击。所设计的机器人移动机构主要由四部分组成:主动轮减速驱动机构、翼板转动机构、自适应路面执行机构、履带及履带轮运动机构,本论文对上述各部分方案分别进行论证、结构设计计算、3D建模,并设计了搜救机器人虚拟样机。关键词:搜救机器人;复合移动机构;模块化设计ABSTRACTCoal mine disasters,especially gas and coal dust explosion, mine environment is very complex and wounded tolls mine face extremely dangerous conditions,be transferred as soon as possible and rescue.and rescue work extremely difficult and dangerous, often resulting in the rescue work in the ambulance casualties.R & D to replace or partially replace the ambulance personnel in a timely manner, quick in-depth environmental exploration and mine disaster relief robot search and rescue work is extremely important. The purpose of this thesis is to design novel structure, its unique portable,shock intelligently tracked mobile robot, in order to be able to adapt to the harsh environment and the complicated road to work.Mobile systems loaded by different modules, search and rescue robots can be achieved using different functions. This resoarch is moving search and rescue robot crawler.The program is modular in design, easy disassembly maintenance, can be complex adaptive sub-surface, active control can turn on both sides of flange module to adjust the robot pose changes, supporting climbing,obstacle and cross-channel.The design of the robot moving mechanism mainly consists of four components. Active wheel reducer drive mechanism, flange rotation institutions, adaptive road implementing agencies, sports organizations track and track wheels, part of the paper on the above programs were carried out feasibility studies, structural designcalculation, 3D modeling , and design a rescue robot prototype.Keywords: search and rescue robots; composite mobile body; modular design 目 录第一章 前 言1第二章 绪 论22.1 课题研究背景及意义22.1.1 课题研究背景22.1.2 课题研究意义22.2 国内外的研究概况32.2.1 国外研究现状32.2.2 国内研究现状52.2.3 发展趋势5第三章 履带搜救机器人的总体结构方案设计63.1 井下复杂环境对救灾机器人的要求63.2 典型移动机构方案论证分析63.2.1 轮式移动机构特点63.2.2 腿式移动机构特点73.2.3 履带式移动机构特点83.2.4 履、腿式移动机构特点93.2.5 轮、履、腿式移动机构性能比较93.3 本研究采用的行走机构93.4 救灾机器人性能指标与设计103.5 本章小结11第四章 矿用履带搜救机器人运动参数设计计算124.1机器人越障分析124.1.1机器人跨越台阶124.1.2跨越沟槽134.2斜坡运动分析144.3 本章小结14第五章 机器人移动平台机械设计165.1驱动电机的选则165.1.1基于平地的最大速度的电机功率计算165.1.2爬坡最大坡度的驱动电机功率计算165.2 本章小结17第六章 驱动轮减速器设计196.1减速器方案分析196.1.1减速器应满足的要求19i6.1.2 减速器方案分析196.2 减速器的设计计算206.2.1减速器的传动方案分析206.2.2配齿计算206.2.3初步计算齿轮的主要参数216.2.4装配条件的计算246.2.5高速级齿轮强度的验算256.2.6 轴的设计及校核326.3 本章小结35第七章 移动机构履带及翼板部分设计367.1履带的选择367.1.1 确定带的型号和节距367.1.2确定主从动轮直径377.1.3确定节线长度和带宽377.2 翼板部分设计397.3 本章小结39第八章 机器人摇臂的设计408.1 摇臂作用概述408.2摇臂传动减速器设计418.3本章小结42第九章 结论43参考文献44致 谢45- 45 -第一章 前 言我国的煤炭资源十分丰富,是世界上最大的煤炭生产国和消费国。在我国的能源工业中,煤炭占我国一次能源生产和消费结构中的70%左右,预计到2050年还将占50%以上,因此,在未来相当长的时间内,煤炭仍然是我国的主要能源,由于我国矿井自然条件差,加上技术和管理等诸多方面不到位,以及近年来国家对煤炭资源需求量的不断增长,使得我国煤矿矿井灾害事故频繁发生,人员伤亡十分惨重。据统计,2006年我国矿难死亡1517人,百万吨死亡率为2.00;2007年全国矿难死亡1600人,百万吨死亡率为2.1;2008年全国煤矿发生伤亡事故1341 起,死亡1389人,百万吨死亡率约为1.84,其中一次死亡39人的重大事故110起,死亡886人。2009年全国安全生产数据显示2009全国共发生一次死亡10人以上的特大事故61起:死亡717人,其中煤矿企业特大事故共发生18起,死亡330人,死亡人数仍高居各类安全事故之首。2010年全国煤矿安全生产形势依然严峻,目前我国煤矿事故死亡人数远远超过世界其他产煤国家煤矿死亡人数的总和,约占世界矿难人数的80%,百万吨死亡率是美国的100倍、南非的30 倍。每年上百次的事故发生,成千人的矿工死亡,煤矿安全形势已经十分严峻。矿井瓦斯爆炸一旦发生,因受高温、烟雾、有害气体和缺氧等影响,以及存在发生二次灾害的可能,救护人员无法知道能否进入或无法直接进入灾害现场执行营救任务,上述事故中的伤亡人员有相当一部分是救护人员,如陕西黄陵矿业公司一号煤矿发生特大瓦斯爆炸事故,2名救护队员在井下不慎滑倒,将呼吸机鼻夹摔脱落,导致一氧化碳中毒死亡;2005年渑池县赵沟八矿井下突然起火,三门峡市矿山救护队接报后立即赶到现场救灾,在救火过程中,突发瓦斯爆炸,4名救护队员殉职;2006年六枝工矿集团公司救护大队的救护队员在井下实施封闭火区措施时,火区发生瓦斯爆炸,造成8名救护队员死亡。由此可见研发代替或部分代替救护人员的救灾机器人及时、快速深入矿井灾区进行环境探测和搜救工作具有极其重要的意义。在救援初期,其主要作用是代替矿山救护人员进入灾区,进行环境探测,并将采集的数据发送至救援指挥中心,这些环境信息主要包括瓦斯、CO、氧气的浓度、环境温度、湿度与粉尘情况以及灾区的通风状况的参数,还应包括生命和图像等信息,为救灾决策提供重要参考。第二章 绪 论2.1 课题研究背景及意义2.1.1 课题研究背景我国是世界上灾害、事故发生次数最多的国家之一,地震、火灾、塌方、以及各类人为事故,给人民生命财产安全造成极大的危害。灾害发生后,如何及时有效的发现被困幸存者并实施快速的救援是灾后应急救援的头等大事。然而复杂危险的灾后环境常常会给救援工作带来困难。危险物质、大火、易燃易爆气体、不稳定的结构等等危险因素的存在,时常威胁到救援队员的生命安全,阻碍救援工作的快速展开。如何能够在最少人员伤亡前提下快速高效地开展搜索救援工作一直是我们重点研究的问题。本文提出的便携式矿用救灾机器人是一种质量轻,易于单个救援人员背负,具有多种运动姿态和抗摔能力,采用履带方式行进的微小型机器人系统。能够适应矿井恶劣的灾后环境,对非结构的地形环境具有良好的自适应能力,具备较好的越障能力和一定高度的抗摔能力。机器人可通过无线电信号进行远程控制,并能够加载各种侦测设备对未知环境进行先期探测并回传井巷环境信息,为及时有效的救灾提供决策参考。2.1.2 课题研究意义我国煤炭资源丰富,是世界上最大的煤炭生产国和消费国。在我国的能源工业中,煤炭占我国一次能源生产和消费结构中的一半以上,在未来相当长的时间内,煤炭仍然是我国的主要能源,由于我国矿井自然条件差,加上技术和管理等诸多方面不到位,以及近年来国家对煤炭资源需求量的不断增长,使得我国煤矿矿井灾害事故频繁发生,人员伤亡十分惨重。据统计,2006年我国矿难死亡1517人,百万吨死亡率为2.00;2007年全国矿难死亡1600人,百万吨死亡率为2.1;2008年全国煤矿发生伤亡事故1341 起,死亡1389人,百万吨死亡率约为1.84,其中一次死亡39人的重大事故110起,死亡886人。2009年全国安全生产数据显示2009全国共发生一次死亡10人以上的特大事故61起:死亡717人,其中煤矿企业特大事故共发生18起,死亡330人,死亡人数仍高居各类安全事故之首。2010年全国煤矿安全生产形势依然严峻,目前我国煤矿事故死亡人数远远超过世界其他产煤国家煤矿死亡人数的总和,约占世界矿难人数的80%,百万吨死亡率是美国的100倍、南非30倍。每年上百次的事故发生,成千人的矿工死亡,煤矿安全形势已经十分严峻。煤矿作为最复杂、最危险的工作环境之一,在发生安全事故之后,常常会因为井下复杂危险的环境而阻碍救援人员深入井下开展工作。但煤矿安全形式十分严峻,瓦斯爆炸等煤矿事故频发,造成了重大的人员伤亡,产生了不良的社会影响。煤矿灾害尤其是瓦斯煤尘爆炸事故发生后,因受高温、烟雾、有害气体和缺氧等影响,以及存在发生二次灾害的可能,矿井环境十分复杂。救护人员无法知道能否进入或无法直接进入灾害现场执行营救任务,上述事故中的伤亡人员有相当一部分是救护人员,如陕西黄陵矿业公司一号煤矿发生特大瓦斯爆炸事故,2名救护队员在井下不慎滑倒,将呼吸机鼻夹摔脱落,导致一氧化碳中毒死亡;2005年渑池县赵沟八矿井下突然起火,三门峡市矿山救护队接报后立即赶到现场搜救,在救火过程中,突发瓦斯爆炸,4名救护队员殉职; 2006 年六枝工矿集团公司救护大队的救护队员在井下实施封闭火区措施时,火区发生瓦斯爆炸,造成8名救护队员死亡。井下因灾受伤人员面临极其危险的状况,需尽快地转移与救护;而救援工作异常困难和危险,往往在救援工作中造成救护人员的伤亡。由此可见研发代替或部分代替救护人员的救灾机器人及时、快速深入矿井灾区进行环境探测和搜救工作具有极其重要的意义。在救援初期,其主要作用是代替矿山救护人员进入灾区,进行环境探测,并将采集的数据发送至救援指挥中心,这些环境信息主要包括瓦斯、CO、氧气的浓度、环境温度、湿度与粉尘情况以及灾区的通风状况的参数,还应包括生命和图像等信息,为救灾决策提供重要参考。2.2 国内外的研究概况2.2.1 国外研究现状目前,在救灾机器人研究方面,美国走在了世界的前列,美国在微小型机器人研制方面投入了大量的人力和物力,特别是新型、高机动、高可靠性移动载体研究方面。如美国移动机器人(TMR)计划中的便携式机器人系统(MPRS)该类机器人主要用于城市战斗与搜救。如美国智能系统和机器人中心开发的RATLER矿井探索机器人用于灾难后的现场侦查工作,采用电传遥控方式,有主动红外摄像机、无线射频信号收发器、陀螺仪和危险气体传感器等装备。无线遥控距离约76 米。美国南佛罗里达大学研制的Simbot矿井搜索机器人,小巧灵活,携带数字低照度摄像机和基本气体监视组件,可以通过一个钻出的小洞钻进矿井,越过碎石和烂泥,并使用其携带的传感器发现受害矿工,探测氧气、甲烷气体含量,生成矿井地图。美国及其它国家在研的各种履带式可变形机器人:这是美国iRobot的一种较小型“PackBot”机器人,现服役于美国军队,这个“PackBot”搭配了一个爆炸物感应系统,有效地探测炸弹。目前这种测试系统还处于实验阶段。“PackBot”机器人还以进行挖掘和拆弹工作。配备了称为“explosive ordnance disposal”(eod)和工程师的全套工具,可以对土壤进行挖掘,然后举起相当于自身重量2倍的炸弹。这种iRobot SUGV的机器人是一种小型地面探测车,重量仅为30磅。它带有一个称为“tactical head”的头部,还有一个相机、一个红外感应器和一个可即时传送影像的摄像头。Foster-miller公司研制了Talon机器人,该机器人采用履带方式行进,内部装备有两台普通直流电机,电机通过两根链条带动履带轮转动,实现机器人运动;另外机器人前后履带轮中间安装有一小型承重轮,该轮不仅能承载一部分负荷同时也能在机器人转向时起到支撑作用,减少履带与地面之间的摩擦,提高机器人转向能力。Talon机器人可以完成各种侦察、巡逻工作。机器人外形参数尺寸为86.4cm57.2cm27.9 cm,重约39Kg,能潜水30.5m,爬45度斜坡。2003年,澳大利亚SIMTARS煤矿研究人员与美国机器人辅助救援中心(CRASAR)合作,开发了一个煤矿灾害搜救机器人,并在澳大利亚昆士兰州的15米地下训练场进行了试验。这个机器人专门是为矿山灾害而研制。它的尺寸大小像一个蜂蜜罐子,它可以通过地面的钻孔进入煤矿井下然后爬过障碍物和泥浆,利用传感器搜寻被困矿工,探测有毒或者可燃性气体,还可以将地面供气供水软管拖到被困矿工身边,给他们新鲜的空气和水。这种机器人在通过钻孔时像一条蛇一样将自己挤过岩石,一旦到达井下地面,就会像一个小型坦克一样行动,搜寻被困矿工。CRASAR希望能够进一步为该机器人添加新型的医学传感器,让救援义务人员能够通过观看、交谈、诊断的方式来了解被困矿工的健康状况。Inuktun公司推出的UGTV机器人具有独特履带可变形功能,可以辅助攀爬和扩大机器人视野,曾在“911”事件的搜救任务中大显身手;加拿大Sherbrook大学研制的AZIMUT机器人,该机器人采用轮、履、腿复合移动机构,具有四个履腿模块,每个履腿模块与本体相连接时有3个自由度,机器人运动功能多样,越障能力强,上下台阶方便;但结构极为复杂,仅电机就有12个,运动控制困难,该机器入主要用于室内环境执行反恐、排爆任务。 仅在一两年前,德国公司出品了一款防爆机器人,现在2006年的新一代机器人已经上市了,其结构比以前的更加轻便,体积更小。这款机器人依靠一个灵活的小型系统有了和一些大型机器人一样的功能。这款机器人依靠一个灵活的小型系统从而有了一些与大型机器人类似的功能,所以它小得以至于可以在地铁车厢或者飞行工具里操作,同时又足够大得可以直接处理一些在所有现行飞机的头顶贮藏室里的可疑项目处理。这款产品具有很大的创新价值,经过数十年经验的累计取得了变结构设计领域的重大发展。它的机械结构由4个独立履带齿轮驱动技术提供了非凡的移动力,它可以爬坡45度,并且可以越障500mm的高度,它做的比其它很多类似机器人都好,它的可伸展的上臂加上一个高度可调的地盘,给予了这款机器人一个可达到的非凡的垂直高度2350mm。它的钳子可以吊起重达5Kg的货物,这就意味着它可以装配弹道系统和其它工具。 2.2.2 国内研究现状我国的搜救机器人技术起步较晚,但是近年来引起了越来越多的关注并取得了一定的成果,沈阳自动化研究所、哈尔滨工业大学、国防科技大学、上海交通大学、广东富卫公司等机构都设计了自己的搜救机器人系统。2005年中科院沈阳自动化研究所与日本国际救援系统研究院联合成立的中日救援与安全机器人技术研究中心,在沈阳揭牌成立,这标志着我国的搜救机器人研究进入了一个更加快速发展的时期。2006年6月22日,由中国矿业大学可靠性与救灾机器人研究所研制的国内首台煤矿搜救机器人(样机)在徐州诞生(如图1-9所示)。这台煤矿搜救机器人采用自主避障和遥控引导相结合的行走控制方式,能在煤矿灾害发生后深入事故现场,探测火灾温度、瓦斯浓度、灾害场景、呼救声讯等信息,并实时回传采集到的信息和图像,为救灾指挥人员提供重要的灾害信息。同时,机器人还能携带急救药品、生命维持液、食品和千斤顶、撬棍等自救工具以协助被困人员实施自救和逃生。2.2.3 发展趋势救灾机器人是智能化机器人在煤矿领域的全新应用,尽管某些关键技术仍需要进一步研究,但救灾机器人具有高度的实用价值和广泛的应用前景。随着计算机技术、传感技术、控制技术、材料技术的发展,特别是网络技术和图像信息处理技术的迅猛发展,智能机器人的研究已取得了丰硕的研究成果。但是,由于矿井救灾机器人特殊的工作环境和工作要求的不断提高,矿井救灾机器人技术方面还需要有所突破:机械性能方面,能够适应矿井恶劣的灾后环境,对非结构的地形环境具有良好的自适应能力,具备较好的越障能力。新技术和新材料的研发,矿井灾后恶劣的环境要求用高强度、抗拉抗压、抗高温阻燃、不产生电火花的材料。优良的导航性能、信息采集能力仍是今后矿井救灾机器人导航技术的主要发展方向。由于矿井中救灾机器人单一的传感器无法满足高精度定位需要,因此需要融合多个传感器测量信息,多传感器信息融合技术也就自然成为发展趋势。多机器人系统是矿井救灾机器人技术发展的主要方向。采用标准化、网络化、模块化技术。机器人装备有通信系统,在与外界进行数据信息交换时,采用标准化接口技术,网络技术可使机器人更具备操控性,同时机器人通信系统的稳定性、可维护性、兼容性也更好。第三章 履带搜救机器人的总体结构方案设计3.1 井下复杂环境对救灾机器人的要求 井下环境和气候与地面不同,井下环境恶劣,特别是事故刚刚发生后的井下条件更为恶劣。搜救机器人需要满足井下工作环境的特殊要求,具备快速搜寻并且准确定位井下失踪人员的功能,还要有简单的急救功能。井下地形矿山井下地形复杂,环境恶劣。巷道路面多积水,有矿车铁轨、水沟、风管、线缆等障碍物;支巷道路面窄而不平,多有坡度;工作面处的路面坡度大,有碎煤、支撑、滑道等障碍。灾害发生后,脱落的顶板、岩石、煤块等形成新的障碍物。复杂的路况要求井下机器人要有较强的越障、避障能力和行驶功能恢复能力。井下气候灾害后,井下通风系统常受到破坏,使井下气候发生明显的变化,常见瓦斯和粉尘浓度增大,灾变区域的温度、湿度增加,风量减少。所以二次瓦斯爆炸的危险也常常是影响救护队员及时下井救护的一个主要因素。为了在高瓦斯下安全工作,搜救机器人需要进行矿用隔爆兼本安型设计;元件在井下温度变化范围内应能可靠地工作;为了防止煤尘和积水进入车体内部和运动副,厢体要进行密封、防水设计。光照与烟雾井下无自然光,机器人只有自带光源。事故后,往往烟雾充斥巷道和工作面,能见度低,对照明产生一定影响。能源使用井下专用蓄电池供电。因此,井下的特殊环境要求所设计的搜救机器人形体较小,载荷较大,运动灵活,具有通过狭小空间、碎煤和岩石区的能力,能够实现较大弧度的转动,较强的越障、爬坡能力,以及防爆、防水、耐高温、视觉防尘等功能。3.2 典型移动机构方案论证分析便携式机器人按移动方式分主要有轮式、履带式、腿足式三种,另外还有步进移动式、蠕动式、混合移动式、蛇行移动式等。3.2.1 轮式移动机构特点轮式移动机构在救灾机器人中是最为普通的运动方式,轮式机器人移动机构普遍具有结构简单、运动速度快、能源利用率高的、机动性好强的特点,同时具有自重轻、不损坏路面、作业循环时间短和工作效率高等优势。控制的角度看,编程简单并有较高的可靠性,每个轮子都可以独立驱动。与履带式移动机器人相比,当跨越不平坦地形时,轮式机器人有着固有的不足,限制了其运动能力,其稳定性和对环境的适应性完全依赖于环境本身的状况,对于进入复杂的环境完成既定任务存在严重的困难。轮式移动机构按轮的数量可分为2轮、3轮、4轮、6轮、8轮。该结构存在着一定的局限性,只能在相对平坦、表面较硬的路面上行驶,如遇到软性地面(如沼泽、草地、雪地、沙地等)容易打滑、沉陷,但可根据具体地面环境采用一些预防措施来缓解该类情况的出现,如采用不同种类的款式轮胎以提高其越野能力,象沙漠车辆、山地车辆等,其各种结构如图2-1所示。图2-1 轮式移动装置示意图3.2.2 腿式移动机构特点腿足式移动机构分2腿、4腿、6腿、8腿等形式。腿式移动机构优点有:(1)腿式机器人的地形适应能力强。腿式机器人运动轨迹由一系列离散点组成,崎岖地形可以给这些离散点提供支撑,使机器人平稳运动;而轮式和履带式机器人的运动是连续规迹,有些起伏较大的地形则不支持这种连续运动轨迹,进而限制了该类机器人活动范围。(2)腿式机器人的腿部具有多个自由度,运动更具有灵活性,通过调节腿的长度可以控制机器人重心位置,因此不易翻倒,稳定性更高;(3)腿式机器人的身体与地面分离,这种机械结构优点在于机器人身体可以平稳地运动而不必考虑地面的租糙程度和腿的放位置,8腿移动机器人如图2-2所示,特点是稳定性好,越野能力强。腿式移动机构缺点有:该类机器人的移动速度慢,机动性较差因此机器人的负载不能太重;腿式机器入对地面适应性和运动灵活性需要进一步提高;腿式机器人控制系统较为复杂,控制方法还有待完善;该机构未进入实用化阶段。图2-2八腿机器人3.2.3 履带式移动机构特点履带式移动机构分为l条履带、2条履带(履带可车体左右布置或者车体前后布置)、3条履带、4条履带,6条履带,履带式移动机构与地面较大的接触面积,因此在较大的区域内分布机器人的重量,较大的接触区域使机器人具有较好的驱动牵引力,机动性能好、越野性能强,缺点是结构复杂、重量大、摩擦阻力大,机械效率低,在自身重量比较大的情况下会对路面产生一定的破坏。履带式移动机构比较轮式移动机构有以下几个特点:(1)撑面积大、接地比压小、滚动阻尼小、通过性比较好;(2)越野机动往能好,爬坡越沟等性能均优于轮式结构;(3)履带支撑面上有履齿不打滑,牵引附着性能好;(4)结构较复杂重量大,运动惯性大,减震功能差,零件易损坏。图2-3为一部分履带式移动机构的简图图2-3 履带式移动装置示意图3.2.4 履、腿式移动机构特点履腿复合移动机构综合了履带式和腿式两种移动机构的优势,在地面适应性能、越障性能方面有良好表现。履带移动机构地面适应性能好,在复杂的野外环境中能通过各种崎岖路面,它的活动范围广,性能可靠,使用寿命长,轮式移动机构无法与其比拟,适合作为机器人的推进系统;传统履带移动机构往往是两条履带与车身相对固定,很大程度上限制了机器人地形适应能力(此时机器人履带高度和长度直接决定了机器人越障、跨沟等性能),为了解决该问题履式移动系统中引入了关节履带机构,两条履带不再相对车体固定而是能绕车身转动,这样能大大提高机器人的环境适应能力,但履、腿复合机构本身存在着一定的不足如结构复杂、运动控制困难等。3.2.5 轮、履、腿式移动机构性能比较车轮式,履带式、腿足式移动系统性能比较见表2-1所示。表2-1典型移动机构的性能对比移动方式轮式履带式腿式移动速度快较快慢越障能力差一般好复杂程度简单一般复杂能耗量小较小大控制难易 易一般复杂3.3 本研究采用的行走机构本文提出来的便携式履带机器人移动系统采用的是履、腿(轮)复合结构,该结构最大优点在于在传统履带移动机构的基础上增加了转动关节,加强了机器人越障、爬坡性能并提高了环境适应能力。机器人能根据地形条件的复杂程度,通过主动调节两侧履带与车身约束关系来选择自适应环境或者是主动适应环境。自适应环境可以提高机器人运动稳定性能、平顺性能;主动适应环境可以提高机器人通过性能,机器人设计方案如下图2-4所示。图 2-4 便携式履带机器人结构组成1. 后轮驱动电机及组件 2.摆臂电机及组件 3.主履带 4.摆臂履带 5.齿轮3.4 救灾机器人性能指标与设计由于煤矿井下环境的特殊性和复杂性煤矿井下搜救机器人的总体设计须满足适合井下复杂地形、防爆、防碰撞等要求,同时所载的子系统安装、使用要方便。在地面移动机器人家族中,履带机器人具有很强的地形适应性,能够适应恶劣的路面条件,因此得到了广泛的应用。但普通的履带移动移动机构结构复杂,重量大,运动惯性大,减震性能差,零件易损坏。为克服普通履带式移动机构的缺点,给煤矿井下搜救机器人履带式移动机构加装前摆。机器人加装前摆臂的优点:机器人重心将前移,实现机器人爬坡和越障的功能,稳定性将更好;实现机器人倾翻后自复位。为提高其地形适应性,前摆臂两个摆臂关节单独控制和单独驱动。总体设计方案如图2-4所示。采用后轮驱动,差速转向,可实现原地360转向。摆臂电动机驱动摆臂可在360范围内旋转,提高机器人跨越沟槽和爬越台阶的越障的能力和翻转后自复位的功能。根据井下环境对机器人的要求,主要设计性能参数如下:L1=600mm,L2=350mm,R=80mm,r=35mm,B(车体宽度)=500mm。车体质量为50kg,摆臂质量不超过5kg,机器人做直线运动最大速度等于1m/s,自备电源运行时间大于等于4小时。最大越障高度H=300mm,跨越最大沟壑宽度C=500mm。如图3.5 本章小结本章重点介绍了国内外履带机器人的移动方式,对三种常见的移动方式(轮式、履带式、腿式)在越野性能、移动速度、机构复杂程度、控制难易程度等几方面进行了比较和分析,就研制的矿用履带搜救机器人应达到的性能指标提出了具体要求。第四章 矿用履带搜救机器人运动参数设计计算4.1机器人越障分析4.1.1机器人跨越台阶(1)越障机理分析当机器人在爬越台阶时,机器人履带底线与地面之间的夹角将随时间而逐渐增加,其重心越过台阶的支撑点时,机器人就跨过了台阶完成爬越动作。(2)越障过程分析煤矿井下搜救机器人爬越台阶的过程如图3-1所示,机器人借助摆臂的初始摆角,在履带机构的驱使下,使其主履带前端搭靠在台阶的支撑点上,机器人继续移动,驱动摆臂逆时针摆动,当机器人重心越过台阶边缘时,旋转摆臂关节,机器人在自身重力影响下,车体下移,机器人成功地爬越台阶。图3-1机器人爬越台阶过程由运动过程可以看出,机器人在越障第三阶段图3-1(C)重心的位置处于临界状态,机器人重心只有越过台阶边缘,机器人才能成功的越过障碍。由此可分析出机器人的最大越障高度。图3-2机器人上台阶临界状态示意图由图3-2所示几何关系可得: (1)变换式(1)可得: (2) (3) 利用式(3)求出,代入式(2)可算出机器人跨越障碍的最大高度。4.1.2跨越沟槽(1)越障机理分析对于小于机器人前后履带轮中心距地沟槽,因机器人重心在机器人车体内,当机器人重心越过下一个沟槽的支撑点时,机器人就越过了沟槽,完成了跨越动作。也可能由于重心未能过去,倾翻在沟槽内。当沟槽大于中心距时,履带式机器人可以看做爬越凸台障碍。(2)越障分析履带式移动机器人跨越沟槽时,机器人重心不断向前移动,当重心越过沟槽边缘时,受重力作用,机器人将产生前倾现象,运动不稳定。由机器人质心变化规律可知机器人重心在以r为半径的圆内,由于摆臂展开后机器人履带与地接触长度变大,为了计算最大跨越壕沟宽度,摆臂履带应处于展开状态。图3-3跨越沟槽示意图机器人在平地图3-3(a)跨越沟槽的宽度: (4) 在角度为的斜坡图3-3 (b) 上跨越沟槽的宽度 : (5)4.2斜坡运动分析机器人在斜坡上运动时,起受力情况如图3-4所示,机器人匀速行驶或静止时,其驱动力: (6)图3-4机器人上坡受力示意图最大静摩擦力系数为,最大静摩擦力为: (7)当时,机器人能平稳行驶。当时,机器人受重力的影响将沿斜面下滑。已知煤矿井下机器人在井下地面最大静摩擦系数,则机器人爬越的最大坡度为: (8)爬坡时克服摩擦力所需的最大加速度为: (9)通过上述分析,可以根据机器人履带与运动面的摩擦系数来确定一些陡坡是否能够安全爬升,并根据坡度和电机的特性,确定其运动过程最大加速及爬升都陡坡的快速性。4.3 本章小结本章重点围绕矿用履带搜救机器人的爬坡性能、越障性能、跨沟性能三方面,对机器人移动原理进行理论分析,运动过程进行数值计算,验证了该机器人在恶劣环境下具有优良机动能力。机器人的爬坡角度最大为;垂直越障高度最大为300mm:最大跨沟宽度为500mm。第五章 机器人移动平台机械设计5.1驱动电机的选则5.1.1基于平地的最大速度的电机功率计算 假设机器人以最大速度匀速前进,轮子作瞬时纯滚动,前进时不考虑空气阻力的影响。如下图所示:平地直线运动受力图根据理论力学平面交汇力系平衡条件和合力矩定理: 则,移动机器人平地直线运动的平衡方程为: 则, 可以得出,机器人两侧电机经减速器后在最大速度下需要提供的极限扭矩为11.76N.m。在最大的行驶速度下,驱动电机经过减速箱减速后需要提供的极限转速为:5.1.2爬坡最大坡度的驱动电机功率计算相对于平地行驶过程,爬坡能力对于机器人的驱动能力是一个重要的衡量标准,所以在进行驱动系统设计时,爬坡指标的计算也应作为选择电机的必须依据。假设移动机器人在最大指标上匀速行驶,速度为0.1。在行驶过程中轮子作纯滚动,不考虑空气阻力的影响。机器人爬坡受力情况如图:机器人爬坡受力图 爬坡的平衡方程为: 解之得:M=43.12Nm,可以得出机器人两侧电机经减速器减速后在最大坡度下爬坡需要提供的极限扭矩为21.56Nm.0.1的速度爬坡时,驱动电机经过减速器后所需提供的转速为:n=11.945.2 本章小结由以上分析可知,机器人平地直线运动时要求的驱动电机输出转速较大,而爬坡时的要求的驱动电机输出扭矩较大。因此在选电机型时,应根据平地直线运动要求转速和爬坡要求扭矩进行选择。 根据最大爬坡要求,初步确定驱动电机经减速器后的功率为:=53.8W 则所需电机的输出功率为: 则可选择如下表4-1电机:表4-1电动机性能参数产品型号电压额定电流转速输出功率效率Maxon-Ec4524V6.5A1800r/min150W79%第六章 驱动轮减速器设计移动减速传动机构是完成机器人前进、后退、转向等各种运动的关键部件,利用齿轮的速度转换,将动力机的转速减低到所需的转速,同时扭矩达增大到所需的扭矩。本机构采用二级减速器,电动机通过减速器的实现减速、增大转矩。电动机安装在减速器前端,通过锥齿轮改变轴的方向,输出履带驱动轮转矩,为复杂状况下救灾机器人提供主要动力。6.1减速器方案分析6.1.1减速器应满足的要求 (1)目前大部分的煤矿都处于深井开采,深度大都为数百米,甚至上千米,远远深于恒温带的深度,随着深度的增加,地温逐渐升高,造成地下温度很高。减速器必须满足在高温下工作要求; (2)我国开采的矿井,大部分都为高瓦斯矿井,井内充满了浓厚的瓦斯。减速器应有隔爆防爆的作用; (3)搜救机器人的行驶路况复杂,在行驶过程的启动、停止、前进与后退换向频繁。其载重较大,要有较大的启动转矩,启动平稳,换向灵敏; (4)搜救机器人遥控操作,电动机用蓄电池提供能源。体积要小,重量要轻。6.1.2 减速器方案分析减速器的种类很多,按照传动类型可分为齿轮减速器、蜗杆减速器和行星减速器以及它们互相组合起来的减速器;按照传动级数可分为单级和多级减速器;按照齿轮形状可分为圆柱齿轮减速器、圆锥齿轮减速器和圆锥-圆柱齿轮减速器;按照传动的布置形式由可以分为展开式、分流式和同轴式减速器。(1) 展开式齿轮减速器结构简单,但齿轮相对于轴承的位置不对称,因此要求轴有较大的刚度。高速级齿轮布置在远离转矩输入端,这样,轴在转矩的作用下产生的扭矩变形和在载荷作用下轴产生的弯曲变形可部分的互相抵消,以减缓沿齿宽载荷分布不均匀的现象。用于载荷比较平衡的场合。(2) 同轴式齿轮减速器横向尺寸较小,两对齿轮侵入油中深度大致相同。但轴向尺寸和重量较大,且中间轴较长、刚度差,沿齿宽载荷分布不均匀,高速轴的承载能力难以充分利用,适合小型、微型机械适用。(3) 蜗轮蜗杆减速机的主要特点是具有反向自锁功能,可以有较大的减速比,输入轴和输出轴不在同一轴线上,也不在同一平面上。但是一般体积较大,传动效率不高,精度不高。(4) 行星减速器其优点是结构比较紧凑,回程间隙小、精度较高,使用寿命很长,额定输出扭矩可以做的很大,但价格略贵。另外行星减速箱,有平齿和斜齿2种,精度和价格都有不同。(5) 谐波减速器的谐波传动是利用柔性元件可控的弹性变形来传递运动和动力的,体积不大、精度很高,但缺点是柔轮寿命有限、不耐冲击,刚性与金属件相比较差,输入转速不能太高,价格较高。根据复杂路况下搜救机器人的行驶速度及各项工作要求,综合各种减速器的特点,本设计采用二级减速传动,依传递运动和转矩,又根据减速箱空间的限制采用二级行星齿轮减速器。6.2 减速器的设计计算6.2.1减速器的传动方案分析 根据上述设计要求可知,该行星轮减速器传递功率高,传动比较大,工作环境恶劣等特点。故采用双级行星齿轮传动。2K-H型结构简单,制造方便,适用于任何情况下的大小功率的传动。选用由两个2X-A型行星齿轮传动串联而成的双级行星齿轮减速器较为合理,名义传动比可分为进行传动。6.2.2配齿计算根据2K-H型行星齿轮传动比的值和按其配齿计算公式,可按第一级传动的内齿,行星齿轮的齿数。先考虑到该行星齿轮传动的外廓尺寸,故选取第一级中心齿轮数为23和行星齿轮数为。根据内齿轮,则。对内齿轮齿数进行圆整后,此时实际的P值与给定的P值稍有变化,但是必须控制在其传动比误差范围内。实际传动比为:6其传动比误差根据同心条件可得行星轮的齿数为所求的适用于非变位或高度变位的行星齿轮传动。再考虑到安装条件为:(整数)第二级传动比为6,选择中心齿数和行星齿轮数目与第一级相同,则。6.2.3初步计算齿轮的主要参数齿轮材料和热处理的选择:中心齿轮和中心齿轮,以及行星齿轮和均采用20CrMnTi,渗碳后淬火,淬透性不错,耐低温冲击,能够满足要求。齿面硬度为58-62HRC,由文献9可知,取,中心齿轮加工精度为6级,高速级与低速级的内齿轮均采用42CrMo,这种材料经过正火和调质处理,以获得相当的强度和硬度等力学性能,调质硬度为217-259HRC,取,轮和的加工精度为7级。高速齿轮的模数m 按弯曲强度的初算公式,为 现已知。中心齿轮的名义转矩为取算式系数,由文献12得系数,查得;取接触强度计算的行星齿轮间载荷分布不均匀系数,由公式可得,查得齿形系数,齿宽系数,则所得的模数m为:取齿轮模数为=0.4mm低速级的齿轮模数m取弯曲强度的初算公式,计算低速级的齿轮的模数m为现已知,中心齿轮的名义转矩,取算式系数,使用系数,综合系数,取接触强度计算的行星齿轮间载荷分布不均匀系数,由公式可得,查表得齿形系数,齿宽系数,则所得的模数m为:mm取齿轮模数为mm啮合参数计算:高速级在两个啮合齿轮副中,中,其标准中心距a为13.8mmmm低速级:在两个啮合齿轮副中中,其标准中心距a为mmmm由此可见,高速级和低速级得标准中心距均相等。因此次行星齿轮传动满足非变位的同心条件,但是在行星轮传动中,采用高度可以避免根切,减少机构的尺寸和质量,还可以改善齿轮副的磨损情况以及提高承载能力。几何尺寸的计算高速级:分度圆直径d基圆直径齿顶圆直径齿顶高:外啮合 内啮合 齿根圆直径齿根高 高速级太阳轮行星轮内齿圈模数m0.40.40.4齿数z2346115分度圆直径d9.218.446齿顶圆直径10.419.245.28齿根圆直径8.617.447低速级:分度圆直径d 基圆直径 齿顶圆直径齿顶高: 外啮合内啮合 齿根圆直径 齿根高 低速级太阳轮行星轮内齿圈模数m0.60.60.6齿数z2346115分度圆直径d13.827.669齿顶圆直径1528.868.28齿根圆直径12.326.170.56.2.4装配条件的计算对设计的齿轮副应满足以下条件的计算:1.邻接条件在行星轮传动中,为保证两相邻行星轮的齿顶不致相碰,相邻两行星轮的中心距应大于两齿顶圆半径之和,由公式验算其邻接条件 (为行星轮的直径,a为中心距) 高速级:18.4213.80.865=23.87低速级:27.6220.70.865=35.81故满足邻接条件。2.同心条件 按公式对于高度变位有,已知高速级,满足公式则满足同心条件。低速级与高速级齿数相同,故满足条件。 3.安装条件 按公式验算安装条件,即得 (C为整数) 即都满足装配条件。6.2.5高速级齿轮强度的验算由于该行星轮传动具有长期有效间断工作的特点,具有结构紧凑,外轮廓尺寸较小的特点,因此应按齿面接触强度和齿根弯曲强度验算。齿面接触疲劳强度的校核由公式可验算:式中 区域系数; _弹性影响系数; 螺旋角系数,直齿轮为1; 重合度系数; b-齿宽,齿轮副中的较小齿宽; 小齿轮分度圆直径; 许用应力; U齿数比;齿轮副中:许用接触应力的计算:由机械零件查得;选取安全系数故 又查得;由于螺旋角,由机械零件得;直齿轮螺旋角系数;重合度系数;齿宽b=3;故161MPa。故满足强度要求。齿轮副中:许用接触应力的计算:由机械零件查得;选取安全系数故 又查得;由于螺旋角,由机械零件得;直齿轮螺旋角系数;重合度系数;5;齿宽b=4;故310MPa。故满足强度要求。齿根弯曲疲劳强度的校核由公式可验算: 式中 齿根危险截面的弯曲应力; 载荷系数; 齿形系数; 应力校正系数。齿轮副:计算载荷系数K: 式中 K-载荷系数; -使用系数; -动载系数; -齿间载荷分配系数; -齿间载荷分布系数。由文献5可查得取=1;根据V=,可得;查文献5可得,,故。由文献5得齿形系数:,得齿形修正系数;许用应力的计算:由文献5得,,安全系数s=1.25,故。因此弯曲疲劳强度:109M,132Mpa故弯曲疲劳强度足够。齿轮副: 计算载荷系数K:由文献5查得,根据v=0.58,对称支撑;由文献5取得,故。查得齿形系数;应力系数;许用应力的计算:由文献5得;由文献5得由文献5取弯曲疲劳强度安全系数S=1.25; ; 因此弯曲疲劳强度 129Mpa 所以弯曲疲劳强度足够。低速级齿轮强度的验算由于该行星轮传动具有长期有效间断工作的特点,具有结构紧凑,外轮廓尺寸较小的特点,因此应按齿面接触强度和齿根弯曲强度验算。齿面接触疲劳强度的校核由公式可验算: 式中 区域系数; _弹性影响系数; 螺旋角系数,直齿轮为1; 重合度系数; -齿宽,齿轮副中的较小齿宽; 小齿轮分度圆直径; 许用应力; U齿数比;齿轮副中:许用接触应力的计算:由机械零件查得;选取安全系数 故 又查得;由于螺旋角,由机械零件得;直齿轮螺旋角系数;重合度系数;齿宽b=4.3;故183MPa。故满足强度要求。齿轮副中:许用接触应力的计算:由机械零件查得;选取安全系数 故 又查得;由于螺旋角,由机械零件得;直齿轮螺旋角系数;重合度系数;5;齿宽b=5.5;故352MPa。故满足强度要求。齿根弯曲疲劳强度的校核由公式可验算: 式中 齿根危险截面的弯曲应力; 载荷系数; 齿形系数; 应力校正系数。齿轮副:计算载荷系数K: 式中 K-载荷系数; -使用系数; -动载系数; -齿间载荷分配系数; -齿间载荷分布系数。由文献5可查得取=1;根据V=1.2,可得;查文献5可得,,故。由文献5得齿形系数:,得齿形修正系数;许用应力的计算:由文献5得,,安全系数s=1.25,故。因此弯曲疲劳强度:,143Mpa故弯曲疲劳强度足够。齿轮副: 计算载荷系数K:由文献5查得,根据v=0.58,对称支撑;由文献5取得,故。查得齿形系数;应力系数;许用应力的计算:由文献5得;由文献5得由文献5取弯曲疲劳强度安全系数S=1.25; ; 因此弯曲疲劳强度 143Mpa 所以弯曲疲劳强度足够。6.2.6 轴的设计及校核1选择轴的材料,确定许用应力根据工作条件选择轴的材料为40Cr钢,调质处理,由教材表15-3查得。2按扭转强度估算轴径根据文献5取=112,故得=4.892mm。输出轴的最小直径是安装联轴器的直径,为了使所选的轴直径与联轴器的孔相适应,故需同时选取联轴器型号。按照计算转矩应小于联轴器的公称转矩的条件,为了隔离震动与冲击,应选用微型弹性联轴器,选用德国KTR公司品牌的ROTEX-GS系列的微型无齿隙弹性联轴器;轴套材质为铝式,加紧式轴套,无键槽,传递扭矩取决于轴径,轴径范围为5-8,联轴器长度,外径。半联轴器的孔,故取,联轴器与轴配合的毂孔长度。 3.轴的结构设计拟定轴上零件的装配方案,用下图所示的装配方案可取,因为轴承同时受有径向力和轴向力的作用,故选择单列圆锥滚子轴承。参照工作要求选择C136079J,其尺寸为:。轴承采用反装形式,用轴肩定位,轴肩高度。4.确定轴上圆角和倒角尺寸取轴端倒角245,各轴间圆角半径见图。5.轴上载荷以及轴的校核图5-1轴的弯矩扭矩图圆周力:=2270/5=108N 径向力:=108tan=39.3N法向力:=/cos=44.2/ cos=114.9N水平支反力为: ,垂直反力:当量弯矩为:垂直面内=320Nmm,=15Nmm水平面内总弯矩为:=401Nmm,=243Nmm轴受转矩为:T=9549/n=95490.15/1800=796Nmm最后按弯矩合成应力校核轴的强度: 进行校核时,通常只校核轴上承受最大弯矩和扭矩的截面的强度,根据以上数据及轴单向旋转,扭转切应力为脉动循环变应力,故取,轴的计算应力所以 满足=70Mpa的条件,故设计的轴有足够的强度,并有一定裕量。6.3 本章小结本章通过对几种主要的减速器进行对比,结合矿用履带搜救机器人的工作环境,外型尺寸,确定所选用减速器的形式。同时设计计算了驱动轮减速锥齿轮,通过校核满足机器人的性能要求。第七章 移动机构履带及翼板部分设计7.1履带的选择由于在考虑履带装置设计时,基于标准化的思考,我们选择了梯形双面齿同步带作为设计履带,梯形双面齿同步带传动具有带传动、链传动和齿轮传动的优点。同步带传动由于带与带轮是靠啮合传递运动和动力,故带与带轮间无相对滑动,能保证准确的传动比。同步带通常以氯丁橡胶为材料,这种带薄而且轻,故可用于较高速度。传动时的线速度可达50m/s,传动比可达10,效率可达98。传动噪音比带传动、链传动和齿轮传动小,耐磨性好,不需油润滑,寿命比摩擦带长。因为同步带传动具有准确的传动比,无滑差,可获得恒定的速比,传动平稳,能吸振,噪音小,传动比范围大等优点,所以传递功率可以从几瓦到百千瓦。传动效率高,结构紧凑,适宜于多轴传动,无污染,因此可在不允许有污染和工作环境较为恶劣的场所下正常工作。从以上对同步带性能的分析中可以得出结论,选用梯形双面齿同步带作为移动装置设计履带能够满足设计性能及工作的环境条件要求。由已知后轴输出功率为(即);由已知设计装置移动速度,根据公式,可得主动轮转速,预先设计履带主动轮直径=160mm,履带从动轮直径=160mm,由公式,可得=120r/min.。故可以得到设计的已知条件如下:(1)传递名义功率.(2)主动轮转速.(3)从动轮转速 (4)中心距. 7.1.1 确定带的型号和节距由设计功率和,考虑到可以用双面交错梯状齿形同步带作为履带使用,由图6-1查得型号选用XH型,对应节距,图6-2为双面交错梯状齿形同步带的结构图,双面齿同步带的节距和齿形等同与单面齿同步带的齿形和节距,图A为DA型双面齿同步带,其两面带齿呈对称排列,图B为DB型双面齿同步带,其两面带齿呈交错位置排列,本装置设计履带选择DB型。XH型同步带W=2.794mm,=15.49mm。图6-1梯形齿同步带,轮选型图图6-2梯形齿形状图7.1.2确定主从动轮直径为了增大摩擦力,应考虑增大履带与接触地面的有效接触面积,所以履带离地面的高度不易过大,故取履带主动轮直径=160mm,履带从动轮直径=160mm。选择履带主动轮型号为23XH,履带从动轮型号为23XH,就近圆整带轮直径,查得履带主动轮直径=162.71mm,履带从动轮直径=162.71mm。7.1.3确定节线长度和带宽确定中心距,中心距大,可以增加带轮的包角,减少单位时间内带的循环次数,有利于提高带的寿命,但是中心距过大,则会加剧带的波动,降低带的传动平稳性,同时增大带传动的整体尺寸,中心距过小,则有相反的利弊,取带传动的中心距为=400mm。(1)计算所选用型号同步带的基准额定功率(kw)式中许用工作拉力,查表得=4048.90N单位长度质量,查表得=1.484Kg/m线速度m/s求解线速度:由已知条件主动轮转速=1220r/min.带入上式得4.049kw(2)计算主动轮啮合齿数(6-6)(3)确定实际所需带宽(6-7)式中带所传递的功率kw=0.17225kw啮合系数,因6,故=1.所以将其取为标准值(6-8)1.4570.17225额定功率大于设计功率,则带的传动能力已足够,所选参数合理。为了减轻履带驱动装置的重量,可以选择硬铝合金作为履带主,从动轮的材料,硬铝合金主要是加入铜,镁,锰元素,故硬铝合金具有密度小,质量低,强度高,硬度高,耐热性好的优点,能够满足设计性能要求。7.2 翼板部分设计履带翼板是整个履带驱动装置中的基础部分,主要起支撑作用,履带从动轮,张紧轮分别安装在翼板上,所设计的机器人移动部分采用的是轮履结合式,这种机构设计使机器人具有良好的越障和爬坡能力,履带驱动部分必须能够实现在履带主动轮转动的过程中翼板也能够绕从动轮的轴线转动,即在有不同角度障碍物的情况下能够顺利越碍。电机、电池组、支撑轮等零件都以前后翼板为固定支架,前后翼板的刚度直接影响着这些零部件工作状态,若前后翼板刚性较差,在受到外界冲击力的作用下易产生变形,那么将会直接导致电机安装位置产生错位,电机驱动齿轮与后同步带轮中的传动齿轮不能正常啮合甚至卡死,或者导致安装在后翼板上的承重轮不能正常支撑同步带,失去承载机器人负荷的作用。为了实现翼板能够绕轴线中心转动,需要使用电机提供扭矩,履带驱动装置需要的扭矩越大,相同型号的电机的尺寸也越大,从经济性的考虑,应尽量减轻整个履带驱动装置的重量,所以在材料选择方面,翼板的材料应满足质量轻,高强度,高硬度,易加工的优点,综合选择,镁合金能够满足一般的性能要求,所以翼板的材料选择镁合金。7.3 本章小结通过本章的分析,选择梯形双面齿同步带作为设计履带,确定了带的型号和节距,主从动轮直径,以及节线长度和带宽,同时也采用了翼板作为支撑,节省了材料第八章 机器人摇臂的设计8.1 摇臂作用概述摇臂的作用是是机器人在越障时起辅助作用,使机器人受力情况改变,更加灵活的适应崎岖的环境。主要作用为以下两点:1支撑摇臂的前轮,使之能够自由滚动。2360度转动时,能够支撑起车体。为了使与摇臂相连的轮能够自由转动,设计成输出轴上套轴承,轴承支撑车轮的形式。为了使摇臂转动时能够支撑起车体,车体前方的输出轴是由摇臂电机经减速器输出的。输出轴通过花键与摇臂翼板固定连接。采用花键的

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

|

2:不支持迅雷下载,请使用浏览器下载

3:不支持QQ浏览器下载,请用其他浏览器

4:下载后的文档和图纸-无水印

5:文档经过压缩,下载后原文更清晰

|

川公网安备: 51019002004831号

川公网安备: 51019002004831号