等臂杠杆工艺及铰削Φ10H7孔用钻床夹具设计 版本2[含CAD图纸,工艺工序卡,说明书等资料全套]

收藏

资源目录

压缩包内文档预览:(预览前20页/共42页)

编号:19469971

类型:共享资源

大小:1.45MB

格式:ZIP

上传时间:2019-05-24

上传人:好资料QQ****51605

认证信息

个人认证

孙**(实名认证)

江苏

IP属地:江苏

20

积分

- 关 键 词:

-

含CAD图纸,工艺工序卡,说明书等资料全套

及铰削Φ10H7孔用钻床夹具设计

及铰削Φ10H7孔用钻床夹具设计含

及 铰削Φ10H7孔用钻床夹具设计

10h7孔用钻床夹具设计

铰2Φ10H7孔

- 资源描述:

-

【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

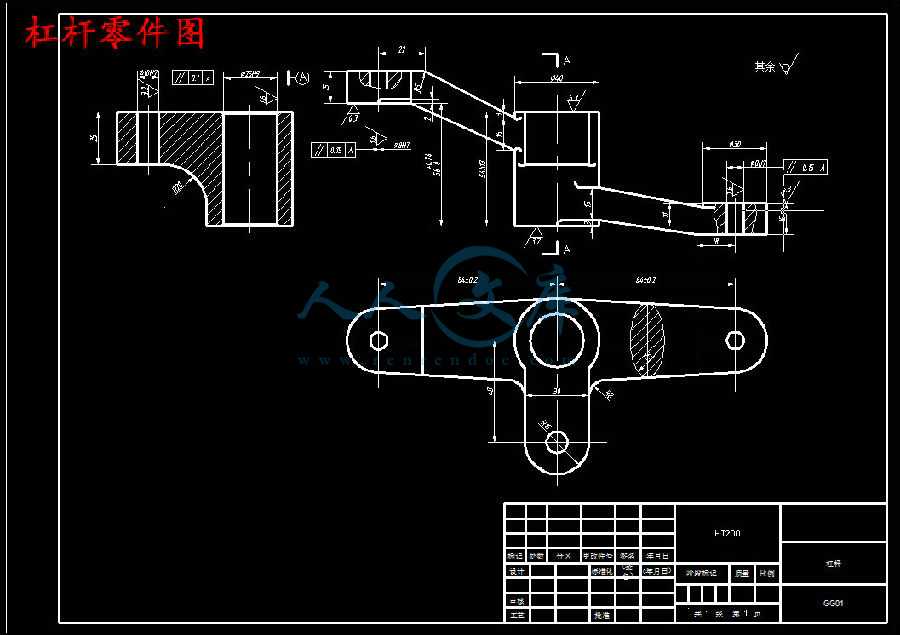

本设计是杠杆零件的加工工艺规程及铰削孔的专用夹具设计。杠杆零件的主要加工表面是平面及孔。一般来说,保证平面的加工精度要比保证孔的加工精度容易。因此,本设计遵循先面后孔的原则。并将孔与平面的加工明确划分成粗加工和精加工阶段以保证孔的加工精度。基准的选择以杠杆外圆面作为粗基准,以孔及其下表面作为精基准。先将底面加工出来,然后作为定位基准,在以底面作为精基准加工孔。整个加工过程选用专用机床。在夹具方面选用专用夹具。考虑到零件的结构尺寸简单,夹紧方式多采用手动夹紧,夹紧简单,机构设计简单,且能满足设计要求。

关键词: 杠杆零件 加工工艺 夹具 定位 夹紧

目 录

第1章 绪论 1

1.1设计背景及发展趋势 1

1.2夹具的基本结构及夹具设计的内容 1

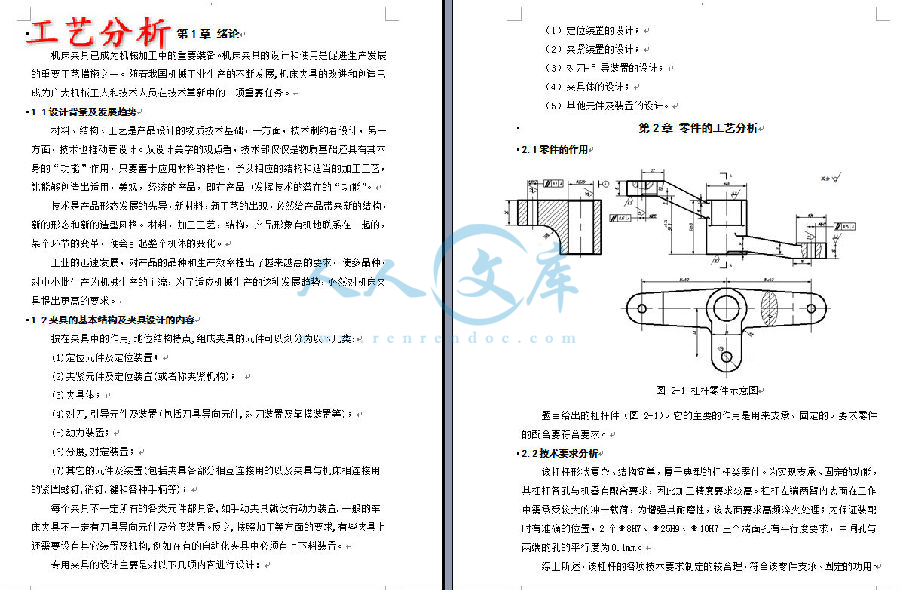

第2章 零件的工艺分析 2

2.1零件的作用 2

2.2技术要求分析 2

2.3审查杠杆的工艺性 3

2.4加工表面的分析 3

2.4.1主要加工面 3

2.4.2主要基准面 3

第3章 杠杆机械加工工艺规程设计 4

3.1计算生产纲领及确定生产类型 4

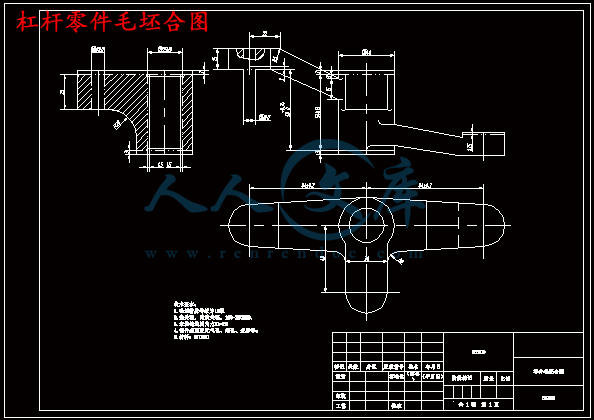

3.2毛坯选择与毛坯图说明 4

3.2.1选择毛坯 4

3.2.2绘制毛坯图 5

3.3工艺路线的确定 5

3.3.1选择定位基准 5

3.3.2零件表面加工方法的确定 6

3.3.3加工阶段的划分 6

3.3.4工序集中与分散 7

3.3.5确定工艺路线 7

3.4工序尺寸的确定及计算 9

3.5确定切削用量(切削速度、进给量、切削深度)及时间定额 9

3.5.1确定切削用量 9

3.5.2确定基本工时 19

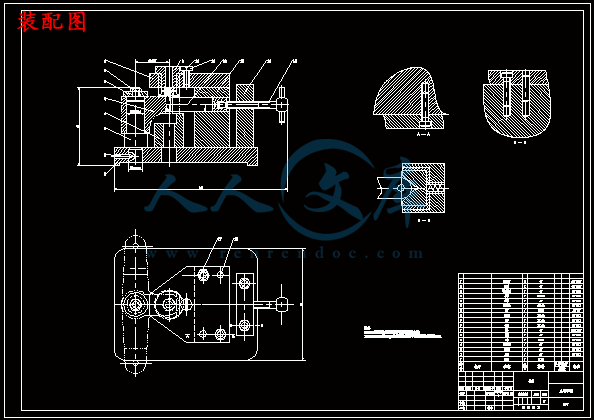

第4章 铰削Φ10H7孔用钻床夹具设计 24

4.1 夹具类型的确定 24

4.1.1通用夹具 24

4.1.2专用夹具 24

4.1.3可调夹具 24

4.1.4组合夹具 24

4.1.5拼装夹具 25

4.2确定工件的定位方案 25

4.3确定工件的夹紧形式 26

4.4确定刀具的导向方式或对刀装置 27

4.5.1定位基准分析 29

4.5.2钻削力计算 29

4.5.3夹紧力计算 30

4.6.1铸造夹具体 30

4.6.2锻造夹具体 31

4.6.3焊接夹具体 31

4.6.4装配夹具体 31

4.7夹具精度校核 31

4.7.1验算中心距48 31

4.7.2验算两孔平行度精度 32

第5章 绘制夹具装配图 34

第6章 总结 35

参考文献 36

第1章 绪论

机床夹具已成为机械加工中的重要装备。机床夹具的设计和使用是促进生产发展的重要工艺措施之一。随着我国机械工业生产的不断发展,机床夹具的改进和创造已成为广大机械工人和技术人员在技术革新中的一项重要任务。

1.1设计背景及发展趋势

材料、结构、工艺是产品设计的物质技术基础,一方面,技术制约着设计,另一方面,技术也推动着设计。从设计美学的观点看,技术部仅仅是物质基础还具有其本身的“功能”作用,只要善于应用材料的特性,予以相应的结构和适当的加工工艺,就能够创造出适用,美观,经济的产品,即在产品中发挥技术的潜在的“功能”。

技术是产品形态发展的先导,新材料,新工艺的出现,必然给产品带来新的结构,新的形态和新的造型风格。材料,加工工艺,结构,产品形象有机地联系在一起的,某个环节的变革,便会引起整个机体的变化。

工业的迅速发展,对产品的品种和生产效率提出了越来越高的要求,使多品种,对中小批生产为机械生产的主流,为了适应机械生产的这种发展趋势,必然对机床夹具提出更高的要求。

- 内容简介:

-

Robotics and Computer-Integrated Manufacturing 21 (2005) 368378 Locating completeness evaluation and revision in fi xture plan H. Song?, Y. Rong CAM Lab, Department of Mechanical Engineering, Worcester Polytechnic Institute, 100 Institute Rd, Worcester, MA 01609, USA Received 14 September 2004; received in revised form 9 November 2004; accepted 10 November 2004 Abstract Geometry constraint is one of the most important considerations in fi xture design. Analytical formulation of deterministic location has been well developed. However, how to analyze and revise a non-deterministic locating scheme during the process of actual fi xture design practice has not been thoroughly studied. In this paper, a methodology to characterize fi xturing systems geometry constraint status with focus on under-constraint is proposed. An under-constraint status, if it exists, can be recognized with given locating scheme. All un-constrained motions of a workpiece in an under-constraint status can be automatically identifi ed. This assists the designer to improve defi cit locating scheme and provides guidelines for revision to eventually achieve deterministic locating. r 2005 Elsevier Ltd. All rights reserved. Keywords: Fixture design; Geometry constraint; Deterministic locating; Under-constrained; Over-constrained 1. Introduction A fi xture is a mechanism used in manufacturing operations to hold a workpiece fi rmly in position. Being a crucial step in process planning for machining parts, fi xture design needs to ensure the positional accuracy and dimensional accuracy of a workpiece. In general, 3-2-1 principle is the most widely used guiding principle for developing a location scheme. V-block and pin-hole locating principles are also commonly used. A location scheme for a machining fi xture must satisfy a number of requirements. The most basic requirement is that it must provide deterministic location for the workpiece 1. This notion states that a locator scheme produces deterministic location when the workpiece cannot move without losing contact with at least one locator. This has been one of the most fundamental guidelines for fi xture design and studied by many researchers. Concerning geometry constraint status, a workpiece under any locating scheme falls into one of the following three categories: 1. Well-constrained (deterministic): The workpiece is mated at a unique position when six locators are made to contact the workpiece surface. 2. Under-constrained: The six degrees of freedom of workpiece are not fully constrained. 3. Over-constrained: The six degrees of freedom of workpiece are constrained by more than six locators. In 1985, Asada and By 1 proposed full rank Jacobian matrix of constraint equations as a criterion and formed the basis of analytical investigations for deterministic locating that followed. Chou et al. 2 formulated the deterministic locating problem using screw theory in 1989. It is concluded that the locating wrenches matrix needs to be full rank to achieve deterministic location. This method has been adopted by numerous studies as well. Wang et al. 3 considered ARTICLE IN PRESS /locate/rcim 0736-5845/$-see front matter r 2005 Elsevier Ltd. All rights reserved. doi:10.1016/j.rcim.2004.11.012 ?Corresponding author. Tel.: +15088316092; fax: +15088316412. E-mail address: hsong (H. Song). locatorworkpiece contact area effects instead of applying point contact. They introduced a contact matrix and pointed out that two contact bodies should not have equal but opposite curvature at contacting point. Carlson 4 suggested that a linear approximation may not be suffi cient for some applications such as non-prismatic surfaces or non-small relative errors. He proposed a second-order Taylor expansion which also takes locator error interaction into account. Marin and Ferreira 5 applied Chous formulation on 3-2-1 location and formulated several easy-to-follow planning rules. Despite the numerous analytical studies on deterministic location, less attention was paid to analyze non-deterministic location. In the Asada and Bys formulation, they assumed frictionless and point contact between fi xturing elements and workpiece. The desired location is q*, at which a workpiece is to be positioned and piecewisely differentiable surface function is gi(as shown in Fig. 1). The surface function is defi ned as giq? 0: To be deterministic, there should be a unique solution for the following equation set for all locators. giq 0;i 1;2;.;n,(1) where n is the number of locators and q x0;y0;z0;y0;f0;c0? represents the position and orientation of the workpiece. Only considering the vicinity of desired location q?; where q q? Dq; Asada and By showed that giq giq? hiDq,(2) where hiis the Jacobian matrix of geometry functions, as shown by the matrix in Eq. (3). The deterministic locating requirement can be satisfi ed if the Jacobian matrix has full rank, which makes the Eq. (2) to have only one solution q q?: rank qg1 qx0 qg1 qy0 qg1 qz0 qg1 qy0 qg1 qf0 qg1 qc0 : qgi qx0 qgi qy0 qgi qz0 qgi qy0 qgi qf0 qgi qc0 : qgn qx0 qgn qy0 qgn qz0 qgn qy0 qgn qf0 qgn qc0 2 6 6 6 6 6 6 6 6 6 4 3 7 7 7 7 7 7 7 7 7 5 8 : 9 = ; 6.(3) Upon given a 3-2-1 locating scheme, the rank of a Jacobian matrix for constraint equations tells the constraint status as shown in Table 1. If the rank is less than six, the workpiece is under-constrained, i.e., there exists at least one free motion of the workpiece that is not constrained by locators. If the matrix has full rank but the locating scheme has more than six locators, the workpiece is over-constrained, which indicates there exists at least one locator such that it can be removed without affecting the geometry constrain status of the workpiece. For locating a model other than 3-2-1, datum frame can be established to extract equivalent locating points. Hu 6 has developed a systematic approach for this purpose. Hence, this criterion can be applied to all locating schemes. ARTICLE IN PRESS X Y Z O X Y Z O (x0,y0,z0) gi UCS WCS Workpiece Fig. 1. Fixturing system model. H. Song, Y. Rong / Robotics and Computer-Integrated Manufacturing 21 (2005) 368378369 Kang et al. 7 followed these methods and implemented them to develop a geometry constraint analysis module in their automated computer-aided fi xture design verifi cation system. Their CAFDV system can calculate the Jacobian matrix and its rank to determine locating completeness. It can also analyze the workpiece displacement and sensitivity to locating error. Xiong et al. 8 presented an approach to check the rank of locating matrix WL(see Appendix). They also intro- duced left/right generalized inverse of the locating matrix to analyze the geometric errors of workpiece. It has been shown that the position and orientation errors DX of the workpiece and the position errors Dr of locators are related as follows: Well-constrained :DX WLDr,(4) Over-constrained :DX WT LWL ?1WT LDr, (5) Under-constrained :DX WT LWLW T L ?1Dr I6?6 ? WT LWLW T L ?1W Ll, (6) where l is an arbitrary vector. They further introduced several indexes derived from those matrixes to evaluate locator confi gurations, followed by optimization through constrained nonlinear programming. Their analytical study, however, does not concern the revision of non-deterministic locating. Currently, there is no systematic study on how to deal with a fi xture design that failed to provide deterministic location. 2. Locating completeness evaluation If deterministic location is not achieved by designed fi xturing system, it is as important for designers to know what the constraint status is and how to improve the design. If the fi xturing system is over-constrained, informa- tion about the unnecessary locators is desired. While under-constrained occurs, the knowledge about all the un- constrained motions of a workpiece may guide designers to select additional locators and/or revise the locating scheme more effi ciently. A general strategy to characterize geometry constraint status of a locating scheme is described in Fig. 2. In this paper, the rank of locating matrix is exerted to evaluate geometry constraint status (see Appendix for derivation of locating matrix). The deterministic locating requires six locators that provide full rank locating matrix WL: As shown in Fig. 3, for given locator number n; locating normal vector ai;bi;ci? and locating position xi;yi;zi? for each locator, i 1;2;.;n; the n ? 6 locating matrix can be determined as follows: WL a1b1c1c1y1? b1z1a1z1? c1x1b1x1? a1y1 : aibiciciyi? biziaizi? cixibixi? aiyi : anbncncnyn? bnznanzn? cnxnbnxn? anyn 2 6 6 6 6 6 6 4 3 7 7 7 7 7 7 5 .(7) When rankWL 6 and n 6; the workpiece is well-constrained. When rankWL 6 and n46; the workpiece is over-constrained. This means there are n ? 6 unnecessary locators in the locating scheme. The workpiece will be well-constrained without the presence of those n ? 6 locators. The mathematical representation for this status is that there are n ? 6 row vectors in locating matrix that can be expressed as linear combinations of the other six row vectors. The locators corresponding to that six row vectors consist one ARTICLE IN PRESS Table 1 RankNumber of locatorsStatus o 6Under-constrained 6 6Well-constrained 646Over-constrained H. Song, Y. Rong / Robotics and Computer-Integrated Manufacturing 21 (2005) 368378370 locating scheme that provides deterministic location. The developed algorithm uses the following approach to determine the unnecessary locators: 1. Find all the combination of n ? 6 locators. 2. For each combination, remove that n ? 6 locators from locating scheme. 3. Recalculate the rank of locating matrix for the left six locators. 4. If the rank remains unchanged, the removed n ? 6 locators are responsible for over-constrained status. This method may yield multi-solutions and require designer to determine which set of unnecessary locators should be removed for the best locating performance. When rankWLo6; the workpiece is under-constrained. 3. Algorithm development and implementation The algorithm to be developed here will dedicate to provide information on un-constrained motions of the workpiece in under-constrained status. Suppose there are n locators, the relationship between a workpieces position/ ARTICLE IN PRESS Fig. 2. Geometry constraint status characterization. X Z Y (a1,b1,c1) 2,b2,c2) (x1,y1,z1) (x2,y2,z2) (ai,bi,ci) (xi,yi,zi) (a Fig. 3. A simplifi ed locating scheme. H. Song, Y. Rong / Robotics and Computer-Integrated Manufacturing 21 (2005) 368378371 orientation errors and locator errors can be expressed as follows: DX Dx Dy Dz ax ay az 2 6 6 6 6 6 6 6 6 6 4 3 7 7 7 7 7 7 7 7 7 5 w11:w1i:w1n w21:w2i:w2n w31:w3i:w3n w41:w4i:w4n w51:w5i:w5n w61:w6i:w6n 2 6 6 6 6 6 6 6 6 6 4 3 7 7 7 7 7 7 7 7 7 5 ? Dr1 : Dri : Drn 2 6 6 6 6 6 6 4 3 7 7 7 7 7 7 5 ,(8) where Dx;Dy;Dz;ax;ay;azare displacement along x, y, z axis and rotation about x, y, z axis, respectively. Driis geometric error of the ith locator. wij is defi ned by right generalized inverse of the locating matrix Wr WT LWLW T L ?1 5. To identify all the un-constrained motions of the workpiece, V dxi;dyi;dzi;daxi;dayi;dazi? is introduced such that V DX 0.(9) Since rankDXo6; there must exist non-zero V that satisfi es Eq. (9). Each non-zero solution of V represents an un- constrained motion. Each term of V represents a component of that motion. For example, 0;0;0;3;0;0? says that the rotation about x-axis is not constrained. 0;1;1;0;0;0? means that the workpiece can move along the direction given by vector 0;1;1?: There could be infi nite solutions. The solution space, however, can be constructed by 6 ? rankWL basic solutions. Following analysis is dedicated to fi nd out the basic solutions. From Eqs. (8) and (9) VX dxDx dyDy dzDz daxDax dayDay dazDaz dx X n i1 w1iDri dy X n i1 w2iDri dz X n i1 w3iDri dax X n i1 w4iDri day X n i1 w5iDri daz X n i1 w6iDri X n i1 Vw1i;w2i;w3i;w4i;w5i;w6i?TDri 0.10 Eq. (10) holds for 8Driif and only if Eq. (11) is true for 8i1pipn: Vw1i;w2i;w3i;w4i;w5i;w6i?T 0.(11) Eq. (11) illustrates the dependency relationships among row vectors of Wr: In special cases, say, all w1jequal to zero, V has an obvious solution 1, 0, 0, 0, 0, 0, indicating displacement along the x-axis is not constrained. This is easy to understand because Dx 0 in this case, implying that the corresponding position error of the workpiece is not dependent of any locator errors. Hence, the associated motion is not constrained by locators. Moreover, a combined motion is not constrained if one of the elements in DX can be expressed as linear combination of other elements. For instance, 9w1ja0;w2ja0; w1j ?w2jfor 8j: In this scenario, the workpiece cannot move along x- or y-axis. However, it can move along the diagonal line between x- and y-axis defi ned by vector 1, 1, 0. To fi nd solutions for general cases, the following strategy was developed: 1. Eliminate dependent row(s) from locating matrix. Let r rank WL; n number of locator. If ron; create a vector in n ? r dimension space U u1:uj:un?r hi 1pjpn ? r; 1pujpn: Select ujin the way that rankWL r still holds after setting all the terms of all the uj th row(s) equal to zero. Set r ? 6 modifi ed locating matrix WLM a1b1c1c1y1? b1z1a1z1? c1x1b1x1? a1y1 : aibiciciyi? biziaizi? cixibixi? aiyi : anbncncnyn? bnznanzn? cnxnbnxn? anyn 2 6 6 6 6 6 6 4 3 7 7 7 7 7 7 5 r?6 , where i 1;2;:;niauj: ARTICLE IN PRESS H. Song, Y. Rong / Robotics and Computer-Integrated Manufacturing 21 (2005) 368378372 2. Compute the 6 ? n right generalized inverse of the modifi ed locating matrix Wr WT LMWLMW T LM ?1 w11:w1i:w1r w21:w2i:w2r w31:w3i:w3r w41:w4i:w4r w51:w5i:w5r w61:w6i:w6r 2 6 6 6 6 6 6 6 6 6 4 3 7 7 7 7 7 7 7 7 7 5 6?r 3. Trim Wrdown to a r ? rfull rank matrix Wrm: r rankWLo6: Construct a 6 ? r dimension vector Q q1:qj:q6?r hi 1pjp6 ? r; 1pqjpn: Select qjin the way that rankWr r still holds after setting all the terms of all the qj th row(s) equal to zero. Set r ? r modifi ed inverse matrix Wrm w11:w1i:w1r : wl1:wli:wlr : w61:w6i:w6r 2 6 6 6 6 6 6 4 3 7 7 7 7 7 7 5 6?6 , where l 1;2;:;6 laqj: 4. Normalize the free motion space. Suppose V V1;V2;V3;V4;V5;V6? is one of the basic solutions of Eq. (10) with all six terms undetermined. Select a term qkfrom vector Q1pkp6 ? r: Set Vqk ?1; Vqj 0 j 1;2;:;6 ? r;jak; ( 5. Calculated undetermined terms of V: V is also a solution of Eq. (11). The r undetermined terms can be found as follows. v1 : vs : v6 2 6 6 6 6 6 6 4 3 7 7 7 7 7 7 5 wqk1 : wqki : wqkr 2 6 6 6 6 6 6 4 3 7 7 7 7 7 7 5 ? w11:w1i:w1r : wl1:wli:wlr : w61:w6i:w6r 2 6 6 6 6 6 6 4 3 7 7 7 7 7 7 5 ?1 , where s 1;2;:;6saqj;saqk;l 1;2;:;6 laqj: 6. Repeat step 4 (select another term from Q) and step 5 until all 6 ? r basic solutions have been determined. Based on this algorithm, a C+ program was developed to identify the under-constrained status and un- constrained motions. Example 1. In a surface grinding operation, a workpiece is located on a fi xture system as shown in Fig. 4. The normal vector and position of each locator are as follows: L1:0, 0, 10, 1, 3, 00, L2:0, 0, 10, 3, 3, 00, L3:0, 0, 10, 2, 1, 00, L4:0, 1, 00, 3, 0, 20, L5:0, 1, 00, 1, 0, 20. Consequently, the locating matrix is determined. WL 0013?10 0013?30 0011?20 010?203 010?201 2 6 6 6 6 6 6 4 3 7 7 7 7 7 7 5 . ARTICLE IN PRESS H. Song, Y. Rong / Robotics and Computer-Integrated Manufacturing 21 (2005) 368378373 This locating system provides under-constrained positioning since rankWL 5o6: The program then calculates the right generalized inverse of the locating matrix. Wr 00000 0:50:5?1?0:51:5 0:75?1:251:500 0:250:25?0:500 0:5?0:5000 0000:5?0:5 2 6 6 6 6 6 6 6 6 4 3 7 7 7 7 7 7 7 7 5 . The fi rst row is recognized as a dependent row because removal of this row does not affect rank of the matrix. The other fi ve rows are independent rows. A linear combination of the independent rows is found according the requirement in step 5 of the procedure for under-constrained status. The solution for this special case is obvious that all the coeffi cients are zero. Hence, the un-constrained motion of workpiece can be determined as V ?1; 0; 0; 0; 0; 0?: This indicates that the workpiece can move along x direction. Based on this result, an additional locator should be employed to constraint displacement of workpiece along x-axis. Example 2. Fig. 5 shows a knuckle with 3-2-1 locating system. The normal vector and position of each locator in this initial design are as follows: L1:0, 1, 00, 896, ?877, ?5150, L2:0, 1, 00, 1060, ?875, ?3780, L3:0, 1, 00, 1010, ?959, ?6120, L4:0.9955, ?0.0349, 0.0880, 977, ?902, ?6240, L5:0.9955, ?0.0349, 0.0880, 977, ?866, ?6240, L6:0.088, 0.017, ?0.9960, 1034, ?864, ?3590. The locating matrix of this confi guration is WL 010515:000:8960 010378:001:0600 010612:001:0100 0:9955?0:03490:0880?101:2445?707:26640:8638 0:9955?0:03490:0880?98:0728?707:26640:8280 0:08800:0170?0:9960866:6257998:24660:0936 2 6 6 6 6 6 6 6 6 4 3 7 7 7 7 7 7 7 7 5 , rankWL 5o6 reveals that the workpiece is under-constrained. It is found that one of the fi rst fi ve rows can be removed without varying the rank of locating matrix. Suppose the fi rst row, i.e., locator L1is removed from WL; the ARTICLE IN PRESS X Z Y L3 L4 L5 L2 L1 Fig. 4. Under-constrained locating scheme. H. Song, Y. Rong / Robotics and Computer-Integrated Manufacturing 21 (2005) 368378374 modifi ed locating matrix turns into WLM 010378:001:0600 010612:001:0100 0:9955?0:03490:0880?101:2445?707:26640:8638 0:9955?0:03490:0880?98:0728?707:26640:8280 0:08800:0170?0:996866:6257998:24660:0936 2 6 6 6 6 6 6

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号