资源目录

压缩包内文档预览:(预览前20页/共68页)

编号:6035139

类型:共享资源

大小:5.29MB

格式:RAR

上传时间:2017-10-23

上传人:闰***

认证信息

个人认证

冯**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

zl05

微型

轮式

装载机

总体设计

- 资源描述:

-

- 内容简介:

-

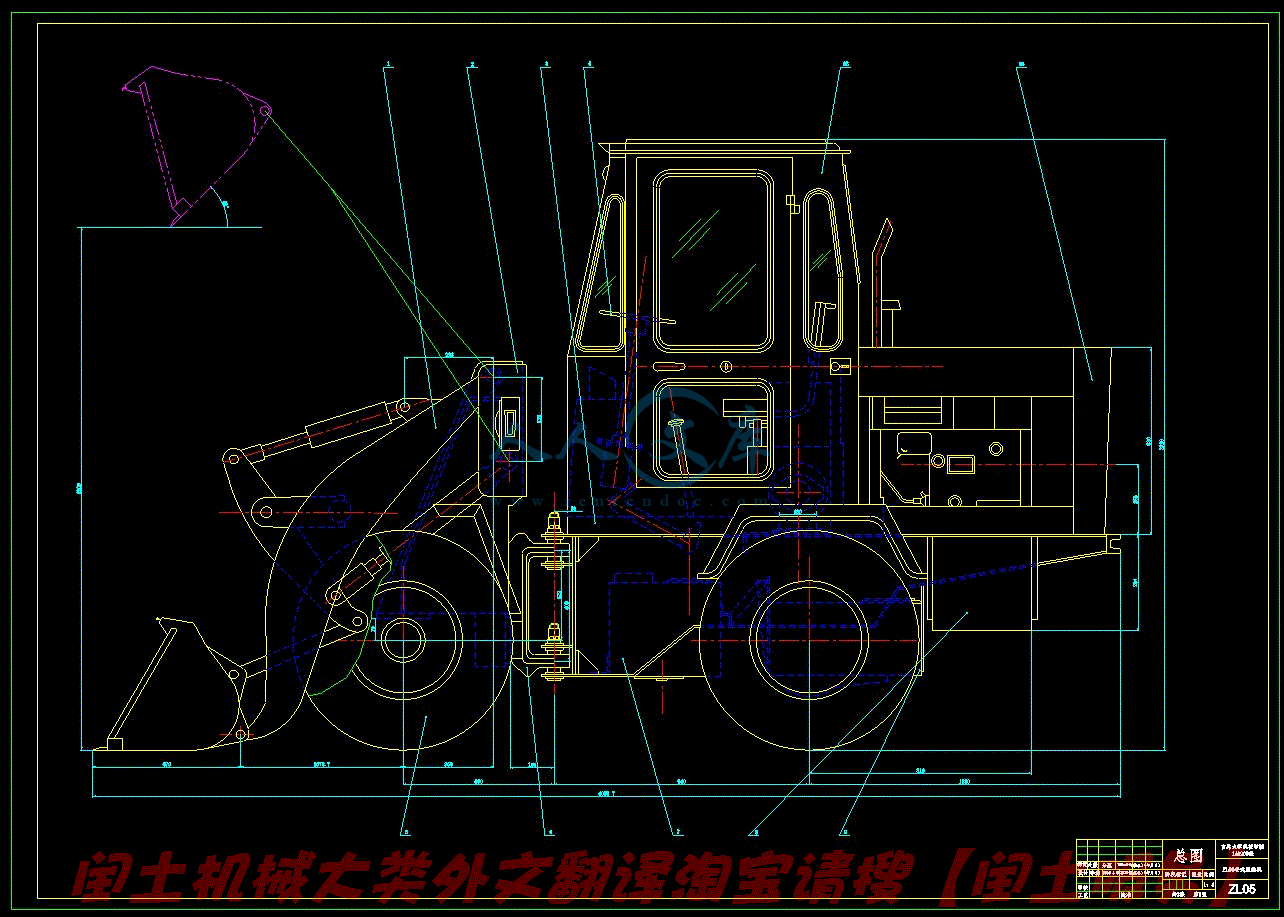

Applied Ergonomics 34 (2003) 265271Aspects to improve cabin comfort of wheel loaders and excavatorsaccording to operatorsL.F.M. Kuijt-Eversa,*, F. Krausea, P. Vinka,baTNO Work and Employment, P.O. Box 718, Hoofddorp 2130 AS, The NetherlandsbIndustrial Design, TU Delft, The NetherlandsReceived 19 April 2002; received in revised form 25 November 2002; accepted 29 December 2002AbstractComfort plays an increasingly important role in interior design of earth moving equipment. Although research has beenconducted on vehicle interiors of wheel loaders and excavators, hardly any information is known about the operators opinion. Inthis study a questionnaire was completed by machine operators to get their opinion about aspects which need to be improved inordertodesignamorecomfortablevehicleinterior.Theresultsshowthatalmosthalfoftheoperatorsratethecomfortoftheircabinaverageorpoor.Accordingtotheoperators,cabcomfortofwheelloaderscanbeincreasedbyimprovingseatcomfort.Besidesimproving seat comfort, cabin comfort of excavators can be improved by changing the cab design (including dimensions, ingress/egress), view, reliability, and climate control.r 2003 Elsevier Science Ltd. All rights reserved.Keywords: Cabin comfort; Operators opinion; Earthmoving equipment1. IntroductionComfort plays an increasingly important role invehicle design. As machine operators of earth movingequipment often spend long hours in their vehiclesometimes even more than 8h a daycomfort is amajor issue in interior design of these machines.Operating earth-moving machinery is not a physicallyheavy job and can be sustained for long periods.Nevertheless, operating such a machine appears to bea risk factor for musculoskeletal disorders, especiallywhen the task is not interrupted by other workingactivities or breaks. Zimmerman et al. (1997) showedthat the main problems of earth-moving machineryoperators concern physical complaints in the neck/shoulder and low back region, general fatigue andfeelings of discomfort. This might be attributed to acombination of static load during prolonged sittingfrequently in awkward posturesexposure to wholebody vibrations, and handling and steering the machine(Zimmerman et al., 1997; Tola et al., 1988; de Loozeet al., 2000).A comfortable well-designed vehicle interior mayreduce awkward postures and provide an environmentthat stimulatesoptimaloperatorperformance. Based ona literature review about musculoskeletal disorders andtheir risk factors, Zimmerman et al. (1997) made fourrecommendations for reducing work-related musculos-keletal disorders among operators: minimizing ofmagnitude and frequency of vibration reaching theoperator; locating controls optimally to minimize reachdistances, trunk exion and trunk rotation; providingmaximum operator visibility from an upright supportedseated posture; and taking regular breaks to minimizethe effects of sustained postures. Improvements of cabcomfort are very often based on reducing the riskfactors for work-related musculoskeletal disorders(Zimmerman et al., 1997; Attebrant et al., 1997). Onlya few studies have mentioned aspects which operatorswishto see improved. Nakada (1997) describes thedesirability ranking for dump trucks and wheel loadersgiven by product creators, designers, design engineers,operatorsandyoungpeople.Nakada,(1997)showsthatmuchdesign attention has been paid to instrumentpanel/monitors and meters and the operator seat.*Correspondingauthor.Tel.:+31-23-55-49-938;fax:+31-23-55-49-305.E-mail address: l.kuijtarbeid.tno.nl (L.F.M. Kuijt-Evers).0003-6870/03/$-see front matter r 2003 Elsevier Science Ltd. All rights reserved.doi:10.1016/S0003-6870(03)00032-2Unfortunately, the operators opinions cannot bedistinguished in Nakadas study (1997).However, in order to design a comfortable vehicleinterior, the opinion of the operators is important asthey are the end-users of the machines. Their userexperience may be of great help designing a morecomfortable vehicle interior. The aim of the currentstudy is to nd aspects mentioned by wheel loader andexcavator operators, which can be used to improve thecomfort of vehicle interiors in the future. In this articlewe describe the results of a questionnaire given to 273machineoperators.Theywereaskedtheiropinionabouttheir current machine, their future demands and aspectsthey considered important to work well with themachine. This allowed us to identify aspects that needimprovement in machine design.2. Method2.1. SubjectsA convenience sample was obtained through ap-proaching operators visiting Bauma (the worlds largestexhibition for construction equipment). Most of theparticipants were wheel loader operators (n 61) andexcavator operators (n 212). The others (n 65) wereoperators of several construction machines (e.g., mobilecranes, dozers, tower cranes, off-road trucks). Only theresults for wheel loader and excavator operators arepresented in this article, as they account for 18% and62.7% of the total number of respondents respectively.Figs.1and2showatypicalwheelloaderandexcavator.2.2. QuestionnaireData were collected by means of a questionnairewhich was completed during an interview. The ques-tionnairewasdividedintothreeparts:(1)characteristicsof the population, (2) evaluation of the current machinebeingoperated,and(3)futuredemandsonearthmovingmachinery. In the rst part we asked the operators age,years of experience as operator, the kind of machinerybeing operated and its age. In the second part of thequestionnaire, operators evaluated their machine byratingoverallcomfortandtheiropinionofspecicpartsof the machine on a four-point scale (very good, good,average,poor).Finally,twoopenquestionsaskedaboutthe operators future demands: what improvementswould make the machine more comfortable and whataspects are the most important to work well with themachine.Fig.1. Excavator.L.F.M. Kuijt-Evers et al. / Applied Ergonomics 34 (2003) 2652712662.3. Data analysisData were sorted by machine type, after which theresponses of wheel loader operators and excavatoroperators were separately analyzed. Within thesegroups, operators of older machinery (X4 years old)were separated from operators of newer machinery (o4years old). In addition, the categories very good andgood were combined (very good/good) and thecategories average and poor were combined(average/poor).Frequency tables were made of the operatorsopinions about overall machine comfort and abouttheir opinions about specic parts of their machines.Chi-square was calculated between age of machine andoverall comfort and between age of machine and theoperators opinion of specic parts of the machine. Weassumedthat if fewer than 80% of the operatorsrated apart of the machine good/very good, improvement ofthis part could contribute to amore comfortable vehicleinterior.Inpartthreeofthequestionnaire,theoperatorsindicated aspects to improve machine comfort andaspects they found necessary to work well with themachine. We classied these aspects into categories andcalculated the percentage responses.3. Results3.1. Characteristics of the populationBoth the wheel loader operators (mean age: 36.579.4years) andthe excavatoroperators(meanage:36.379.3years) who participated in this study, were experiencedwitha mean of 12.3 ( 78.1) and 13.4 (79.2) years ofservice, respectively. Half of the operators operatemachines less than 4 years old (53% of the wheel loaderand 50% of the excavator operators; see Fig.3).3.2. Evaluation of current machine57.4% of wheel loader operators and 55.9% of theexcavator operators rated the overall cabin comfortgood/verygood.Fig.4showsthatoperatorsofnewermachinery (o4 years old) rated the overall cab comfortasgood/verygoodmoreoftenthanoperatorsofolderFig.2. Wheel loader.Age of machinesPercentage of machines per category0102030405060Excavators Wheel loadersMachines (%)less than 4 years old 4 years or moreFig.3. The participants machines are divided into two categories:machines o4 years old and machines =4 years old.L.F.M. Kuijt-Evers et al. / Applied Ergonomics 34 (2003) 265271 267machines (X4 years old). This was found both amongwheel loaders (w218:5; po0:04) and among excava-tors(w2123:0; po0:001).Seventy-eightpercentoftheoperators driving wheel loaders less than 4 years old,rated the comfort oftheir machine asgood/very good.Withexcavator operators this gure was 81%. Theseresults show that during recent years the experienced cabcomfort of excavators and wheel loaders has improved.Fig.5 illustrates the opinion of the operators aboutspecic parts of the machines less than 4 years old. Asseen in Table 1, fewer aspects of wheel loaders are ratedaverage/poor by more than 20% of the operators,than excavators. Common aspects which can contributeto increase of cab comfort are dashboard and displays,adjustability of seats and controls, vibration anddamping, noise reduction, and seat comfort. Excavatoroperators would also like to see improvementof climateGeneral opinion about comfort of the cabPercentage of operators rating good/very good020406080100Excavators Wheel loadersOperators (%)less than 4 years old 4 years or moreFig.4. Percentage of operators rating their machines good andvery good on cab comfort.Excavators less than 4 years old Percentage operators rating good and very good 0204060801002040608010Seat comfortAdjustablility of seat and controlsWay controls workPedalsDashboard and displaysViewClimate controlCab dimension/interior spaceMachines appearanceNoise reductionVibration and dampingOperators (%)Good Very goodGood Very goodWheel loaders less than 4 years old Percentage operators rating good and very goodSeat comfortAdjustablility of seat and controlsWay controls workPedalsDashboard and displaysViewClimate controlCab dimension/interior spaceMachines appearanceNoise reductionVibration and dampingOperators (%)Fig.5. Opinion of excavator and wheel loader operators about specic parts of the machines.L.F.M. Kuijt-Evers et al. / Applied Ergonomics 34 (2003) 265271268control, improved machine appearance, and better cabdimensions (including interior space, ingress/egress),view, and reliability.3.3. Future demandsThe participants generated 467 items desired toimprove the machines comfort. We classied theseaspects into 15 categories (see Table 2). Fig.6 showswhich features should be improved according to theoperators. Seat comfort, climate control and accessoriesare often mentioned for bothwheel loaders (20%, 12%,15%, resp.) and excavators (21%, 19%, 12%, resp.).Excavator operators also mention cab design (includingdimensions, ingress/egress; 19%).The aspects considered most important to work wellwith the machine are summarized in Table 3. Machineperformance is by far the most important issue if welook at the averages. Other aspects like view andreliability play less important roles.Table 2Classication of aspects mentioned by operatorsCategories ExamplesTCO (total cost of ownership) Costs of machine (procurement,service costs, rest value)Machine performance Performance, hydraulics, gearServiceability Cleaning of the machine,manufacturer serviceReliability ReliabilitySeat comfort Seat pan, lumbar support, armrests, curvature of back supportAdjustabilityofseatandcontrols Adjustability of seat height,adjustability of controlsOperability Joystick, steering wheel,interaction joystick and beamView View of work, dead angles,position of mirrorsDashboard and displays Usability of dashboard/controls,readability, absent information,position of displaysClimate control Temperature, dust lters,ventilation, blower positionDesign/dimensions/ingress andegressDesign and dimensions of cabinand machine, position of steps,grab railsNoise and vibration Noise, vibration, dampingAccessories Radio, fridge, storage space, cupholderSafety and stability Feelings of safety, stability ofmachineEnvironment Noise outside the machine,exhaust fumesTable 1Aspects rated average or poor by more than 20% of the operators for both wheel loaders and excavators less than 4 years oldWheel loaders ExcavatorsAspect Operators (%) Aspect Operators (%)Dashboard and displays 32.0 Seat comfort* 29.5Adjustability of seat and controls 31.2 Vibration and damping* 27.0Vibration and damping* 28.1 Dashboard and displays 26.0Noise reduction 28.1 Climate control* 24.1Seat comfort 24.9 Machines appearance 24.0Cab dimensions, interior space, ingress and egress* 22.3Noise reduction* 21.9View 21.9Adjustability of seat and controls* 21.0Reliability 20.9Aspects marked by* are rated by signicantly more operators of newer machinery (less than 4 years old) as good or very good compared tomachines older machinery (4 years or more).Fig.6. Aspects which need improvement according to excavator andwheel loader operators.L.F.M. Kuijt-Evers et al. / Applied Ergonomics 34 (2003) 265271 2694. DiscussionThe aim of the current study was to nd aspectsmentioned by wheel loader and excavator operatorswhich can be used to improve the comfort of vehicleinteriors in future. In order to nd these aspects, weasked questions about three issues.*aboutcomfortofspecicaspectsofthecab(ratingona four-point scale);*about aspects necessary to improve the cab comfort(open question);*about aspects important to work well withthemachine (open question).Excavator and wheel loader operators mentionedimproved seat comfort, climate control and accessoriesas ways to increase cab comfort. Excavator operatorsalso mentioned cab design (including dimensions,ingress/egress). These aspects were also rated asaverage/poor by more than 20% of the operators(except accessories because this was not an item in thesecond part of the questionnaire). Other aspects whichcan be taken into account withcab design are thosewhich operators mention as most important aspects towork well with the machine. Especially when theseaspects are also rated as average/poor by more than20% of the operators, they need special attention.Improving these aspects have priority in designing amore comfortable cab.In our study, we collected our data among visitors tothe Bauma exhibition in 2001. The advantage of thiscollection method is that it is possible to reach a largegroup of operators within a short period of time, at thesame time getting a large response, which wouldnormally be very difcult. A disadvantage might bethat the vast majority of respondents were Germanwhichcouldmeanthattheresultshavealimitedvalidityamong operators in other countries. The Germanoperators may have other ideas about cab comfort thanoperators,whoworkinothercountries.Thedemandsofthe operators on their machine depend on the workingenvironment (e.g., climate, landscape, dust) and theirtasks (e.g., driving off road, driving on the main road),which can be different between countries. Besides, theoperators based their opinion on their current machine.It is possible that in Germany certain brands areoverrepresented compared to other countries and thatthe operators opinion might vary according to thebrand. The most common brands would thereforeinuence the results of our study as many operatorsuse one of these machines (Excavators: brand A 22.6%,brandB22.2%;Wheelloaders:brandA21.3%,brandB18%, brand C 11.5%).Since we used a short questionnaire to collect thedata, no detailed information could be asked. The goalof our study was to get a global view on the operatorsopinion. The open questions gave the operators theopportunity to think open-minded which may rendervaluable information. Open questions are less suitablefor data analysis, because we needed to categorizeanswers. Inevitably information is lost in this process,but the goal of obtaining a global view was neverthelessachieved.Our results show that seat comfort, climate control,accessories (for wheel loaders and excavators) and cabdesign (including dimensions, ingress/egress), view, andreliability (for excavators only) are the aspects whichcan improve cab comfort. All these aspects are ratedaverage/poorbymorethan 20%oftheoperatorsandthey are also mentioned as aspects which need improve-ment in order to increase cab comfort. In our opiniondesigners should give priority to these items whenredesigning cabs. It is interesting that operators didnot mention vibration as an aspect which can improvecomfort, as it was ranked high on the list of machineparts rated average/poor. Besides, whole body vibra-tionisaserioushealthhazard(Houtmanetal.,2001).Itis possible that the operators did not mention vibrationbecause they may see vibration as an engine property oran inevitable consequence of working on earthmovingequipment.Operatorsmighthavetheideathatvibrationcannot be reduced by redesigning only the cab. It is,however, unclear why operators did not mentionvibration.When comparing excavators and wheel loaders,improving seat comfort is an issue for bothwheelloaders and excavators. Although seat comfort inexcavators has been improved during recent years (seeTable 1), improvements are still necessary. However,thisisnoteasyassittingcomfortdependsonmanyotherfactors more or less related to seat design: e.g.,adjustability of seat and controls, vibration and damp-ing, and view. For example, a bad view from the cabincan result in awkward body postures, which reducescomfort in spite of a comfortable seat.Beyond the common aspect seat comfort, manydifferences exist between wheel loaders and excavators.One difference we found between the excavator and theTable 3Aspects considered most important to work well with the machineaccording to wheel loader and excavator operatorsWheel loaders ExcavatorsAspect Responses(%)Aspect Responses(%)Machinesperformance40.3 Machinesperformance37.0View 12.5 Reliability 14.6Reliability 11.8 View 11.5Operability 11.1The aspects noted in more than 10% of the answers are presented.L.F.M. Kuijt-Evers et al. / Applied Ergonomics 34 (2003) 265271270wheel loader was that excavator cab design (inc

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号