资源目录

压缩包内文档预览:(预览前5页/共19页)

编号:10048698

类型:共享资源

大小:1.85MB

格式:RAR

上传时间:2018-04-23

上传人:柒哥

认证信息

个人认证

杨**(实名认证)

湖南

IP属地:湖南

28

积分

- 关 键 词:

-

jhb

型回柱

绞车

设计

说明书

仿单

cad

- 资源描述:

-

- 内容简介:

-

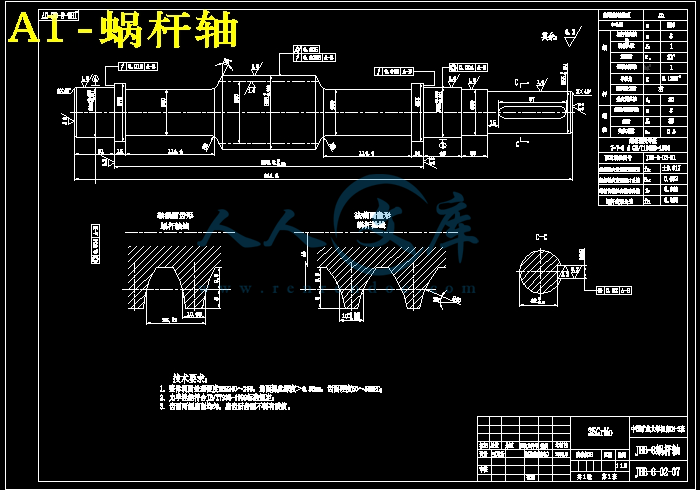

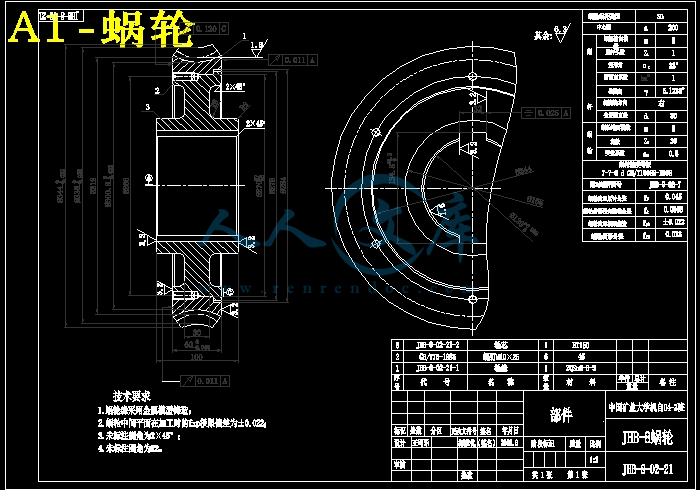

中国矿业大学2008届本科生毕业设计第1页翻译部分英文原文中国矿业大学2008届本科生毕业设计第2页PARAMETRICSTUDYOFDYNAMICSOFWORMANDWORMGEARSETUNDERSUDDENLYAPPLIEDROTATINGANGLEMYCHUNG,DSHAWDEPARTMENTOFPOWERMECHANICALENGINEERING,NATIONALTSINGHUAUNIVERSITY,NO101KUNGFUROADSECTIONII,HSINCHU,TAIWAN,ROCRECEIVED13SEPTEMBER2006RECEIVEDINREVISEDFORM23JANUARY2007ACCEPTED25FEBRUARY2007AVAILABLEONLINE17APRIL2007ABSTRACTTHEDYNAMICSOFAWORMGEARSETUNDERINSTANTLYAPPLIEDROTATINGANGLEAREAFFECTEDBYSEVERALFACTORSINCLUDINGTHEFRICTIONFORCEANDELASTICDEFORMATIONOFTHESURFACEBETWEENGEARTEETHITISFOUNDTHATTHOSEFACTORSCAUSEANONNEGLIGIBLEROTATIONALPOSITIONINGERRORTHEGOALSOFTHISSTUDYARETO1SETUPAMATHEMATICMODEL,2CARRYOUTANUMERICALSIMULATION,AND3CARRYOUTANEXPERIMENTANDCOMPAREITWITHTHENUMERICALRESULTSTHEEXPERIMENTSANDNUMERICALRESULTSHAVEVERYGOODAGREEMENTINTHISRESEARCH,THEMOMENTINERTIAOFFLYWHEEL,FRICTION,RIGIDITYOFSHAFTANDRIGIDITYOFGEARTOOTHAREALSOSTUDIEDTHERESULTSCANBEUSEDASERRORESTIMATIONSOFRELEVANTANGLES,ANGULARSPEEDANDANGULARACCELERATIONUNDERASUDDENLYAPPLIEDROTATIONALANGLE,ANDAREUSEFULFORESTABLISHINGTHEERRORCOMPENSATIONREQUIREDFORPOSITIONCONTROL1INTRODUCTIONWHENRADARTRACKSANAIRCRAFTWHICHTURNSATASHARPANGLETHERADARMAYNOTBEABLETOLOCKONTOTHETARGETDUETOTHESMALLOSCILLATIONOFTHEANTENNASOMETIMES,THEOSCILLATIONEVENCAUSESAFAILUREOFTHERADARSYSTEMACCURATEPOSITIONINGISACRUCIALSUBJECTINATRACKINGSYSTEMHOWEVER,DUETOTHEDESIGNOFTHETRACKINGTRANSMISSIONMECHANISMISRESTRICTEDBYBOTHSPACEANDWEIGHT,中国矿业大学2008届本科生毕业设计第3页THEVOLUMEANDTHEWEIGHTOFTHETRANSMISSIONMECHANISMMUSTBELIMITEDTHEWORMGEARSETISAGOODCHOICEDUETOITSSMALLVOLUMEANDHIGHREDUCTIONRATIOOWINGTOTHEOSCILLATIONOFTHEANTENNAISANIMPORTANTDYNAMICSBEHAVIORFORHIGHPRECISIONPOSITIONINGOFRADARSYSTEM,THEDYNAMICSOFAWORMGEARSETUNDERINSTANTLYAPPLIEDLARGETORQUEISVERYIMPORTANTTOUNDERSTANDTHISBEHAVIORTHISBEHAVIORISAFFECTEDBYSEVERALFACTORSINCLUDINGTHEFRICTIONFORCEANDELASTICDEFORMATIONOFTHESURFACEBETWEENGEARTEETHTOUNDERSTANDTHEEFFECTOFTHOSEFACTORS,ALOTOFRESEARCHHASBEENCONDUCTEDYUKSELANDKAHRAMAN1STUDIEDTHEINUENCEOFSURFACEWEARONTHEDYNAMICBEHAVIOROFATYPICALPLANETARYGEARSETTHEWEARMODELEMPLOYEDAQUASISTATICGEARCONTACTMODELTOCOMPUTECONTACTPRESSURESANDARCHARDSWEARMODELTODETERMINETHEWEARDEPTHDISTRIBUTIONSPARKERETAL2ANALYZEDTHEDYNAMICRESPONSEOFASPURPAIROFAWIDERANGEOFOPERATINGSPEEDSANDTORQUESCOMPARISONSWEREMADETOOTHERRESEARCHERSPUBLISHEDEXPERIMENTSTHATREVEALCOMPLEXNONLINEARPHENOMENATHEDYNAMICRESPONSEOFASPURPAIRWASINVESTIGATEDUSINGANITEELEMENT/CONTACTMECHANICSMODELTHATOFFERSSIGNICANTADVANTAGESFORDYNAMICGEARANALYSESMALIHA3CREATEDANONLINEARDYNAMICMODELOFASPURGEARPAIR,WHICHWASCOUPLEDWITHLINEARNITEELEMENTMODELSOFTHESHAFTSCARRYINGTHEM,ANDWITHDISCRETEMODELSOFBEARINGSANDDISKSTHEEXCITATIONSCONSIDEREDINTHEMODELWEREEXTERNALSTATICTORQUEANDINTERNALEXCITATIONCAUSEDBYMESHSTIFFNESSVARIATION,GEARERRORSANDGEARTOOTHPROLEMODICATIONBRITTON4PRODUCEDASUPERNISHEDGEARTEETHWITHAAPPROXIMATELY005MMRAFILMANDTHEFRICTIONTRACTIONINTHEEXPERIMENTSWERESIMULATEDTHEORETICALLYUSINGATHINLMNONNEWTONIANMICROELASTOHYDRODYNAMICLUBRICATIONSOLVERANDENCOURAGINGAGREEMENTBETWEENFRICTIONMEASUREMENTSANDTHEORETICALPREDICTIONSWASOBTAINEDKONG5PREDICTEDELASTICCONTACTANDELASTOHYDRODYNAMICLMTHICKNESSINWORMGEARSUSINGTHEUNDEFORMEDGEOMETRYOFTHEGAPBETWEENGEARTEETHINCONTACTATHREEDIMENSIONALELASTICCONTACTSIMULATIONTECHNIQUEHADBEENDEVELOPEDFORCALCULATIONOFTHETRUEAREAOFELASTICCONTACTUNDERLOADRELATIVETHEWHEELANDWORMSURFACESTUTTLE6STUDIEDTHEHARMONICDRIVES,WHICHEXHIBITEDVERY中国矿业大学2008届本科生毕业设计第4页NONLINEARDYNAMICBEHAVIOR,INHISMODELNOTONLYDYNAMICMODELSINCLUDEACCURATEREPRESENTATIONOFTRANSMISSIONFRICTION,COMPLIANCEANDKINEMATICALERRORWEREUNDERSTAND,BUTALSOIMPORTANTFEATURESOFHARMONICDRIVEGEARTOOTHGEOMETRYANDINTERACTIONEXPERIMENTALOBSERVATIONSWEREUSEDTOGUIDETHEDEVELOPMENTOFAMODELTODESCRIBEHARMONICDRIVEOPERATIONITISIMPORTANTTOBEAWARETHATWORMGEARPERFORMANCEISINUENCEDBYTHELUBRICANTAPPLIEDANDMAINTAINEDHELOUVRY7DISCUSSEDTHEISSUEOFTHESERVOORIENTATIONCONTROLBEINGAFFECTEDBYASURGEOFBOTHMAXIMUMSTATICFRICTIONFORCEANDDYNAMICFRICTIONFORCETHEYREPORTEDTHEOCCURRENCEOFASTABLEPOSITIONINGERROR,ASWELLASTHESTOPPINGORSTOKINGDURINGTRACKINGATTHETURNINGPOINTOFALIMITINGLOOPOFTHETRACKINGSYSTEMWHENTHESYSTEMWASINAONEDIRECTIONALLOWSPEEDTRACKING,ITWASPOSSIBLEFORTHESTICKSLIPPHENOMENONTOOCCURDUETOTHEFACTTHATTHEFRICTIONALFORCETOVELOCITYCURVEAPPEARSTOBEANEGATIVESLOPEANDINUENCESTHESTATICFRICTIONFORCEITWASALSOFOUNDTHATASIMILARPHENOMENONOCCURSATHIGHSPEEDTRACKINGDOUPONT8PROPOSEDAFRICTIONALFORCEMODELWITHNEGATIVESLOPEINTHEREFERENCE,RELATIVEMOTIONFROMSTATICTOHIGHSPEEDSLIDINGWASDIVIDEDINTOFOURSTAGESINTHERSTSTAGE,THEEXTERNALFORCEWASLESSTHANTHEMAXIMUMSTATICFRICTIONFORCEINTHESECONDSTAGE,TWOCONTACTINGSURFACESSTARTEDTODEVELOPASMALLRELATIVEVELOCITYINTHETHIRDSTAGE,THERELATIVEVELOCITYSTARTEDTOINCREASEBETWEENTWOOBJECTS,ANDLUBRICANTGOTINTOTHECONTACTAREAANDDECREASEDTHEFRICTIONALFORCEINTHEFOURTHSTAGE,THELUBRICANTHADFULLYLLEDTHECONTACTAREA,ANDTHEVISCOUSCHARACTERISTICANDTHEFRICTIONALFORCEINCREASEDWITHTHEVELOCITYOGURIDESIGNHANDBOOK9INCLUDEDSEVERALEMPIRICALCHARTSANDCALCULATIONFORMULAEOFTHEFRICTIONCOEFCIENTVSSLIDINGVELOCITY,THEALLOWABLEERROROFMANUFACTURING,THERECOMMENDEDVALUEFORTHEGAPSBETWEENTWOTEETH,ANDTHEALLOWABLECONTACTPRESSURESHIGLEY10DISCUSSEDTHEWORMSPITCHCIRCLELINEVELOCITYASWELLASTHETRANSMISSIONFRICTIONALCOEFCIENTINTHISSTUDY,ONLYTHEFRICTIONFORCEANDELASTICDEFORMATIONOFTHESURFACEBETWEENGEARTEETHAREINTERESTEDTHEZKTYPEWORMGEARSETISUSEDTOELIMINATETHEBACKLASHPREVIOUSRESEARCHWORKSONGEARSANDGEARSETSWEREFOCUSEDONTHELIMITINGLOADING,PRESSUREDISTRIBUTIONANDALLOWABLEPRESSURE中国矿业大学2008届本科生毕业设计第5页LOADINGOFGEARS,ANDONTHERELATIONSHIPBETWEENFRICTIONCOEFCIENTANDSLIDINGVELOCITYMOSTINVESTIGATIONSAREBASEONTHEASSUMPTIONTHATTHETOOTHISRIGIDTHISSTUDYISFOCUSEDONTHEEFFECTSOFTHEELASTICDEFORMATIONOFTHEGEARTOOTHSURFACEANDTHENONLINEARFRICTIONCOEFCIENTONTHESYSTEMDYNAMICSTOSTUDYTHEDYNAMICSOFTHEWORMGEARSET,ADYNAMICMODELOFTHEWORMGEARSETISDEVELOPEDANDTHECOMPARISONBETWEENTHEEXPERIMENTALRESULTSANDTHENUMERICALRESULTSISALSOSTUDIEDTHEPARAMETERSOFTHEDYNAMICMODELAREADJUSTEDBYTHENDINGSOFTHECOMPARISONOFTHEANALYSISANDTHEEXPERIMENTFINALLY,THEEFFECTSOFMOMENTINERTIAOFYWHEEL,FRICTION,RIGIDITYOFSHAFTANDRIGIDITYOFGEARTOOTHONTHENONLINEARBEHAVIOROFTHETRANSMISSIONMECHANISMAREALSOSTUDIED2THEDYNAMICMODELSOFTHEWORMGEARSET21THEEQUILIBRIUMEQUATIONSOFTHEWORMANDWORMGEARSETTHEGEOMETRICOFWORMGEARSETISSHOWNINFIG1THEREAREAWORM,AWORMGEAR,TWOSHAFTS,FOURBEARINGSANDAYWHEELTHESHAFTOFWORMISDRIVENBYANANGLEY1THEROTATIONALANGLEOFTHEYWHEELISY4THEROTATIONALANGLEOFTHEWORMSBODYISY2DUETOTHEELASTICDEFORMATIONOFTHEWORMSHAFTY16Y2THEROTATIONANGLEOFWORMGEARBODYISY3THEMOMENTOFINERTIAOFTHEWORMISJWTHEPITCHRADIUSOFTHEWORMSHELICALTOOTHISRWTHEWORMSROTATIONALINERTIAASARIGIDBODYISJGTHEPITCHRADIUSOFTHEWORMGEARISRGTHEMOMENTINERTIAOFTHEYWHEELISJ4INTHISSTUDY,TONEGLECTTHEEFFECTOFBACKLASH,ZKTYPEWORMANDWORMGEARAREUSEDBOTHINANALYSISANDEXPERIMENTTOSIMPLIFYTHETHEORETICALMODEL,THEBASICASSUMPTIONSARELISTEDASFOLLOWS1THEYWHEELISRIGID2THEWORMSANDWORMGEARTEETHAREELASTIC3THEBODYOFTHEWORMGEARISRIGID中国矿业大学2008届本科生毕业设计第6页4WORMANDWORMGEARAREPERPENDICULARTOEACHOTHER5THECLEARANCEBETWEENTEETHISIGNORED6NOERRORONTHEGEARTOOTHPROLE7THEWORMISSINGLETHREAD8THEWORMSHAFTANDWORMGEARSHAFTARETWOROTATIONALSPRINGTHEDYNAMICBEHAVIORISNEGLECTED9TRANSLATIONALDEGREEOFFREEDOMFORALLTHEELEMENTSISNOTCONSIDERED10ONLYFRICTIONISCONSIDERED,NOOTHERDAMPINGEFFECTISCONSIDERED22THEAXIALSPRINGCONSTANTOFBEARINGS,WORMSHAFTANDWORMGEARSHAFTTHERESULTSOFEXPERIMENTTONDTHERELATIONBETWEENLOADANDTHEAXIALDISPLACEMENTOFBEARINGARESHOWNINFIG2THEAXIALSPRINGCONSTANTOFWORMBEARINGKBTWSANDWORMGEARBEARINGKBTGSAREOBTAINEDBYUSINGFIG2FURTHERMORE,KLWSANDKBTWSCANBETREATASTWOSERIESCONNECTEDSPRINGASWELLASKLGSANDKBTGSCANALSOBETREATASTWOSERIESCONNECTEDSPRINGTHEREFORE,KWSCANBEEXPRESSEDINTERMSOFKLWSWITHKBTWSANDKGSCANALSOBEEXPRESSEDINTERMSOFKLGSWITHKBTGSTHEEQUATIONSARELISTEDASFOLLOWINGLWSBTSSGSGSLBTSK中国矿业大学2008届本科生毕业设计第7页FIG1GEOMETRICOFWORMANDWORMGEAR23THEFRICTIONCOEFFICIENTOFCONTACTGEARTEETHTHERELATIVEMOTIONBETWEENWORMTEETHANDWORMGEARTEETHISCONSIDEREDPURESLIDING,SOTHEFRICTIONPLAYSANIMPORTANTROLEONTHEPERFORMANCEOFWORMGEARSETTHEEFCIENCYOFGEARSETISDIRECTLYAFFECTEDBYTHECOEFCIENTOFFRICTIONTHECOEFCIENTOFFRICTIONISINUENCEDBYTHESURFACESLIDINGSPEEDOFTHEBOTHTEETHTHEFRICTIONISREDUCEDASTHERELATIVESLIDINGVELOCITYINCREASESNOFORMULAECANBEUSEDTOCALCULATETHEFRICTIONCOEFCIENTPRECISELYINTHISSTUDY,THEFORMULAISBASEDONTHESLIDINGVELOCITYOFTHEMEANWORMDIAMETER8,9,1805236723,047130549EINABOVEFORMULA,NTHERELATIVESLIDINGVELOCITYOFTHEMEANWORMDIAMETER中国矿业大学2008届本科生毕业设计第8页,THERELATIVEIANGULARVELOCITYOFTHEMEANWORMDIAMETERANDRWWTHEPITCHRADIUSOFTHEWORMSHELICALTOOTHFIG2THERELATIONOFAXIALDIRECTIONDISPLACEMENTSOFBEARINGANDAXIALLOADS3EXPERIMENTALSETUPEXPERIMENTALSETUPISSHOWNINFIG3ANDTHESPECICATIONSOFTHEWORMGEARSETARELISTEDINTABLE1THEZKTYPEWORMGEARSETWASUSEDTOELIMINATETHEBACKLASHTHEREDUCTIONRATIOOFGEARSETIS156ANDTHEMODULEOFGEARIS2INFIG3,ACOMPUMOTORSSTEPPINGMOTOR,MODELNOOEM5783,WITHRESOLUTIONOF1000STEPS/REV0361/STEPWASUSEDTODRIVETHEWORMSHAFTANACCELEROMETERKS77POSITIONEDONTHEUPPERLOCATIONOFTHEWORMGEARSHAFTWASUSEDTOMEASURETHEANGLEACCELERATIONOFY2ANDY4THEANGLEDISPLACEMENTOFY2ANDY4AREOBTAINEDBYINTEGRATEDTHEMEASUREDANGULARACCELERATIONTWICETHENIUSB6009DAQSYSTEMEQUIPPEDWITHLABVIEWSOFTWAREWASEMPLOYEDTOPICKANDFETCHTHEVOLTAGEDATAFROMACCELEROMETERATTHEBEGINNINGOFTHEEXPERIMENT,THESYSTEMWASSETATRESTCONDITIONTHESAMPLINGRATEOFDATAACQUISITIONWAS25_10_6SWHENTHEEXPERIMENTSTARTED,THEMOTORWASACCELERATEDTOITSMAXIMUMSPEEDALONGTHEWORMAXISFOLLOWINGTHEREQUIREDACCELERATIONCURVE,THENSTOPAFTERTHEINPUTANGLE中国矿业大学2008届本科生毕业设计第9页REACHESY1Y101130973RAD,18STEPSTHEDATAACQUISITIONSYSTEMRECORDEDTHEACCELERATIONOFTHEACCELEROMETERWHICHATTACHEDONTHEBARENDOFWORMANDGEARTHEANGULARACCELERATIONCANBECALCULATEDFROMACCELERATIONBYUSINGGEOMETRICRELATIONFIG3THEEXPERIMENTDEVICEOFWORMGEARSETTABLE1SPECICATIONSOFWORMGEARSETMODULUSM2中国矿业大学2008届本科生毕业设计第10页31EXPERIMENTALRESULTSTHEMEASUREMENTRESULTSOFTHEWORMANGLEACCELERATIONY2CURVEANDTHEYWHEELOFTHEWORMGEARAXISY4CURVEARESHOWNINFIG4THEACCELERATIONOSCILLATESBETWEENTHEZEROLINETHEANGULARACCELERATIONOFY_2ANDY_4AREINTEGRATEDTWICETOGETANGULARDISPLACEMENT,WHICHISSHOWNINFIG5中国矿业大学2008届本科生毕业设计第11页FIG4THEMEASUREDRESULTSAANGULARACCELERATIONY2ANDBANGULARACCELERATIONY4FIG5THEANGULARDISPLACEMENTOBTAINEDBYINTEGRATINGTHEACCELERATIONTWICEAANGLEY2ANDBANGLEY44CONCLUSIONSINTHISSTUDY,THEDYNAMICEQUILIBRIUMEQUATIONSOFWORMGEARSETCONSIDERINGTHERIGIDITYOFTHETOOTHWEREDEVELOPEDTHEANALYZEDRESULTSWERECOMPAREDWITHTHEMEASUREDDATATHECOMPARISONSHOWSTHATTHEMATHEMATICSMODELISREASONABLECORRECTTHEINUENCEOFMOMENTINERTIA,FRICTION,RIGIDITYSHAFTANDRIGIDITYGEARTOOTHWEREALSOSTUDIEDTHEPARAMETERSSTUDYHASFOLLOWINGCONCLUSIONS1THEDIAMETEROFTHEYWHEELISREDUCEDGRADUALLY,THEAMPLITUDEOFOSCILLATINGREDUCEDGRADUALLY2THELARGERTHEMODULEOFGEAR,THEHIGHERTHEMAXIMUMAMPLITUDEOFANGLESY2ANDY43MOSTOSCILLATIONOFY2COMESFROMWORMSHAFT,NOTFROMGEARTOOTHASTOTHE中国矿业大学2008届本科生毕业设计第12页OSCILLATINGOFY4,THEEFFECTOFTHERIGIDITYOFTHESHAFTISNOTIMPORTANT4THEEFFECTOFTHERIGIDITYOFTHEGEARTOOTHOFTHEWORMISNOTASMUCHASTHATOFWORMGEAR5THEEFFECTOFFRICTIONISLARGERFORY2THANTHATFORY4ABOVECONCLUSIONSINDICATETHATWHENDESIGNAWORMGEARSETFORHIGHPRECISIONPOSITIONING,THERIGIDITYOFTHEWORMGEARISVERYIMPORTANT,THATTHEMATERIALOFTHEWORMGEARSHOULDBEUSEDMORERIGIDMATERIALTHANTHATOFTHEWORM中国矿业大学2008届本科生毕业设计第13页中文译文应用参数动力学研究蜗杆与蜗轮的旋转角度清华大学电力机械工程系摘要应用于旋转角度的动态蜗轮订下瞬间是受多种因素的影响包括摩擦力和轮齿表面之间的弹性变形结果发现,这些因素造成了不可忽略的转动定位误差本研究的目的是1建立一个数学模型,2进行数值模拟,3进行实验并与数值计算的结果作比较实验结果和实际数值是一致的在这项研究中,飞轮的惯性,摩擦力,刚性轴和轮齿的刚度也被研究结果,可作为误差估计应用于旋转角度的相关的角度,角速度和角加速度,并且用于建立误差补偿所需的位置控制1概述当采用雷达跟踪正以快速角度旋转的飞机时,该雷达可能由于小振荡的天线无法到达锁定目标,有时,振荡甚至导致失败的雷达系统在跟踪系统中,准确定位是一个至关重要的问题然而,由于跟踪传导机制的设计受到空间和重量,体积和重量限制蜗杆齿轮集是一个很好的选择,因为它具有小体积和高还原度的特点由于高的精度定位雷达系统振动天线是一个重要的动力学表现,要理解这种表现应用于大扭矩的动态蜗轮订下瞬间是非常重要的此表现是受若干因素影响,包括摩擦力和轮齿表面之间的弹性变形为了了解这些因素的影响,大量的研究工作已进行了YUKSEL和KAHRAMAN1研究有关一个典型行星齿轮的动态特性表面磨损的影响。磨损模型采用了准静态齿轮接触模型计算接触压力,并结合ARCHARD磨损模型来确定磨损深度的分布等2分析了大范围的运行速度和力矩的动态响应。并比较了其他研究者发表的揭示复杂的非线性现象实验,通过调查采用铌元/接触力学模型的动态响应,提供了大量的科学的齿轮动态分析3MALIHA创造了有关直齿圆柱齿轮的非线性动力学模型,这是加上线性铌元素模型的轴向载荷,与离散型号的轴承和软盘考虑在模型中的外部静扭矩和内部激励引起的刚度变化,齿轮误差和间隙占374。4BRITTON制作一个超级的全齿大约005毫米,在摩擦牵引实验中理论上用薄镑非牛顿微润滑求解和鼓励协定之间的摩擦和测量理论预测得到5预策弹性接触和蜗杆用几何之间的差距齿接触三维弹性接触仿真技术。已研制出相对轮齿表面计算的真实面积弹性接触负荷6研究谐波传动,具有相当的非线性动力学体现,在他设中国矿业大学2008届本科生毕业设计第14页计的模型中,不仅动态模型包括精准有意义的摩擦传动,间隙和运动学误差的理解。更重要的特点是,谐波传动齿轮齿面几何与互动实验观察是用来指导发展的一个模型来描述谐波传动运行更重要的是了解蜗轮在选择润滑剂应用和保养方面7讨论了受最大静摩擦力和动摩擦力两者的动态伺服定位控制受他们在报告中说发生了稳定的定位误差,以及停车状态,在跟踪时的转折点限制回路中的跟踪制度当系统以单方向的低速跟踪时,这是可以做到的粘滑现象发生,事实上,由于摩擦力的速度曲线,似乎是一个负斜率的静摩擦力同时,还发现了类似的现象发生在高速跟踪中。8提出了有关摩擦力的负斜率。在参考中,相对运动,从静态到高速滑动被分为四个阶段在启始阶段中,外力小于最大静摩擦力在第二阶段,两个接触表面开始发生一个小的相对速度。在第三阶段,开始增加两物体的相对速度,润滑剂进入两者的接触面积,目的是降低摩擦力。在第四阶段,润滑油已电弧的接触面积,粘性特性和摩擦力来增加速度。9包括几个实证图表和计算公式中的摩擦系数与滑动速度,允许误差产生在两个轮齿之间的差距中,同时也允许接触压力的产生。10讨论了齿轮的节圆线速度以及传输摩擦系数。在这项研究中,只有两齿表面之间的摩擦力和弹力的变化是重要的,一般的ZK型蜗轮集是用来消除反弹力的。在以往的研究工程中,齿轮和齿轮套均集中极限承载,在压力分布和压力允许中装载齿轮,并且影响到两者的摩擦系数和滑动速度。在大多数调查中假定轮齿之间的相对滑动速度是不变的。这项研究中着重考察了弹性变形的齿面和系统动力学非线性摩擦。在发达国家中研究动态的蜗轮集和动态模型的蜗轮集现在越来越广泛。在实际值和测量值之间进行了大量的实验。最后,探讨了矩惯性轮齿摩擦,刚性轴和刚度齿的非线性特性的传输机制进行了研究。2蜗轮的动态模型21蜗杆与蜗轮集的平衡方程几何蜗轮载列于图1有蜗杆,蜗轮,两轴,四轴承和一个轮齿,轴蜗杆驱动的角度的Y1。旋转角度的旋转角度的本体Y2由于弹性变形的蜗杆轴Y16组。转角蜗轮传动机构是扭矩和惯性矩。圆形半径的斜齿是DVDRW的他的

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号