资源目录

压缩包内文档预览:(预览前15页/共20页)

编号:10048986

类型:共享资源

大小:2.19MB

格式:RAR

上传时间:2018-04-23

上传人:柒哥

认证信息

个人认证

杨**(实名认证)

湖南

IP属地:湖南

28

积分

- 关 键 词:

-

led

光柱

注塑

模具设计

说明书

仿单

cad

- 资源描述:

-

【温馨提示】 购买原稿文件请充值后自助下载。

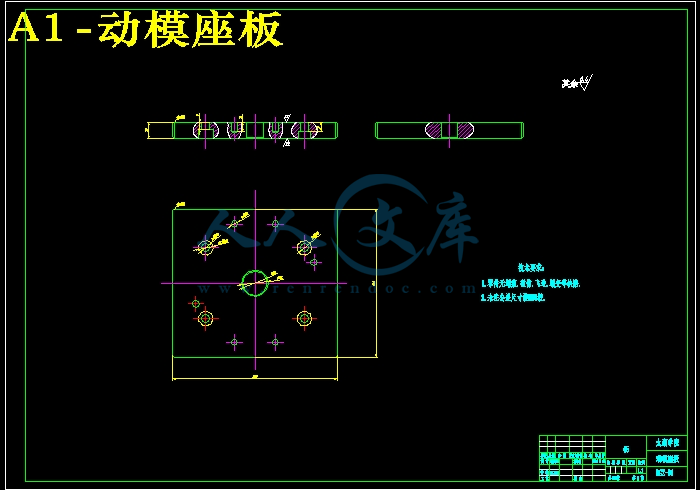

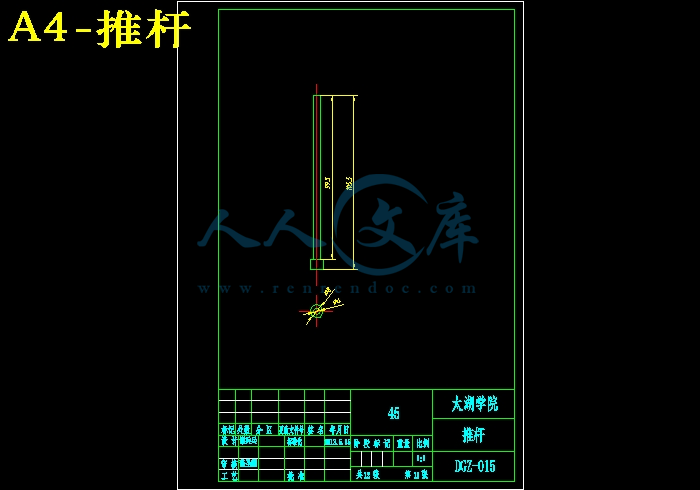

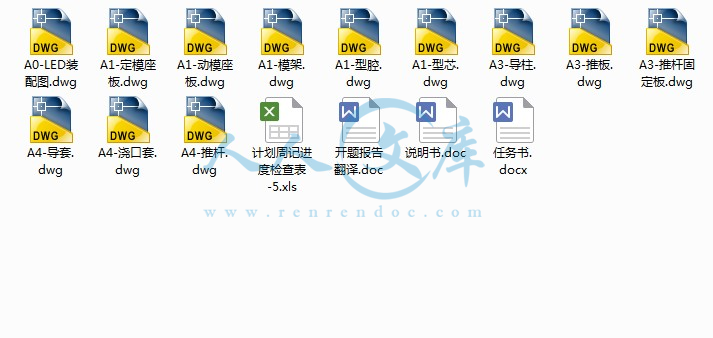

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得,所见即所得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:12401814

- 内容简介:

-

编号无锡太湖学院毕业设计(论文)相关资料题目LED导光柱注塑模具设计信机系模具设计与制造专业学号0923259学生姓名谢兵兵指导教师范圣耀(职称副教授)(职称)2013年5月25日目录一、毕业设计(论文)开题报告二、毕业设计(论文)外文资料翻译及原文三、学生“毕业论文(论文)计划、进度、检查及落实表”四、实习鉴定表无锡太湖学院毕业设计(论文)开题报告题目LED导光柱注塑模具设计信机系模具设计与制造专业学号0923259学生姓名谢兵兵指导教师范圣耀(职称副教授)(职称)2012年11月25日课题来源经学校老师的介绍,我在无锡某模具厂实习,该厂大批量生产导光柱,经过几个月时间的亲身实践,我对导光柱的尺寸以及加工的流程都有了一定程度的了解,因此选择自己熟悉的产品作为毕业论文的课题是一个明智的选择。科学依据(包括课题的科学意义;国内外研究概况、水平和发展趋势;应用前景等)(1)课题科学意义塑料模具在现代生活中的地位越来越高,因此对塑料模具质量的要求也越来越高,这就要求塑料模具的开发、设计与制造的水平也必须越来越高。各种塑料模具越来越趋于微型化、精密化,其零件结构设计中的槽逢孔尺寸要求在03MM以下,尺寸精度要求越来越高。如BP机中零件尺寸极其微小,对模具的要求更高。这类微型冲件和塑件用的模具,已成为高技术模具或专利型模具。随着现代化工业和科学技术的发展,塑料模具的应用越来越广泛,其适应性也越来越强。已成为工业国家制造工艺水平的标志和独立的基础工业体系。(2)国内外研究概况、水平和发展趋势当前来看,国内塑料模具市场以注塑模具需求量最大,其中发展重点为工程塑料模具。近来我国模具工业发展迅速,前景光明。以上海为主的长三角洲地区是中国塑料模具工业最为发达的地区。目前相当多的发达国家塑料模具企业移师中国,是国内塑料模具工业迅速发展的重要原因之一。中国技术人才水平普遍提高以及平均劳动力成本低都是吸引外资的优势,这些都是塑料模具市场迅速成长的重要因素所在,所以中国塑模市场的前景一片光明。近几年来,虽然我国塑料模具无论是在数量上,还是在质量、技术和能力等方面都有了很大发展,但总体上还是与工业发达的国家相比仍有较大的差距。例如,许多先进的技术如CADCAECAM技术的普及率还不高。另外,我国塑料模具行业与其发展需要和国外先进水平相比,还存在很多方面的问题。现在应用模具CADCAM技术设计模具已较为普遍,随着通用机械CAD/CAM技术的发展,塑料注射模CAD/CAM已经不断的深化。现代模具是多学科知识集聚的高新技术产业的一部分,是国民经济的装备产业,其技术、资金与劳动相对密集。研究内容分析零件工艺用途及结构;掌握注塑模具的原理;了解注塑模具的各种结构以及各自的特点;掌握注塑模具上各个部分的作用;对于注塑模具设计,能够掌握模具中各个部分的设计原则以及合理分析各因素对设计的影响。拟采取的研究方法、技术路线、实验方案及可行性分析在毕业实习调研以及查阅有关资料的基础上,结合零件的外形及加工要求,可以先分析本课题的装配图以及各部分零件图,然后通过工艺性分析,分别进行成型部分的设计、浇注系统的设计、导向机构的设计、推出机构的设计、排气系统的设计等等,最后设计出来的制件还要通过相应的检验。研究计划及预期成果研究计划2012年11月12日2012年12月2日按照任务书要求查阅论文相关参考资料,填写毕业设计开题报告书。2012年12月3日2013年3月1日填写毕业实习报告。2013年3月4日2013年3月14日按照要求修改毕业设计开题报告。2013年3月15日2013年3月21日学习并翻译一篇与毕业设计相关的英文材料。2013年3月22日2013年4月11日注塑模具正文设计。2013年4月12日2013年4月25日绘制装配图和零件图。2013年4月26日2013年5月20日毕业论文撰写和修改工作。预期成果通过不同方案的比较,以及考虑不同因素的影响,最后确定合理的LED导光柱注塑模具设计方案,该方案能够最大程度地满足使用要求。特色或创新之处(1)适用于本厂的某生产线的优化设计;(2)在不影响加工精度的前提下最大限度的减少成本,并降低工人的劳动强度和生产成本;(3)本课题的在满足使用要求的同时,充分考虑产品的外形美观。已具备的条件和尚需解决的问题(1)设计思路已经非常明确,对注塑模具的设计流程有充分的认识;(2)通过四年的大学学习,我已经积累了一定的相关方面的经验;(3)学院图书馆收藏了许多有关专业方面的知识书籍和期刊等;(4)虽然在老师的指导下设计了相应的方案,但是依然会有某些因素没有充分考虑,另外产品能否符合人们的要求也依然未知。指导教师意见指导教师签名年月日教研室(学科组、研究所)意见教研室主任签名年月日系意见主管领导签名年月日CHINASPLASTICMOLDINDUSTRYANDITSDEVELOPMENTTRENDFIRSTCHINASPLASTICMOLDINDUSTRYCHINASINDUSTRIALPLASTICMOULDSFROMTHESTARTTONOW,AFTERMORETHANHALFACENTURY,THEREHASBEENGREATDEVELOPMENT,MOLDLEVELSHAVEBEENGREATLYENHANCEDMOULDHASBEENATLARGECANPRODUCE48INCHBIGSCREENCOLORTVMOLDEDCASEINJECTIONMOLD,65KGCAPACITYWASHINGMACHINEFULLOFPLASTICMOLDS,ASWELLASTHEOVERALLCARBUMPERSANDDASHBOARDS,ANDOTHERPLASTICMOULDPRECISIONPLASTICMOLDS,THECAMERAISCAPABLEOFPRODUCINGPLASTICMOULD,MULTICAVITYMOLDSMALLMODULUSGEARANDMOLDINGMOLDSUCHASTIANJINANDYANTAIDAYSELECTRICALCO,LTDPOLARISIKCOMANUFACTUREDMULTICAVITYMOLDVCDANDDVDGEAR,THEGEARPRODUCTIONOFSUCHSIZEPRECISIONPLASTICPARTS,COAXIAL,BEATINGREQUIREMENTSHAVEREACHEDASIMILARFOREIGNTHELEVELOFPRODUCT,BUTALSOTHEAPPLICATIONOFTHELATESTGEARDESIGNSOFTWARETOCORRECTCONTRACTIONASARESULTOFTHEMOLDINGPROFILEERRORTOTHESTANDARDINVOLUTEREQUIREMENTSPRODUCTIONCANONLY008MMTHICKNESSOFATWOCAVITYMOLDANDTHEAIRCUPDIFFICULTYOFPLASTICDOORSANDWINDOWSOUTOFHIGHMODULUS,ANDSOONMODELCAVITYINJECTIONMOLDINGMANUFACTURINGACCURACYOF002TO005MM,SURFACEROUGHNESSRA02M,MOLDQUALITY,ANDSIGNIFICANTLYINCREASELIFEEXPECTANCY,NONHARDENINGSTEELMOULDLIFEUPTO1030MILLION,HARDENINGSTEELFORMUPTO5010MILLIONTIMES,SHORTENTHEDELIVERYTIMETHANBEFORE,BUTSTILLHIGHERTHANABROADTHEPRESENTCONDITIONOFTHEPLASTICMOULDLEVELATHOMEANDABROADTHEWHOLE,CHINAPLASTICMOULDWHETHERINQUANTITY,ORINQUALITY,TECHNOLOGYANDABILITYHASMADEAGREATPROGRESS,BUTWITHTHENEEDSOFTHEDEVELOPMENTOFTHENATIONALECONOMY,THEWORLDADVANCEDLEVEL,COMPAREDTOAGAPSTILLSOMELARGE,SOPHISTICATED,COMPLEX,THELONGLIFEOFHIGHGRADEPLASTICMOULDSTILLNEEDTOIMPORTALOTOFEVERYYEARINTHETOTALAMOUNTOFDEMANDEXCEEDINGSUPPLYATTHESAMETIME,SOMECHEAPPLASTICMOLDBUTSUPPLYEXCEEDSDEMAND,MARKETCOMPETITIONISINTENSE,ANDSOMETECHNICALCONTENTISTOOHIGHMIDDLEGRADEPLASTICMOULDALSOHASTHETRENDOFSUPPLYEXCEEDSDEMANDJOININGTHEWTO,PLASTICMOLDANDDIEINDUSTRYTOBRINGHUGECHALLENGE,ATTHESAMETIMEBRINGMOREOPPORTUNITIESBECAUSEOFCHINASCHEAPPLASTICMOLDTOPRODUCTS,PRODUCTPRICEOBVIOUSADVANTAGES,SOMEEVENONLY1/5OFTHEPRICETHEFOREIGNPRODUCTONETHIRDTO,TOJOINTHEWTO,FOREIGNSIMILARPRODUCTSTODOMESTICLITTLEIMPACT,ANDCHEAPCHINESEEXPORTSOFMOULDISINCREASEINTHEHIGHPRECISIONMOULD,BEFOREJOININGTHEWTOWASMAINLYRELYONIMPORTS,JOINWTO,NOTONLYFORTHEEXQUISITEPRODUCTSIMPORTHASBROUGHTMORECONVENIENT,BUTALSOLEADTOMOREFOREIGNINVESTMENTTOCHINAFACTORY,BRINGFOREIGNADVANCEDMOULDTECHNOLOGYANDMANAGEMENTEXPERIENCE,TOCULTIVATECHINESEPROFESSIONALMOULDTALENTSTOTHEROLEINRECENTYEARS,CHINESEPLASTICMOULDMANUFACTURINGCONDITIONSHAVEIMPROVEDGREATLYLARGEPLASTICMOULDHASPRODUCEDSINGLESETOFWEIGHTCANUPTO50TONSOFINJECTIONMOLD,PRECISIONPLASTICMOULDHASREACHEDTHEACCURACYOF2M,PRECISIONPARTSHIGHSMALLMODULEGEARMOULDANDREACHTHEREQUIREMENTSOFTHEHIGHLIGHTSLEARNLAMPMOULDETCHASALSOCANPRODUCE,PLASTICMOLDCAVITYHASBEENABLETOPRODUCEAMODEOFPLASTICMOLDCAVITY7800,HIGHSPEEDMOLDPRODUCTIONSPEEDCANHAVEUPTO6M/MINABOVETHEHIGHSPEEDPLASTICDIFFERENTPROFILEEXTRUSIONDIEANDTHEDUALCHAMBERCOEXTRUSIONPROFILES,DOUBLECOLORCOEXTRUSION,SOFTHARDCOEXTRUSION,WERECROWDED,AGAINOFEXTRUSIONANDLOWFOAMINGRAWSTEELPLASTICCOEXTRUSION,ETCVARIOUSKINDSOFMOLDINTHEPRODUCTIONMEANS,MOULDENTERPRISEEQUIPMENTTONUMERICALCONTROLRATEHASINCREASEDGREATLY,CAD/CAE/CAMTECHNOLOGYHASGREATLYEXPANDEDTHEAPPLICATIONS,HIGHSPEEDPROCESSINGANDRP/RTADOPTIONOFADVANCEDTECHNOLOGIESSUCHASHASBEENMOREANDMORE,STANDARDMOULDUSINGCOVERAGEANDDIECOMMERCIALIZATIONRATEISGREATLYIMPROVED,THESHAREOFMOULDOFHOTFLOWPATHAREIMPROVEDGREATLYINADDITION,FOREIGNINVESTEDENTERPRISEVIGOROUSDEVELOPMENTOFFURTHERPROMOTEDTHEPLASTICMOULDDESIGNANDMANUFACTURELEVELANDIMPROVETHEMANAGEMENTLEVELOFENTERPRISES,SOMEENTERPRISEALREADYINFORMATIZATIONMANAGEMENTANDDIGITALNOPICMANUFACTURINGASMOULDDESIGNANDPROCESSINGENTERPRISESTORAISETHELEVELOF,MOULDMANUFACTURINGISFROMTHEPASTRELIESMAINLYONTHETRANSFORMATIONOFTHESKILLSOFFITTERMAINLYRELYONTECHNOLOGYTHISISNOTONLYTHEMEANSOFPRODUCTIONCHANGE,ANDCHANGETHEWAYOFPRODUCTIONANDTHERISEOFTHECONCEPTTHISISATRENDTHATTHESTANDARDIZATIONOFMOULDCONTINUOUSIMPROVEMENT,THEPRECISIONOFMOREANDMOREHIGH,PRODUCTIONCYCLEISMOREANDMORESHORT,FITTERPROPORTIONMOREANDMORELOW,ANDFINALLYPROMOTETHEOVERALLLEVELOFTHEDIEANDMOULDINDUSTRYISRISINGCHINAMOLDANDDIEINDUSTRYATPRESENTMORETHAN10NATIONALHIGHANDNEWTECHNOLOGYENTERPRISE,ABOUT200HIGHTECHNOLOGYANDNEWTECHNOLOGYENTERPRISEANDADAPTTOTHETREND,THEMAINPRODUCTIONMOLDBACKBONESTRENGTHFROMSKILLTALENTEDPERSONGRADUALLYINTOTECHNOLOGYTALENTSISANINEVITABLEREQUIREMENTOFCOURSE,NOWANDFORQUITEALONGTIME,ANDHIGHLYTALENTEDPERSONSTILLVERYIMPORTANT,BECAUSEAFTERALL,HARDTOGETRIDOFMOULDTOSKILLDEPENDONEXISTINGMAINPROBLEMSCHINAPLASTICMOULDINDUSTRYANDFOREIGNSTANDARDS,MAINLYEXISTINTHEFOLLOWINGQUESTIONS1THEUNBALANCEDDEVELOPMENT,PRODUCTOVERALLLEVELISLOWALTHOUGHTHEINDIVIDUALENTERPRISEPRODUCTSHASREACHEDORCOMECLOSETOTHEADVANCEDINTERNATIONALLEVEL,BUTOVERALL,THEACCURACY,THEROUGHNESSOFTHECAVITYSURFACE,PRODUCTIONCYCLE,LIFEINDEXANDINTERNATIONALADVANCEDLEVELTHEREISABIGGAPBETWEENCOMPAREDINCLUDINGPRODUCTIONMODEANDTHEOVERALLLEVELOFENTERPRISEMANAGEMENT,WITHFOREIGNINDUSTRIALDEVELOPEDCOUNTRIESTHEREARECOMPAREDFORMORETHAN10YEARSTHEGAP2PROCESSEQUIPMENTBACKWARD,ORGANIZATIONANDCOORDINATIONABILITYISPOORTHOUGHSOMEOFTHETECHNOLOGICALTRANSFORMATIONOFTHEENTERPRISEAFTERINRECENTYEARS,HASBEENMOREADVANCEDTECHNOLOGYANDEQUIPMENTLEVEL,SOMEOFTHEFOREIGNINVESTEDENTERPRISELEVELOFEQUIPMENTISNOTBEHINDABROAD,BUTMOSTOFTHEENTERPRISEPROCESSEQUIPMENTISSTILLLAGBEHINDMOREIMPORTANTLY,THEENTERPRISEORGANIZATIONCOORDINATEDABILITYISPOOR,DIFFICULTTOINTEGRATEORTRANSFEROFSOCIALRESOURCESUSE,THUSITWILLBEDIFFICULTTOUNDERTAKELARGERPROJECTS3MOSTENTERPRISEDEVELOPMENTABILITYISWEAK,THEINNOVATIONABILITYISNOTENOUGHONTHEONEHAND,LOWLEVELOFTECHNICALPERSONNELPROPORTIONISNOTQUITEHIGH,ONTHEOTHERHANDISTHESCIENTIFICDEVELOPMENTLESSINPUTMOREIMPORTANTCONCEPTSBACKWARD,INSUFFICIENTATTENTIONTOINNOVATIONANDDEVELOPMENTMOULDENTERPRISENOTONLYTOPAYATTENTIONTOTHEDEVELOPMENTOFTHEMOULD,ALSOWANTTOPAYATTENTIONTOTHEINNOVATIONOFTHEPRODUCT4SHORTTERMRELIEFTOTHECONTRADICTIONBETWEENSUPPLYANDDEMANDINRECENTYEARS,DOMESTICPLASTICSMOULDDOMESTICMARKETMEETRATEHASBEENLESSTHAN74,INCLUDINGALARGE,PRECISION,LONGLIFEMOLDMEETMORERATELOW,LESSTHAN60ESTIMATEMEANWHILE,INDUSTRIALDEVELOPEDCOUNTRIESAREACCELERATINGTHEMOULDTRANSFERRINGTOCHINA,INTERNATIONALPURCHASINGMOREANDMORE,THEINTERNATIONALMARKETHASAGOODPROSPECTTHEMARKETDEMAND,PRODUCTIONISDIFFICULTTOKEEPUPWITHDEVELOPMENTATTHATTIME,INSHORTSUPPLYSITUATIONWILLCONTINUEFORAPERIODOFTIMETHEREAREMANYREASONSWHICHCREATESTHEABOVEDISPARITY,THEMOLDLONGTERMHASNOTOBTAINEDTHEVALUEBESIDESTHEHISTORYINASTHEPRODUCTWHICHSHOULDHAVE,ASWELLASTHEMOSTSTATEOWNEDENTERPRISESMECHANISMCANNOTADAPTTHEMARKETECONOMY,BUTALSOHASTHEFOLLOWINGSEVERALREASONS1COUNTRYTOMOLDINDUSTRYPOLICYSUPPORTDYNAMICSALSOINSUFFICIENTLYALTHOUGHTHECOUNTRYALREADYWASCLEARABOUTHASPROMULGATEDTHEMOLDPROFESSIONINDUSTRIALPOLICY,BUTNECESSARYPOLICYFEW,CARRIEDOUTDYNAMICSTOBEWEAKATPRESENTENJOYEDTHEMOLDPRODUCTINCREMENTDUTYENTERPRISENATION185,THEMAJORITYENTERPRISESTILLTHETAXBURDENISONLYOVERWEIGHTTHEMOLDENTERPRISECARRIESONTHETECHNOLOGICALTRANSFORMATIONSINTRODUCTIONEQUIPMENTTOHAVETOPAYTHECONSIDERABLEAMOUNTTHETAXMONEY,AFFECTSTHETECHNOLOGYADVANCEMENT,MOREOVERPRIVATELYOPERATEDENTERPRISELOANEXTREMELYDIFFICULT2TALENTEDPERSONSERIOUSINSUFFICIENT,THESCIENTIFICRESEARCHDEVELOPMENTANDTHETECHNICALATTACKINVESTMENTTOOURINEMOLDPROFESSIONISTHETECHNOLOGY,THEFUND,THEWORKCROWDEDINDUSTRY,ALONGWITHTHETIMEPROGRESSANDTHETECHNICALDEVELOPMENT,GRASPSTHETALENTEDPERSONWHICHANDSKILLEDUTILIZESTHENEWTECHNOLOGYEXCEPTIONALLYSHORT,THEHIGHQUALITYMOLDFITTERANDTHEENTERPRISEMANAGEMENTTALENTEXTREMELYISALSOANXIOUSBECAUSETHEMOLDENTERPRISEBENEFITUNSATISFACTORYANDTAKESINSUFFICIENTLYTHESCIENTIFICRESEARCHDEVELOPMENTANDTHETECHNICALATTACK,THESCIENTIFICRESEARCHUNITANDTHEUNIVERSITIES,COLLEGESANDINSTITUTESEYESTARESATISCREATINGINCOME,CAUSESTHEMOLDPROFESSIONINVESTSTOOFEWINTHESCIENTIFICRESEARCHDEVELOPMENTANDTHETECHNICALATTACKASPECT,CAUSESTHEMOLDTECHNOLOGICALDEVELOPMENTSTEPNOTTOBEBIG,PROGRESSESNOTQUICK3THECRAFTEQUIPMENTLEVELTOBELOW,ALSONECESSARYISNOTGOOD,THEUSEFACTORLOWRECENTYEARSOURCOUNTRYENGINEBEDPROFESSIONPROGRESSEDQUICKLY,HASBEENABLETOPROVIDETHEQUITECOMPLETEPRECISIONWORKEQUIPMENT,BUTCOMPAREDWITHTHEOVERSEASEQUIPMENT,STILLHADABIGGERDISPARITYALTHOUGHTHEDOMESTICMANYENTERPRISESHAVEINTRODUCEDMANYOVERSEASADVANCEDEQUIPMENT,BUTTHEOVERALLEQUIPMENTLEVELLOWAREVERYMORETHANTHEOVERSEASMANYENTERPRISESASARESULTOFASPECTTHEANDSOONSYSTEMANDFUNDREASON,INTRODUCESTHEEQUIPMENTNOTNECESSARY,THEEQUIPMENTANDTHEAPPENDIXNOTNECESSARYPHENOMENONAREEXTREMELYCOMMON,THEEQUIPMENTUTILIZATIONRATELOWQUESTIONCANNOTOBTAINTHECOMPARATIVELYPROPERLYSOLUTIONFORALONGTIME4SPECIALIZATION,STANDARDIZATION,COMMERCIALIZEDDEGREELOW,THECOOPERATIONABILITYBECAUSERECEIVES“LARGEANDCOMPLETE“SMALLANDENTIRE“THEINFLUENCESINCELONGAGO,MOLDSPECIALIZATIONLEVELLOW,THESPECIALIZEDLABORDIVISIONISNOTCAREFUL,THECOMMERCIALIZEDDEGREEISLOWATPRESENTDOMESTICEVERYYEARPRODUCESMOLD,COMMODITYMOLDMINISTER40ABOUT,OTHERFORFROMPRODUCEUSESFORONESELFBETWEENTHEMOLDENTERPRISECOOPERATESIMPEDED,COMPLETESTHECOMPARATIVELYLARGESCALEMOLDCOMPLETETASKWITHDIFFICULTYMOLDSTANDARDIZATIONLEVELLOW,MOLDSTANDARDLETTERUSECAVERAREISLOWALSOTOTHEMOLDQUALITY,THECOSTHASAMORETREMENDOUSINFLUENCE,SPECIALLYHASVERYTREMENDOUSINFLUENCE5TOTHEMOLDMANUFACTURECYCLETHEMOLDMATERIALANDTHEMOLDCORRELATIONTECHNOLOGYFALLSTHEMOLDMATERIALPERFORMANCE,THEQUALITYANDTHEVARIETYQUESTIONOFTENCANAFFECTTHEMOLDQUALITY,THELIFEANDTHECOST,THEDOMESTICALLYPRODUCEDMOLDINGTOOLSTEELANDOVERSEASIMPORTSTHESTEELPRODUCTSTOCOMPAREHASABIGGERDISPARITYPLASTIC,PLATE,EQUIPMENTENERGYBALANCE,ALSODIRECTINFLUENCEMOLDLEVELENHANCEMENTPROCESS,THEMULTIMATERIALPLASTICMOLDINGDIE,EFFICIENTMULTICOLORINJECTIONMOULD,INSERTSEXCHANGESTRUCTUREANDCOREPULLINGSTRIPPINGTHEINNOVATIVEDESIGNHASALSOMADEGREATPROGRESSGASASSISTEDINJECTIONMOLDING,THEUSEOFMOREMATURETECHNOLOGIES,SUCHASQINGDAOHISENSECO,LTD,TIANJINFACTORYCOMMUNICATIONSANDBROADCASTINGCOMPANIES,SUCHASMOLDMANUFACTURERSSUCCEEDEDIN2934INCHTVTHICKWALLEDSHELL,ASWELLASSOMEPARTSONTHEUSEOFGASASSISTEDMOULDTECHNOLOGYSOMEMANUFACTURERSALSOUSETHECMOLDGASASSISTEDSOFTWAREANDACHIEVEDBETTERRESULTSPRESCOTT,SUCHASSHANGHAI,SUCHASTHENEWCOMPANYWILLPROVIDEUSERSWITHGASASSISTEDMOLDINGEQUIPMENTANDTECHNOLOGYBEGANPROMOTINGHOTRUNNERMOLD,ANDSOMEPLANTSUSERATEOFMORETHAN20PERCENT,THEGENERALHEATTHERMALHOTRUNNER,ORDEVICE,ASMALLNUMBEROFUNITSWITHTHEWORLDSADVANCEDLEVELOFRIGOROUSHOTRUNNERNEEDLEDEVICE,ASMALLNUMBEROFUNITSWITHWORLDADVANCEDLEVELOFRIGOROUSNEEDLEHOTRUNNERMOULDHOWEVER,THEUSEOFHOTRUNNEROVERALLRATEOFLESSTHAN10,WITHOVERSEASCOMPAREDTO5080,THEGAPLARGERINTHEMANUFACTURINGTECHNOLOGY,CAD/CAM/CAETECHNOLOGYONTHELEVELOFAPPLICATIONOFANEWLEVELTOTHEENTERPRISEFORTHEPRODUCTIONOFHOUSEHOLDAPPLIANCESREPRESENTATIVESHAVEINTRODUCEDACONSIDERABLENUMBEROFCAD/CAMSYSTEMS,SUCHASTHEUNITEDSTATESEDSUG,THEUNITEDSTATESPARAMETRICTECHNOLOGYPRO/ENGINEER,THEUNITEDSTATESCVCADS5COMPANY,THEBRITISHCOMPANYDOCT5DELTACAM,HZSSCRADEJAPAN,THECOMPANYSCIMATRONISRAEL,THEUNITEDSTATESACCTECHMOLDCOMPANYANDAUSTRALIASMPAMOLDFLOWMOLDANALYSISSOFTWARE,ANDSOONTHESESYSTEMSANDTHEINTRODUCTIONOFTHESOFTWARE,ALTHOUGHALOTOFMONEYSPENT,BUTINOURCOUNTRYDIEINDUSTRY,ANDACHIEVINGACAD/CAMINTEGRATION,ANDTOSUPPORTCAETECHNOLOGYTOFORMINGPROCESSESSUCHASMOLDINGANDCOOLING,SUCHASCOMPUTERSIMULATION,ANDACHIEVEDCERTAINTHETECHNICALANDECONOMICBENEFITS,PROMOTEANDFACILITATECHINASCAD/CAMTECHNOLOGYINRECENTYEARS,CHINASOWNDEVELOPMENTOFTHEPLASTICMOULDCAD/CAMSYSTEMHASACHIEVEDSIGNIFICANTDEVELOPMENT,THEMAINGUARANTORSOFTWAREENGINEERINGINSTITUTE,ISTHEDEVELOPMENTOFCAXA,HUAZHONGUNIVERSITYOFSCIENCEHSC50DEVELOPMENTOFTHESYSTEMANDINJECTIONMOLDCAESOFTWARE,ANDSOON,THESEDIEOFDOMESTICSOFTWAREWITHTHESPECIFICCIRCUMSTANCESINTHEAPPLICATIONOFCOMPUTERANDLOWERPRICES,ANDOTHERCHARACTERISTICS,INORDERTOFURTHERUNIVERSALCAD/CAMTECHNOLOGYHASCREATEDGOODCONDITIONSINRECENTYEARS,CHINAHASBEENMOREEXTENSIVEUSEOFSOMENEWPLASTICMOLDSTEEL,SUCHASP20,3CR2MO,PMS,SM,SM,ANDTHEQUALITYOFLIFEOFMOLDHASADIRECTSIGNIFICANTIMPACTONTHEOVERALLUSEOFTHESTILLLESSPLASTICMOULDSSTANDARDMODELPLANES,SUCHASSTANDARDPUTTERANDSPRINGHASGIVENMOREAPPLICATIONS,ANDTHEREHAVEBEENSOMEOFTHECOMMERCIALIZATIONOFDOMESTICHOTRUNNERSYSTEMCOMPONENTSHOWEVER,ATPRESENTCHINADIELEVELOFSTANDARDIZATIONANDCOMMERCIALIZATIONINTHEGENERALLEVELOFBELOW30PERCENTANDFOREIGNADVANCEDINDUSTRIALCOUNTRIESHASREACHED70PERCENTCOMPAREDTO80PERCENT,STILLALARGEGAPTABLE1,ATHOMEANDABROADPLASTICMOULDTECHNOLOGYCOMPARISONTABLEDOMESTICPROJECTSABROADCAVITYINJECTIONMODELMM002ACCURACYOF0005001005MMCAVITYSURFACEROUGHNESSRA001005MRA020MNONHARDENEDSTEELDIELIFE10TO60MILLION1030MILLIONHARDENEDSTEELDIELIFE160300MILLIONOF50100MILLIONHOTRUNNERMOULDOVERALLUTILIZATIONRATEOFMORETHAN80PERCENTLESSTHAN10PERCENTLEVELOFSTANDARDIZATIONOF7080LESSTHAN30OFMEDIUMSIZEDPLASTICMOULDPRODUCTIONCYCLEABOUTAMONTH24MONTHSINTHEMOLDINDUSTRYINTHEAMOUNTOF30TO4025TO30ACCORDINGTOTHEPARTIESCONCERNEDFORECAST,THEMARKETSOVERALLVIGOROUSMOLDISASMOOTHUPWARD,INTHENEXTDIEMARKET,THEDEVELOPMENTOFPLASTICMOULDFASTERTHANTHEOTHERDIE,DIEINTHEPROPORTIONOFINDUSTRYWILLGRADUALLYIMPROVEWITHTHECONTINUOUSDEVELOPMENTOFTHEPLASTICSINDUSTRY,PUTONTHEPLASTICMOLDGROWINGDEMANDSISANORMAL,ANDSOSOPHISTICATED,LARGESCALE,COMPLEX,LONGLIFEPLASTICMOULDDEVELOPMENTWILLBEHIGHERTHANTHEOVERALLPACEOFDEVELOPMENTATTHESAMETIME,IMPORTSINRECENTYEARSBECAUSEOFTHEMOLD,PRECISION,LARGE,COMPLEX,LONGLIFEDIEINTHEMAJORITY,THEREFORE,REDUCEIMPORTS,INCREASEGUOCHANHUALUPERSPECTIVE,INTHEMOLDOFSUCHHIGHENDMARKETSHAREWILLGRADUALLYINCREASETHERAPIDDEVELOPMENTOFTHECONSTRUCTIONINDUSTRYSOTHATTHEVARIOUSPROFILEEXTRUSIONDIE,PVCPLASTICPIPEFITTINGSDIEDIEMARKETBECOMEANEWECONOMICGROWTHPOINT,THERAPIDDEVELOPMENTOFHIGHWAYS,CARTIRESALSOPUTAHIGHERDEMAND,RADIALTIREDIE,DIEPARTICULARLYACTIVEPACEOFDEVELOPMENTWILLALSOBEHIGHERTHANTHEOVERALLAVERAGELEVELOFTHEPLASTICANDWOOD,PLASTICANDMETALTOMAKEPLASTICMOLDSINTHEAUTOMOTIVE,MOTORCYCLEINDUSTRYINTHEDEMANDFORHUGEHOUSEHOLDAPPLIANCESINDUSTRYINTHE“10THFIVEYEARPLAN“PERIODHAVEGREATERDEVELOPMENT,ESPECIALLYREFRIGERATORS,AIRCONDITIONERSANDMICROWAVEOVENS,ANDOTHERPARTSOFTHEGREATDEMANDFORPLASTICMOULDS,ANDELECTRONICSANDCOMMUNICATIONSPRODUCTS,INADDITIONTOAUDIOVIDEOPRODUCTS,SUCHASCOLORTELEVISIONS,LAPTOPCOMPUTERSANDSETTOPBOXESWILLBEGIVENAWIDERNETWORKDEVELOPMENT,WHICHAREPLASTICMOLDMARKETISTHEGROWTHPOINTSECONDTHEDIRECTIONOFTHEFUTUREMAJORDEVELOPMENTSOFCHINASPLASTICMOULDINDUSTRIAL1RRAISINGLARGE,SOPHISTICATED,COMPLEX,LONGLIFEMOLDDESIGNANDMANUFACTURINGSTANDARDSANDPROPORTIONTHISISDUETOTHEMOLDINGPLASTICMOULDPRODUCTSINCREASINGLYLARGE,COMPLEXANDHIGHPRECISIONREQUIREMENTS,ASWELLASREQUIREMENTSFORHIGHPRODUCTIVITYANDTHEDEVELOPMENTOFAMULTIMODEDUE2INTHEDESIGNANDMANUFACTUREOFPLASTICMOULDFULLYPROMOTETHEUSEOFCAD/CAM/CAETECHNOLOGYCAD/CAMTECHNOLOGYHASDEVELOPEDINTOARELATIVELYMATURETECHNOLOGYCOMMONINRECENTYEARSCAD/CAMTECHNOLOGYHARDWAREANDSOFTWAREPRICESHASBEENREDUCEDTOSMESGENERALLYACCEPTABLELEVELOFPOPULARITYFORFURTHERCREATEGOODCONDITIONSBASEDONNETWORKCAD/CAM/CAESYSTEMINTEGRATIONSTRUCTURETHEINITIALSIGNSOFEMERGING,ANDITWILLSOLVETHETRADITIONALMIXEDCAD/CAMSYSTEMCANNOTMEETTHEACTUALPRODUCTIONPROCESSREQUIREMENTSOFTHEDIVISIONOFCOLLABORATIONCAD/CAMSOFTWAREWILLGRADUALLYIMPROVEINTELLIGENCEPLASTICPARTSANDTHE3DMOLDDESIGNANDPROTOTYPINGPROCESS3DANALYSISWILLBEINOURPLASTICMOULDINDUSTRIESPLAYANINCREASINGLYIMPORTANTROLE3PROMOTETHEUSEOFHOTRUNNERTECHNOLOGY,GASASSISTEDINJECTIONMOLDINGTECHNOLOGYANDHIGHPRESSUREINJECTIONMOLDINGTECHNOLOGYUSINGHOTRUNNERMOULDTECHNOLOGYCANIMPROVETHEPRODUCTIVITYANDQUALITYOFPARTSANDPLASTICPARTSCANBESUBSTANTIALSAVINGSOFRAWMATERIALSANDENERGYCONSERVATION,EXTENSIVEAPPLICATIONOFTHISTECHNOLOGYISABIGPLASTICMOULDCHANGESHOTRUNNERCOMPONENTSFORMULATENATIONALSTANDARDS,ANDACTIVELYPRODUCECHEAPHIGHQUALITYCOMPONENTS,THEDEVELOPMENTOFHOTRUNNERMOLDISTHEKEYGASASSISTEDINJECTIONMOLDINGPRODUCTQUALITYCANBEGUARANTEEDUNDERTHEPREMISEOFSUBSTANTIALLYLOWERCOSTCURRENTLYINTHEAUTOMOTIVEANDAPPLIANCEINDUSTRIESGRADUALLYPROMOTETHEUSEOFTHECHIANGKAISHEKGASASSISTEDINJECTIONMOLDINGOFTHEORDINARYTHANTHETRADITIONALINJECTIONOFMOREPARAMETERSNEEDTOIDENTIFYANDCONTROL,ANDITSMORECOMMONLYUSEDINLARGE,COMPLEXPRODUCTS,MOLDDESIGNANDCONTROLMOREDIFFICULT,THEREFORE,THEDEVELOPMENTOFGASASSISTEDMOLDINGFLOWANALYSISSOFTWAREITSEEMSVERYIMPORTANTONTHEOTHERHANDINORDERTOENSUREPRECISIONPLASTICPARTSTOCONTINUETOSTUDYTHEDEVELOPMENTOFTE

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号