0059-缠绕式双卷筒提升机【优秀含8张CAD图+说明书+文献翻译】

收藏

资源目录

压缩包内文档预览:

编号:10073137

类型:共享资源

大小:4.21MB

格式:RAR

上传时间:2018-05-05

上传人:hon****an

认证信息

个人认证

丁**(实名认证)

江苏

IP属地:江苏

30

积分

- 关 键 词:

-

缠绕

卷筒

提升

晋升

优秀

优良

cad

说明书

仿单

文献

翻译

- 资源描述:

-

摘 要

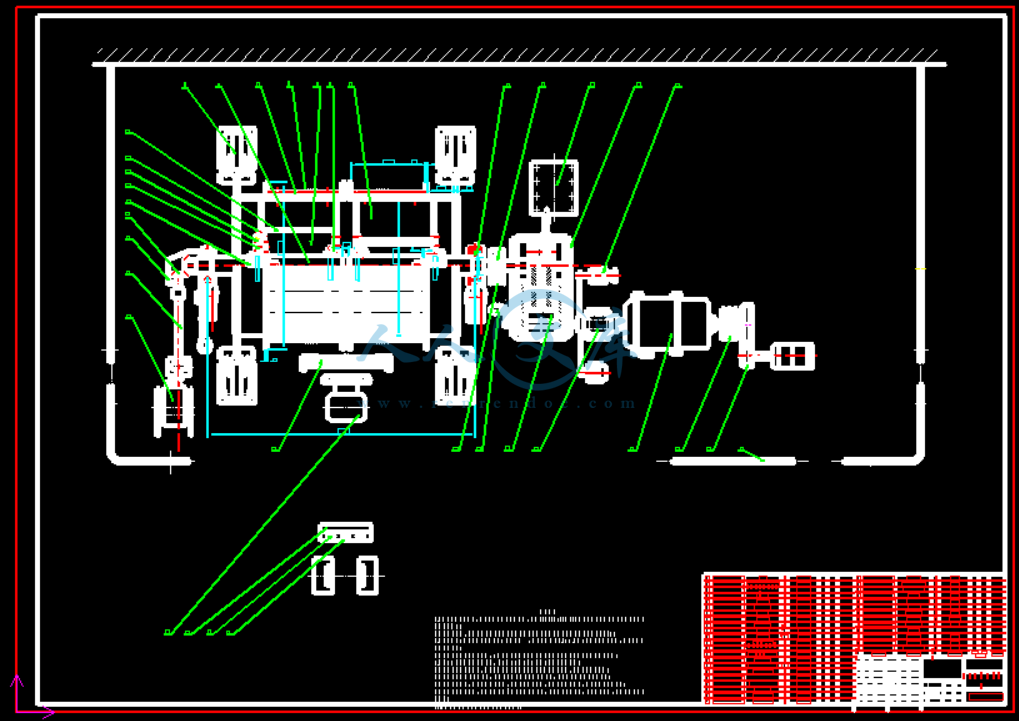

单绳缠绕式矿井提升机的工作原理:钢丝绳的一端用钢丝绳夹持固定在卷筒幅板上,另一端经卷筒的缠绕后,通过井架天轮悬挂提升容器。这样,利用主轴旋转方式的不同,将钢丝绳缠绕上或放松,以完成提升或下降容器的工作。

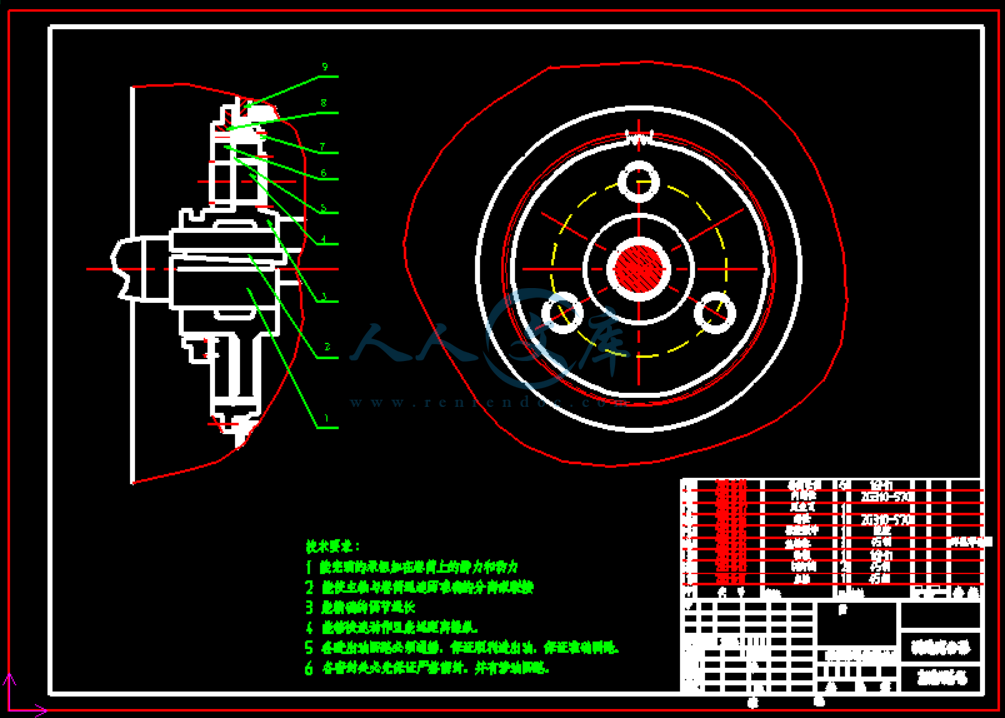

主轴装置是单绳缠绕式矿井提升机的主要工作机构,它的作用是: ①缠绕提升机钢丝绳;②承受各种正常载荷(包括固定载荷和工作载荷);③承受各种积极情况所造成的非常载荷。在非常载荷作用下,主轴装置部分不应有残余变形。单绳缠绕式矿井提升机的主轴装置是其核心部件,要求我们应认真设计,精心制造,这对于确保矿井提升机安全可靠运行,预防和杜绝故障及事故的发生,也具有十分重要的意义。

本设计根据生产实际和预选的数据,以提升机的配套设备为核心,经过科学的计算和分析,设计、选择了一套矿井提升机的传动系统设备,并采用了光电测速传感器作为深度指示系统的数据采集装置,实现了从机械控制到数电控制的转变,同时为提升机控制系统的技术改造奠定了基础。

关键词:提升机,主轴,制动器,光电测速传感器

- 内容简介:

-

JOURNALOFMATERIALSPROCESSINGTECHNOLOGY831998151158MACHININGOFALSICPARTICULATEMETALMATRIXCOMPOSITESPARTITOOLPERFORMANCEMELGALLABA,MSKLADB,APRATTANDWHITNEYCANADA,MISSISSAUGA,ONTARIO,L5T1J3,CANADABDEPARTMENTOFMECHANICALENGINEERING,MCMASTERUNI6ERSITY,HAMILTON,ONTARIO,L8S4L7,CANADARECEIVED20MARCH1997ABSTRACTDESPITETHESUPERIORMECHANICALANDTHERMALPROPERTIESOFPARTICULATEMETALMATRIXCOMPOSITES,THEIRPOORMACHINABILITYHASBEENTHEMAINDETERRENTTOTHEIRSUBSTITUTIONFORMETALPARTSTHEHARDABRASIVEREINFORCEMENTPHASECAUSESRAPIDTOOLWEARDURINGMACHININGAND,CONSEQUENTLY,HIGHMACHININGCOSTSASERIESOFDRYHIGHSPEEDTURNINGTESTSWEREPERFORMEDTOSELECTTHEOPTIMUMTOOLMATERIAL,TOOLGEOMETRYANDCUTTINGPARAMETERSFORTHETURNINGOF20SICALMETALMATRIXCOMPOSITESTHERESULTSINDICATETHATPOLYCRYSTALLINEDIAMONDTOOLSPCDPROVIDESATISFACTORYTOOLLIFECOMPAREDTOALUMINAANDCOATEDCARBIDETOOLS,WHERETHELATTERTOOLSSUFFEREDFROMEXCESSIVEEDGECHIPPINGANDCRATERWEARDURINGTHEMACHININGOFTHEMETALMATRIXCOMPOSITEUNDERSTUDYFURTHERMORE,THECOSTOFPCDTOOLSCOULDBEJUSTIFIEDBYUSINGDRYCUTTINGATFEEDRATESASHIGHAS045MMREV1,CUTTINGSPEEDSOF894MMIN1ANDADEPTHOFCUTOF15MMWITHTHESECUTTINGPARAMETERS,THERELATIVELYSMALLBUILTUPEDGEFORMEDONTHETOOLPROTECTSITFROMFURTHERWEARBYABRASIONANDMICROCUTTINGPOLYCRYSTALLINETOOLSWITHZERORAKEANGLEANDLARGETOOLNOSERADIIARERECOMMENDEDFORTHEROUGHINGOPERATIONS1998ELSEVIERSCIENCESAALLRIGHTSRESERVEDKEYWORDSMETALMATRIXCOMPOSITESTOOLWEAR1INTRODUCTIONMETALMATRIXCOMPOSITESMMCSFORMONEGROUPOFTHENEWENGINEEREDMATERIALSTHATHAVERECEIVEDCONSIDERABLERESEARCHSINCETHETRIALSBYTOYOTAINTHEEARLY1980S1THEMOSTPOPULARREINFORCEMENTSARESILICONCARBIDEANDALUMINAALUMINIUM,TITANIUMANDMAGNESIUMALLOYSARECOMMONLYUSEDASTHEMATRIXPHASETHEDENSITYOFMOSTMMCSISAPPROXIMATELYONETHIRDTHATOFSTEEL,RESULTINGINHIGHSPECIFICSTRENGTHANDSTIFFNESS2DUETOTHESEPOTENTIALLYATTRACTIVEPROPERTIESCOUPLEDWITHTHEINABILITYTOOPERATEATHIGHTEMPERATURES,MMCSCOMPETEWITHSUPERALLOYS,CERAMICS,PLASTICSANDREDESIGNEDSTEELPARTSINSEVERALAEROSPACEANDAUTOMOTIVEAPPLICATIONSTHELATTERMATERIALS,HOWEVER,MAYNOTHAVEMUCHFURTHERCAPACITYFORTHEINEVITABLEFUTUREINCREASESINSERVICELOADS3PARTICULATEMETALMATRIXCOMPOSITESPMMCSAREOFPARTICULARINTEREST,SINCETHEYEXHIBITHIGHERDUCTILITYANDLOWERANISOTROPYTHANFIBERREINFORCEDMMCS2MOREOVER,PMMCSOFFERSUPERIORWEARRESISTANCE3WHILEMANYENGINEERINGCOMPONENTSMADEFROMPMMCSAREPRODUCEDBYTHENEARNETSHAPEFORMINGANDCASTINGPROCESSES,THEYFREQUENTLYREQUIREMACHININGTOACHIEVETHEDESIREDDIMENSIONSANDSURFACEFINISHTHEMACHININGOFPMMCSPRESENTSASIGNIFICANTCHALLENGE,SINCEANUMBEROFREINFORCEMENTMATERIALSARESIGNIFICANTLYHARDERTHANTHECOMMONLYUSEDHIGHSPEEDSTEELHSSANDCARBIDETOOLS4THEREINFORCEMENTPHASECAUSESRAPIDABRASIVETOOLWEARANDTHEREFORETHEWIDESPREADUSAGEOFPMMCSISSIGNIFICANTLYIMPEDEDBYTHEIRPOORMACHINABILITYANDHIGHMACHININGCOSTS2LITERATUREREVIEWFROMTHEAVAILABLELITERATUREONPMMCS,ITISCLEARCORRESPONDINGAUTHORFAX19055727944EMAILMECHMACMCMASTERCA092401369819001998ELSEVIERSCIENCESAALLRIGHTSRESERVEDPIIS0924013698000545MELGALLAB,MSKLADJOURNALOFMATERIALSPROCESSINGTECHNOLOGY831998151158152TABLE1TYPICALPHYSICALPROPERTIESOFDURALCANF3S20S20PROPERTYDENSITYGCM3277THERMALCONDUCTIVITYCALCM1S1K1AT22C047SPECIFICHEATCALG1K0218100C0239200C0259300CAVERAGECOEFFICIENTOFTHERMALEXPANSION17550100C50300C21121450500CULTIMATESTRENGTHMPA262YIELDSTRENGTHMPA21419ELONGATION986ELASTICMODULUSGPA67915ROCKWELLHARDNESSBTABLE2TOOLGEOMETRYTOOLGEOMETRYPCDTIPPED80RHOMBOIDRAKEANGLE,A5,0,5CLEARANCEANGLE7APPROACHANGLE5TOOLNOSERADIUSMM,R08,16TINCOATEDCARBIDERAKEANGLE,A0TRIANGULARCLEARANCEANGLE7APPROACHANGLE5TOOLNOSERADIUSMM,R16RAKEANGLE,A0AL2O3TICCERAMICTRIANGULARCLEARANCEANGLE7APPROACHANGLE5TOOLNOSERADIUSMM,R16CRYSTALLINEDIAMONDPCDTOOLSARETHEONLYTOOLMATERIALTHATISCAPABLEOFPROVIDINGAUSEFULTOOLLIFEDURINGTHEMACHININGOFSICALPMMCSPCDISHARDERTHANAL2O3ANDSICANDDOESNOTHAVEACHEMICALTENDENCYTOREACTWITHTHEWORKPIECEMATERIALTOMACETAL5COMPAREDTHEPERFORMANCEOFCHEMICALVAPORDEPOSITIONCVDINSERTSTOTHATOFTIN,TICNANDAL2O3COATEDTOOLSCVDTOOLSOFFEREDBETTEROVERALLPERFORMANCETHANTHATOFTHEOTHERTOOLSLANEETAL18STUDIEDTHEPERFORMANCEOFDIFFERENTCVDTOOLSWITHTHINANDTHICKFILMSACCORDINGTOTHEIROBSERVATIONS,CVDTOOLSWITHTHINFILMSFAILEDCATASTROPHICALLYDURINGTHEENDMILLINGOF20SICALPMMCTHISTOOLFAILUREWASATTRIBUTEDTOCOATINGSPALLINGANDCONSEQUENTDAMAGETOTHERELATIVELYSOFTCARBIDESUBSTRATEFURTHERMORE,PCDTOOLSWITHAGRAINSIZEOF25MMBETTERWITHSTANDABRASIONWEARBYMICROCUTTINGTHANTOOLSWITHAGRAINSIZEOF10MM8,14FURTHERINCREASESINPCDGRAINSIZEDONOTBENEFITTHETOOLLIFE,BUTRATHERCAUSESIGNIFICANTDETERIORATIONINTHESURFACEFINISHTHISTHATTHEMORPHOLOGY,DISTRIBUTIONANDVOLUMEFRACTIONOFTHEREINFORCEMENTPHASE,ASWELLASTHEMATRIXPROPERTIES,AREALLFACTORSTHATAFFECTTHEOVERALLCUTTINGPROCESS2,4,BUTASYETRELATIVELYFEWWORKSRELATEDTOTHEOPTIMIZATIONOFTHEPRODUCTIVITYPROCESSHAVEBEENPULISHEDFOREXAMPLE,MONAGHAN2STUDIEDTHEWEARMECHANISMOFCARBIDETOOLSDURINGTHEMACHININGOF25SICALPMMCATSPEEDSBELOW20MMIN1TOMACETAL5DEVELOPEDATOOLLIFERELATIONSHIPFORCARBIDETOOLSDURINGTHEMACHININGOFSICALPMMCSATSPEEDSLOWERTHAN100MMIN1HOWEVER,THEAUTHORSOFREF5RECOMMENDEDFURTHERRESEARCHONTHEBUILTUPEDGEPHENOMENONTHATISOBSERVEDINALLTOOLSDURINGTHEMACHININGOFSICALPMMCSOREILLYETAL6RANKEDVARIOUSTOOLMATERIALSWITHRESPECTTOTOOLWEAR,HOWEVER,THEIRCUTTINGPARAMETERSDIDNOTEXCEED125MMIN1AND10MMDEPTHOFCUT,WHICHWASACHIEVEDUSINGCUBICBORONNITRIDETOOLSSIMILARTESTRESULTSWEREREPORTEDBYBRUNETAL7WHORELATEDTHETOOLWEARRATE,MAINLYDUETOABRASION,TOTHETOOLHARDNESSWINERT8ATTRIBUTEDTHEWEAROFTHECARBIDETOOLSTOABRADINGAL2O3PARTICLESTHATFORMONTHESURFACEANDRUBTHETOOLINTHEDIRECTIONOFTHECHIPFLOWHOWEVER,PULLEDSICPARTICLESCOULDALSOLEADTOTHESAMEEFFECT,SICPARTICLESALSOBEINGHARDERTHANTHEWCTOMACETAL5SUGGESTEDTHATCOATINGSWITHLESSHARDNESSTHANTHATOFAL2O3ANDSICOFFERLITTLETONOADVANTAGEDURINGTHEMACHININGOFSICALPMMCS,BRUNETAL7SUGGESTEDUSINGLOWERCUTTINGSPEEDSTOREDUCETHECUTTINGTEMPERATURE,WHICHACCELERATEDIFFUSIONANDADHESIONWEARANDTHERMALLYWEAKENTHETOOLSINCEALUMINIUMTENDSTOSEIZEONTHETOOLFACEANDSINCEGRAINBOUNDARIESARETHESITESOFSEIZURE,THEAUTHORSRECOMMENDEDUSINGCEMENTEDCARBIDETOOLSWITHALARGEGRAINSIZESEVERALRESEARCHERS725HAVEINDICATEDTHATPOLYFIG1SEMFIGURESHOWINGWEARONAL2O3TOOL6488MMIN1,F02MMREV1,DOC05MM,R16MM,A0MELGALLAB,MSKLADJOURNALOFMATERIALSPROCESSINGTECHNOLOGY831998151158153TABLE3EFFECTOFTOOLMATERIALONCUTTINGFORCESANDTEMPERATURESR16MMA0MEASUREDCUTTOOLMATERIALMEASUREDCUTTINGTEMPERATURECTINGFORCENPCD6894MMIN19700440F045MMREV1DOC25MM9810PCD6670MMIN1410F025MMREV1DOC15MM520AL2O36248MMIN118385F02MMREV1DOC05MM14352500TIN6248MMIN1F02MMREV1DOC05MMFIG3EFFECTOFDEPTHOFCUTONTHECUTTINGFORCESPCDTOOLR16MM,A0SQUAREPOINTS6894MMIN1,DOC15MMROUNDPOINTS6894MMIN1,DOC25MMOFCUTTHATAREASAGGRESSIVEASPOSSIBLEDURINGTHEROUGHINGOPERATIONSFINALLY,WITHREGARDTOTHECOOLANTAPPLICATION,RESEARCHERSATDURALCANUSA1123,RECOMMENDINVESTIGATINGTHEPOSSIBILITYOFDRYROUGHMACHININGINORDERTOTAKEADVANTAGEOFTHEPROTECTIVEBUILTUPEDGEPHENOMENONINSUMMARY,THELITERATUREREVIEWCARRIEDOUTSHOWEDTHATTHEEFFECTOFMOREAGGRESSIVECUTTINGPARAMETERSSPEED,FEEDANDDEPTHOFCUTSTILLNEEDSFURTHERRESEARCHINORDERTOIMPROVETHEECONOMICSOFTHECUTTINGPROCESSALSO,SEVERALIMPORTANTPARAMETERSHAVEBEENOVERLOOKEDBYPREVIOUSRESEARCHERS,AMONGWHICHARETHETOOLGEOMETRYANDCOOLANTAPPLICATION3TESTMATERIALANDCUTTINGTOOLS31WORKPIECEMATERIALTHEMACHININGINVESTIGATIONSWERECARRIEDOUTUSINGDURALCANF3S20SALSICMETALMATRIXCOMPOSITETHESICPARTICLESHADANAVERAGEDIAMETEROF12MMTABLE1SHOWSSOMEOFTHEPHYSICALANDMECHANICALPROPERTIESOFA35620SICPMMCPRIORTOCARRYINGOUTTHECUTTINGEXPERIMENTS,THETESTMATERIALWASFULLYHEATTREATEDTOTHET71CONDITIONTHETESTMATERIALWASINTHEFORMOFBARSOF1778MMDIAMETERAND305MMLENGTH32CUTTINGTOOLSVARIOUSTOOLMATERIALSCOATEDCARBIDE,AL2O3TICANDPCDANDGEOMETRIESWEREEMPLOYEDINTHESTUDYOBLIQUETURNINGTESTSWERECARRIEDOUTANDDIFFERENTCUTTINGPARAMETERSWEREEMPLOYEDFOREACHTOOLMATERIALHOWEVER,FORTHEPURPOSEOFCOMPARINGTOOLWEAR,ALLCUTTINGTESTSWERECARRIEDOUTATAFIXEDVOLUMEOFMETALREMOVED300MM3TABLE2SUMMARIZESTHETOOLDATAISBECAUSEPCDGRAINSWITHSIZE25MMAREEASILYPULLEDOUTOFTHECUTTINGEDGEREGARDINGTHEEFFECTOFTHECUTTINGPARAMETERSONTHETOOLLIFE,LANEETAL1115,1719ATTRIBUTEDTHEINCREASEINTHEWEAROFPCDTOOLSBYABRASIONTOINCREASEINKINETICENERGYGAINEDBYABRADINGSICPARTICLESONTHEOTHERHAND,BRUNETAL7ATTRIBUTEDTHEINCREASEINTOOLWEARINTHETHERMALDEGRADATIONOFTHETOOLMATERIALTOOLWEARWASFOUNDTOBEINVERSELYPROPORTIONALTOTHEFEEDRATE9TOMACETAL5ATTRIBUTEDTHEINCREASEINTOOLLIFEATHIGHERFEEDRATESTOTHETHERMALSOFTENINGOFTHECOMPOSITETHEAUTHORSSUGGESTTHATTHEWORKPIECEMATERIALBECOMESSOFTERANDTHESICPARTICLESBECOMEPRESSEDINTOTHEWORKPIECE,CAUSINGLESSABRASIONONTHETOOLITSELFHOWEVER,FINNETAL24ANDMORINETAL25ATTRIBUTEDTHEREDUCTIONINTOOLWEARWITHGREATERFEEDRATESTOTHEREDUCEDCONTACTBETWEENTHECUTTINGEDGEANDTHEABRASIVESICPARTICLESDESPITETHECONTROVERSYINEXPLAININGTHEMECHANISMBEHINDTHETOOLWEARATDIFFERENTFEEDRATES,ALLRESEARCHERSRECOMMENDUSINGFEEDRATESANDDEPTHSFIG2EFFECTOFCUTTINGSPEEDONTHECUTTINGFORCESPCDTOOLR16MM,A0SQUAREPOINTS6670MMIN1,DOC15MMROUNDPOINTS6894MMIN1,DOC15MMMELGALLAB,MSKLADJOURNALOFMATERIALSPROCESSINGTECHNOLOGY831998151158154DRYTURNINGTESTSWERECARRIEDOUTONA10HPSTANDARDMODERNNCLATHETHECUTTINGFORCECOMPONENTSFX,FY,FZANDTOOLWEARWEREMEASUREDCONTINUOUSLYFOREACHCOMBINATIONOFCUTTINGPARAMETERSTHETOOLFORCESWEREMEASUREDUSINGAKISTLER3COMPONENTDYNAMOMETERANDTHECUTTINGCONDITIONSWERESELECTEDCAREFULLYFOREACHTOOLMATERIALINSOMEOFTHECUTTINGTESTS,THETOOLTEMPERATUREWASMEASUREDUSINGKTYPETHERMOCOUPLESTHATWEREGLUEDONTOTHETOOLRAKEFACE,1MMAWAYFROMTHECUTTINGEDGETHERELIABILITYOFTHEMEASUREMENTTECHNIQUESWASCHECKEDCONSTANTLYBYREPEATINGTHEEXPERIMENTSANDTHERESULTSOFEACHSETOFEXPERIMENTSWEREACCEPTEDIFTHEYEXHIBITEDAVARIANCEOFLESSTHAN5ATTHEENDOFEACHCUTTINGTEST,THETOOLWEARWASEXAMINEDUSINGASCANNINGELECTRONMICROSCOPEANDTHEXRAYDISPERSIONTECHNIQUETHETOOLFIG5ABUILTUPEDGEONPCDTOOLS6670MMIN1,F045MMREV1DOC25MM,R16MMBASFORFIG5A,BUTFOR6894MMIN1FIG4ABUILTUPEDGEONPCDTOOLS6670MMIN1,F025MMREV1,DOC25MM,R16MM,A0BXRAYDISPERSIONOFBUILTUPEDGESHOWNINFIG4AFLANKWEARVBWASMEASUREDUSINGATOOLMAKERSMICROSCOPE4RESULTSANDDISCUSSION41EFFECTOFTOOLMATERIALASERIESOFPRELIMINARYTESTSWASCONDUCTEDTOASSESTHEEFFECTOFTOOLMATERIALONTHETOOLWEAR,CUTTINGFORCESANDCUTTINGTEMPERATUREDURINGTHEROUGHTURNINGOF20SICALPMMCFIG1SHOWSTHATAL2O3TICTOOLSSUFFEREDEXCESSIVEWEARINTHEFORMOFEDGECHIPPINGAL2O3PARTICLESAREPULLEDOUTBYTHEABRADINGWORKPIECEPARTICLES,WHICHHAVEAGREATERVICKERSHARDNESSNUMBERVHNTHANTHEAL2O3PARTICLESVHNFORAL2O3TIC2500KGFMM2VHNFORSIC3000KGFMM2CRATERWEARWASALSOOBSERVED,WHICHISDUETOTHEWIDENINGOFGROOVESTHATWERECAUSEDBYABRASIONDUETOSEVEREEDGECHIPPING,THECUTTINGFORCESFORTHEMELGALLAB,MSKLADJOURNALOFMATERIALSPROCESSINGTECHNOLOGY831998151158155AL2O3TICTOOLWEREMUCHHIGHERTHANTHOSEEXPERIENCEDBYTINCOATEDTOOLSTABLE3THETINCOATINGPROVIDEDSOMEPROTECTIONAGAINSTTHEABRASIVEEFFECTSOFTHESICPARTICLESTHESUPERIORPERFORMANCEOFPOLYCRYSTALLINEDIAMONDTOOLS,COMPAREDTOBOTHAL2O3TICANDTINCOATEDCARBIDETOOLS,ISATTRIBUTEDTOTHEIRHIGHABRASIONRESISTANCEANDHIGHTHERMALCONDUCTIVITY,WHICHLEDTOLOWERCUTTINGTEMPERATURES,ASSHOWNINTABLE3THEREFORE,ALLMACHINABILITYSTUDIESCARRIEDOUTTHEREAFTERWERECONCERNEDWITHTHEOPTIMIZATIONOFTHECUTTINGPROCESSUSINGPCDTOOLS42EFFECTOFCUTTINGPARAMETERSFIGS2AND3SHOWTHATASTHECUTTINGSPEEDANDORTHEDEPTHOFCUTINCREASE,THECUTTINGFORCESDECREASETHISCOULDBEATTRIBUTEDTOTHERMALSOFTENINGOFTHEWORKPIECEMATERIALANOTHERPOSSIBLEREASONISDUETOTHECHANGESINTRODUCEDINTOTHETOOLGEOMETRYUPONTHEFORMATIONOFBUILTUPEDGEFIG4BSHOWSTHEXRAYDISPERSIONOFTHEBUILTUPMATERIALSHOWNINFIG4AFIG7ASEMIMAGEILLUSTRATINGTHEWEARONTHEPCDTOOLRAKEFACEAFTERDISSOLVINGTHEBUEWITHNAOH6670MMIN1,F015MMREV1,DOC15MM,R16MM,A0BHIGHERMAGNIFICATIONOFRAKEFACEOFTHETOOLSHOWNINFIG7AFIG6ABUILTUPEDGEONPCDTOOLS6670MMIN1,F035MMREV1,DOC15MM,R16MM,A0BASFORFIG6A,BUTFORDOC25MMBUILTUPEDGEWASOBSERVEDINALLTOOLSUNDERALLCUTTINGCONDITIONSTHISISBECAUSEPARTICULATESICALMMCSHAVEALLOFTHECHARACTERISTICSOFMATERIALSTHATFORMFIG8EFFECTOFCUTTINGSPEEDONTHETOOLFLANKWEARPCDTOOLR16MM,A0SQUAREPOINTS6670MMIN1,DOC15MMROUNDPOINTS6894MMIN1,DOC15MMMELGALLAB,MSKLADJOURNALOFMATERIALSPROCESSINGTECHNOLOGY831998151158156FIG9EFFECTOFDEPTHOFCUTONTHETOOLFLANKWEARPCDTOOLR16MM,A0,6894MMIN1SQUAREPOINTSDOC15MMROUNDPOINTSDOC25MMILLUSTRATETHISPOINT,INTHECASEOFAGREATERDEPTHOFCUTALARGERSURFACEAREAOFTHETOOLFLANKFACEISEXPOSEDTOABRASIONINCREASINGTHEFEEDRATEHADABENEFICIALEFFECTASSHOWNINFIGS8AND9,ASTHEFEEDRATEINCREASES,THETOOLWEARDECREASESINTHECASEOFHIGHERFEEDRATES,FORAFIXEDVOLUMEOFMETALREMOVAL,THETOOLSURFACESWILLHAVELESSCONTACTWITHTHEABRASIVEPMMCANOTHERFIG10AEFFECTOFPCDTOOLRAKEANGLEONTOOLFLANKWEAR6894MMIN1,DOC25MM,R16MMSQUAREPOINTS0ROUNDPOINTS5STARPOINTS,5BEFFECTOFPCDTOOLRAKEANGLEONTHECUTTINGFORCES6894MMIN1,DOC25MM,R16MMSQUAREPOINTS0ROUNDPOINTS5STARPOINTS,5CSEMIMAGEILLUSTRATINGTHEPCDTOOLWEARBYPITTING6670MMIN1,DOC15MM,F025MMREV1,R16MM,A5BUEIESTRAINHARDENEDTWOPHASEMATERIALUNDERHIGHTEMPERATUREANDPRESSUREATHIGHCUTTINGSPEEDS6894MMIN1FIG5B,ASMALLERBUEISFORMED,COMPAREDTOTHEBUEFORMEDAT6670MMIN1FIG5ATHEHEIGHTOFTHEBUEWASMEASUREDPERPENDICULARTOTHERAKEFACEINCONTRAST,BYINCREASINGTHEDEPTHOFCUTFROM15TO24MM,ALARGEBUEISFORMEDFIG6A,B,WHICHCOULDBREAKOFFTHETOOLCAUSINGTOOLCHIPPINGANDCONSEQUENTADVERSEEFFECTSONTHEWORKPIECESURFACEROUGHNESSANDDIMENSIONALACCURACYTOPOGRAPHIESOFTHETOOLINDICATETHATTHEMAINWEARMECHANISMOFPCDISABRASIONMANIFESTEDASGROOVESPARALLELTOTHECHIPFLOWDIRECTIONTHESEGROOVESCOULDBEATTRIBUTEDTOTHREEFACTORSTHEFIRSTISTHATAL2O3ISFORMEDATTHETOOLEDGE,WHICHISHARDENOUGHTOPRODUCEGROOVINGWEARINTHEPCDTHESECONDEXPLANATIONFORTHEPCDGROOVINGISALUMINIUMSEIZUREANDTHEPULLOUTPROCESSOFTHEPCDGRAIN,ASSHOWNINFIG7A,BTHETHIRDPOSSIBLEREASONBEHINDPCDGROOVINGISTHATSICPARTICLESABRADETHETOOLSTHUS,PCDTOOLSWITHPCDGRAINSLARGERTHANTHEGRAINSIZEOFTHESICPARTICLESCOULDBETTERWITHSTANDTHEABRASIONANDMICROCUTTINGBYTHESICPARTICLESHOWEVER,ONESHOULDNOTETHATASTHESIZEOFTHEPCDGRAINSINCREASES,THEFRACTUREPROPERTIESOFTHEPCDTOOLDETERIORATES,DUETOANINCREASEDNUMBEROFFLAWSINTHEMATERIALTHEGROOVESTHATWEREFORMEDONTHETOOLFACEWEREFILLEDWITHTHEWORKPIECEMATERIALTHISADHERINGLAYERSOMEWHATPROTECTEDTHETOOLSRAKEFACEAGAINSTFURTHERABRASIONNONETHELESS,THETOOLFLANKFACECONTINUEDTOBESUBJECTEDTOABRASIONHENCE,FLANKWEARVBWASTAKENASTHETOOLLIFECRITERIONWITHVB1IM018MMFIG8SHOWSTHATASTHECUTTINGSPEEDINCREASES,THEFLANKWEARINCREASESTHISCOULDBEATTRIBUTEDTOTHEINCREASEINTHEKINETICENERGYOFTHEABRADINGPARTICLES,ASPREVIOUSLYHYPOTHESIZEDBYLANE17INCREASINGTHEDEPTHOFCUTLEADSTOANINCREASEINTHEFLANKWEARFIG9THISISATTRIBUTEDTOENHANCEDABRASIONBYMICROCUTTINGATTHETOOLFLANKFACETOMELGALLAB,MSKLADJOURNALOFMATERIALSPROCESSINGTECHNOLOGY831998151158157FIG11ASEMIMAGEILLUSTRATINGTHEPCDTOOLWEARBYCHIPPING6894MMIN1,DOC15MM,F035MMREV1,R08MM,A0BEFFECTOFTOOLNOSERADIUSONTHETOOLFLANKWEAR6894MIN,DOC25MM,A0TOOLFWSQUAREPOINTS,R16MMROUNDPITCHPOINTS,R08MMWEARINTHECASEOFNEGATIVERAKEANGLE,ISTHEGREATERCUTTINGFORCESENCOUNTEREDWITHSUCHARAKEANGLEFIG10BMOREOVER,THECHIPSPRODUCEDBECAMECAUGHTBETWEENTHETOOLANDTHEWORKPIECE,CAUSINGDAMAGETOTHETOOLSURFACETOOLSWITHPOSITIVERAKEANGLESHOWEDIRREGULARFLANKWEARANDEXCESSIVEPITTINGINTHECUTTINGEDGEZONE,ASSHOWNINFIG10CTHETOOLNOSERADIUSPLAYSAKEYROLEINDETERMININGTHEWEARMODEOFTHETOOLASTHETOOLNOSERADIUSWASDECREASEDFROM16TO08MM,THETOOLWASFOUNDTOSUFFERFROMEXCESSIVECHIPPINGANDCRATERWEAR,ASSHOWNINFIG11ATHISTOOLCHIPPINGLEADSTOANINCREASEINCUTTINGFORCESANDFLANKWEAR,ASSHOWNINFIG11BTOOLSWITHSMALLNOSERADIIARETHUSRECOMMENDEDFORFINISHINGOPERATIONSWHERELIGHTCUTTINGPARAMETERSAREUSEDSMALLNOSERADIIAREALSOEXPECTEDTOYIELDBETTERGEOMETRICALACCURACY5CONCLUSIONTHERESULTSOFTHEMACHINABILITYSTUDIESCARRIEDOUTON20SICALPARTICULATEMETALMATRIXCOMPOSITESINDICATEDTHEFOLLOWING1THEMAINTOOLWEARMECHANISMISABRASIONANDMICROCUTTINGOFTOOLMATERIALGRAINS,MANIFESTEDASGROOVESONTHETOOLFACEPARALLELTOTHECHIPFLOWDIRECTIONALLOFTHETOOLSTESTEDALSOSUFFEREDFROMFLANKWEARDUETOABRASIONTHEREWASNOEVIDENCEOFCHEMICALWEAREGBYDIFFUSION2PCDTOOLSSUSTAINEDTHELEASTTOOLWEARCOMPAREDTOTINCOATEDCARBIDETOOLSANDAL2O3TICTOOLSTHISISUNDOUBTEDLYDUETOPCDSSUPERIORHARDNESSANDWEARRESISTANCE,ASWELLASLOWCOEFFICIENTOFFRICTION,TOGETHERWITHHIGHTHERMALCONDUCTIVITYTHISLEDTOLOWERCUTTINGTEMPERATURESWHENPCDTOOLSWEREEMPLOYEDONTHEOTHERHAND,THETINCOATEDCARBIDETOOLSANDAL2O3TICTOOLSSUFFEREDFROMEXCESSIVECRATERWEARANDEDGECHIPPING3THEGROOVESFORMEDONTHERAKEFACEOFPCDTOOLSWEREFILLEDWITHSMEAREDWORKPIECEMATERIALTHISFORMOFBUILTUPEDGEISBENEFICIAL,SINCEITPROTECTSTHETOOLRAKEFROMFURTHERABRASION4THECUTTINGPARAMETERSPLAYAKEYROLEINDETERMININGTHEAMOUNTOFTOOLFLANKWEAR,ASWELLASTHESIZEOFTHEBUILTUPEDGETOOLWEARISMINIMIZEDBYINCREASINGTHEFEEDRATE,WHICHLEADSTOAREDUCTIONINCONTACTBETWEENTHETOOLANDTHEABRADINGSICPALTHOUGHINCREASINGTHECUTTINGSPEEDISEXPECTEDTOACCELERATETHEFLANKABRASIONWEARDRAMATICALLY,THERESULTSINDICATEDTHATTHEINCREASEINWEARISMINIMALHIGHERCUTTINGSPEEDSWEREASSOCIATEDWITHTHEINCREASEINTHECUTTINGTEMPERATURES,WHICHLEDTOTHEFORMATIONOFAPROTECTIVESTICKINGTHINLAYEROFWORKPIECEMATERIALONTHETOOLTHISFORMOFPROTECTIVEBUILTUPEDGEWASPREVENTEDFROMGROWINGINSIZEBYTHEINCREASESPEEDOFADVANTAGEGAINEDBYINCREASINGTHEFEEDRATEISTHECHANGEINCHIPFORMATLOWFEEDRATES,THECHIPSFORMEDWERECONTINUOUS,ALSOBEINGDIFFICULTANDHAZARDOUSTOHANDLEATHIGHFEEDRATESANDHIGHDEPTHSOFCUTF035,DOC20MM,THECHIPSFORMEDWEREDISCONTINUOUSDESPITETHEFACTTHATINALLEXPERIMENTSWITHPCDTOOLSHIGHFEEDRATESRESULTEDINLOWERTOOLWEAR,ACONCLUSIVEDECISIONABOUTTHEOPTIMUMCUTTINGPARAMETERSSHOULDTAKEINTOCONSIDERATIONTHEEFFECTOFTHECUTTINGPARAMETERSONTHESURFACEINTEGRITYANDSUBSURFACEDAMAGEPRODUCEDINTHEWORKPIECECOMPREHENSIVEANALYSISOFTHESURFACEINTEGRITYANDCHIPMORPHOLOGYWILLBEPRESENTEDINTHEPARTIIOFTHISRESEARCHSTUDY43EFFECTOFTOOLGEOMETRYTHETOOLRAKEANGLEHADAPROFOUNDEFFECTONTHEWEAROFPCDTOOLSTHREEDIFFERENTRAKEANGLESWEREEXAMINEDASCANBESEENFROMFIG10A,TOOLSWITH0RAKEANGLEOUTPERFORMEDPOSITIVEANDNEGATIVERAKEANGLETOOLSAPOSSIBLEREASONFORTHEINCREASEDFLANKMELGALLAB,MSKLADJOURNALOFMATERIALSPROCESSINGTECHNOLOGY831998151158158RUBBINGWITHINTHETESTEDRANGEOFCUTTINGPARAMETERS,THESPEEDOF894MMIN1,F045MMREV1ANDDEPTHOFCUT15MMRESULTEDINTHESMALLESTTOOLWEARTHESECUTTINGPARAMETERSENHANCETHEPRODUCTIVITYRATESUPONUSINGPCDTOOLS5PCDTOOLSWITHNOSERADII16MMANDRAKEANGLE0ALSOLEDTOLOWERFLANKWEARACKNOWLEDGEMENTSTHEAUTHORSWOULDLIKETOTHANKRBRUSKI,FROMDURALCAN,USAANDDDYERFROMGESUPERABRASIVES,FORSUPPLYINGTHETESTMATERIALANDCUTTINGTOOLSANDFORTHEIRHELPFULCOMMENTSTHROUGHOUTTHERESEARCHPROJECTTHEEXPERIMENTSWERECONDUCTEDI

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号