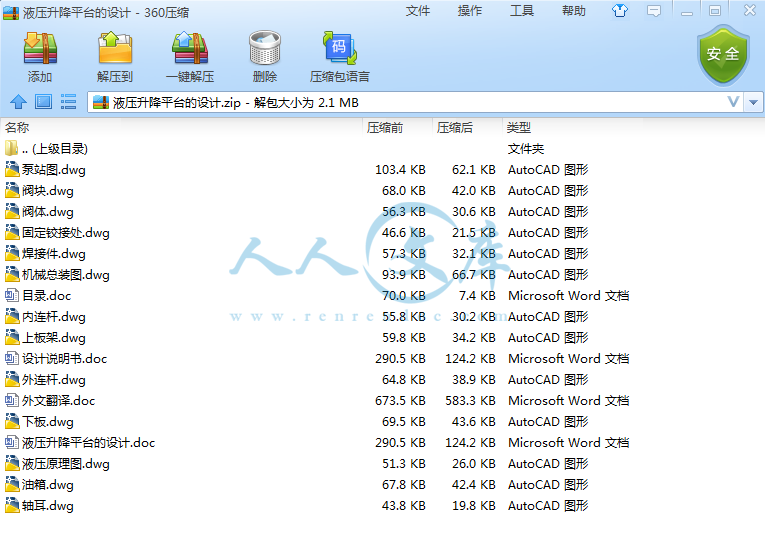

资源目录

压缩包内文档预览:

编号:10099223

类型:共享资源

大小:1.39MB

格式:ZIP

上传时间:2018-05-13

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

液压

升降

平台

设计

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

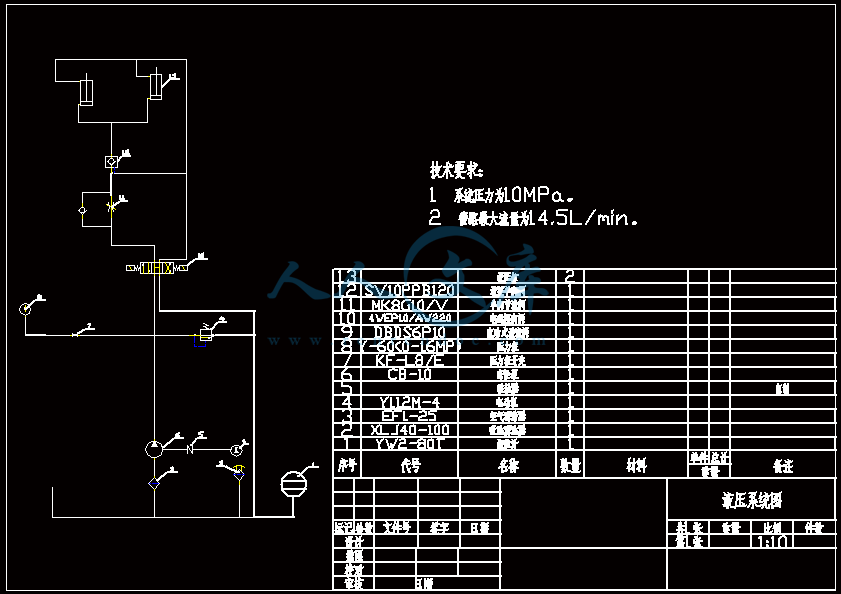

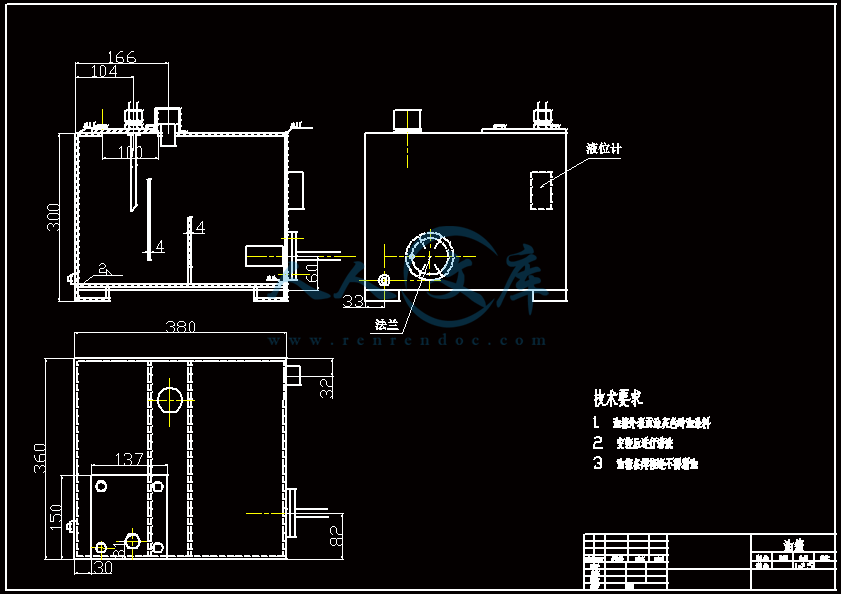

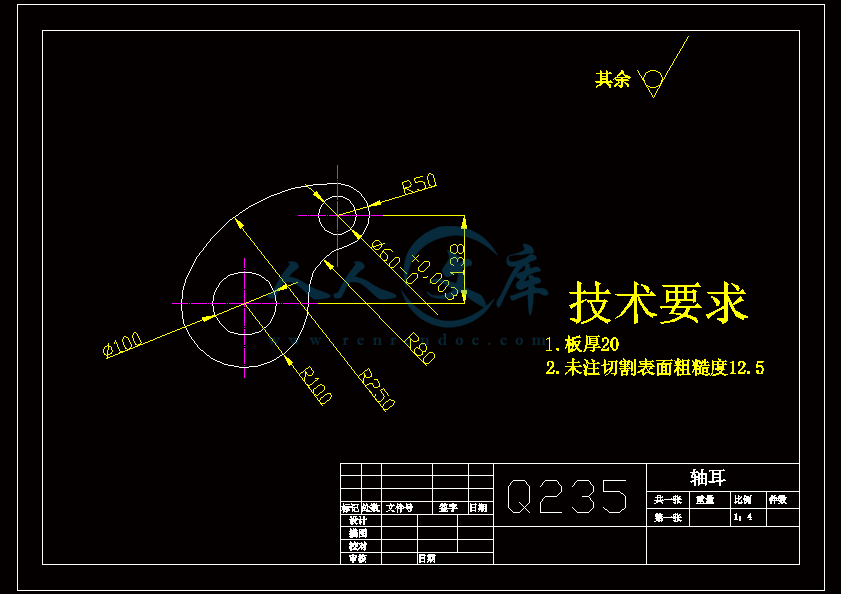

英文文献HYDRAULICEQUIPMENTOFPLIABLEFORCEFORMAINTENANCEANDMECHANICALWORKINGABSTRACTTHECOLLABORATIONBETWEENTHEHYDRAULICANDPNEUMATICACTINGSYSTEMSENGINEERINGDEPARTMENTANDTHESCHYDRAMOLDSRLFIRMLEDTOTHEREALIZATIONOFSOMEPERFORMANCESPRODUCTSONTHEHYDRAULICSANDPNEUMATICSSEGMENTTHEPAPERPROPOSESTOOFFERTHEMOSTREPRESENTATIVEHYDRAULICPLIABLEEQUIPMENTSFORCEFORMECHANICALWORKINGANDMAINTENANCEABIGPARTFROMTHEHYDRAULICEQUIPMENTSISPATENTEDORCLAIMOFPATENT,THETECHNOLOGYANDTECHNOLOGICALORIGINALITYBEINGTOTALLYPARTOFTHOSEBECAUSETHEPAPERHASAPREVALENTTECHNICALCHARACTER,INTHEPRESENTATIONWILLBEGOTOFFESPECIALLYTHEPERFORMANCECHARACTERISTICSOFTHEAREASUSEDANDTHEHYDRAULICEQUIPMENTSADVANTAGESOFTHEPLIABLEFORCEKEYWORDSHYDRAULICEQUIPMENT,MAINTENANCE,MECANICALWORKING1INTRODUCTIONTHEMULTIFUNCTIONALMODULAREQUIPMENTS,PLIABLE,FORMECHANICALWORKING,THATAREBASEDONTHEHYDRAULICDRIVEAREDESTINEDTOTHEMANUFACTURINGPLANTIMMALSOTOTHEMANUFACTURINGPLANTOFMAINTENANCEOFTHEBIGCOMPANYFRAMEWORKFROMENERGETIC,PETROCHEMISTRY,TRANSPORTALLTHEEQUIPMENTSWHATAREADDUCEDINWORKARESUBMITTEDINTHEFRAMEWORKOFDISAHPRESEARCHANDMAKETHESTUDYOFOTHERPAPERSTAKINGACCOUNTTHEFINITESPACEOFAWORK,THEREWILLBEPROPOSEDFROMTHELARGEPALETTEOFHYDRAULICPLIABLEEQUIPMENTSFORCEANEWORMODERNIZEDEQUIPMENTSSERIESFROMEACHSEGMENTDEVELOPEDBYTHESCHYDRAMOLDSRLFIRMPRESSURESOURCES,HYDRAULICPRESSES,HYDRAULICTOOLS,HYDRAULICEQUIPMENTOF3000BAR,HYDRAULICLIFTEQUIPMENT,FOLLOWINGASINTHENEXTWORKSITWILLBEPUBLISHEDOTHERMODERNHYDRAULICEQUIPMENTS2HYDRAULICEQUIPMENTSANALYSISFORCE21PRESSURESOURCESTHEPRESSURESOURCESOFTHEFORCEHYDRAULICEQUIPMENTSYIELDEDBYTHESCHYDRAMOLDSRLARETHEHYDRAULICACTINGUNITSTHATHAVEELECTRICORTHERMALENGINEANDTHEHYDRAULICMANUALORPEDALPUMPSHYDRAULICDRIVEUNITDESCRIPTIONWITHELECTRICENGINETHEELECTROHYDRAULICDRIVEUNITSHUEHAREHIGHPRESSURESOURCESFORTHEHYDRAULICCYLINDERSUPPLYINGWITHSIMPLEORDOUBLEACTIONFROMSOMEEQUIPMENTSSTRUCTURE,HYDRAULICINSTALLATIONSORAPPLIANCES,ANDTHEYWORKWITHRELATIVESMALLRATEFLOWANDPRESSURESOFUNTIL700BARS,FIG1THEWORKINGDEVELOPEDPRESSURECANBEADJUSTEDDEPENDINGONTASK30700BARFIG1THEELECTROHYDRAULICDRIVEUNIT11ELECTRICENGINE2MULTIPLIER3OILRECEIVER4OPERATORSDESKTABLE1ADVANTAGESTHEELECTROHYDRAULICDRIVEUNITADVANTAGESHUEHARETHEYOFFERTHEPOSSIBILITYTOMAINTAININTOTHEPRESSURE,RESPECTIVELYTHEHYDRAULICOBSTRUCTOFTHETASKANDDISPOSEOFAPRECISESETTINGOFTHEPRESSUREDEPENDINGONTHETASKUNTIL700BARITALLOWSTHEPERMANENTCONTROLOFTHECYLINDERSTROKEANDALSOTHEAUTOMATICCOMMUTATIONFROMTHEFIRSTSTEPTOTHESECONDPRESSURESTEPRESPECTIVELYFROMTHEFASTSTARTTOTHETECHNOLOGICALBREAKTHROUGHITALLOWSELECTRICREMOTECOMMAND,WHILETHECHARGINGVOLTAGEISOF24VCC,HAVINGTHEOILTEMPERATUREMONITORINGPOSSIBILITYANDTHEAUTOMATICDISCONNECTTOTHEVALUEOF55CITHASTHEHYDRAULICCOMPONENTSOFTHEHYDRAULICPANELPUMP,VALVE,SLIDEVALVEANDITFUNCTIONSINOPTIMALBEHAVIORTOMAXIMUMFROMTHEHALFNOMINALPRESSURE,PROVIDINGFORADVANCEDRELIABILITYITHASALOWLEVELNOISEUNDER70DBITCONFERSTHESIMULTANEOUSSUPPLYINGPOSSIBILITYOF2,3OR4CYLINDERSTHROUGHTOANATTACHEDBRANCH2,3THEHYDRAULICDRIVEUNITDESCRIPTIONWITHHEATENGINETHEHYDRAULICDRIVEUNITSWITHHEATENGINEHUMUTHPROCEEDFROMTHENEWPRODUCTSSCALEWITHADISTINGUISHEDRESILIENCEINTOTHEFIELD,ANDTHEYFUNCTIONWITHSMALLFLOWRATEANDPRESSURESOFUNTIL700BAR,FIG2FIG2THEHYDRAULICDRIVEUNITWITHHEATENGINE41HEATENGINE2MULTIPLIER3OPERATORSDESK4OILRECEIVERTABLE2THEHYDRAULICDRIVEUNITCHARACTERISTICSWITHHEATENGINE1THEHYDRAULICDRIVEUNITWITHHEATENGINEHASAMANUALCOMMANDFORTHESTARTANDTHECHANGINGOFTHEPRESSURESTEPSFROMTHE1STSTEPTOTHE2NDSTEPITMAKESMANUALTOO4ADVANTAGESTHEHYDRAULICDRIVEUNITOFFERSSIMILARADVANTAGESWITHTHOSEPRESENTEDATTHEHYDRAULICDRIVEUNITWITHELECTRICENGINETHEADDITIONALADVANTAGECONSISTSOFTHEMOBILITYINTOTHEFIELDASTHERESULTOFALOWWEIGHTANDITDOESNTDEPENDOFAFIXEDPOWERSOURCEFOREXAMPLETHECONNECTEDOFTHEUNITTOTHELINESYSTEM22HYDRAULICPRESSESTHEHYDRAULICPRESSWORKSHOPHPH075ISCOMPOSEDFROMASTANDSHUTFRAMEWORKFIXEDTOPTRAVERSECOLUMNS,ADJUSTABLEBOTTOMTRAVERSE,BASICPLATEREMOVABLE,AHYDRAULICCYLINDERWITHDOUBLEACTIONHCHD075150INSTALLEDONATRANSVERSALCARRIAGE,APLATESSET,PRESSINGBOLTSANDNUTS,FIG3FIG3THEHYDRAULICPRESS75TF1BASICPLATE2COLUMNS3BOTTOMTRAVERSE4HYDRAULICCYLINDERHCHD0751255TOPTRAVERSE6PRESSINGBOLTS7PRESSINGPLATESTABLE3THEHYDRAULICPRESSCHARACTERISTICS1AMONGTHEDIRECTAPPLICATIONSOFTHISHYDRAULICPRESSESDESERVEREMINDEDPRESSINGANDGEARPULLEROFFOFTHETRANSMISSIONSHAFTSFROMTHEGEARBOXESPRESSINGANDPULLERBALLBEARINGSFROMTHEATTACKPINIONSFROMTHETAPERINGGROUPSPRESSINGANDEXTRACTIONFROMJAMMEDSUBSETSCOLDDEFORMATIONFORVARIOUSPROOFSAMPLEADVANTAGESTHEHYDRAULICPRESSHASAMODULARCONSTRUCTION,REMOVABLE,HAVINGANINDEXEDSETTLEMENTSYSTEMOFTHEINFERIORTRAVERSE,ATTHEVARIOUSDETERMINATEHEIGHTSOFRANGEOF75MMTHETRANSVERSECARRIAGEOFPRESSREPRESENTSANEASYSETTLEMENTSYSTEMOFTHEHYDRAULICCYLINDERPOSITIONALLOWINGTHUSTHEPRESSINGAXLEREGULATIONTHEHYDRAULICPRESSHASPLATESSET,BOLTSANDPRESSINGNUTSFORTHEREALIZATIONOFALLTECHNOLOGICALOPERATIONSFROMTHEPRESSPROJECTRESULTANOPTIMALREPORTBETWEENITSWEIGHTANDACHIEVEDFORCEOWINGTOTHEACTINGTOMAXIMUMPRESSURES700BAR,ASEFFECTOFAREDUCEDWEIGHTITISEASYOFCARRIED23HYDRAULICTOOLSTHEHYDRAULICTOOLSCALEUSEDINTHEMECHANICALPROCESSINGANDMAINTENANCEISVARIOUS,WITHMANYAPPLICATIONSINTHEMECHANICALENGINEERINGTHEREAREREMINDEDAMONGTHESEHYDRAULICTOOLSTHEDEVICEOFTHEBENDINGPIPESANDTHEHYDRAULICDEVICEOFCUTTINGTHEDEVICEDESCRIPTIONOFBENDINGPIPESTHEBENDINGTEMPLATE,FIXEDONACTINGRODOFTHEHYDRAULICCYLINDERANDHAVINGTHESUITABLESKEWERSPROFILESOPIPEDIMENSIONASWELLASINFLEXIONBEAM,ITWILLACTOVERPIPETHATFOLLOWSTOBEDISTORTEDTHEPIPEGUIDESONTHETWOFERRIESOFTHEREST,FIXEDBETWEENTHEDEVICEPLATESTHESUPERIORPLATEOFTHEAPPLIANCEITCANBATETOALLOWTHEINTRODUCTIONOFTHETEMPLATEANDOFTHEFERRIESOFTHERESTFIG5THEDEVICEOFBENDINGPIPESTYPEHDITM020300ISANEQUIPMENT,HYDRAULICDRIVENANDITISDESTINEDTOTHEBENDINGATCOLDOFTHEINSTALLATIONSPIPESINTHEMAINTENANCEANDREPAIRSSECTORSTABLE4THEDEVICECHARACTERISTICSOFBENDINGPIPES1FIG5THEDEVICEOFBENDINGPIPES11TRIPOD2FIXEDPLATE3TURNOVERPLATE4BOLT5HYDRAULICCYLINDERHCHD020300,6FORMTABLE5THEWORKINGCHARACTERISTICSOFDEVICEOFBENDINGPIPESHDITM0203001THEHYDRAULICDEVICEDESCRIPTIONOFCUTTING20TFTHEDEVICEISFORMEDFROMAMETALLICBODY,REALIZEDTHROUGHWELDEDCONSTRUCTION,AHYDRAULICCYLINDERWITHSIMPLEACTIONHCHS020028,AMOVABLEKNIFEJOINTLYMOUNTEDWITHTHECYLINDERRODANDAFIXEDKNIFEBODY,FIG6THEHYDRAULICCYLINDERACTINGITREALIZESTHROUGHTHECONNECTIONTOAHIGHPRESSURESOURCEMANUALPUMPHPHM700ORHYDRAULICPEDALPUMPHPHP700,THROUGHAFASTCOUPLINGANDHYDRAULICFLEXIBLEPIPETHESEMIFINISHEDPRODUCTITINSTALLSBETWEENTHETWOKNIVES,WHILETHECUTTINGKNIFEANDTHECOUNTERKNIFEESTABLISHTHEDEBITINGOFTHESEMIFINISHEDPRODUCTFROMTHESTEELTHERETIREMENTOFTHECUTTINGKNIFEITREALIZESBYASPRINGINCORPORATEDINTOACYLINDERTHEHYDRAULICDEVICEOFCUTTINGHFMO020028ISAHYDRAULICDRIVEDEVICE,USEDINTHEPRODUCINGPROCESSESANDMAINTENANCEWITHTHEVIEWOFCUTTINGSATCOLDOFTHECIRCULAR,SQUARE,HEXAGONALANDFLATBARSSTEELTHEMOVABLEKNIFERUNISOF28MMANDTHEMAXIMUMPRESSURE700BAR,1FIG6THEHYDRAULICDEVICEOFCUTTING20TF12MOVABLEKNIFE3FIXEDKNIFE4FEEDNIPPLEWITHOILUNDERPRESSURETABLE6THEWORKINGCHARACTERISTICSOFHYDRAULICDEVICEOFCUTTINGTYPEHFMO020028,1ADVANTAGESTHEREAREIMPORTANTTONOTICE,AMONGTHEHYDRAULICDEVICEADVANTAGESOFCUTTINGTHECOMPACTSTRUCTUREANDMODERNDESIGNTHEEASYDRIVABILITYANDTHEREDUCEDWEIGHTITELIMINATESTHEUSELESSPHYSICALSWORKOFTHEOPERATORITLOWERSTHEAPPROPRIATEDTIMEPROCEDURESCALINGBEHAVIOUROFPRESSUREDRIVENMICROHYDRAULICSYSTEMSABSTRACTTHISPAPERPRESENTSALUMPEDNETWORKAPPROACHFORTHEMODELLINGANDDESIGNOFMICROHYDRAULICSYSTEMSAHYDRAULICOSCILLATORHASBEENBUILTCONSISTINGOFHYDRAULICRESISTORS,CAPACITORSANDTRANSISTORSPRESSURECONTROLLEDVALVESTHESCALINGOFMICROHYDRAULICNETWORKSCONSISTINGOFLINEARRESISTORS,CAPACITORSANDINERTANCESHASBEENSTUDIEDANIMPORTANTRESULTISTHATTOMAKESMALLERNETWORKSFASTER,DRIVINGPRESSURESSHOULDINCREASEWITHREDUCINGSIZE1INTRODUCTIONMICROHYDRAULICSYSTEMSCANBEMODELEDANDDESIGNEDUSINGAGENERALIZEDPHYSICALSYSTEMDESCRIPTION1,2THISAPPROACHISBASEDONTHEASSUMPTIONTHATITISPOSSIBLETOSEPARATEANDCONCENTRATEPROPERTIESOFASYSTEMINTOINTERCONNECTEDSUBSYSTEMSITHASPROVENITSGREATVALUEINTHEDESIGNOFELECTRONICCIRCUITSTHELUMPEDNETWORKAPPROACHALSOOFFERSAPOWERFULDESIGNTOOLFORMICROFLUIDICSYSTEMS35TOILLUSTRATETHEFARREACHINGANALOGYBETWEENDIFFERENTPHYSICALDOMAINS,WEHAVEREBUILTANELECTRONICASTABLEMULTIVIBRATORNETWORKINTHEHYDRAULICDOMAIN4THESYSTEMCONSISTSOFHYDRAULICCAPACITORS,RESISTORS,TRANSISTORSANDPARASITICCOILSBASEDONTHISMICROHYDRAULICSYSTEMTHESCALINGBEHAVIOUROFLOWREREYNOLDSNUMBERHYDRAULICSYSTEMSHASBEENANALYZED2HYDRAULICFUNDAMENTALSINEVERYPHYSICALDOMAINACONSERVEDQUANTITYQCANBEDISTINGUISHED1THEFLOWISTHERATEOFEXCHANGEOFTHISCONSERVEDQUANTITYBETWEENSUBSYSTEMSINTHEHYDRAULICDOMAINTHEFLOWVARIABLEISTHEVOLUMEFLOWTHEEFFORTISTHETENSIONTHATGOVERNSTHEEXCHANGEOFTHECONSERVEDQUANTITYBETWEENSUBSYSTEMSINTHEHYDRAULICDOMAINTHEEFFORTVARIABLEISTHEPRESSUREPPA21HYDRAULICRESISTORSTHEHYDRAULICRESISTORPHYSICALLYISALIQUIDFLOWRESTRICTION,SYMBOLICALLYREPRESENTEDASINFIG1AFORALINEARFLOWRESISTOR,THERESISTANCERISDEFINEDBYWHEREP12P1P2ISTHEPRESSUREDROPACROSSTHERESISTOR,ANDTHEVOLUMEFLOWTHROUGHTHERESISTORATSUFFICIENTLOWRETHEFLOWINADUCTISLAMINARANDFULLYDEVELOPEDPOISSEUILLEFLOW,ANDTHEPRESSUREDROPPACROSSTHEDUCTISPROPORTIONALTOTHEVOLUMEFLOWRATEFORADUCTOFARBITRARYCROSSSECTIONTHERESISTANCEISGIVENBY6WHEREFISTHEFANNINGFRICTIONFACTOR,LISTHELENGTHOFTHECHANNEL,ISTHEVISCOSITYOFTHELIQUID,DHTHEHYDRODYNAMICDIAMETER,ANDATHECROSSSECTIONALAREAFORALAMINARFULLYDEVELOPEDFLOWTHEPRODUCTFREK,ADIMENSIONLESSCONSTANTONLYDEPENDINGONTHESHAPEOFTHECROSSSECTIONTHEHYDRAULICRESISTORSWEHAVETESTED,WEREREALIZEDBYANISOTROPICKOHETCHINGINTOASILICONWAFERANDCLOSINGOFTHECHANNELBYANODICBONDINGOFAGLASSWAFERONTOTHESILICONFIG1BDSHOWASIDEVIEW,ACROSSSECTIONANDATOPVIEWOFTHEIMPLEMENTEDRESTRICTIONSRESPECTIVELYFIGURE1HYDRAULICRESISTORASYMBOLICREPRESENTATIONBSIDEVIEWOFREALIZEDRESTRICTIONSCCROSSSECTIONOFEALIZEDRESTRICTIONSDTOPVIEWOFAREALIZEDRESTRICTIONFORTHESETRIANGULARCHANNELSWITHATOPWIDTHOF2WTHERESISTANCEISGIVENBYTHELIMITSOFTHELINEARREGIMEHAVEBEENDETERMINEDANALYTICALLYANDVERIFIEDEXPERIMENTALLYFORLIQUIDS7ENTRANCEANDEXITEFFECTSRESULTINANONLINEARRELATIONBETWEENP12ANDTHEYCANBENEGLECTEDIFTHECHANNELISLONGCOMPAREDTOTHEHYDRODYNAMICENTRANCELENGTHATLOWRETHEENTRANCELENGTHLHYINCREASESLINEARLYWITHREFORCIRCULARCHANNELSWITHADIAMETERDTHISISEXPRESSEDBY622HYDRAULICCAPACITORSTHEHYDRAULICCAPACITORPHYSICALLYISANELASTICMEMBRANEACROSSWHICHAPRESSUREDIFFERENCECANBEMAINTAINEDITISSYMBOLICALLYREPRESENTEDINFIG2ATHECAPACITORESTABLISHESARELATIONBETWEENTHEPRESSUREDROPACROSSTHEMEMBRANEANDTHEDISPLACEDVOLUMEFORALINEARCAPACITORTHECAPACITANCECISDEFINEDBYWHEREVISTHEVOLUMEOFTHEDISPLACEDLIQUIDBYBENDINGOFTHEMEMBRANEBECAUSETHEVOLUMEVISCREATEDBYACCUMULATIONOFTHEVOLUMEFLOW,5CANBEREWRITTENTOFINDARELATIONBETWEENEFFORTANDFLOWFIGURE2HYDRAULICCAPACITORASYMBOLICREPRESENTATIONBCROSSSECTIONOFACAPACITORREALIZEDINGLASSSILICONGLASSTECHNOLOGY,SHOWINGTHEDEFLECTIONOFTHEMEMBRANEUNDERINFLUENCEOFAPRESSUREDIFFERENCEFIG2BSHOWSACROSSSECTIONOFACAPACITORREALIZEDINAGLASSSILICONGLASSSANDWICHFORDEFLECTIONSSMALLERTHANTHETHICKNESSOFTHEMEMBRANETHEREISALINEARRELATIONBETWEENTHEAPPLIEDPRESSUREDIFFERENCEANDTHEMEMBRANEDEFLECTIONINTHISCASEASIMPLEEXPRESSIONFORTHECAPACITANCECANBEDERIVEDWHEREAISTHERADIUSOFTHEMEMBRANE,ANDDISTHEFLEXURALRIGIDITYOFTHEMEMBRANE,DEFINEDBY,INWHICHEPAISTHEYOUNGSMODULUS,THEPOISSIONSRATIO,ANDHMTHETHICKNESSOFTHEMEMBRANE中文翻译柔韧力液压设备维修和机械加工摘要液压和气动代理系统工程部门和SCHYDRAMOLDSRL公司的合作实现了一些表演上的液压与气动领域的产品文章提出了提供最具代表性的为机械加工和维护液压圆滑设备力量。液压设备的大部分组成部分是有专利的或是专利的要求,技术或技术创新即这些专利的整个部分因为文章有一个普遍的技术特征,在演示文稿将完成特别是使用地区和液压设备的柔韧力优势的性能特点。关键词液压装置、维修、力学性能工作。介绍使机械工作具有柔韧性的多功能模块化设备,这在液压传动基础上,实现了IMM的生产厂从有力的石化,交通方面的公司向维护大公司的框架生产公司的转化。所有的同时考虑到有限的工作空间,将有提出从大型液压设备的调色板柔韧力由公司的SCHYDRAMOLD(压力源,液压机,液压工具,液压设备而开发的每一段新的或现代化的设备系列3000酒吧,液压升降设备),在它下面将公布下一液压设备等现代作品。在工作中用到的设备呈现在DISAHP框架研究报告中并对其他文件作了研究。2液压设备分析力21压力源力量水力设备的压力来源由SCHYDRAMOLDSRL产生了是有电或热量引擎和水力指南或脚蹬泵浦的水力代理单位与电引擎的水力驱动装置描述电动液压的驱动装置HUEH是供应以简单或双重行动的液压缸的高压来源从一些设备结构、水力设施或者装置,并且他们与直到700个酒吧一起使用相对小率流程和压力,FIG1。工作被发展的压力可以根据任务被调整30700吧。FIG1电动液压的驱动装置11电引擎2乘算器3油接收器4工作台。表1电动液压驱动驱动装置特点1油接收器L10203040电引擎KW154高压流速L/MIN0515低压流速L/MIN616最大压力吧700重量KG84176优势电动液压的驱动装置好处HUEH是他们提供可能性维护入压力,各自水力阻碍任务并且根据直到700吧的任务处理压力的一个精确设置它允许圆筒冲程的永久控制并且从第一步的自动换向到第二压力步分别从快速的开始到技术突破它允许电遥远的命令,而电荷电势是24VCC,有油温监视可能性和自动断开对55C的价值它有水力盘区泵浦、阀门,滑阀的液压元件,并且它在优选的行为起作用对从半公称压力的最大值,提供先进的可靠性它有低级噪声在70DB以下它同时供应的可能性的2,3或4圆筒通过对一个附上分支2,3。用热引擎的液压驱动装置描述用热引擎HUMUTH的液压驱动装置从与卓越的韧性的新产品标度入领域和他们进行起作用与直到700吧小流速和压力,FIG2。图2热发电机的液压驱动装置41热机,2加速器3操作台,4油接收器表2用热引擎1的水力驱动装置特征油接收器L10电动发动机功率KW12高压流速L/MIN035低压流速L/MIN33最大压力巴700重量KG40用热机的液压驱动装置有一个开始的命令,压力的变化从第一步到第二步同样使人工操作化4优点水力驱动装置提供与那些的相似的好处被提出在与电引擎的水力驱动装置的优点。另外的好处包括流动性到由于低重量的领域里和它不依靠一个固定的电源例如被连接对于系统的单元。22液压机液压机是用于各种各样的应用的设备例如冷的变形、切割,固化,煞车皮和推力板,压力轴承拉出器。这些水压机可以为其他适合他们是需要的机械的应用按提取强迫要求作用。液压机描述水压机车间HPH075从被关闭的立场组成框架固定的上面横断专栏、可调整的底部横断,基本的板材可移动的,在具有双重作用的HCHD075150的液压缸上安装的一横截支架,被设置的板材,按螺栓和螺母,FIG3。FIG3液压机75TF1基本盘2专栏;3底部横断;4液压缸HCHD0751255上部横断6压力螺栓7压力板材。表3液压机特点力TF70冲程MM150压力BAR700在直接应用这之中水压机该当提醒脱套和齿轮制帽工人从工具箱的传动轴从攻击小齿轮末端的紧迫和制帽滚珠轴承从逐渐变细的小组从被阻塞的子集的按和提取各种各样的证明样品的冷的变形。优点液压机具有模化构造,可移动,并且有下等横断的一个被标注的解决系统,在各种各样的75MM的范围的确定高度。锻压横向支架代表液压缸位置的一个容易的解决系统因而允许紧迫的轨章程液压机有实现所有技术操作的板材设置,螺栓和紧迫螺母从这个项目结果,因为减少的重量的作用它是容易运载,在它的重量和达到的力量之间的一个优选的报告由于行动对最大值达到700吧。23液压工具在机械加工和维修的过程中使用的工具是多种多样的,许过应用在机械工程里。那些在液压工具之中被提到的弯曲管道的设备和切割的液压设备。弯曲的管子的设备描述弯曲的模板,固定在液压缸的代理标尺和有适当的串描出,因此用管道输送维度并且变化射线,它将行动在跟随被变形的管子在休息的二条轮渡的管子指南,固定在设备板材之间。它可能降低允许模板介绍和剩余装置的优越板材FIG5的渡轮。弯曲管子类型设备HDITM020300是液压驱动的设备,并且它注定在维护的并且修理区段的设施管子寒冷时弯曲。表4弯管的设备特点描述1过载TF200冲程MM60管直径2”4”压力BAR700图5弯管设备11三脚架2固定板材3转板4螺栓5HCHD020300,6型液压缸表5HDITM020300型弯管设备的工作特点1外径TOLI/MM3/8171/221,253/43/426,4133,511/442,2511/248,25260管的弯曲壁厚MM2,753,253,5444,254,5曲率半径MM506490120150200235形式最大弯曲角度GRAD120指导数2支,普遍的切割20TF的力的液压设备的描述设备有一个金属体,通过被焊接的构造实现,这个构造就是简型HCHS020028液压缸。一个可以一个可以移动的刀具和液压杆和一个固定的刀体装在一起,(如图6)实行操作的液压缸通过与一个高压源(HPHP700的人工泵或液压脚蹬泵),通过一个快速的联结和液压的灵活的管子。半成品位于两把刀具之

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号