摘要

模具是工业生产中使用极为广泛的主要工艺装备,它是当代工业生产的重要手段和工艺发展方向,许多现代工业的发展和技术水平的提高,在很大程度上取决于模具工业的发展水平。

本文介绍了注射模具的特点及发展趋势,叙述了电话机听筒注射模具设计与计算的详细过程,介绍了该塑件成型工艺、注射模具的结构特点与工作过程,阐述了在有斜滑杆抽芯的注射模设计中应注意的事项。

采用此模具能够保证塑件尺寸外形以及表面要求,而且成本低、结构简单、开模容易、效率高,具有较强的实用性。

关键词:电话听筒;注射模具;抽芯

The Plastic Mold Design of Telephone HandsetCover

Abstract

Mold is widely used in industrial production the main technological equipment, It is an important means of modern industrial production and process development direction ,Many modern industrial development and the improvement of the technical levels ,Largely depends on the development of die and mold industry level.

The characteristics and developments of injection mold will be introduced in this paper. The designing and calculating of injection mold of microphone will be stated in detail. The forming process of the product and the structure characteristics as well as working process of the injection mold will be introduced .The attention should be paid in the design of the injection mold for the part with lifters also will be stated.

Using this mold can guarantee plastics dimension appearance and surface requirements,And low cost, simple structure and easy to open mold, high efficiency, with strong practicability.

Key Words: microphone;injection mold;core pulling

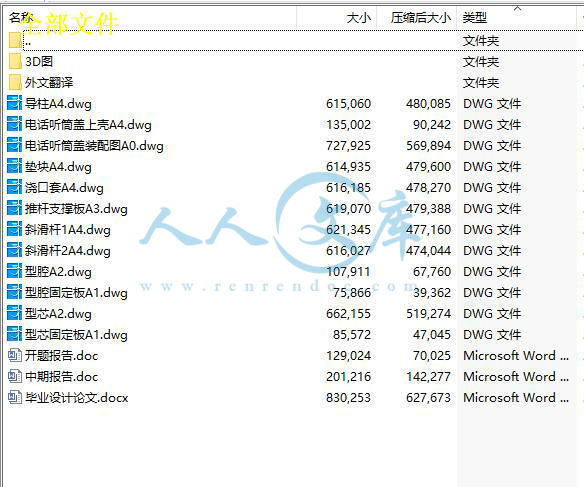

目录

1 绪论 1

1.1前言 1

1.2塑料模具的特点 1

1.3塑料模具设计的发展概况 2

1.4课题的研究方向 3

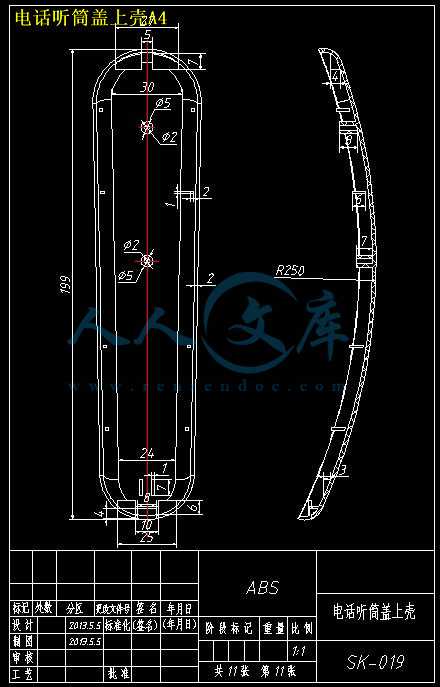

2 塑件的材料选择及工艺分析 4

2.1塑件材料选择 4

2.2塑件工艺性 4

2.3塑件的结构设计 5

2.4塑件尺寸及精度 6

2.5塑件表面粗糙度 7

2.7塑件的体积和质量 7

2.8塑件分型面的确定 7

3 注射成型工艺方案及模具结构的分析和确定 8

3.1注射成型工艺过程分析 8

3.2浇口种类的确定 8

3.3型腔数目的确定 9

3.4注射机的选择和校核 9

3.3.1注射量的校核 9

3.3.2工艺参数校核 10

3.3.3安装参数校核 10

4 浇注系统的设计 12

4.1浇注系统的组成 12

4.2浇注系统设计原则 12

4.3流道系统的设计 12

4.3.1主流道的设计 12

4.3.2分流道的设计 13

4.3.3浇口的设计 14

4.3.4冷料穴的设计 15

5 成型零部件工作尺寸的计算 16

5.1成型零部件结构设计 16

5.2成型零部件的工作尺寸计算 17

5.2.1型腔径向尺寸计算 17

5.2.2型腔的深度尺寸 18

5.2.3型芯的径向尺寸 18

5.2.4型芯的高度尺寸 18

5.2.5中心距尺寸计算 18

5.4模架的选用 19

5.4.1模具基本类型的确定 19

5.4.2模架的选择 19

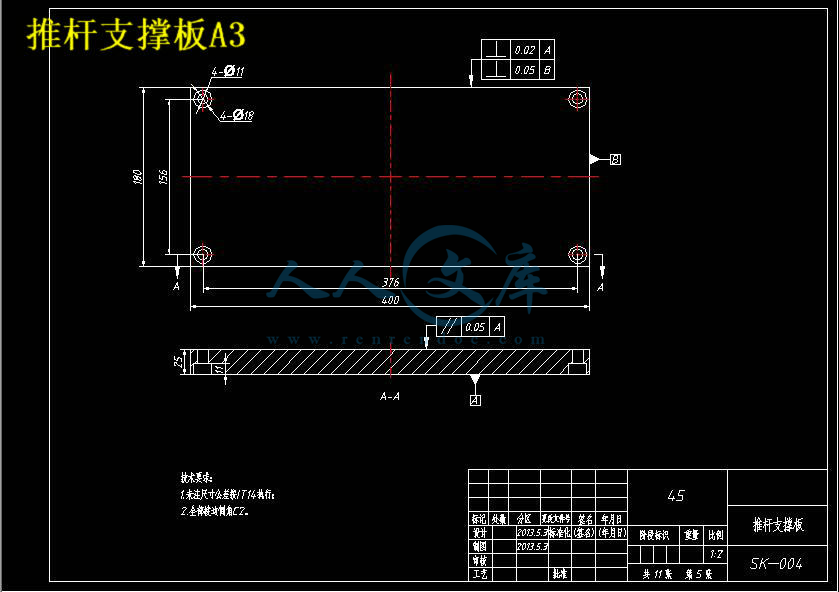

6 脱模机构的设计 21

6.1脱模机构的选择 21

6.2顶杆机构设计 21

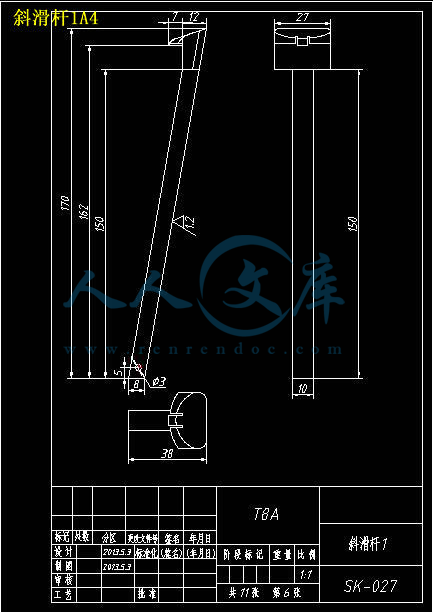

6.3斜滑杆侧抽芯机构设计 22

7 注射模温度调节系统 23

7.1温度调节对塑件质量的影响 23

7.2冷却系统的设计规则 23

7.3排气结构设计 24

8 模具的材料 25

8.1成型零件材料的选用 25

8.2注射模用钢种 25

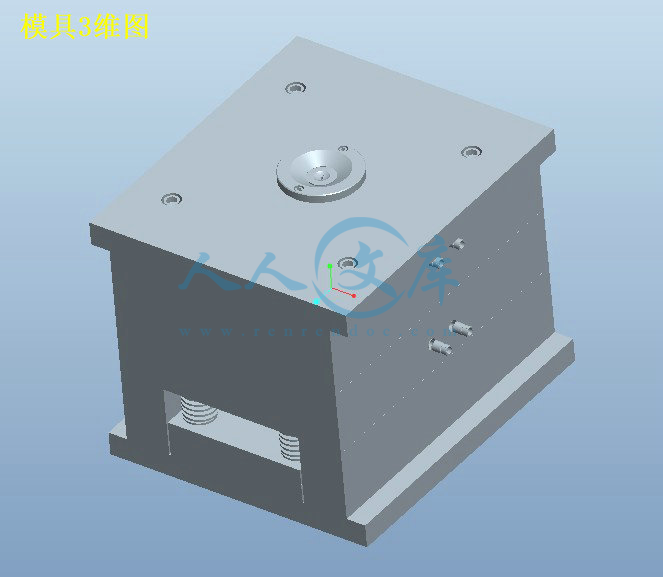

9 模具装配图 26

10 模具的可行性分析 28

10.1本模具的特点 28

10.2市场前景与经济效益分析 28

11 结论 29

致谢 30

参考文献 31

毕业设计(论文)知识产权声明 32

毕业设计(论文)独创性声明 33

1 绪论

1.1前言

随着中国当前的经济形势的日趋好转,在“实现中华民族的伟大复兴”口号的倡引下,中国的制造业也日趋蓬勃发展,而模具技术已成为衡量一个国家制造业水平的重要标志之一,模具工业能促进工业产品生产的发展和质量提高,并能获得极大的经济效益,因而引起了各国的高度重视和赞赏[1]。在日本,模具被誉为“进入富裕的原动力”,德国则冠之为“金属加工业的帝王”,在罗马尼亚则更为直接“模具就是黄金”,可见模具工业在国民经济中重要地位。我国对模具工业的发展也十分重视,早在1989年3月颁布的《关于当前国家产业政策要点的决定》中,就把模具技术的发展作为机械行业的首要任务。

川公网安备: 51019002004831号

川公网安备: 51019002004831号