摘 要

本文主要介绍了淋浴喷头支架塑料件的注射模设计,其间要参考大量与塑料成型相关的资料和翻阅各种模具设计手册,并通过计算以确定模具的具体模具制造技术迅速发展,已成为现代制造技术的重要组成部分。如模具的CAD/CAM技术,模具的激光快速成型技术,模具的精密成形技术,模具的超精密加工技术。根据成型工艺要求,在原有塑料件的基础上介绍了其注塑成型模具的结构,阐述了模具设计要点及工作过程。首先要从塑料生产工艺上对所要设计的产品进行工艺的分析与计算,然后在分析计算的基础上并参看相关的资料确定成型工艺方案,再在此基础上进入模具总装配图的结构设计。在此基础上对注塑模具的主要零部件的尺寸进行设计与计算,期结构及尺寸,通过不断的计算与修改,并在指导老师的悉心关怀和耐心指导下进行不间断的反复修改,最终独立完成这次毕业设计。其材料为ABS。根据ABS塑料的工艺特性和产品的使用要求,分析了手表盒盒底的结构特点和成型工艺。本设计采用CAD技术进行模具装配图及零件图的绘制。对模具进行了成型零部件、浇注系统、侧向抽芯机构、推出脱模机构及冷却系统的设计分析。最后,完成模具总装图设计及主要零件图的绘制,从而确保模具结构的可靠性、合理性和实用性。

关键词:塑料;模具设计;CAD

shower bracket plastic injecting mold design

Abstract

This article mainly introduced the shower bracket plastic injection mould design, which to refer to a lot of useful information related to the plastic molding and through all kinds of mold design manual, and through the calculation to determine the specific mold die & mould manufacturing technology rapid development, has become an important part of modern manufacturing technology. Such as mould CAD/CAM technology, die of laser rapid prototyping technology, mold's precision forming technology and die of super precision machining technology. According to the forming process requirement, on the basis of the original plastic its injection molding mold structure is introduced, this paper expounds the key points of die design and working process. Must first from the plastic on the production process to design products for process analysis and calculation, and then on the basis of the analysis and calculation and see the relevant data to determine the molding process, and on this basis into the mold structure design of general assembly drawing. On the basis of the size of the main parts of injection mold design and calculation, phase structure and the size, through continuous calculation and modification, and in guiding the teacher's careful care under the guidance and patience to constantly modify repeatedly, finally completed the graduation design independently. Its material is ABS. According to process characteristics and product requirements of the ABS plastic, watches boxes were analyzed with the structure characteristics and molding process. This design using CAD technology to drawing die assembly drawing and part drawing. Has carried on the molding parts to mould the lateral core-pulling mechanism, gating system, and launched demoulding mechanism and cooling system design and analysis. Finally, complete the mold assembly design and main parts graph mapping, to ensure the reliability, rationality and practicability of the mold structure.

Key Words: Plastic; Mould design; CAD

主 要 符 号 表

T——成形周期

K——注射机最大注射量的利用系数,一般取0.8

M——注射机的额定塑化量(g/h或cm3/h)

M——浇注系统所需塑料质量和体积(g或cm3)

M——单个制品的质量和体积(g或cm3)

F——注射机的额定锁模力(N)

A——单个制品在模具分型面上的投影面积(mm2)

A——浇注系统在模具分型面上的投影面积(mm2)

p——塑料熔体在模腔内的平均压力(MPa),通常模腔内压力

S——注射机最大开模行程(mm)

H——推出距离(脱模距离)(mm)

H——包括浇注系统在内的制品高度(mm)

Q——抽拔力(N)

A——侧型芯被包紧的截面周长(cm)

h——成型部分深度(cm)

q——单位面积积压力

μ——摩擦系数

a——脱模斜度

目 录

1 概论 1

1.1绪论 1

1.2国内、外塑料模具发展现状 1

1.3塑料模具发展走势 2

2 塑件结构和材料分析 4

2.1塑件结构分析 4

2.2塑件材料的分析 6

2.3塑件结构的工艺分析 6

3 成型零件结构设计 7

3.1分型面的设计 7

3.1.1分型面的基本形式 7

3.1.2分型面选择的基本原则 7

3.1.3分型面的确定 7

3.2型腔布局 9

3.2.1型腔数目的确定 9

3.2.2型腔分布 9

3.3成型塑件的结构设计 9

3.4成型零件工作尺寸的计算 10

3.4.1模具成型零件的工作尺寸计算 10

3.4.2型腔壁厚的计算 10

4 注射机的初选择 11

4.1 塑件体积的计算 11

4.2计算塑件的质量 11

4.3按注射机的最大注射量与初确定型腔数目 11

4.4选择注射机及注射机的主要参数 12

4.4.1选择注射机 12

4.4.2注射机主要参数 12

4.5 注射基本压力 13

4.6 锁模力的计算 13

4.7模具厚度与开模行程 14

4.7.1模具厚度 14

4.7.2开模行程 14

5 浇注系统的设计 15

5.1浇注系统的组成 15

5.2主流道的设计 15

5.3分浇道的设计 16

5.4浇口的设计 17

5.5冷料穴的设计 18

6 分型与抽芯机构的设计 19

6.1斜导柱的结构尺寸设计 19

6.2斜导柱长度计算 19

6.3抽芯力 20

6.4型腔和型芯工作尺寸计算 20

6.4.1凹模的径向尺寸计算 21

6.4.2凹模的深度尺寸计算公式 22

6.4.3凸模型芯直径的计算 23

6.4.4凸模型芯高度的计算 24

7 厚度计算 26

8 导向机构的设计 27

8.1导向零件的作用 27

8.2导柱、导套的设计 27

8.2.1导柱的设计 28

8.2.2 导套的设计 28

9 推出机构的设计 29

9.1采用顶杆的形式及其固定方法 29

9.2 推件力的计算 30

9.3 推杆的设计 30

10 温度调节系统的设计 32

10.1冷却水回路布置的基本原则 32

10.2 冷却系统的作用 32

10.3冷却时间的计算 33

10.4冷却水道热传面积 33

10.4.1 冷却水道热传面积 33

10.4.2冷却水的体积流量 34

10.4.3冷却水道热传面积 34

11 模具的校核 35

11.1注塑工艺参数的校核 35

11.1.1 最大注塑量的校核 35

11.1.2注射压力的校核 35

11.1.3锁模力的校核 35

11.2模具安装尺寸的校核 35

11.2.1喷嘴尺寸的校核 35

11.2.2模具厚度校核 36

11.2.3模具外形尺寸校核 36

11.3开模行程的校核 36

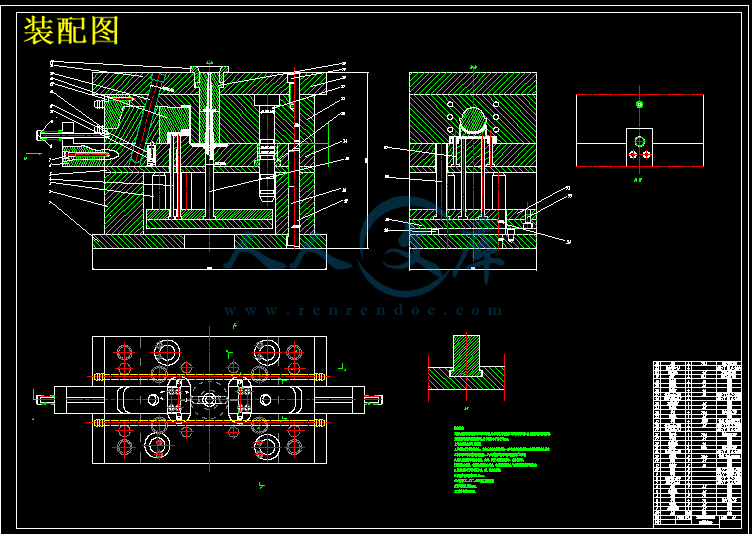

12 确定装配图 37

13 结论 38

13.1总结 38

13.2体会 38

参考文献 39

致 谢 40

毕业设计(论文)独创性 41

毕业设计(论文)知识产权声明 42

1概论

1.1绪论

塑料模具的设计和制造水平反映了机械设计和加工的水平,模具的设计已应用了当代先进的设计手段。CAD、CAM、CAE的逐渐广泛应用,使模具的设计效率大大提高,快速成型技术的应用以及现代加工技术的使用如高精度加工中心、特种加工技术的大量使用是模具的制造精度越来越高,加工周期越来越短。各行各业对模具的需求量与日俱增,我国的模具行业蒸蒸日上,正需要大量的模具设计与制造的技术人才。本课题为中等以上难度的塑料模具设计,从模具的结构设计,各种参数的设计与计算,材料的选择与处理,零件的加工工艺方案的制定,三维造型等均得到锻炼。

川公网安备: 51019002004831号

川公网安备: 51019002004831号