资源目录

压缩包内文档预览:

编号:10109297

类型:共享资源

大小:2.18MB

格式:ZIP

上传时间:2018-05-17

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

小型

挖掘机

液压

系统

设计

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

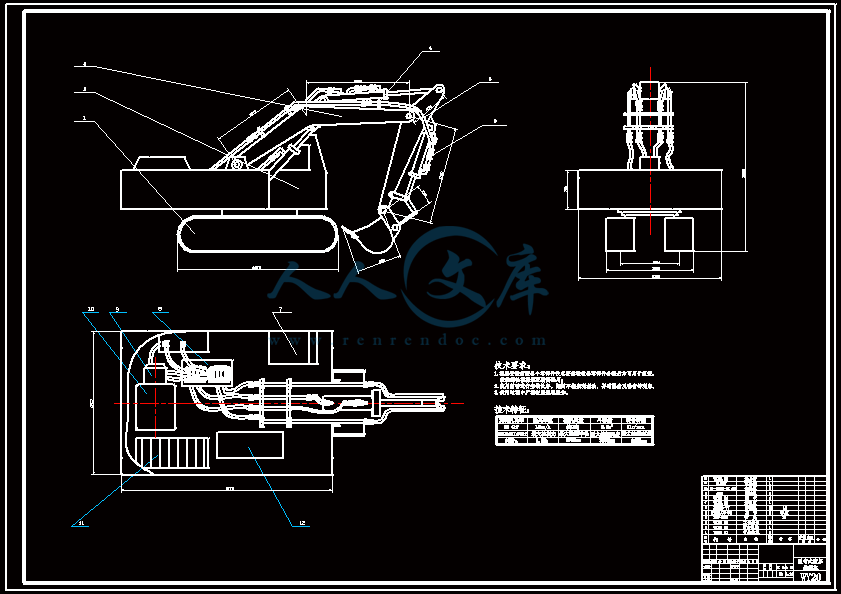

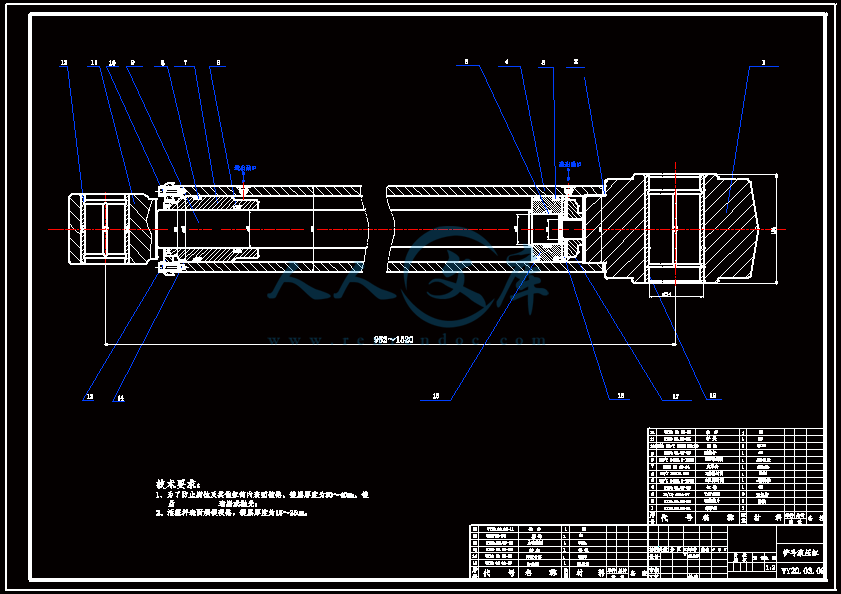

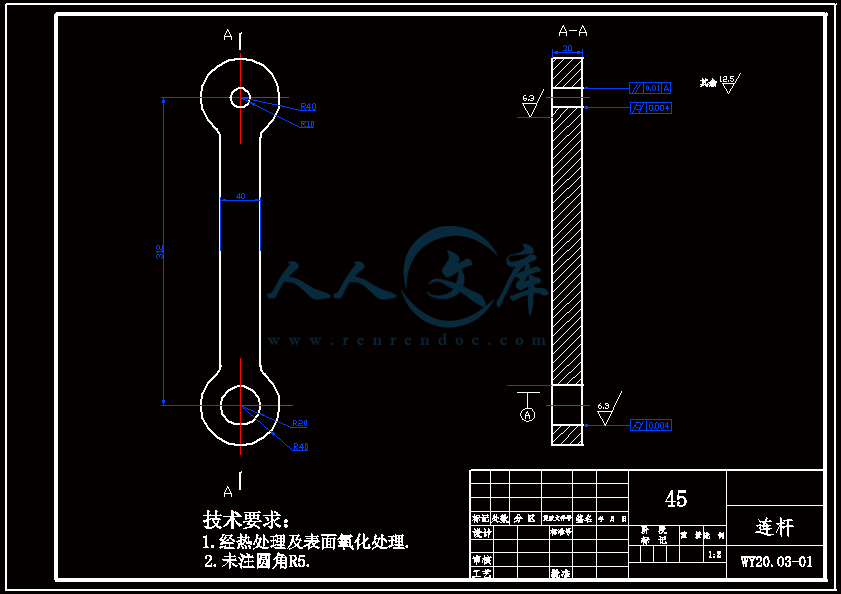

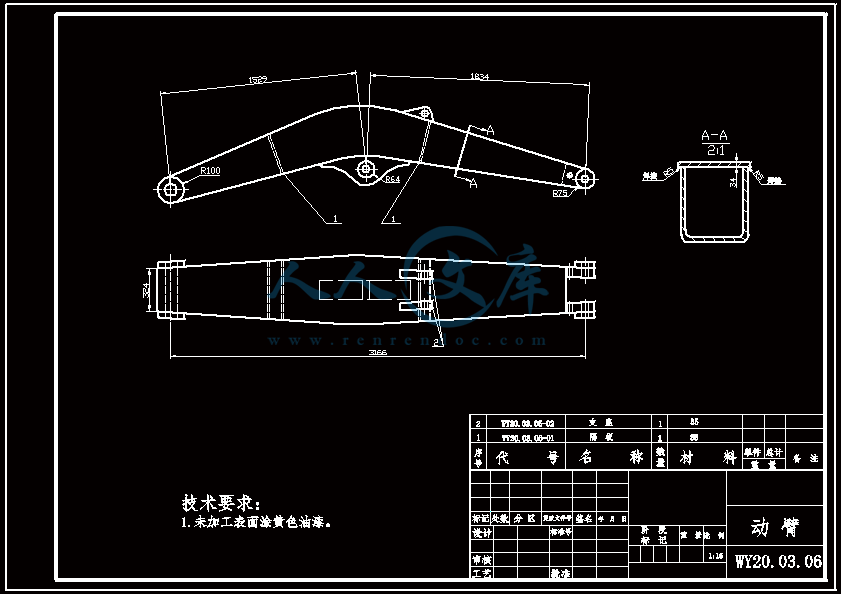

1毕业设计(论文)专用纸Modern construction machinery industry of technical progressLarge-size mechanical mining excavator is used widely in international and domestic engineering construction and mining performance, and its property defines the efficiency much.Now because the international market is opened step step, how to promote the quality of excavator is the key that a factory reinforces its competing force.In our country,the designing elevation and production quality on excavator can not keep up with international advanced technology applying on excavator.Now the advanced technology has already applied advanced designing method on excavator designing,such as electronic simulating theory,dynamic design, reliability design and so on.But in our country ,the most excavator design has still applied the traditional design method ,the modern design method has not began to be actually applied .The prime display is that the capability of self-design is not enough and the basic work has not done perfectly especially the excavator kinetics .The construct of excavator is very complex and the multiple movers often work simultaneously.at the same time its working environment is very bad and the eternal load varies randomly.As a result ,when designing the new product of excavator ,in order to ensure the performance safety,the designer not only has the basic theory analysis on static load computing ,but also do necessary work about the kinetics of mechanism to qualify the dynamic reliability in the period of designing .Trough the kinetic analysis ,the load property of all the elements in excavator can be decided so as to design reliable product .From the 1980s of the 20th century to the beginning of this century. Chinese and foreign engineering machinery technology products come from a maturity period of modernization along with a new technological revolution, Mechanical engineering products integrated technology to a new level. Electronic technology, micro-computer, 毕业2设计(论文)专用纸sensors, electro-hydraulic servo control system integration and transformation of the traditional mechanical engineering products, Computer-aided design and computer-aided manufacturing and computer-aided management of construction machinery and equipment manufacturing, IT network technology equipment, construction machinery sales and information transfer systems, thus enabling people to see a brand new construction machinery industry. New construction machinery products in the efficiency and operational quality, environmental protection, performance and automation are many areas due to the past. and toward the further robotic and intelligent direction. 1、 operating principles of Innovation : groundbreaking new law with the high-frequency vibration With scientific and technological research in the development, engineering machinery operating theory is constantly innovating. Operating mechanical engineering principles, including the cutting of earth, broken ground on the screen geotextile material, mixed with heating, right mixture of paving, leveling and compaction, etc. These operations Jimmy initially bionics and Newtonian mechanics-based, Modern science and the development of engineering machinery operating principle of laying the foundation for innovation. For example, mechanical vibration and pulse jet, the photoelectric effect and thermal physics, the application of mechanical engineering to save resources and improve the quality of construction improve production efficiency, reliability and driving comfort and a degree of automation to create conditions. Excavators, bulldozers, loaders, and other earthmoving machinery cutting groundbreaking project, we had no struggle milling, high-frequency vibration, Liquid gas jet method and porous ground breaking law. Groundbreaking use of the new operating principle of transformation to a bucket, can loosen the soil excavation for the high-intensity rock, Under normal circumstances can reduce the unit cost of earthwork 3毕业设计(论文)专用纸and improve production efficiency, and the soil near the building when substitute bored-blasting method.Vibratory Roller is a mechanical vibration and have reached a “sluggish vibration to“ operational effectiveness of the most powerful note. High-frequency vibration compaction technology is the application of modern dynamics in the mechanical engineering important research results, In vibratory roller simultaneously with the application of vibration isolation theory. 90s of the 20th century, there have been a level of vibration (vibration) and vertical vibration directional vibration compaction method, and an AM-vibration and different from the harmonic vibration of chaotic vibration vibratory compaction operating principle, and the formation of the corresponding series of vibratory roller. Impact Roller broke the existing traditional cylindrical roller structure, Use 3-5 edge with the pressure roller polygon dragged by a tractor, 2-3 times per second in order to impact on the ground. This has dramatic impact on the seismic wave propagation characteristics, the depth of compaction several times with the RCC and incremental, 5m in the depths of the degree of compaction of up 90%-92%. Impact Roller is static shock, vibration and rub it smashes the comprehensive role for large fill, Collapse dry sand and soil filling the compaction. Asphalt paver Weiping equipment is operating principles of mechanical engineering innovation typical example. Fung plate diesel, liquefied petroleum gas or electric heating and 60 Hz frequency of vibration, and using infrared, ultrasonic or laser leveling, is a multidisciplinary high-tech applications. This leveling the technology can be applied to the ground plane, as amlodipine or fine leveling the slope. Transfer frequency mechanical vibration is also commonly used for drilling, stone crushing and sieving and Shen pulling piling works. The stone drying can use diesel, fuel oil and coal combustion of various fuels on the asphalt from the barrel, heating and asphalt mixture, stirring and insulation process is the full use of thermal theory of physics. 毕业设计(论文)专用纸4Asphalt emulsion and some are modified chemical reaction physical specific application. 2、drive innovation : universal hydraulic and electric drive Hydraulic drive in the 20th century, the 1960s applied to the roller, only 10 years on the time has been spread and popularize. Now roller travel, vibration, steering and braking systems has achieved the full hydraulic drive. Hydraulic drive greatly simplified the roller drive and control system design, hydraulic drive a smooth, convenient manipulation effort, easy to achieve variable speed and automation, in general, improve the production efficiency of roller compaction and quality. Now foreign markets have seen very little mechanical transmission of the roller.Hydrostatic drive technology in the 1970s began to use bulldozers, and will soon be extended to a number of small and medium bulldozers and loaders, the United States John Deere, Caterpillar, Germany Bohai benefit companies and Dole produced by Komatsu of Japan has production and sales pushed Temple hydraulic machines and loaders. Hydrostatic drive not to use hydraulic torque converter, which dispense with the left lane and brake parts and mechanical drive, use of a safety valve on mechanical and hydraulic systems overload protection, and the index of smaller power play biggest index, its remaining power available in the auxiliary machinery operation. German company Deutsche mark and Lee Bohai Fall of other public companies in 1954 and in 1955 took the lead in developing a hydraulic excavator , but the hydrostatic transmission in large excavator is the popularization and application of the 1970s. Since the early 1980s, excavators and subdivided, is gradually realized - powered, rotary and the hydraulic excavator of. In the international market excavators, were all eliminated various mechanical drive. Late history of the birth of the road is more mechanical hydraulic drive-based, such as paver, soil stabilizer, Pavement milling machine, hydraulic transmission smoothness 毕业设计(论文)专用纸5help improve the quality of the roads paved. Drilling in the car and drilling machines, hydraulic transmission has replaced the previous aerodynamic, Wheeled modern cranes and machinery also piling work to the whole in the direction of hydraulic development. Electricity in industrial production while the application has a long history, but in mobile machinery is seldom used. This is because, firstly, to the motor capacity of, a motor with the same power as compared to the hydraulic motor, its weight and bulk to good times, to the machinery space layout brought great difficulties. In addition, the efficiency of electrical transmission over low efficiency and consumption of a large volume of non-ferrous metals. But electric drive can be well realized variable speed, braking and electrical power streaming - Drive more convenient and easy to large tub, large excavator and large loaders, engine-generator-electric wheels will transfer power. Germany Vogele also been developed for electric power will transfer wheel. Germany Vogele also been developed electric drive an asphalt paver, the aircrafts systems are all rotary motor driven electricity, Only Hopper CDCC and comfort slab leveling tank still use hydraulic transmission. The other is the regional mobile operations in the smaller mining site, the use of electric drive large excavator loaders, Such use of electric drive power transmission cables without the engine installed on the machines.3、ergonomic innovations : a people-oriented and simplified operation 1980s of the 20th century, Many of the worlds largest engineering machinery manufacturing company has invested considerable human and financial resources for modern design methodology of the research and used. Ergonomics is a “people-oriented“ design, with emphasis on the machines mutual coordination and crew safety, driving comfort, convenience in the drivers operation and maintenance technologies, such drivers both improved working conditions, and increased production efficiency, and some of the engineering machinery vibration, noise, emissions and the prevention of 毕业设计(论文)专用纸6roller drop from the development of the new standard, and even those laws. Now all kinds of projects are mechanical design roller defense and falling-object protective devices to protect the personal safety of the drivers, with the cab and are designed and installed. Indoor driving sufficient human space and broad vision, and to take the necessary seals, vibration, noise and temperature control measures. Indoor chairs, pieces of the stick, gauges and the monitor according to ergonomics and design and minimize the manipulation and control of parts. To reduce driver fatigue, to choose the suspension damping chairs, and to develop a gas-liquid system hanging with the cab floor. Electronic technology, mechanical engineering applications, which greatly simplifies the drivers operational procedures and to the machines technical performance. The use of electronic control machine can automatically choose the mode of operation, such as excavators to the three operating modes - boom priority, Rotary priorities and micro-adjustment tandem wheels all vibration and vibration. Electronic monitoring can detect and remove machines system failures, such as engine oil pressure loss. Fan fracture belt drive, hydraulic oil contamination or overheating and oil filter blockage, can promptly lights or audible alarm, by the use of electronic sensor device can handle automatic detection machines quality of the work, If random vibration testing of the degree of compaction roller, automatic detection and adjustment of the asphalt mixture ratio and size distribution outlet temperature.American muffler technology company developed an electronic silencer, electronic equipment engine exhaust noise analysis of the wave structure, and produce a phase difference of 180 with the acoustic interference, This “anti-noise“ and the engine exhaust noise offset, which over the purpose of the muffler. Such a muffler - can be used to eliminate the basic engine noise and the noise indoor driving. Muffler and isolation 毕业设计(论文)专用纸through the engineering machinery driving indoor noise can be reduced to 70dB (A) below.7In addition, by concentrating on lubrication, automatic lubrication and fault alarm, greatly reducing the engineering and mechanical maintenance workload. Dreiser companies axis articulated loader lubrication cycle extended to 2000h. oil and filter replacement cycle extended to 250h; Caterpillar loader routine maintenance to shorten the time 3.45min. 100 hours use of the technical maintenance for only 6-7min. 4、Creative : industrial design with the environment Modern science and technology of high-speed development, promoting social progress, for humanity to a high degree of material civilization and spiritual civilization. Industrial design is the product of industrial product design, product also known as the art form. Mechanical Products art forms should be able to demonstrate its function in a rational and external quality of uniformity, the product should reflect the advanced technology and meet the aesthetic requirements of modernity. For mechanical engineering, said it was “a Paper goods sold,“ That is an exaggeration, but not to modeling design is certainly not desirable. Modeling the mechanical engineering design of the machine can shape their structure, function and use requirements, paying and with the psychological and physical coordination. This modeling design should include ministries of proper body fluid, color coordination, Instrumentation layout beautiful and easy to operate and intuitive sign in the trademark symbol. Now the worlds major companies have attached great importance to the products of industrial design, and a specialized research and design. A world leader left the compactor manufacturers - BMW, his third of the mechanical compaction machine modeling experts from the industrial design Louis.L.lepoix design, have a good overall result. The series dismounting replacement 毕业设计(论文)专用纸filter, transmission pieces, hoses and routine maintenance is very convenient. Adopt modern arc-shaped dip in the cab and the engine hood broadminded, fluent lines, with the flavor of the times. Driving the steering wheel height and angle adjustable, choose a 8comfortable high back seats adjustable damping. Drivers prepare for a good operating environment. Instrumentation site design, easier to observe and control, tilt hood of the driver to provide a good perspective. Hydraulic steering gear shifted to the cab, driving to reduce indoor heat and noise. Arc-shaped windscreen of the cab and four SUPPORT able to isolate noise and vibration. indoor noise below 70dB (A).Many other engineering machinery are also different degrees of emphasis on industrial design, layout components such as depression, to reduce the center of gravity of the aircraft; Supporting appropriate to expand the area to increase the machines stability; about as symmetrical layout, to meet the aesthetic; Appearance removed some of the corner, the edge, to show the fluency, and other lines. Construction Machinery paint more of its industrial design is an important part of the unit should be interesting colors, increase the safety of the working environment, and with the field construction site is pure green fields, coordination, Topping the use of the waist line and increase the level to get off the color machines can increase the concentration of visual stability.、artificial intelligence Innovation : intelligent robotic machines Mechanical engineering in the construction field instead of the manual to expand the functions of the hands and feet, traditional machinery can be resolved in good physical and physiological burden, not to mention the relief of spiritual and psychological burden. Modern engineering machinery should be given its soulful, intelligent engineering machinery is a thinking mind (microcomputer) sensorium (sensors), neural network (electronic transmission). Derrnatopathy (power and transmission), and hand, foot bones (work with devices running) for telecommunications systems integration. Machine is not electromechanical integration of telecommunications and 毕业设计(论文)专用纸information technology with a simple, it poses the system must have five functions : detection and identification with the objects of their work and working conditions of the function; goal with under their own decision-making function; have to respond to the 9decision-making, implementation support movement functions; w

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号