骨轮零件的注射模设计注塑模具设计(全套含CAD图纸)

收藏

资源目录

压缩包内文档预览:

编号:10126789

类型:共享资源

大小:1.99MB

格式:ZIP

上传时间:2018-05-29

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

零件

注射

设计

注塑

模具设计

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

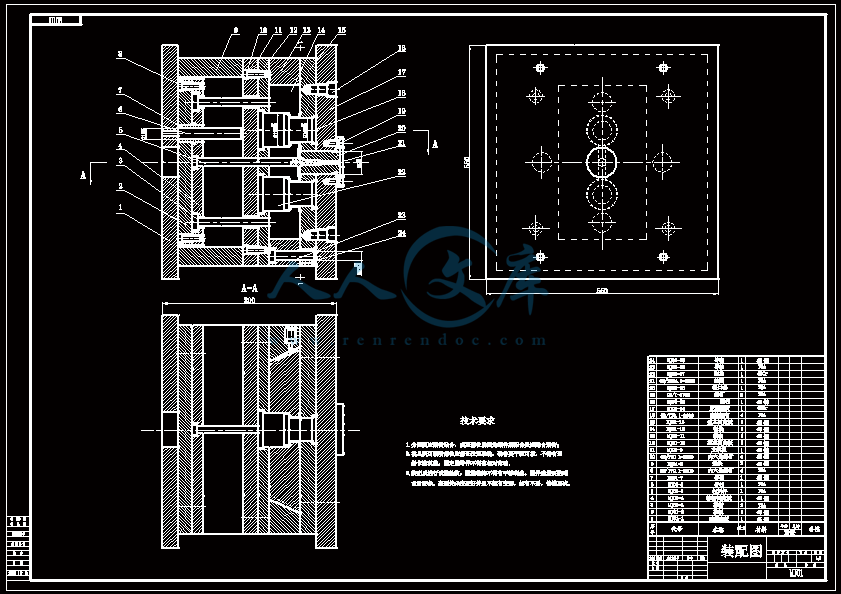

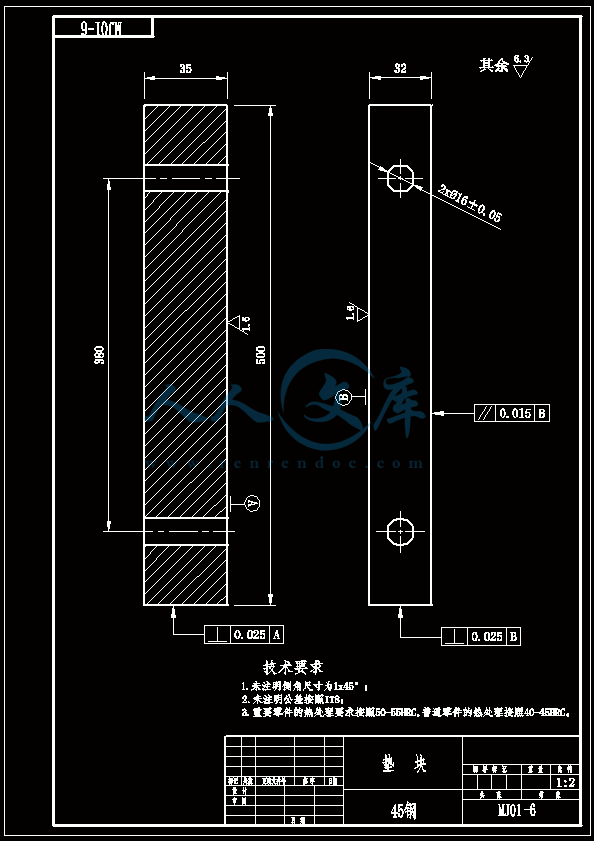

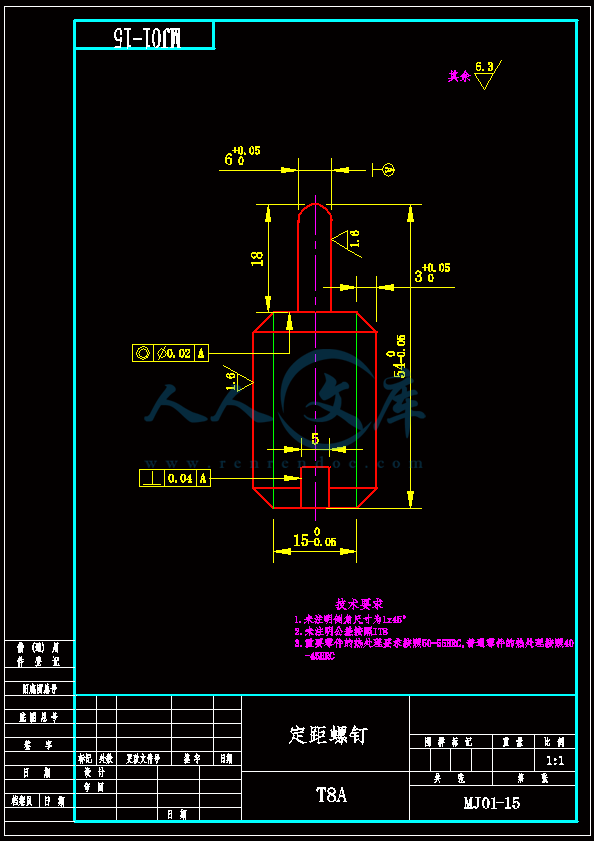

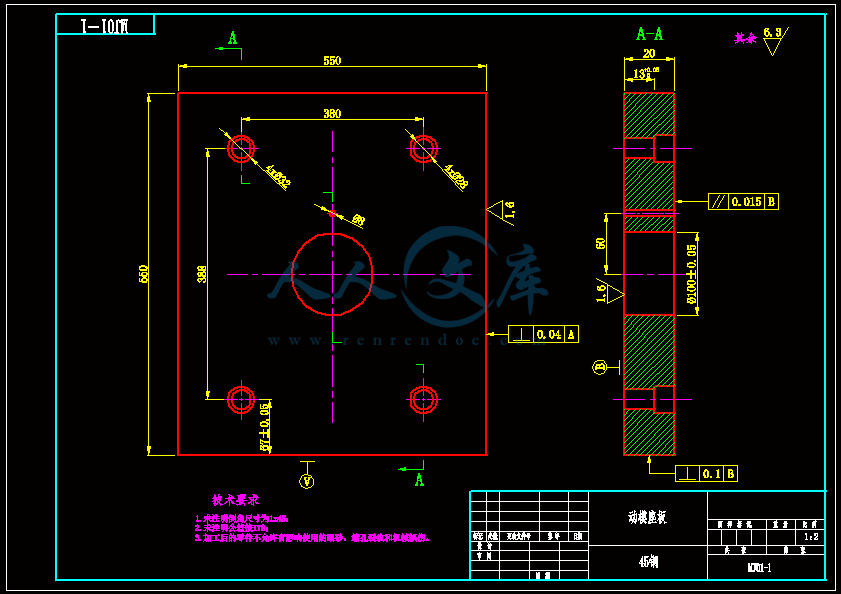

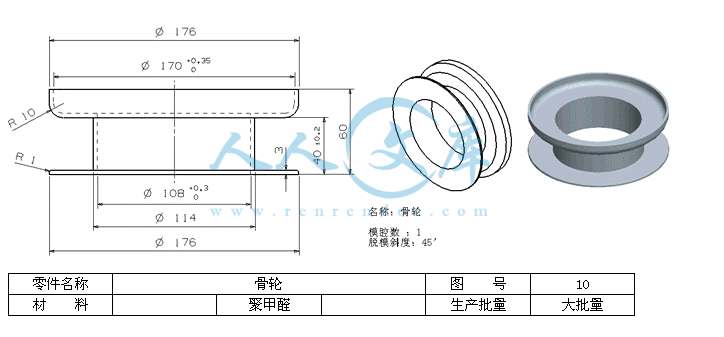

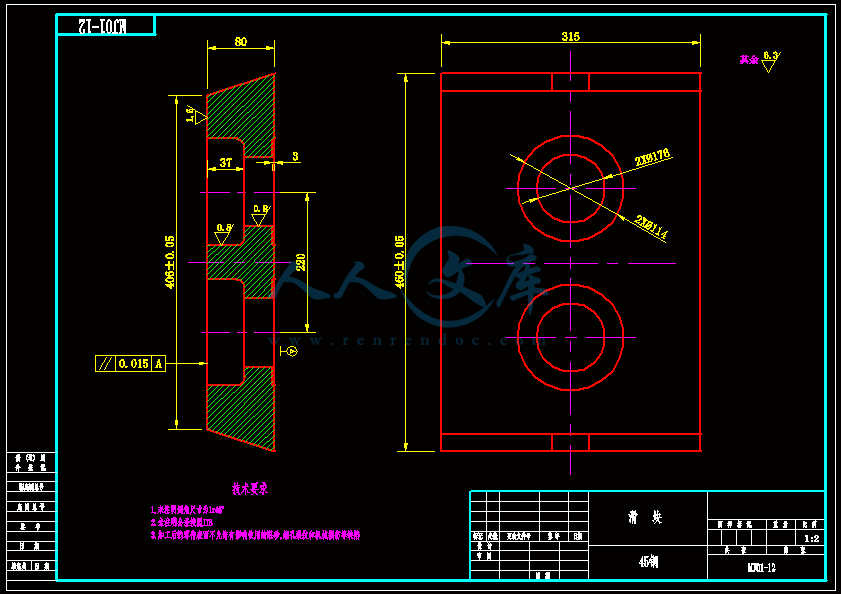

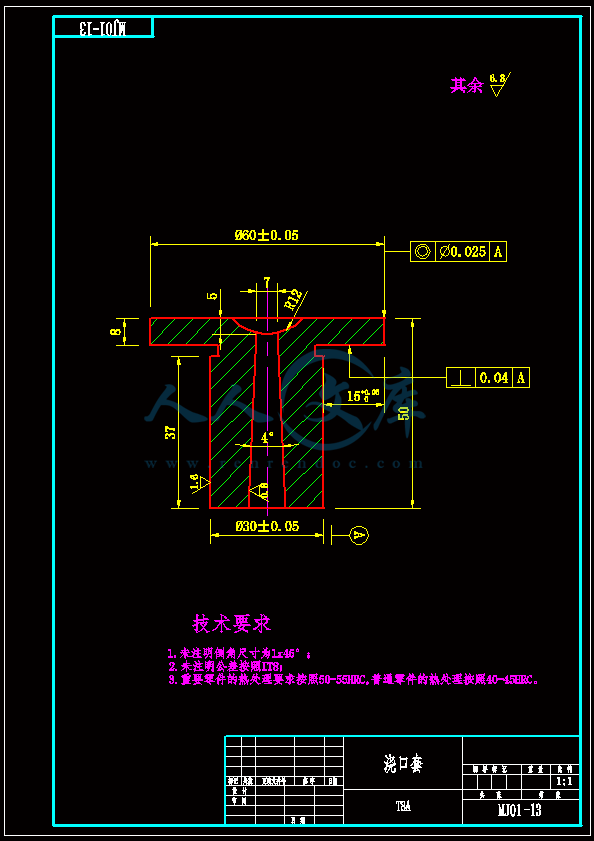

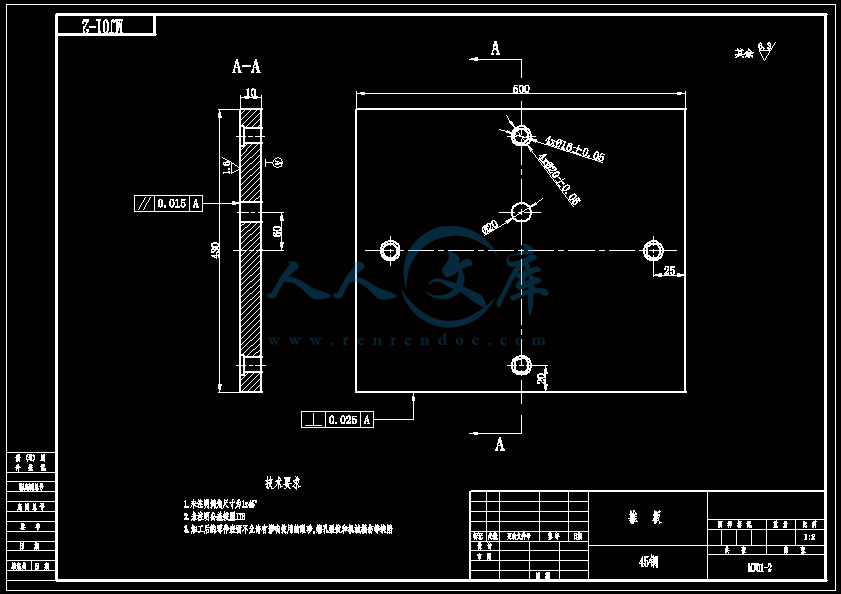

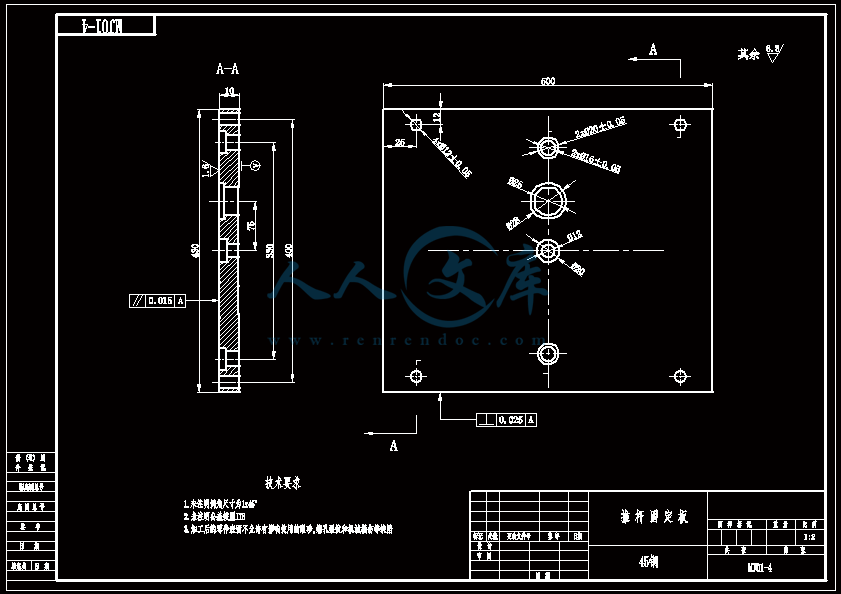

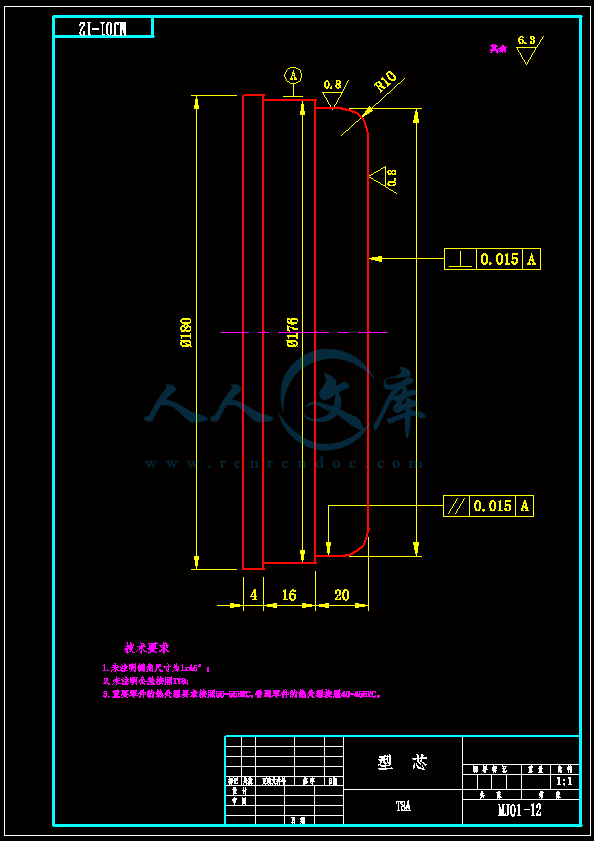

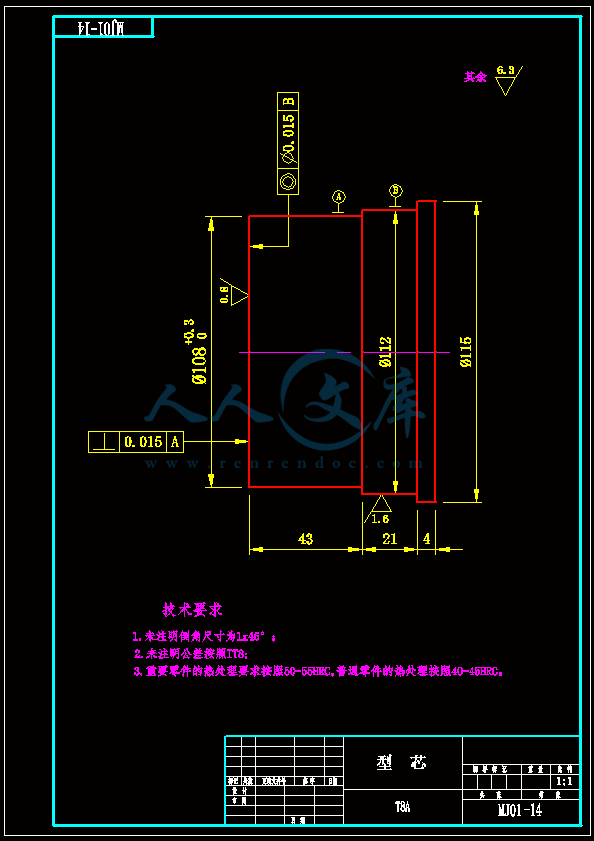

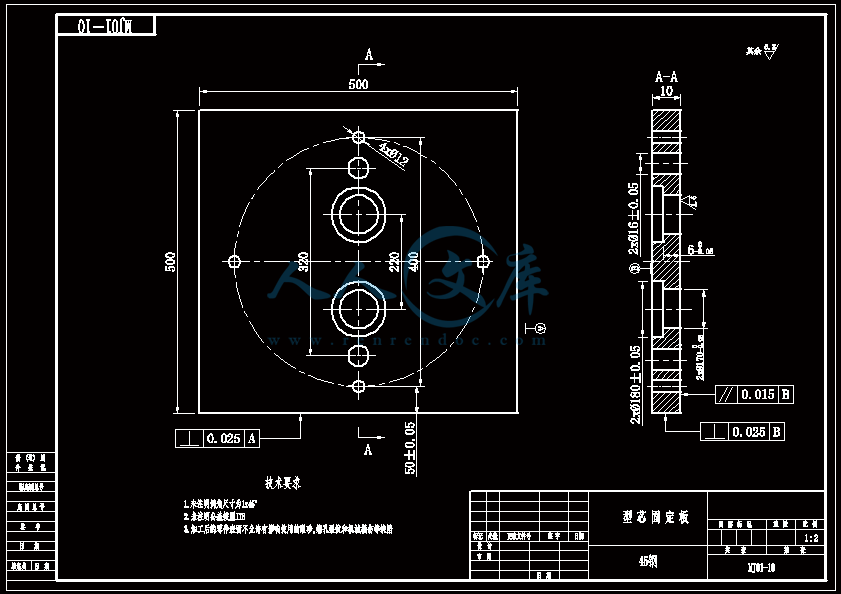

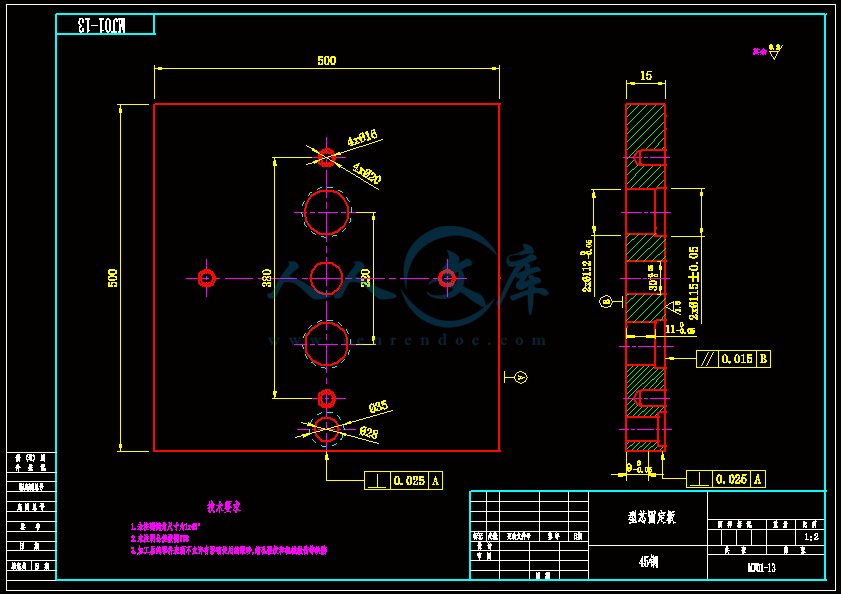

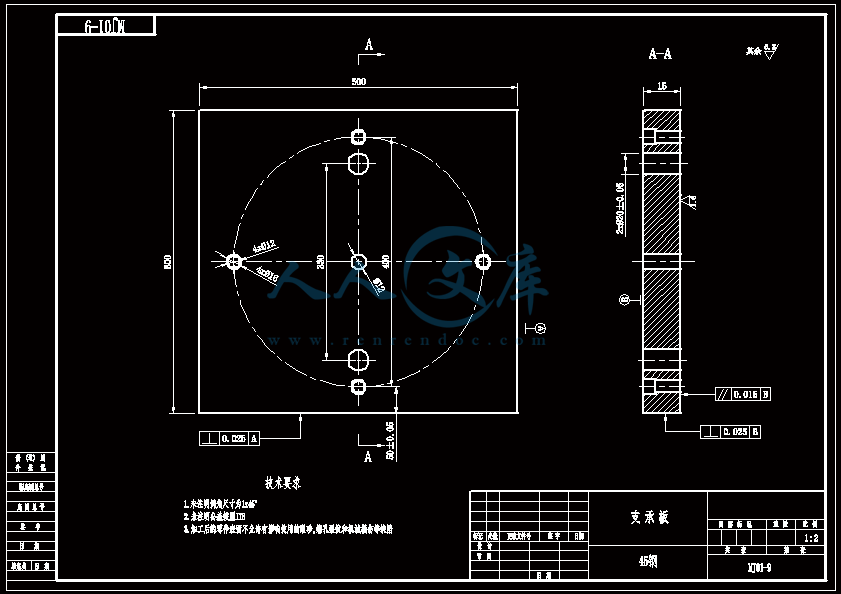

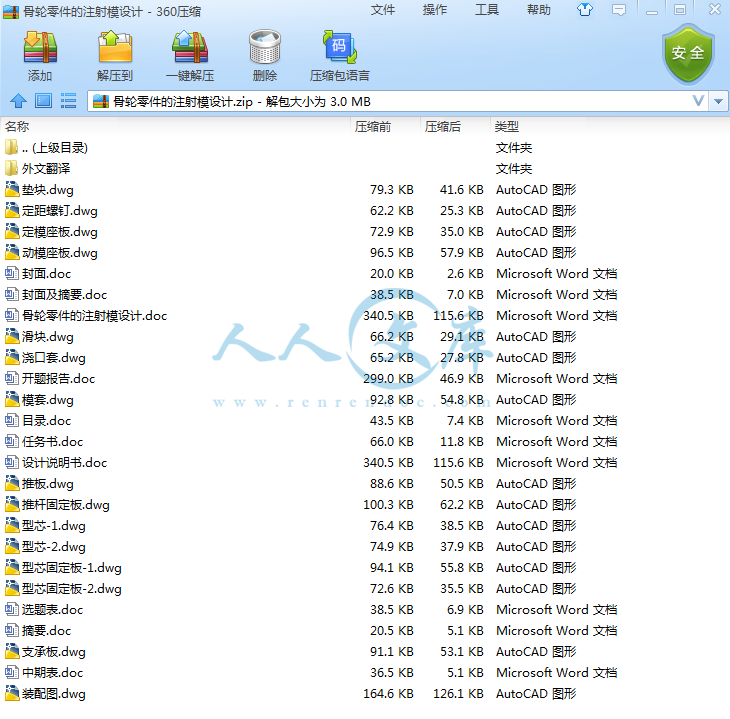

下载后包含有 CAD 图纸和说明书,咨询 Q 197216396 或 11970985摘要本论文是根据实际的需要设计出骨轮的注射模。在设计中采用的是聚甲醛的塑料,成型的方式为一模两腔,分析了产品的工艺性,确定了塑料的工艺参数和设计方案,以及它的总体结构和具体结构,并进行了一些必要的尺寸计算和强度校核。本文还对分型面、浇注系统、侧抽芯机构、顶出机构、脱模机构和温度调节系统进行了分析设计,完成了模具三维设计和工程图设计。通过设计,综合应用了大学期间的多数基础和专业知识,加深所学知识体系,掌握了应用 ProE 进行塑料模具的设计方法和技巧,熟悉了工程应用设计。关键词:注射模 塑料 成型 结构设计下载后包含有 CAD 图纸和说明书,咨询 Q 197216396 或 11970985AbstractThe present paper actual completes the plastic injection mould of gulun according to the practical necessary. Uses the POM plastic injection in the design to take shape, the formation way is a mold two cavities. The paper concretely studies products technology capability, and determines the formation equipment and the designing concept. Else, it determines the gross construction, each effective range concrete structure and carries on some essential size computation and the intensity examination. The paper also designs the halving-profile, the irrigate system, shuck institution, temperature adjust system and other systems. Finally, it completes the triaxiality models and the schedule drawings of the mould.Through this design, we have applied the university period most foundations and the specialized knowledge, deeply studies the knowledge system, have mastered the methods and skills of designing plastic mould with ProE, and have been familiar with the project application design.Keywords Plastic injection mould Plastic Forming structure design下载后包含有 CAD 图纸和说明书,咨询 Q 197216396 或 11970985目 录1 引言 .11.1 塑料模具的现状及发展 .11.2 塑料注塑模具的设计步骤 .41.3 课程任务要求 .72 方案分析与设计 .83 注塑成型的准备 .93.1 注塑成型工艺简介 .93.2 注塑机的选择 .113.3 注射模具分型面的选择 .133.4 注射模具浇注系统的设计 .143.5 注射模具成型零件和模体的设计 .183.6 注射模具的侧抽芯机构 .233.7 注射模具的顶出机构的设计 .243.8 塑料注射模具的排气设计 .253.9 塑料注射模具的温度调节系统设计 .253.10 模具结构设计 .264 注射模加工工艺设计 .264.1 坯料确定 .274.2 模板的平面加工 .274.3 塑料注射模具型腔常用加工方法及设备 .284.4 成型零件加工 .29结束语 .30致 谢 .31参 考 文 献 .33附录:设计图纸(另外装订)下载后包含有 CAD 图纸和说明书,咨询 Q 197216396 或 11970985下载后包含有 CAD 图纸和说明书,咨询 Q 197216396 或 11970985下载后包含有 CAD 图纸和说明书,咨询 Q 197216396 或 119709851 引言1.1 塑料模具的现状及发展模具是工业生产中的重要工艺装备,模具工业是国民经济各领域发展的重要基础工业之一。塑料模具是用于成型塑料的模具,它是型腔模具的一种类型。下载后包含有 CAD 图纸和说明书,咨询 Q 197216396 或 119709851.1.1 国外模具技术发展及水平模具是工业生产的基础工艺装备。在电子、汽车、电机、电器、仪器、仪表、家电和通讯等产品中,60%-80%的零部件都要依靠模具成型。用模具生产所表现出来的高精度、高复杂程度、高一致性、高生产率和低消耗,是其它加工方法所不能比拟的。模具生产技术水平的高低,己成为衡量一个国家产品制造水平高低的重要标志。近年来由于汽车、建筑、家用电器、食品、医药等产业对注射制品日益增长的需要,推动了注射成型技术水平的发展,主要表现在以下几个方面:(1)模具 CADCAMCAE 技术模具 CADCAMCAE 技术是模具技术发展的一个重要里程碑,实现了数字建模、产品设计、仿真分析、测试直至数控加工的产品研发全过程的一体化。随着模具生产中软、硬件技术的不断发展,采用 CADCAMCAE 技术以实现模具设计与制造的一体化和建立模具制造柔性加工系统是模具设计和制造的发展方向。(2)高寿命和快速经济模具为了适应大批量生产的需要,研究人员正在从模具结构设计、模具材料及热处理、模具表面强化、模具制造等方面提高模具寿命。当前研究和应用模具钢(如仿美国生产的预硬钢 P20、国产的易切削预硬钢 5NiSCa 等)以及模具表面强化新技术,使塑料模具的精度和寿命大大提高。同时,为了适应多品种、少批量生产,开发快速经济模具越来越引起人们的重视。如各种超塑性材料制作的模具、中低熔点合金模具等。(3)微型化、超大型化和精密化塑件的日趋大型化,以及由于高效率生产要求的一模多腔(如塑封模已达到一模几百腔)使模具日趋大型化。同时随着零件微型化以及模具结构发展的要求,精密模具的精度已由原来的 5um 提高到 2um3um,今后有些模具的加工精度公差要求在 1um 以下,这就要求发展超精加工技术。(4)模具标准化和专业化生产模具标准化和标准件的专业化生产是现代模具设计与制造的基础,是提高模具质量、缩短模具制造周期的根本措施,也是模具的发展方向。目前在工业下载后包含有 CAD 图纸和说明书,咨询 Q 197216396 或 11970985技术先进的国家,中小型冲模、塑料注射模、压铸模等模具标准件使用覆盖率已达 8090。而我国只有 30左右,但已经制定了冲压模、塑料注射模及压铸模等模具的国家标准。在沿海工业发达的地区,模具制造企业已采用了国际通用的模具标准及相应的标准件。(5)模具制造先进设备和技术现在高速、精密、数控、自动化的模具加工设备更新发展很快,数控铣床、加工中心和各种数控电加工机床的广泛应用,对保证塑料模具的加工精度和缩短加工周期起了关键性的作用。同时,模具加工的新技术、新工艺不断涌现,如快速成型(RPM)技术、高速铣削加工技术以及三维曲面模具研磨抛光工艺与技术等,都进一步促进了模具制造技术的发展。(6)高速扫描及数字化系统英国雷尼绍公司的模具扫描系统,已在我国 200 多家模具厂中得到应用,取得良好效果。该系统提供了从模型或实物扫描到加工出期望的产品所需的诸多功能,大大缩短了研制制造周期(扫描速度最高可达 3m/min) 。该系统已在汽车、摩托车、家电等行业得到成功应用。随着模具高速扫描及数字化系统的发展,今后“逆向工程”和“并行工程”将得到更广泛的应用 1。1.1.2 国内模具技术发展及水平中国的模具企业大都是中小企业,从作坊式的企业成长起来,甚至目前仍有许多模具企业是作坊式的管理,在模具交货期、成本、质量的控制方面问题层出不断。面对激烈的市场竞争,落后的管理手段和水平,使模具企业中的管理和技术人员只有疲于奔命。因此,模具制造企业要提高管理水平,具备快速反应和及时调整的能力,没有一套先进的管理系统实现管理的信息化是很难做到的。通过信息化建设,实现模具制造。所谓信息化的模具企业,就是在模具企业应用 INTERNET、ERP 等信息化技术,把模具企业上下游业务过程,技术沟通过程,以及模具企业内部业务管理过程,以 IT 形式固定下来,最终提高模具企业的经营管理水平,提高模具企业运转的效率。目前,CAD/CAM 技术的推广已由“甩图板”阶段跨入到了深化应用阶段。CAPP 技术的应用,可以大大提高企业工艺编制的效率和准确性;PDM 系统的应下载后包含有 CAD 图纸和说明书,咨询 Q 197216396 或 11970985用,可以对产品开发数据进行有效的管理;MIS/ERP 系统的应用,则可以从根本上降低企业的成本,提高生产和管理效率 7,9。这些系统之间实现信息的集成和功能上的配合,并逐步实现企业的全面信息化,已成为 CAD/CAM 技术深化应用的主题, 是模具发展的第二次变革。未来的十年,中国模具工业和技术的主要发展方向包括: (1)提高大型、精密、复杂、长寿命模具的设计制造水平; (2)在模具设计制造中广泛应用 CAD/CAE/CAM 技术;(3)大力发展快速制造成形和快速制造模具技术; (4)在塑料模具中推广应用热流道技术、气辅注射成型和高压注射成型技术;(5)提高模具标准化水平和模具标准件的使用率; (6)发展优质模具材料和先进的表面处理技术; (7)逐步推广高速铣削在模具加工的应用; (8)进一步研究开发模具的抛光技术和设备; (9)研究和应用模具的高速测量技术与逆向工程; (10)开发新的成形工艺和模具 2,3。1.2 塑料注塑模具的设计步骤1.2.1 塑件的工艺性分析(1)塑件成型工艺性分析塑件如图 1 所示。图 1 塑件名称:骨轮材料:聚甲醛(POM)下载后包含有 CAD 图纸和说明书,咨询 Q 197216396 或 11970985数量:大批量生产要求:塑件外侧表面光滑,塑件脱模斜度为 45。(a)塑件材料基本特性聚甲醛是继尼龙之后发展起来的一种性能优良的热塑性工程塑料,其性能不亚于尼龙,而价格却比尼龙低廉。聚甲醛树脂为白色粉末,经造粒后为淡黄色或白色,半透明有光泽的硬粒。聚甲醛有较高的抗拉、抗压性能和突出的耐疲劳强度,特别适合于用于长时间反复承受外力的齿轮材料;聚甲醛尺寸稳定、吸水率小,具有优良的减摩、耐磨性能;能耐扭变,有突出的回弹能力,可用于制造塑料弹簧;常温下一般不溶于有机溶剂,能耐醛、酯、醚、烬及弱酸、弱碱,耐汽油及润滑油性能也很好,但不耐强酸;有较好的电气绝缘性能。聚甲醛的缺点是成型收缩率大,在成型温度下的热稳定性较差。(b)塑件材料主要用途聚甲醛特别适合于制作轴承、凸轮、滚轮、辊子、齿轮等耐磨传动零件,还可用于制造汽车仪表板、汽化器、各种仪器外壳、罩盖、箱体、化工容器、泵叶轮、鼓风机叶片、配电盘、线圈座、各种输油管、塑料弹簧等。(c)塑件材料成型特点聚甲醛的收缩率大;其熔融温度范围小,热稳定性差,因此过热或在允许温度下长时间受热,均会产生分解,分解产物甲醛对人体和设备都有害。聚甲醛的熔融或凝固十分迅速,熔融速度快有利于成型,缩短成型周期,但凝固速度快会使熔料结晶化速度快,塑件容易产生熔接痕等表面缺陷。所以,在成型时注射速度要快,注射压力不宜过高。其摩擦系数低、弹性高,浅侧凹槽可采用强制脱出,塑件表面可带有皱纹花样 1。(2)塑件成型工艺参数的确定查相关手册得到 POM 塑料成型工艺参数:收缩率 1.23.0;注射机类型 螺杆式;螺杆转速 170r/min180r/min;料筒温度 前段 170。 C190 。 C,中段 170。 C190 。 C,后段南京理工大学泰州科技学院毕业设计(论文)外文资料翻译系 部: 机械工程系 专 业: 机械工程及自动化 姓 名: 李薇薇 学 号: 05010201 外文出处:Int J Adv Manuf Technol (2006) 28: 61-66 附 件: 1.外文资料翻译译文;2.外文原文。 指导教师评语:译文基本符合翻译原文,个别词汇不符合语境。语句较为通顺,条理比较清楚,专业用语翻译基本恰当,符合中文语法,整体翻译质量较好。签名: 年 月 日附件 1:外文资料翻译译文基于注塑模具钢研磨和抛光工序的自动化表面处理摘要 本文研究了注塑模具钢自动球面研磨与抛光加工工序的可能性,这种注塑模具钢 PDS5 的塑性曲面是在数控加工中心完成的。这项研究已经完成了磨削刀架的设计与制造。最佳表面研磨参数是在钢 PDS5 的加工中心测定的。对于PDS5 注塑模具钢的最佳研磨参数是以下一系列的组合:研磨材料的磨料为氧化铝,进给量 50 毫米/分钟,磨削深度 20 微米,磨削转速为 18000rpm。用优化的参数进行表面研磨,表面粗糙度 Ra 值可由大约 1.60 微米改善至 0.35 微米。用抛光工艺和参数化抛光,可以进一步改善表面粗糙度 Ra 值从 0.343 微米至0.06 微米。对模具内部曲面的测试,用最佳参数的表面研磨、抛光,曲面表面粗糙度就从 2.15 微米可以提高到约为 0.07 微米。关键词 自动化表面处理 抛光 磨削加工 表面粗糙度 田口方法 1 引言塑胶工程材料由于其重要特点,如耐化学腐蚀性、低密度、易于制造,并已日渐取代金属部件在工业中广泛应用。注塑成型对于塑料制品是一个重要工艺。注塑模具的表面质量是设计的本质要求,因为它直接影响了塑胶产品的外观和其性能。加工工艺如球面研磨、抛光常用于改善表面光洁度。研磨工具(轮子)的安装已广泛用于传统模具的制造产业。自动化表面研磨加工工具的几何模型将在1中介绍。自动化表面处理的球磨研磨工具将在2中得到示范和开发。磨削速度,磨削深度,进给速率和砂轮尺寸、研磨材料特性(如磨料粒度大小)是球形研磨工艺中主要的参数,如图 1(球面研磨过程示意图)所示。注塑模具钢的球面研磨最优化参数目前尚未在文献得到确切的依据。近年来,已经进行了一些研究,确定了球面抛光工艺的最优参数(图 2,球面抛光过程示意图) 。比如,人们发现, 用碳化钨球滚压的方法可以使工件表面的塑性变形减少,从而改善表面粗糙度、表面硬度、抗疲劳强度3,4,5,6。抛光的工艺的过程是由加工中心3,4和车床5,6共同完成的。对表面粗糙度有重大影响的抛光工艺主要参数,主要是球或滚子材料抛光力、进给速率、抛光速度、润滑、抛光率及其他因素等。注塑模具钢 PDS5 的表面抛光的参数优化,分别结合了油脂润滑剂、碳化钨球、抛光速度 200 毫米/分钟、抛光力 300 牛、40 微米的进给量7。采用最佳参数进行表面研磨和球面抛光的深度为 2.5 微米。通过抛光工艺,表面粗糙度可以改善大致为 40%至 90%37。 此项目研究的目的是,发展注塑模具钢的球形研磨和球面抛光工序,这种注塑模具钢的曲面实在加工中心完成的。表面光洁度的球研磨与球抛光的自动化流程工序,如图 3 所示。我们开始自行设计和制造的球面研磨工具及加工中心的对刀装置。利用田口正交法,确定了表面球研磨最佳参数。选择为田口L18 型矩阵实验相应的四个因素和三个层次。用最佳参数进行表面球研磨则适用于一个曲面表面光洁度要求较高的注塑模具。为了改善表面粗糙, 利用最佳球面抛光工艺参数,再进行对表层打磨。PDS 试样的设计与制造选择最佳矩阵实验因子确定最佳参数实施实验分析并确定最佳因子进行表面抛光应用最佳参数加工曲面测量试样的表面粗糙度球研磨和抛光装置的设计与制造图 3 自动球面研磨与抛光工序的流程图2 球研磨的设计和对准装置实施过程中可能出现的曲面的球研磨,研磨球的中心应和加工中心的 Z 轴相一致。球面研磨工具的安装及调整装置的设计,如图 4(球面研磨工具及其调整装置)所示。电动磨床展开了两个具有可调支撑螺丝的刀架。磨床中心正好与具有辅助作用的圆锥槽线配合。拥有磨床的球接轨,当两个可调支撑螺丝被收紧时,其后的对准部件就可以拆除。研磨球中心坐标偏差约为 5 微米, 这是衡量一个数控坐标测量机性能的重要标准。机床的机械振动力是被螺旋弹簧所吸收。球形研磨球和抛光工具的安装,如图 5(a.球面研磨工具的图片;b.球抛光工具的图片)所示。为使球面磨削加工和抛光加工的进行,主轴通过球锁机制而被锁定。 3 矩阵实验的规划3.1 田口正交表:利用矩阵实验田口正交法,可以确定参数的有影响程度8。为了配合上述球面研磨参数,该材料磨料的研磨球(直径10毫米)、进给速率、研磨深度,在次研究中电气磨床被假定为四个因素(参数),指定为从A到D(见表1实验因素和水平) 。三个层次(程度)的因素涵盖了不同的范围特征,并用了数字1、2、3标明。挑选三类磨料,即碳化硅(SiC),白色氧化铝(Al 2O3,WA),粉红氧化铝(Al2O3,PA)来研究。这三个数值的大小取决于每个因素实验结果。选定L18型正交矩阵进行实验,进而研究四三级因素的球形研磨过程。3.2 数据分析的界定:工程设计问题,可以分为较小而好的类型,象征性最好类型,大而好类型,目标取向类型等8。信噪比(S/N)的比值,常作为目标函数来优化产品或者工艺设计。被加工面的表面粗糙度值经过适当地组合磨削参数,应小于原来的未加工表面。因此,球面研磨过程属于工程问题中的小而好类型。这里的信噪比(S/N) 、,按下列公式定义8: =10 log (平方等于质量特性)10=10 log10niy2这里,y 不同噪声条件下所观察的质量特性in实验次数从每个 L18 型正交实验得到的信噪比(S/N)数据,经计算后,运用差异分析技术(变异)和歼比检验来测定每一个主要的因素8。优化小而好类型的工程问题问题更是尽量使 最大而定。各级 选择的最大化将对最终的 因素有重大影响。最优条件可视研磨球而待定。4 实验工作和结果这项研究使用的材料是 PDS5 工具钢(相当于艾西塑胶模具)9,它常用于大型注塑模具产品在国内汽车零件领域和国内设备。该材料的硬约 HRC33(HS46)9。 具体好处之一是,由于其特殊的热处理前处理,模具可直接用于未经进一步加工工序而对这一材料进行加工。式样的设计和制造,应使它们可以安装在底盘,来测量相应的反力。PDS5 试样的加工完毕后,装在大底盘上在三坐标加工中心进行了铣削,这种加工中心是由杨*钢铁公司所生产(中压型三号),配备了 FANUC-18M 公司的数控控制器(0.99 型)10。用 hommelwerket 4000 设备来测量前机加工前表面的粗糙度,使其可达到 1.6 微米。图 6 试验显示了球面磨削加工工艺的设置。一个由 Renishaw 公司生产的视频触摸触发探头,安装在加工中心上,来测量和确定和原始式样的协调。数控代码所需要的磨球路径由PowerMILL 软件产。这些代码经过 RS232 串口界面,可以传送到装有控制器的数控加工中心上。完成了 L18 型矩阵实验后,表 2(PDS5 试样光滑表层的粗糙度)总结了光滑表面的粗糙度 RA 值,计算了每一个 L18 型矩阵实验的信噪比(S/N),从而用于方程 1。通过表 2 提供的各个数值,可以得到 4 中不同程度因子的平均信噪比(S/N) ,在图 7 中已用图表显示。球面研磨工艺的目标,就是通过确定每一种因子的最佳优化程度值,来使试样光滑表层的表面粗糙度值达到最小。因为 log 是一个减函数,我们应当使信噪比(S/N)达到最大。因此,我们能够确定每一种因子的最优程度使得 的值达到最大。因此基于这个点阵式实验的最优转速应该是 18000RPM,如表4(优化组合球面研磨参数)所示。通过使用数据方差分析的技术和 F 比检验方法,进一步确定了每一种因子有什么主要的影响,从而确定了它们的影响程度(见表 5 信噪比和表面粗糙度)。F0.1,2,13 的 F 比的比值是 2.76,相当于 10%的影响程度(或者置信水平为90%) 。这个因子的自由度是 2,自由度误差是 13,根据 F 分布表11。如果 F比值大于 2.76,就可以认为对表面粗糙度有显著影响。结果,进给量和磨削深度都对表面粗糙度有显著影响。为了观察使用最优磨削组合参数的重复性能,进行了 5 种不同类别的实验,如表 6 所示。获得被测试样的表面粗糙度值 RA 大约是 0.35 微米。使用球研磨组合参数,可使表面粗糙度提高了 78%。使用球面抛光的优化参数,光滑表面进一步被抛光。经过球面抛光可获得粗糙度 RA 值为 0.06 微米的表面。被改善了的抛光表面,可以在 30x 光学显微镜观察下进行观察,如图 8(未加工表面、光滑面和抛光面的测试样品的显微镜象(30x)的比较)所示。经过抛光工艺,工件机加工前的表面粗糙度改善了近 95%。从田口矩阵实验获得的球面研磨优化参数,适用于曲面光滑的模具,从而改善表面的粗糙度。选择香水瓶为一个测试载体。对于被测物体的模具数控加工中心,由 PowerMILL 软件来模拟测试。经过精铣,通过使用从田口矩阵实验获得的球面研磨优化参数,模具表面进一步光滑。紧接着,使用打磨抛光的最佳参数,来对光滑曲面进行抛光工艺,进一步改善了被测物体的表面粗糙度 (见图 9)。模具内部的表面粗糙度用 hommelwerket4000 设备来测量,模具内部的表面粗糙度 RA 的平均值为 2.15 微米,光滑表面粗糙度 RA 的平均值为 0.45 微米,抛光表面粗糙度 RA 的平均值为 0.07 微米。被测物体的光滑表面的粗糙度改善了:(2.15-0.45)/2.15=79.1%,抛光表面的粗糙度改善了:(2.15-0.07)/2.15=96.7%。5 结论在这项工作中,对注塑模具的曲面进行了自动球面研磨与球面抛光加工,并将其工艺最佳参数成功地运用到加工中心上。设计和制造了球面研磨装置(及其对准组件)。通过实施田口 L18 型矩阵进行实验,确定了球面研磨的最佳参数。对于 PDS5 注塑模具钢的最佳球面研磨参数是以下一系列的组合:材料的磨料为粉红氧化铝,进给量料 500 毫米/分钟,磨削深度 20 微米,转速为 18000RPM。通过使用最佳球面研磨参数,试样的表面粗糙度 RA 值从约 1.6 微米提高到0.35 微米。应用最优化表面磨削参数和最佳抛光参数,来加工模具的内部光滑曲面,可使模具内部的光滑表面改善 79.1%,抛光表面改善 96.7%。鸣谢:作者感谢中国国家科学理事会对本次研究的支持,NSC 89-2212-E-011-059。参考文献:1 国家评估陈严,安装粉磨几何模型工具自动化表面加工工艺,台北:第六届国际自动化技术会议议事录,2000.5.9-11,43-47.2 国家评估陈严,达菲那,球形研磨工具的表面自动化处理系统,国际科技Manuf产物1期(第1版)J,1997,17-26.3 蕙新罕布什尔州,谭资深大律师,影响球表面光洁度的参数文献调查和讨论,大意工程10期(第4版) ,1988,215-220.4 蕙新罕布什尔州,谭资深大律师,宫泽喜一,产生球表面上粗糙度的调研 J,国际工具Manuf产物31期(第1版) ,1991,75-81.5 玉十,王岚,不同参数对带有金刚石工具的铝合金球形凸出面表面粗糙度的影响J,国际工具Manuf产物39期,1999,459-469.6 Liermann部Klocke先生,轧辊抛光成表面,国际工具Manuf产物38期(第5版) ,1996,419-423.7 修福建,注塑钢球面参数的最佳测定J,国际Manuf技术,2003.8 Phadke,坚固设计的质量工程,新泽西州的 Englewood 悬崖处普伦蒂斯- 大会堂,1989.9 大东公司的技术手册,塑料注塑模具钢的选择,台湾,1985.10 杨钢铁厂的技术手册中压-3A 型立式加工中心,台湾,1996.11 威利,蒙哥马利直流设计与实验分析,纽约,1991.附件 2:外文原文(复印件)DOI 10.1007/s00170-004-2328-8ORIGINAL ARTICLEInt J Adv Manuf Technol (2006) 28: 6166Fang-Jung Shiou Chao-Chang A. Chen Wen-Tu LiAutomated surface finishing of plastic injection mold steelwith spherical grinding and ball burnishing processesReceived: 30 March 2004 / Accepted: 5 July 2004 / Published online: 30 March 2005 Springer-Verlag London Limited 2005Abstract This study investigates the possibilities of automatedspherical grinding and ball burnishing surface finishing pro-cesses in a freeform surface plastic injection mold steel PDS5on a CNC machining center. The design and manufacture ofa grinding tool holder has been accomplished in this study.The optimal surface grinding parameters were determined usingTaguchis orthogonal array method for plastic injection moldingsteel PDS5 on a machining center. The optimal surface grind-ing parameters for the plastic injection mold steel PDS5 werethe combination of an abrasive material of PA Al2O3, a grind-ing speed of 18 000 rpm, a grinding depth of 20 m, and a feedof 50 mm/min. The surface roughness Raof the specimen can beimproved from about 1.60 mto0.35 m by using the optimalparameters for surface grinding. Surface roughness Racan befurther improved from about 0.343 mto0.06 mbyusingtheball burnishing process with the optimal burnishing parameters.Applying the optimal surface grinding and burnishing parame-ters sequentially to a fine-milled freeform surface mold insert,the surface roughness Raof freeform surface region on the testedpart can be improved from about 2.15 mto0.07 m.Keywords Automated surface finishing Ballburnishing process Grinding process Surface roughness Taguchis method1 IntroductionPlastics are important engineering materials due to their specificcharacteristics, such as corrosion resistance, resistance to chemi-cals, low density, and ease of manufacture, and have increasinglyF.-J. Shiou (a117) C.-C.A. Chen W.-T. LiDepartment of Mechanical Engineering,National Taiwan University of Science and Technology,No. 43, Section 4, Keelung Road, 106 Taipei, Taiwan R.O.C.E-mail: shiou.twTel.: +88-62-2737-6543Fax: +88-62-2737-6460replaced metallic components in industrial applications. Injec-tion molding is one of the important forming processes for plas-tic products. The surface finish quality of the plastic injectionmold is an essential requirement due to its direct effects on theappearance of the plastic product. Finishing processes such asgrinding, polishing and lapping are commonly used to improvethe surface finish.The mounted grinding tools (wheels) have been widely usedin conventional mold and die finishing industries. The geometricmodel of mounted grinding tools for automated surface finish-ing processes was introduced in 1. A finishing process modelof spherical grinding tools for automated surface finishing sys-tems was developed in 2. Grinding speed, depth of cut, feedrate, and wheel properties such as abrasive material and abrasivegrain size, are the dominant parameters for the spherical grind-ing process, as shown in Fig. 1. The optimal spherical grindingparameters for the injection mold steel have not yet been investi-gated based in the literature.In recent years, some research has been carried out in de-termining the optimal parameters of the ball burnishing pro-cess (Fig. 2). For instance, it has been found that plastic de-formation on the workpiece surface can be reduced by usinga tungsten carbide ball or a roller, thus improving the surfaceroughness, surface hardness, and fatigue resistance 36. Theburnishing process is accomplished by machining centers 3, 4and lathes 5, 6. The main burnishing parameters having signifi-cant effects on the surface roughness are ball or roller material,burnishing force, feed rate, burnishing speed, lubrication, andnumber of burnishing passes, among others 3. The optimal sur-face burnishing parameters for the plastic injection mold steelPDS5 were a combination of grease lubricant, the tungsten car-bide ball, a burnishing speed of 200 mm/min, a burnishing forceof 300 N, and a feed of 40 m 7. The depth of penetration of theburnished surface using the optimal ball burnishing parameterswas about 2.5 microns. The improvement of the surface rough-ness through burnishing process generally ranged between 40%and 90% 37.The aim of this study was to develop spherical grinding andball burnishing surface finish processes of a freeform surface62plastic injection mold on a machining center. The flowchart ofautomated surface finish using spherical grinding and ball bur-nishing processes is shown in Fig. 3. We began by designing andmanufacturing the spherical grinding tool and its alignment de-vice for use on a machining center. The optimal surface sphericalgrinding parameters were determined by utilizing a Taguchisorthogonal array method. Four factors and three correspondinglevels were then chosen for the Taguchis L18matrix experiment.The optimal mounted spherical grinding parameters for surfacegrinding were then applied to the surface finish of a freeformsurface carrier. To improve the surface roughness, the groundsurface was further burnished, using the optimal ball burnishingparameters.Fig. 1. Schematic diagram of the spherical grinding processFig. 2. Schematic diagram of the ball-burnishing processFig. 3. Flowchart of automated surface finish using spherical grinding andball burnishing processes2 Design of the spherical grinding tool and itsalignment deviceTo carry out the possible spherical grinding process of a freeformsurface, the center of the ball grinder should coincide with thez-axis of the machining center. The mounted spherical grindingtool and its adjustment device was designed, as shown in Fig. 4.The electric grinder was mounted in a tool holder with two ad-justable pivot screws. The center of the grinder ball was wellaligned with the help of the conic groove of the alignment com-ponents. Having aligned the grinder ball, two adjustable pivotscrews were tightened; after which, the alignment componentscould be removed. The deviation between the center coordi-nates of the ball grinder and that of the shank was about 5 m,which was measured by a CNC coordinate measuring machine.The force induced by the vibration of the machine bed is ab-sorbed by a helical spring. The manufactured spherical grind-ing tool and ball-burnishing tool were mounted, as shown inFig. 5. The spindle was locked for both the spherical grindingprocess and the ball burnishing process by a spindle-lockingmechanism.63Fig. 4. Schematic illustration of the spherical grinding tool and its adjust-ment device3 Planning of the matrix experiment3.1 Configuration of Taguchis orthogonal arrayThe effects of several parameters can be determined efficientlyby conducting matrix experiments using Taguchis orthogonalarray 8. To match the aforementioned spherical grinding pa-rameters, the abrasive material of the grinder ball (with the diam-eter of 10 mm), the feed rate, the depth of grinding, and therevolution of the electric grinder were selected as the four experi-mental factors (parameters) and designated as factor A to D (seeTable 1) in this research. Three levels (settings) for each factorwere configured to cover the range of interest, and were identi-Fig. 5. a Photo of the spherical grinding tool bPhoto of the ball burnishing toolTable 1. The experimental factors and their levelsFactor Level123A. Abrasive material SiC Al2O3,WA Al2O3,PAB. Feed (mm/min) 50 100 200C. Depth of grinding (m) 20 50 80D. Revolution (rpm) 12 000 18 000 24 000fied by the digits 1, 2, and 3. Three types of abrasive materials,namely silicon carbide (SiC), white aluminum oxide (Al2O3,WA), and pink aluminum oxide (Al2O3, PA), were selected andstudied. Three numerical values of each factor were determinedbased on the pre-study results. The L18orthogonal array was se-lected to conduct the matrix experiment for four 3-level factorsof the spherical grinding process.3.2 Definition of the data analysisEngineering design problems can be divided into smaller-the-better types, nominal-the-best types, larger-the-better types,signed-target types, among others 8. The signal-to-noise (S/N)ratio is used as the objective function for optimizing a product orprocess design. The surface roughness value of the ground sur-face via an adequate combination of grinding parameters shouldbe smaller than that of the original surface. Consequently, thespherical grinding process is an example of a smaller-the-bettertype problem. The S/N ratio, , is defined by the followingequation 8: =10 log10(mean square quality characteristic)=10 log10bracketleftBigg1nnsummationdisplayi=1y2ibracketrightBigg. (1)where:yi: observations of the quality characteristic under different noiseconditionsn: number of experimentAfter the S/N ratio from the experimental data of each L18orthogonal array is calculated, the main effect of each factorwas determined by using an analysis of variance (ANOVA) tech-nique and an F-ratio test 8. The optimization strategy of the64smaller-the better problem is to maximize ,asdefinedbyEq.1.Levels that maximize will be selected for the factors that havea significant effect on . The optimal conditions for sphericalgrinding can then be determined.4 Experimental work and resultsThe material used in this study was PDS5 tool steel (equiva-lent to AISI P20) 9, which is commonly used for the molds oflarge plastic injection products in the field of automobile com-ponents and domestic appliances. The hardness of this materialis about HRC33 (HS46) 9. One specific advantage of this ma-terial is that after machining, the mold can be directly usedfor further finishing processes without heat treatment due to itsspecial pre-treatment. The specimens were designed and manu-factured so that they could be mounted on a dynamometer tomeasure the reaction force. The PDS5 specimen was roughly ma-chined and then mounted on the dynamometer to carry out thefine milling on a three-axis machining center made by Yang-Iron Company (type MV-3A), equipped with a FUNUC Com-pany NC-controller (type 0M) 10. The pre-machined surfaceroughness was measured, using Hommelwerke T4000 equip-ment, to be about 1.6 m. Figure 6 shows the experimentalset-up of the spherical grinding process. A MP10 touch-triggerprobe made by the Renishaw Company was also integrated withthe machining center tool magazine to measure and determinethe coordinated origin of the specimen to be ground. The NCcodes needed for the ball-burnishing path were generated byPowerMILL CAM software. These codes can be transmitted tothe CNC controller of the machining center via RS232 serialinterface.Table 2 summarizes the measured ground surface roughnessvalue Raand the calculated S/N ratio of each L18orthogonal ar-ray using Eq. 1, after having executed the 18 matrix experiments.The average S/N ratio for each level of the four factors can beobtained, as listed in Table 3, by taking the numerical values pro-vided in Table 2. The average S/N ratio for each level of the fourfactors is shown graphically in Fig. 7.Fig. 6. Experimental set-up to determine the op-timal spherical grinding parametersTable 2. Ground surface roughness of PDS5 specimenExp. Inner array Measured surface Responseno. (control factors) roughness value (Ra)ABCD y1y2y3S/N ratio Mean(m) (m) (m) (dB) y (m)1 1 1 1 1 0.35 0.35 0.35 9.119 0.3502 1 2 2 2 0.37 0.36 0.38 8.634 0.3703 1 3 3 3 0.41 0.44 0.40 7.597 0.4174 2 1 2 3 0.63 0.65 0.64 3.876 0.6405 2 2 3 1 0.73 0.77 0.78 2.380 0.7606 2 3 1 2 0.45 0.42 0.39 7.520 0.4207 3 1 3 2 0.34 0.31 0.32 9.801 0.3238 3 2 1 3 0.27 0.25 0.28 11.471 0.2679 3 3 2 1 0.32 0.32 0.32 9.897 0.32010 1 1 2 2 0.35 0.39 0.40 8.390 0.38011 1 2 3 3 0.41 0.50 0.43 6.968 0.44712 1 3 1 1 0.40 0.39 0.42 7.883 0.40313 2 1 1 3 0.33 0.34 0.31 9.712 0.32714 2 2 2 1 0.48 0.50 0.47 6.312 0.48315 2 3 3 2 0.57 0.61 0.53 4.868 0.57016 3 1 3 1 0.59 0.55 0.54 5.030 0.56017 3 2 1 2 0.36 0.36 0.35 8.954 0.35718 3 3 2 3 0.57 0.53 0.53 5.293 0.543Table 3. Average S/N ratios by factor levels (dB)Factor A B C DLevel 1 8.099 7.655 9.110 6.770Level 2 5.778 7.453 7.067 8.028Level 3 8.408 7.176 6.107 7.486Effect 2.630 0.479 3.003 1.258Rank2413Mean 7.428The goal in the spherical grinding process is to minimize thesurface roughness value of the ground specimen by determin-ing the optimal level of each factor. Since log is a monotonedecreasing function, we should maximize the S/N ratio. Conse-quently, we can determine the optimal level for each factor asbeing the level that has the highest value of . Therefore, based65Fig. 7. Plots of control factor effectson the matrix experiment, the optimal abrasive material was pinkaluminum oxide; the optimal feed was 50 mm/min; the optimaldepth of grinding was 20 m; and the optimal revolution was18 000 rpm, as shown in Table 4.The main effect of each factor was further determined byusing an analysis of variance (ANOVA) technique and an F ratiotest in order to determine their significance (see Table 5). TheF0.10,2,13is 2.76 for a level of significance equal to 0.10 (or90% confidence level); the factors degree of freedom is 2 andthe degree of freedom for the pooled error is 13, according toF-distribution table 11. An F ratio value greater than 2.76 canbe concluded as having a significant effect on surface roughnessand is identified by an asterisk. As a result, the feed and the depthof grinding have a significant effect on surface roughness.Five verification experiments were carried out to observe therepeatability of using the optimal combination of grinding pa-rameters, as shown in Table 6. The obtainable surface roughnessvalue Raof such specimen was measured to be about 0.35 m.Surface roughness was improved by about 78% in using the op-Table 4. Optimal combination of spherical grinding parametersFactor LevelAbrasive Al2O3,PAFeed 50 mm/minDepth of grinding 20 mRevolution 18 000 rpmTable 5. ANOVA table for S/N ratio of surface roughnessFactor Degrees Sum Mean F ratioof freedom of squares squaresA 2 24.791 12.396 3.620B 2 0.692 0.346C 2 28.218 14.109 4.121D 2 4.776 2.388Error 9 39.043Total 17 97.520Pooled to error 13 44.511 3.424F ratio value 2.76 has significant effect on surface roughnessTable 6. Surface roughness value of the tested specimen after verificationexperimentExp. no. Measured value Ra(m) Mean y (m) S/N ratioy1y2y31 0.30 0.31 0.33 0.313 10.0732 0.36 0.37 0.36 0.363 8.8023 0.36 0.37 0.37 0.367 8.7144 0.35 0.37 0.34 0.353 9.0315 0.33 0.36 0.35 0.347 9.163Mean 0.349 9.163timal combination of spherical grinding parameters. The groundsurface was further burnished using the optimal ball burnishingparameters. A surface roughness value of Ra= 0.06 m was ob-tainable after ball burnishing. Improvement of the burnished sur-face roughness observed with a 30 optical microscope is shownin Fig. 8. The improvement of pre-machined surfaces roughnesswas about 95% after the burnishing process.The optimal parameters for surface spherical grinding ob-tained from the Taguchis matrix experiments were applied tothe surface finish of the freeform surface mold insert to evalu-ate the surface roughness improvement. A perfume bottle wasselected as the tested carrier. The CNC machining of the mold in-sert for the tested object was simulated with PowerMILL CAMsoftware. After fine milling, the mold insert was further groundwith the optimal spherical grinding parameters obtained fromthe Taguchis matrix experiment. Shortly afterwards, the groundsurface was burnished with the optimal ball burnishing parame-ters to further improve the surface roughness of the tested object(see Fig. 9). The surface roughness of the mold insert was meas-ured with Hommelwerke T4000 equipment. The average surfaceroughness value Raon a fine-milled surface of the mold insertwas 2.15 m on average; that on the ground surface was 0.45 mFig. 8. Comparison between the pre-machined surface, ground surface andthe burnished surface of the tested specimen observed with a toolmakermicroscope (30)66Fig. 9. Fine-milled, ground and burnished mold insert of a perfume bottleon average; and that on burnished surface was 0.07 monaver-age. The surfa

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号