40T门座起重机-行走机构设计(全套含CAD图纸)

收藏

资源目录

压缩包内文档预览:(预览前20页/共87页)

编号:10131135

类型:共享资源

大小:17.56MB

格式:ZIP

上传时间:2018-05-30

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

40

起重机

行走

机构

设计

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

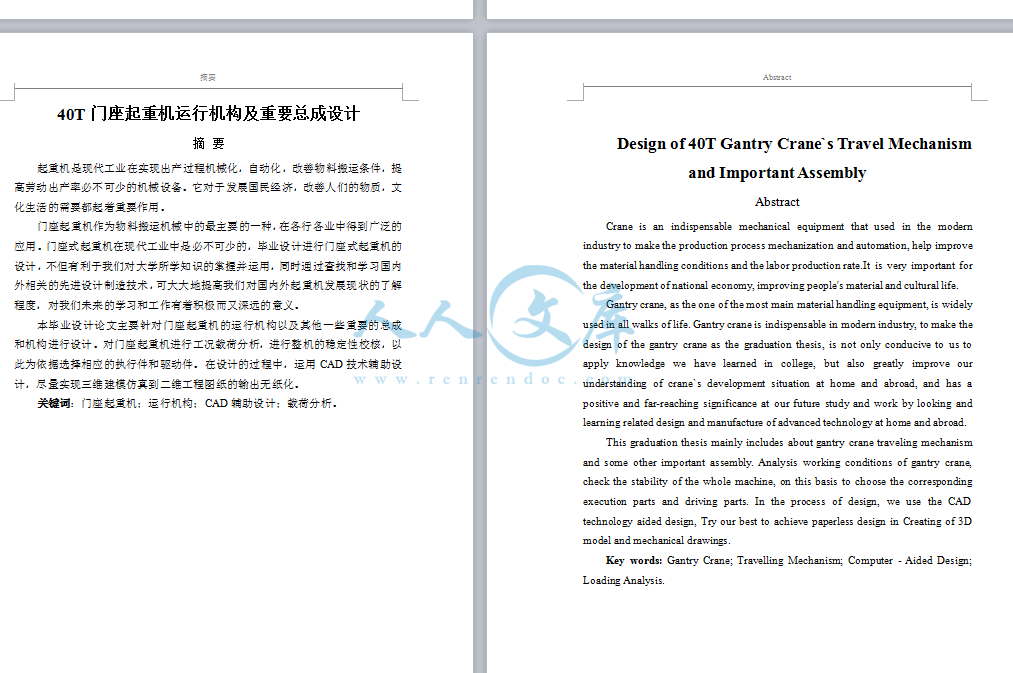

下载后包含有 CAD 图纸和说明书,咨询 Q 197216396 或 11970985密级: 公开 NANCHANG UNIVERSITY学 士 学 位 论 文THESIS OF BACHELOR(2009 2013 年)题 目 40T 门座起重机运行机构及重要总成设计 学 院:专业班级:学生姓名:下载后包含有 CAD 图纸和说明书,咨询 Q 197216396 或 11970985指导教师:起讫日期:学士学位论文原创性申明本人郑重申明:所呈交的论文是本人在导师的指导下独立进行研究所取得的研究成果。除了文中特别加以标注引用的内容外,本论文不包含任何其他个人或集体已经发表或撰写的成果。对本文的研究做出重要贡献的个人和集体,均已在文中以明确方式表明。本人完全意识到本申明的法律后果由本人承担。作者签名: 日期:学位论文版权使用授权书本学位论文作者完全了解学校有关保留、使用学位论文的规定,同意学校保留并向国家有关部门或机构送交论文的复印件和电子版,允许论文被查阅和下载后包含有 CAD 图纸和说明书,咨询 Q 197216396 或 11970985借阅。本人授权南昌大学可以将本论文的全部或部分内容编入有关数据库进行检索,可以采用影印、缩印或扫描等复制手段保存和汇编本学位论文。保密,在 年解密后适用本授权书。本学位论文属于不保密。(请在以上相应方框内打“” )作者签名: 日期:导师签名: 日期:下载后包含有 CAD 图纸和说明书,咨询 Q 197216396 或 11970985I40T 门座起重机运行机构及重要总成设计摘 要起重机是现代工业在实现出产过程机械化,自动化,改善物料搬运条件,提高劳动出产率必不可少的机械设备。它对于发展国民经济,改善人们的物质,文化生活的需要都起着重要作用。门座起重机作为物料搬运机械中的最主要的一种,在各行各业中得到广泛的应用。门座式起重机在现代工业中是必不可少的,毕业设计进行门座式起重机的设计,不但有利于我们对大学所学知识的掌握并运用,同时通过查找和学习国内外相关的先进设计制造技术,可大大地提高我们对国内外起重机发展现状的了解程度,对我们未来的学习和工作有着积极而又深远的意义。本毕业设计论文主要针对门座起重机的运行机构以及其他一些重要的总成和机构进行设计。对门座起重机进行工况载荷分析,进行整机的稳定性校核,以此为依据选择相应的执行件和驱动件。在设计的过程中,运用 CAD 技术辅助设计,尽量实现三维建模仿真到二维工程图纸的输出无纸化。关键词:门座起重机;运行机构;CAD 辅助设计;载荷分析。下载后包含有 CAD 图纸和说明书,咨询 Q 197216396 或 11970985IIDesign of 40T Gantry Cranes Travel Mechanism and Important Assembly AbstractCrane is an indispensable mechanical equipment that used in the modern industry to make the production process mechanization and automation, help improve the material handling conditions and the labor production rate.It is very important for the development of national economy, improving peoples material and cultural life.Gantry crane, as the one of the most main material handling equipment, is widely used in all walks of life. Gantry crane is indispensable in modern industry, to make the design of the gantry crane as the graduation thesis, is not only conducive to us to apply knowledge we have learned in college, but also greatly improve our understanding of cranes development situation at home and abroad, and has a positive and far-reaching significance at our future study and work by looking and learning related design and manufacture of advanced technology at home and abroad.This graduation thesis mainly includes about gantry crane traveling mechanism and some other important assembly. Analysis working conditions of gantry crane, check the stability of the whole machine, on this basis to choose the corresponding execution parts and driving parts. In the process of design, we use the CAD technology aided design, Try our best to achieve paperless design in Creating of 3D model and mechanical drawings.Key words: Gantry Crane; Travelling Mechanism; Computer - Aided Design; Loading Analysis.下载后包含有 CAD 图纸和说明书,咨询 Q 197216396 或 11970985- 0 -目录摘 要 .IAbstract.II第一章 绪论 .21.1 门座起重机的特点及分类 .21.2 门座起重机的结构 .31.3 门座起重机的现状及发展趋势 .41.4 课题研究内容 .6第二章 门座式起重机总体设计 .82.1 门座起重机的性能参数及工况环境 .82.2 确定起重机设计主要内容 .92.2.1 起升机构的组成及工作原理 .92.2.2 变幅机构的组成及工作原理 .122.2.3 旋转机构的组成及工作原理 .182.2.4 运行机构的组成及工作原理 .212.2.5 门座起重机的安全设置 .222.3 确定起重机金属结构形式 .27第三章 各工作机构和金属结构的计算载荷及载荷组合 .31本节所作分析与计算均以依据 GB/T3811-2008 起重机设计规范依据。 .313.1 计算载荷 .313.1.1 自重载荷 .313.1.2 起升载荷 .31下载后包含有 CAD 图纸和说明书,咨询 Q 197216396 或 11970985- 1 -3.1.3 自重震动载荷 .313.1.4 起升动载荷 .323.1.5 突然卸载时的动力效应 .323.1.6 运行冲击载荷 .333.1.7 起重机运行惯性力 .333.1.8 货物偏摆载荷 .333.1.9 风载荷 .343.2 载荷组合 .37第四章 整机稳定性校核 .394.1 基本原则 .394.2 验算工况、载荷系数和载荷组合 .394.2.1 门座起重机的验算工况 .394.2.2 载荷系数和载荷组合 .394.2.3 门座起重机抗倾覆稳定性的力矩表达式 .404.3 轮压计算 .45第五章 门座起重机运行机构设计分析 .495.1 运行机构概述 .495.1.1 运行机构设计所需要解决的问题 .495.1.2 运行机构设计所需要的主要原始数据 .505.2 决定运行机构的结构形式 .505.3 选择车轮与轨道并验算其强度 .505.3.1 验算车轮的耐久性 .50下载后包含有 CAD 图纸和说明书,咨询 Q 197216396 或 11970985- 2 -5.3.2 验算车轮的强度 .515.4 有轨运行机构的驱动装置 .515.4.1 运行静阻力的计算 .515.4.2 按满载运行静功率初选电动机 .535.4.3 减速装置计算 .535.4.4 电动机过载能力验算 .555.4.5 制动器的选择 .555.5 有轨运行机构其他机构和安全辅助装置 .56第六章 总结与展望 .576.1 工作总结 .576.2 工作展望 .57参考文献 .59致谢 .60附件一 起重机行走机构设计图纸 .61下载后包含有 CAD 图纸和说明书,咨询 Q 197216396 或 11970985- 3 -下载后包含有 CAD 图纸和说明书,咨询 Q 197216396 或 11970985- 4 -门座起重机总体设计参考同等工况和起重级别的门座起重机的设计资料,根据本毕业设计的工况要求,确定适当的性能参数。确定门座起重机组成机构形式和工作原理计算门座起重机工况载荷并进行载荷组合确定门座起重机金属结构形式门座起重机性能参数及工况环境不符合要求符合要求进行行走机构轮压计算选择起重机车轮与轨道计算选择行走机构电机计算选择行走机构制动器计算选择行走机构减速器设计选用行走机构附属装置YESNOYESYESNONO根据起重机工况载荷、车轮、装配工艺性、经济性等。计算总传动比,分配减速器传动比、参考最大输入功率。参考运行速度、工况情况和安全需求。根据计算轮压,参考国家标准本科生毕业设计任务书(工科及部分理科专业适用)题目: 50T 门座起重机行走机构及重要总成设计 题目来源:省部级以上 市厅级 横向 自选题目性质:理论研究 应用与理论研究 实际应用研究学 院:专业班级:学生姓名:起讫日期:指导教师:指导教师所在单位: 机电工程学院 学院审核(签名): 审核日期: 二 0 一三 年制说 明1. 毕业设计任务书由指导教师填写,并经专业学科组审定,下达到学生。2. 进度表由学生填写,至少每两周交指导教师签署审查意见,并作为毕业设计工作检查的主要依据。进度表中的周次是指实际的毕业设计进程中的周次。3. 学生根据指导教师下达的任务书独立完成开题报告,于 3 周内提交给指导教师批阅。4. 本任务书在毕业设计完成后,与论文一起交指导教师,作为论文评阅和毕业设计答辩的主要档案资料,是学士学位论文成册的主要内容之一。一、毕业设计的主要内容和基本要求50T 门座式起重机设计,我的主要设计内容是:1港口装卸门座式起重机 MQ5010 总体设计计算:1) 确定主要工作机构(吊钩总成、变幅悬臂、行走机构等)和金属结构的形式;2) 确定组合式臂架结构主要尺寸;3) 货物水平位移补偿系统设计;4) 杠杆活对重式臂架自重平衡系统设计; 5) 各工作机构、金属结构的计算工况、计算载荷以及载荷组合;6) 进行总体稳定性计算;7) 进行轮压计算;8) 整机稳定性计算;9) 绘制总体方案图 1 张(A1) ;10)绘制相关机构总成图;11)绘制相关零件图;12)完成起重机总体设计计算书。2MQ5010 起重机虚拟样机制作:1) 利用三维建模软件(如 PRO/E)建立起重机主要零部件三维装配模型;2) 尝试利用 ADAMS 软件建立整机虚拟样机;3) 尝试对虚拟样机进行运动学和动力学仿真分析。50T 门座式起重机设计主要性能参数、要求:1. 基本参数:1) 起重量 50T;2) 起升高度 20m;3) 变幅幅度 10m(极限状态吊臂水平竖直角度皆为 15) ;4) 回转角度 左右各 180;5) 轨道坡度 按照起重机铁路轨道设计国家标准。2. 动态参数:1) 起升 最大速度 3m/s,加速时间 3s;2) 变幅 均速 1m/s,加速时间 2s;3) 回转速度 18/s,加速时间 2s;4) 行走速度 1m/s,加速时间 2s。3. 工况参数:1) 内河港口起重机;2) 安全系数取 1.2;3) 使用年限 15 年,每天工作 8 小时。2二、毕业设计图纸内容及张数起重机设计图纸1) 起重机设计总图一张2) 吊钩总成图纸一张3) 行走机构装配总图一张4) 行走轮系图纸一张5) 其他的非标零件图纸若干6) 起重机三维整体模型及若干零件模型起重机毕业设计开题报告一篇起重机毕业设计任务书起重机毕业设计论文一篇三、毕业设计应完成的软硬件的名称、内容及主要技术指标( 例 如 : 软 件 、 电 路 板 、 机 电 装 置 、 新 材 料 、 新 制 剂 、 结 构 模 型 或 其 他 )50T 门座起重机结构模型3四、毕业设计进度计划序号 各阶段工作内容 起讫日期 实施地点1 熟悉课题的背景,收集资料,阅读参考书;2013.03.01 2013.03.04(3 天)学校2 南昌昌北码头毕业实习,撰写实习报告;2013.03.05 2013.03.06(2 天)昌北码头学校3 撰写毕业设计开题报告,明确设计任务;2013.03.06 2013.03.10(4 天)学校4 撰写毕业设计任务书,明确设计流程及阶段性目标;2013.03.10 2013.03.13(2 天)学校5 方案的选择及总体方案的确定;2013.03.14 2013.03.19(5 天)实验室6 各工作机构、金属结构的计算工况、计算载荷以及载荷组合2013.03.20 2013.03.22(2 天)实验室7 吊钩总成的设计计算; 2013.03.23 2013.03.24(1 天)实验室8 计算并选用钢丝绳; 2013.03.24 2013.03.25(1 天)实验室9 吊钩总成的设计计算; 2013.03.25 2013.03.26(1 天)实验室10 货物水平位移补偿系统的设计;2013.03.27 2013.03.29(2 天)实验室11 臂架的设计与校核; 2013.03.30 2013.04.05(6 天)实验室12 行走机构的设计,轮压计算; 2013.04.06 2013.04.16(10 天)实验室13 起重机其他总成及相关机构的整体设计;2013.04.17 2013.04.19(2 天)实验室14 起重机整机稳定性计算; 2013.04.20 2013.04.23(2 天)实验室415 绘制相关图纸,建立起重机三维模型,尝试建立虚拟样机;2013.04.24 2013.05.21(28 天)实验室16 完成毕业设计论文,准备好答辩 PPT 及其他材料。2013.05.22 2013.05.30(7 天)实验室五、主要参考资料1哈尔滨建筑工程学院主编.工程起重机 (第一版)中国建筑工业出版社.1981。2起重机设计手册 编写组编.起重机设计手册 (第一版)机械工业出版社.1980。3陈道南等编.起重运输机械 (第一版)机械工业出版社.1981。4起重运输设备选用手册编写组编.起重运输设备选用手册 (第一版)机械工业出版社.1991。5孙桂林主编.起重搬运机械安全技术 (第一版)中国物资出版社.1991。6饶振刚编著.行星齿轮传动设计 (第一版)化学工业出版社.2003。7濮良贵 纪名刚主编 机械设计 (第七版)高等教育出版社.2001。8王昆等编 机械设计课程设计 (第一版)高等教育出版社.2000。9余俊等编. 机械设计 (第二版)高等教育出版社.1986。10减速器实用技术手册编委会编减速器实用技术手册 (第一版)机械工业出版社.1992。11唐保宁 高学满主编机械设计与制造简明手册 (第二版)同济大学出版社出版.1993。12段嗣福等编 .机械设计基础 (第一版)中国矿业大学出版.1994。六、毕业设计进度表(本表至少每两周由学生填写一次,交指导教师签署审查意见)5第一、二周( 月 日至 月 日)学生主要工作:指导教师审查意见:签名: 年 月 日第三、四周( 月 日至 月 日)学生主要工作:指导教师审查意见:签名: 年 月 日第五、六周( 月 日至 月 日)学生主要工作:指导教师审查意见:签名: 年 月 日6第七、八周( 月 日至 月 日)学生主要工作:指导教师审查意见:签名: 年 月 日第九、十周( 月 日至 月 日)学生主要工作:指导教师审查意见:签名: 年 月 日第十一周至毕业设计工作结束( 月 日至 月 日)学生主要工作:指导教师审查意见:签名: 年 月 日7七、其他(学生提交)1开题报告 1 份 2外文资料译文 1 份(2000 字以上,并附资料原文) 3论文 1 份(8000 字以上) 指 导 教 师: 学科组负责人: 学生开始执行任 务 书 日 期 : 学 生 姓 名 : 送交毕业设计日 期 : Engineering, 2011, 3, 935-941 doi:10.4236/eng.2011.39115 Published Online September 2011 (http:/www.SciRP.org/journal/eng) Cop yrigh t 20 11 S ciRes . ENG Stress Analysis of Crane Hook and Validation by Photo-Elasticity Rashmi Uddanwadiker Department Mechanical Engineering, Visvesvaraya National Institute of Technology, Nagpur, India E-mail: rashmiu71 Received July 27, 2011; revised August 12, 2011; accepted August 26, 2011 Abstract Crane Hooks are highly liable components and are always subjected to failure due to accumulation of large amount of stresses which can eventually lead to its failure. To study the stress pattern of crane hook in its loaded condition, a solid model of crane hook is prepared with the help of CMM and CAD software. Real time pattern of stress concentration in 3D model of crane hook is obtained. The stress distribution pattern is verified for its correctness on an acrylic model of crane hook using Diffused light Polariscope set up. By predicting the stress concentration area, the shape of the crane is modified to increase its working life and reduce the failure rates. Keywords: Photo-Elasticity, Crane Hook, Finite Element Method, Curved Beam, Stress Optic Law 1. Introduction Crane Hooks are highly liable components that are typi- cally used for industrial purposes. It is basically a hoist- ing fixture designed to engage a ring or link of a lifting chain or the pin of a shackle or cable socket and must follow the health and safety guidelines 1-4. Thus, such an important component in an industry must be manu- factured and designed in a way so as to deliver maximum performance without failure. Thus, the aim of the project is to study the stress distribution pattern of a crane hook using finite element method and verify the results using Photo elasticity. 2. Failure of Crane Hook To minimize the failure of crane hook 5, the stress in- duced in it must be studied. Crane is subjected to con- tinuous loading and unloading. This causes fatigue of the crane hook but the fatigue cycle is very low 6. If a crack is developed in the crane hook, it can cause frac- ture of the hook and lead to serious accident. In ductile fracture, the crack propagates continuously and is more easily detectible and hence preferred over brittle fracture. In brittle fracture, there is sudden propagation of the crack and hook fails suddenly 7. This type of fracture is very dangerous as it is difficult to detect. Strain aging embrittlement 8 due to continuous loading and unloading changes the microstructure. Bending stress and tensile stress, weakening of hook due to wear, plastic deformation due to overloading, and ex- cessive thermal stresses are some of the other reasons for failure. Hence continuous use of crane hooks may in- crease the magnitude of these stresses and ultimately result in failure of the hook. 3. Methodology of Stress Analysis The analysis is carried out in two phase: 1) Finite ele- ment stress analysis of an approximate (acrylic) model and its verification by photo elasticity theory 2) Analyti- cal analysis assuming hook as a curved beam and its verification using Finite element analysis of the exact hook. To establish the finite element procedure a virtual model similar to the acrylic mode is prepared in ANSYS and the results of stress analysis are cross checked with that of photo elasticity. After establishing the procedure a virtual model similar to actual crane hook sample is cre- ated using CAD software and the results of finite element analysis are now verified with that of analytical method. 4. Finite Element Analysis (FEA) Finite element method 9,10 has become a powerful tool for numerical solution of a wide range of engineering problems. For the stress analysis of the acrylic model of R. UDDANWADIKER 936crane hook the outer geometry or profile of the model is drawn in ANSYS 11.0. It is then extruded to 9.885 mm to form a 3-D model of hook. Here 9.885 is the average thickness of the model. Material properties and element type are fed and the model is meshed using smart size option with the global size of the element as 3. Loading and constraint are applied to the meshed model as shown in the Figure 1 and the finite element model is then solved. Principal stress and von mises stress patterns are thus obtained as shown in Figure 2. 5. Theory of Photo Elasticity For the verification of the results obtained from FEM, the experimentation is conducted using the concept of photo elasticity. The concept is used to determine stress distribution and stress concentration factors in irregular geometries. The method is based on the property of bire- fringence, which is exhibited by certain transparent ma- terials. Birefringence is a property by virtue of which a ray of light passing through a birefringent material ex- periences two refractive indices. Thus, a crane hook model made out of such material is selected for the. Figure 1. Meshed constraint model. Figure 2. Principle stresses in the model. study. T t of the 5.1. Stress Optic Law When plane polarized light passes through a photo elas- he model has geometry similar to tha structure on which stress analysis is to be performed. This ensures that the state of stress in the model is simi- lar to that of the structure. tic material, it resolves along the two principal stress directions and each of these components experiences different refractive indices 11. The difference in the refractive indices leads to a relative phase retardation between the two component waves. The magnitude of the relative retardation is given by the stress optic law: RC t 11 22 where R is the induced retardation, C is the stress optic po- la ation of disc is done to find the material fringe va w value, coefficient, t is the specimen thickness, 11is the first principal stress, and 22is the second principal stress. The two waves are then brought together in a riscope set up. Thus, the state of stress at various points in the material can be determined by studying the fringe pattern. Calibr lue f . An acrylic model of disc is taken and subjected to compressive load in the circular polariscope setup. Figure 3 shows fringe pattern on a loaded disc. Values of loads are noted down for various fringe orders Using the formula f = 8P/ DN = 11.15 here P = Load applied at particular fringe N = Fringe order at corresponding load D = diameter of the disc = 7.01 cm Figure 3. stress pattern of photo elastic model under so- dium light. Cop yrigh t 20 11 S ciRes . ENG R. UDDANWADIKER 937 gnitude at a point is given by: ( 1 2 )/2 = N f / re 1= major principal stress, 2= minor principal 6. Results For the approximate model of crane hook, stresses in- maximum principal stress Stress ma t whe stress, t = thickness of hook. duced during finite element analysis are compared with that of photo elasticity experiment. For the acrylic model of crane hook the results are as under: ANSYS v/s Experimental As shown in Figure 4, (a) (b) Figure 4. Stress distribution pattern for acrylic model (a) 5 N/mm 2 while that e reasons for variation might be due to the fact th sults confirm that the FEA procedure is w Since the crane hook is a curved beam 12, simple the- Using fem; (b) Using photo-elasticity. value obtained from ANSYS = 12.3 obtained experimentally = 11.121 N/mm 2 . The results are closely in agreement with a very small percentage error = 5.76%. Possibl at it is difficult to find the magnitude of stress exactly on the plane of the fringe closest to inner surface and thus the value 12.35 may not be accurate. Figure 5 shows the exact location of maximum stress on the ap- proximate model of crane hook as obtained from AN- SYS software. The above re ell established and can be used for complex and accu- rate models also. Hence in the second phase of the study, analytical calculations are carried out for the exact model of crane hook and the results are validated from that of ANSYS. 7. Analytical Method ory of bending for shallow, straight beam does not yield accurate results. Stress distribution across the depth of such beam, subjected to pure bending, is non linear (to be precise, hyperbolic) and the position of the neutral surface is displaced from the centroidal surface towards the centre of curvature. In case of hooks as shown in Figure 6, the members are not slender but rather have a sharp curve and their cross-sectional dimensions are large compared to their radius of curvature. Figure 5. Variations due to limitations. Cop yrigh t 20 11 S ciRes . ENG R. UDDANWADIKER 938Neutral Surface Centroidal Surface M M r n r c e cg c c c d d b c o c i r o y c b d Figure 6. Curved beam with its cross section area. The strain at a radius r = 11 22 d n rr dd 0 d 1 d d(where ) () .where . . . . AA n A c A cn n n n n i i i o o o n AE A r A Ar r rr A A MEA e err rA e M rr Mr r My yrr Ae Ae r y Mc Aer Mc Aer RC t d rr r The strain is clearly zero at the neutral axis and is maximum at the outer radius of the beam. Using the rela- tionship of stress/strain = E, the normal stress is simply. n d EE rr r The location of the neutral axis is obtained by equating the product of the normal stress and the area elements over the whole area to 0 d dd n AA rr AE A r 0 reduces to d n A A Ar r d n A A r A r Therefore, The stress resulting from an applied bending moment is d the fact, that the resisting moment is sim erived from ply the integral of the product of moment arm over whole section from the neutral axis and dA. The maxi- mum stress occurs at either the inner or outer surface. The centroid of the section is 1 d rr A c A A Therefore, dwhere cn M EA e err .where n n n n rA e M rr Mrr My yrr Ae Ae r y The maximum stress occurs at either the inner or ou surface: Stress at inner surface ter . , . i i M c A i er Stress at outer surface . . . o M c o A o er The curved beam flexure form la is in reasonable agreement for beams with a ratio of curvature to beam dept r h 8(a ured for the modeling in ANSYS software. u h ( c / ) 5 (rectangular section). As this ratio in- creases, the difference between the maximum stress cal- culated by curved beam formula and the normal beam formula reduces. The above equations are valid for pure bending. In case of crane hooks, the bending moment is due to forces acting on one side of the section under con- sideration. For calculations the area of cross section is assumed to be trapezoidal 13. Values of stresses as shown in Figure 7 are found out at the A-A section as it is the section where maximum stress is induced. 8. Finite Element Method for the Exact Model A crane hook prepared by forging, as shown in Figure ), is proc Using digital Coordinate Measuring Machine (CMM) the cloud points are obtained and the model is prepared in Cop yrigh t 20 11 S ciRes . ENG R. UDDANWADIKER 939 F 50 mm b o b i r 1 r o h A AFigure 7. Analysis of crane hook. Pro-E software. The virtual model prepared in Pro-E software is i llowing e steps of FEM as discussed earlier the stress analysis obtained from analytical calcula- ed in the Section 7, are compared with re- sults obtained by FEA software. .372 N/mm se harmony with a small per- ce ue to the as ch of ensile stress is 150.72 N/mm on the inner su /mm . As shown in Fi 6)/135.46 = 10.12% N/mm ; Stress analyti-= 1.01 % mported in ANSYS environment. Fo th is conducted for the actual model in ANSYS environ- ment and the results are obtained. Figure 8(b) shows the magnitude and location of stress. 9. Results The induced stresses as tions, explain ANSYS v/s analytical Max value obtained analytically=12.35 N/mm 2 while value obtained from ANSYS = 13 2 The results are in clo ntage error = (13.372 12.35)/12.35 = 8.26% Possible reasons for variation might be the d sumption that 1) Loading is considered as point load- ing in analytical calculation while it is taken on a bunnodes in ANSYS. 2) Cross sectional area is assumed to be trapezoidal and 3) Plane sections remain plane after deformation. Using analytical calculations the stress variation yields the results as shown in Figure 9. Maximum t 2 rface of the crane hook and on the outer surface of the hook, compressive stress is 44.23 N 2 gure 9, the stress goes on decreasing from a max value to zero and again increases from zero to a certain value. Innermost point of section: Max stress by ANSYS= 135.46 N/mm 2 ; Max stress analytically= 150.72 N/mm 2 % error= (150.72 135.4 Outermost point of A-A section: Stress by ANSYS= 43.728 2 cally = 44.23 N/mm 2 ; % error = (44.23 43.728)/43.728(a) (b) Figure 8. (a) Actual crane hook; (b) Stresses obtained usin fem. g 2 3 4 5 6 o 158.72 N/mm 2 44.23 N/mm 2Figure 9. Variation of Stress with depth for the actual model. Cop yrigh t 20 11 S ciRes . ENG R. UDDANWADIKER 940 Reasons for variation: Various assumptions made during the analytical cal- culations (discussed earlier). Profile of the hook obtained from Pro-E Modeling software may not be exactly the same as actual one. 10. Conclusions The complete study is an initiative to establish a FEA procedure, by validating the results, for the measurement of stresses. For reducing the failures of hooks the estima-important. Analytical calculation becomes com- re too complicated. rging is preferred to casting as been in casting the molten metal when solidifies, it has some tion of stresses, their magnitudes and possible locations are very plex as the newer designs a Suggestions to reduce failure Manufacturing process: Fothe crane hooks produced from forging are much stronger than that produced by casting. The reason (a) (b) Figure 10. (a) Hook with Material Removed; (b) Hook with Material Removed. residual stresses due to non uniform solidification. Thus casted crane hooks cannot bear high tensile loads. Grain size: The stress bearing capacity depends on the homogeneity of the material i.e. the relative sizes of the grains in various areas of the component. Smaller the grain size better is the stress bearing capacity. So grain refinement process such as normalizing is advisable after forging. Processes such as welding should be avoided as they increase the stress concentration points which eventually lead to failure. Removal of metal from the hook body is not feasible as it increases the amount of stresses in the hook. This is validated by the following illustration: It is clear from the Fig 10(a) that removal of a small amount of material from minimum stress concen- Ca- 6 Fatigue Cycle. /gkstarns/ME417 S. Suresh, “Fatigue Crack dy of the Structural Relaxa- Tion-Induced Embrittlement of Hypoeutectic ZrCuAl Gro ure tration areas increases the stress slightly though reducing the cost of material. The Figure 10(b) validates the fact that when consid- erable amount of material is removed stresses increase by a good enough margin which

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号