电位器接线片多工位级进模及自动送料装置的设计(全套含CAD图纸)

收藏

资源目录

压缩包内文档预览:

编号:10180396

类型:共享资源

大小:4.36MB

格式:ZIP

上传时间:2018-06-08

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

电位器

接线

片多工位级进模

自动

装置

设计

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

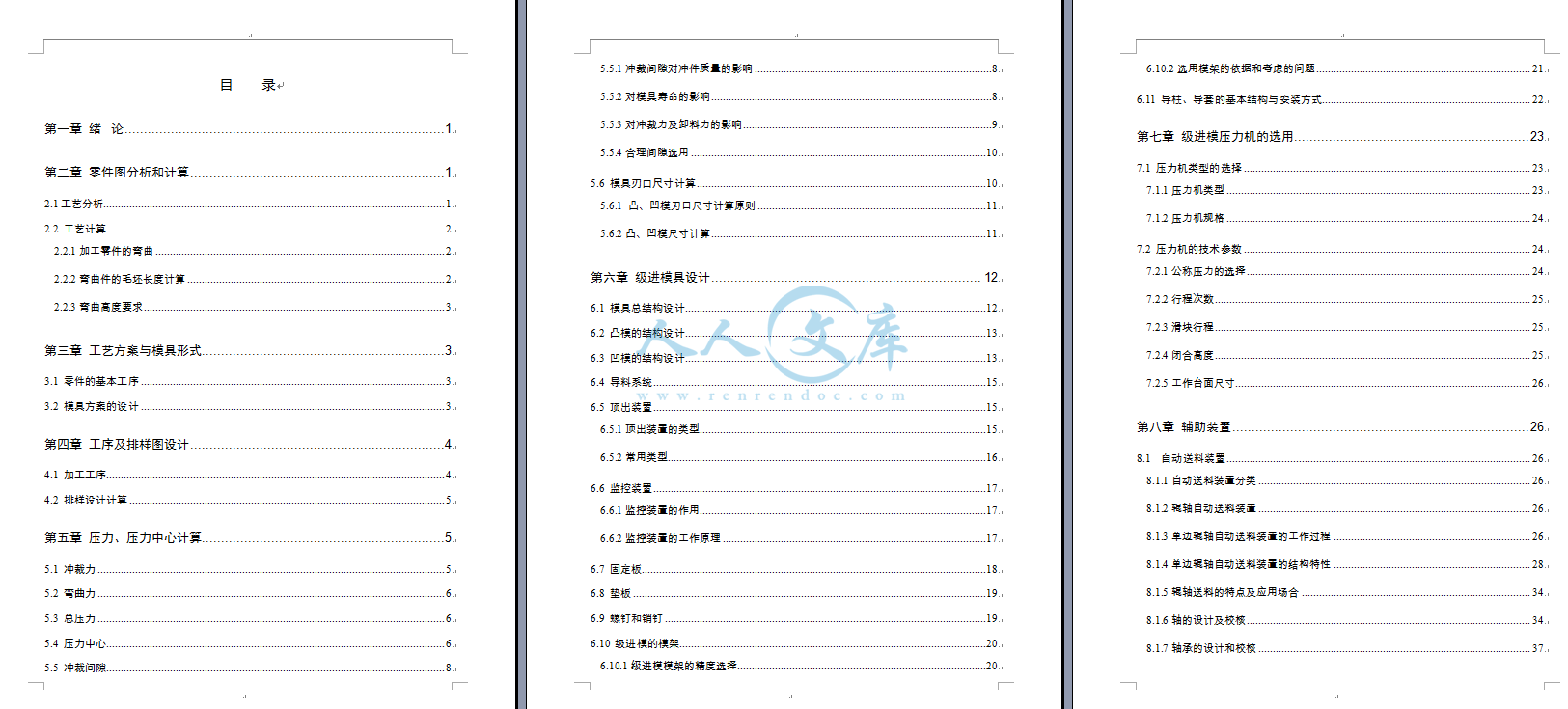

下载后文件包含有 CAD图纸和说明书,咨询 Q 197216396 或 11970985 毕业设计(论文)说明书题 目:电位器接线片多工位级进模及自动送料装置的设计学 院: 机电工程学院 专 业:机械设计制造及其自动化学生姓名:学 号:指导教师单位:姓 名:职 称:题 目 类 型 : 理 论 研 究 实 验 研 究 工 程 设 计 工 程 技 术 研 究 软 件 开 发下载后文件包含有 CAD 图纸和说明书,咨询 Q 197216396 或 11970985摘 要电位器在日常生活中的应用非常之广泛,尤其是在电子设备上。它是一种可调的电子元件,由一个电阻体和一个转动或滑动系统组成,主要起分压和分流作用,其工作原理跟可变电阻器比较相近,而且种类也比较的多。近来多工位级进模在模具冲压中越来越重要,本次模具毕业设计研究的是电位器接线片的冲压工艺与模具设计,主要通过运用多工位级进模来完成,将有效提高冲压件质量与生产效率。在本次设计中绘制了产品零件图并分析了电位器接线片的成型工艺特点,其中包括利用对工件展开图的尺寸计算、工件的工艺分析、冲裁力与拉深力的计算、模具设计中的难点,如接线片的弯曲和修边,确定了级进模的排样方案和模具总体结构及自动送料装置。该级进模有冲裁、拉深、整形、胀形等 7 个工位。详细介绍了凸模、凹模、固定板、卸料装置等零部件的设计和制造,压力机的选用以及相关的辅助装置。同时阐述了模具的工作过程、各成形动作的协调性、以及凸模和凹模镶块的装配间隙,并制定典型零件的加工工艺。关键词:电位器;接线片;多工位级进模;压力机;自动送料下载后文件包含有 CAD 图纸和说明书,咨询 Q 197216396 或 11970985AbstractPotentiometer applications in daily life is very extensive, especially in electronic devices. It is an adjustable electronic components, by a resistor body and a rotating or sliding system components, main and diverted from the partial pressure, it works with the variable resistors are quite close, but also more multi-species. Recently, multi-position progressive die stamping more and more important in the mold, this mold is the design of graduate potentiometer lug stamping process and die design, primarily through the use of multi-position progressive die to complete, will effectively improve the stamping pieces of quality and production efficiency. In this design drawing parts in the graph and analyze the potential wiring film forming process features, including the use of the size of the workpiece calculated expansion plan, part of the process analysis, the blanking force and drawing force calculation, mold design of the difficulties, such as lugs bending and trimming, set the layout for progressive die and mold the overall program structure and automatic feeding device. The progressive die with blanking, drawing, shaping, expansion, etc. 7 station. Details of the punch and die, fixed plate, unloading equipment and other parts of the design and manufacture of presses and related auxiliary equipment used. It illustrates the working process of the mold, the forming coordination of movements, as well as punch and die inserts assembly space, and to develop typical machining process. Key words : potentiometers;lug;multi-postion progressive die;press;automatic feeding下载后文件包含有 CAD 图纸和说明书,咨询 Q 197216396 或 11970985目 录第一章 绪 论 .1第二章 零件图分析和计算 .12.1 工艺分析.12.2 工艺计算.22.2.1 加工零件的弯曲 .22.2.2 弯曲件的毛坯长度计算 .22.2.3 弯曲高度要求 .3第三章 工艺方案与模具形式 .33.1 零件的基本工序.33.2 模具方案的设计.3第四章 工序及排样图设计 .44.1 加工工序.44.2 排样设计计算.5第五章 压力、压力中心计算 .55.1 冲裁力.55.2 弯曲力.65.3 总压力.65.4 压力中心.65.5 冲裁间隙.85.5.1 冲裁间隙对冲件质量的影响 .85.5.2 对模具寿命的影响 .85.5.3 对冲裁力及卸料力的影响 .9下载后文件包含有 CAD 图纸和说明书,咨询 Q 197216396 或 119709855.5.4 合理间隙选用 .105.6 模具刃口尺寸计算.105.6.1 凸、凹模刃口尺寸计算原则 .115.6.2 凸、凹模尺寸计算 .11第六章 级进模具设计 .126.1 模具总结构设计.126.2 凸模的结构设计.136.3 凹模的结构设计.136.4 导料系统.156.5 顶出装置.156.5.1 顶出装置的类型 .156.5.2 常用类型 .166.6 监控装置.176.6.1 监控装置的作用 .176.6.2 监控装置的工作原理 .176.7 固定板.186.8 垫板.196.9 螺钉和销钉.196.10 级进模的模架.206.10.1 级进模模架的精度选择 .206.10.2 选用模架的依据和考虑的问题 .216.11 导柱、导套的基本结构与安装方式.22第七章 级进模压力机的选用 .237.1 压力机类型的选择.237.1.1 压力机类型 .237.1.2 压力机规格 .247.2 压力机的技术参数.247.2.1 公称压力的选择 .247.2.2 行程次数 .25下载后文件包含有 CAD 图纸和说明书,咨询 Q 197216396 或 119709857.2.3 滑块行程 .257.2.4 闭合高度 .257.2.5 工作台面尺寸 .26第八章 辅助装置 .268.1 自动送料装置.268.1.1 自动送料装置分类 .268.1.2 辊轴自动送料装置 .268.1.3 单边辊轴自动送料装置的工作过程 .268.1.4 单边辊轴自动送料装置的结构特性 .288.1.5 辊轴送料的特点及应用场合 .348.1.6 轴的设计及校核 .348.1.7 轴承的设计和校核 .378.1.8 键的设计和校核 .398.2 卸料装置.408.2.1 卸料装置的设计 .408.3 选择冲压设备.43结论 .44致谢 .45参考文献 .46附录 .47下载后文件包含有 CAD 图纸和说明书,咨询 Q 197216396 或 11970985下载后文件包含有 CAD 图纸和说明书,咨询 Q 197216396 或 119709851第一章 绪 论模具在我们日常生活中的应用非常之广,所用器具几乎均需用模具来成型实现,例如在电子、汽车、电机、电器、仪器、仪表、家电和通信等产品中,其中 60%80%的零部件都要依靠模具成形。用模具生产制件所具备的高精度、高复杂程度、高一致性、高生产率和低消耗,是其他加工制造方法所不能比拟的。模具又被称为“效益放大器”,用模具生产的最终产品的价值往往是模具自身价值的几十倍甚至是上百倍。冲压模具如今在生产中的地位越来越重要,而标志冲模技术先进水平的多工位级进模,是我国重点发展的精密模具品种。级进模能够在一副模具内完成复杂零件的冲裁,弯曲,拉深,立体成型以及装配等复杂工艺,具有生产效率高,操作安全可靠,可以加工复杂零件等特点而推崇备至。有代表性的是集机电一体化的铁芯精密自动叠片多功能模具,已达到国际水平。其他如 48、54、68 条腿集成电路柜架多工位级进模、电子枪硬质合金多工位级进模、别克轿车安全带座式多工位级进模、空调器散热片多工位级进模,均达到国外同类产品水平。但总体上和国外多工位级进模相比,在制造精度、使用寿命、模具结构和功能上,仍存在一定差距。本文将对电位器接线片冲压工艺与多工位级进模设计作一个系统、详细的介绍。毕业设计的意义就在于综合运用所学课程的理论和生产实际知识,进行多工位级进模设计工作的实际训练,培养个人独立工作能力和创新能力,树立理论联系实际和严谨求实的工作作风。巩固、扩充模具专业课程所学内容,掌握多工位级进模的设计方法和步骤。掌握多工位级进模设计的基本技能,如计算分析、计算机绘图、查阅设计资料和撰写设计说明书,熟悉标准和规范。第二章 零件图分析和计算2.1 工艺分析1.工件图采用厚 的黄铜带制成,尺寸公差,形位公差都有较高的要求,外0.4m形复杂,产量大,用级进模生产最为合理,其他加工方法都不经济。2.主要工序有落料、冲孔、成形和弯曲。3.工件图如图 2-1 所示。2图 2-1 电位器接线片示意图2.2 工艺计算2.2.1 加工零件的弯曲表 2-1 弯曲 时,变薄系数 和应变中性层位移系数 的数值90Xrt0.1 0.25 0.5 1.0 2.0g 0.82 0.87 0.92 0.96 0.99X0.32 0.35 0.38 0.42 0.445r弯曲半径(mm) ,t料厚(mm)2.2.2 弯曲件的毛坯长度计算这类( )零件变薄不严重且断面畸变较轻,可以按应变中性层长度等于毛r.t坯长度的原则来计算。毛坯长度等于零件直线长度和弯曲部分应变中性层长度之和,即:编号: 毕业设计(论文)外文翻译(原文)院 (系): 机电工程学院 专 业:机械设计制造及其自动化 学生姓名:学 号:指导教师单位:姓 名:职 称:1The development trend of the numerical control technology1. NUMERICAL CONTROLNumerical control(NC)is a form of programmable automation in which the processing equipment is controlled by means of numbers,letters,and other symbolsThe numbers,letters,and symbols are coded in an appropriate format to define a program of instructions for a particular workpart or jobWhen the job changes,the program of instructions is changedThe capability to change the program is what makes NC suitable for low-and medium-volume productionIt is much easier to write programs than to make major alterations of the processing equipmentThere are two basic types of numerically controlled machine tools:pointtopoint and continuouspath(also called contouring)Pointtopoint machines use unsynchronized motors,with the result that the position of the machining head Can be assured only upon completion of a movement,or while only one motor is runningMachines of this type are principally used for straightline cuts or for drilling or boring The NC system consists of the following components:data input,the tape reader with the control unit,feedback devices,and the metalcutting machine tool or other type of NC equipmentData input,also called“mantocontrol link”,may be provided to the machine tool manually,or entirely by automatic meansManual methods when used as the sole source of input data are restricted to a relatively small number of inputsExamples of manually operated devices are keyboard dials,pushbuttons,switches,or thumbwheel selectorsThese are located on a console near the machineDials ale analog devices usually connected to a syn-chro-type resolver or potentiometerIn most cases,pushbuttons,switches,and other similar types of selectors aye digital input devicesManual input requires that the operator set the 2controls for each operationIt is a slow and tedious process and is seldom justified except in elementary machining applications or in special casesIn practically all cases,information is automatically supplied to the control unit and the machine tool by cards,punched tapes,or by magnetic tapeEightchannel punched paper tape is the most commonly used form of data input for conventional NC systemsThe coded instructions on the tape consist of sections of punched holes called blocksEach block represents a machine function,a machining operation,or a combination of the twoThe entire NC program on a tape is made up of an accumulation of these successive data blocksPrograms resulting in long tapes all wound on reels like motion-picture filmPrograms on relatively short tapes may be continuously repeated by joining the two ends of the tape to form a loopOnce installed,the tape is used again and again without further handlingIn this case,the operator simply loads and unloads the partsPunched tapes ale prepared on type writers with special tapepunching attachments or in tape punching units connected directly to acomputer systemTape production is rarely error-freeErrors may be initially caused by the part programmer,in card punching or compilation,or as a result of physical damage to the tape during handling,etcSeveral trial runs are often necessary to remove all errors and produce an acceptable working tape While the data on the tape is fed automatically,the actual programming steps ale done manuallyBefore the coded tape may be prepared,the programmer,often working with a planner or a process engineer, must select the appropriate NC machine tool,determine the kind of material to be machined,calculate the speeds and feeds,and decide upon the type of tooling needed. The dimensions on the part print are closely examined to determine a suitable zero reference point from which to start the programA program manuscript is then written which gives coded numerical instructions describing the sequence of operations that the machine tool is required to follow to cut the part to the drawing specifications3The control unit receives and stores all coded data until a complete block of information has been accumulatedIt then interprets the coded instruction and directs the machine tool through the required motionsThe function of the control unit may be better understood by comparing it to the action of a dial telephone,where,as each digit is dialed,it is storedWhen the entire number has been dialed,the equipment becomes activated and the call is completedSilicon photo diodes,located in the tape reader head on the control unit,detect light as it passes through the holes in the moving tapeThe light beams are converted to electrical energy,which is amplified to further strengthen the signalThe signals are then sent to registers in the control unit, where actuation signals are relayed to the machine tool drivesSome photoelectric devices are capable of reading at rates up to 1000 characters per secondHigh reading rates are necessary to maintain continuous machinetool motion;otherwise dwell marks may be generated by the cutter on the part during contouring operationsThe reading device must be capable of reading data blocks at a rate faster than the control system can process the dataA feedback device is a safeguard used on some NC installations to constantly compensate for errors between the commanded position and the actual location of the moving slides of the machine toolAn NC machine equipped with this kind of a direct feedback checking device has what is known as a closed-loop systemPositioning control is accomplished by a sensor which,during the actual operation,records the position of the slides and relays this information back to the control unitSignals thus received ale compared to input signals on the tape,and any discrepancy between them is automatically rectifiedIn an alternative system,called an openloop system,the machine is positioned solely by stepping motor dri4ves in response to commands by a controllersThere are three basic types of NC motions, as follows: Point-to-point or Positional Control In point-to-point control the machine tool elements (tools, table, etc.) are moved to programmed locations and the machining operations performed after the motions are completed. The path or speed of movement between locations is unimportant; only the coordinates of the end points of the motions are accurately controlled. This type of control is suitable for drill presses and some boring machines, where drilling, tapping, or boring operations must be performed at various locations on the work piece. Straight-Line or Linear Control Straight-Line control systems are able to move the cutting tool parallel to one of the major axes of the machine tool at a controlled rate suitable for machining. It is normally only possible to move in one direction at a time, so angular cuts on the work piece are not possible, consequently, for milling machines, only rectangular configurations can be machined or for lathes only surfaces parallel or perpendicular to the spindle axis can be machined. This type of controlled motion is often referred to as linear control or a half-axis of control. Machines with this form of control are also capable of point-to-point control.Continuous Path or Contouring Control In continuous path control the motions of two or more of the machine axes are controlled simultaneously, so that the position and velocity of the can be tool are changed continuously. In this way curves and surfaces can be machined at a controlled feed rate. It is the function of the interpolator in the controller to determine the increments of the individual controlled axes of the machines necessary to produce the desired motion. This type of control is referred to as continuous control or a full axis of control.Some terminology concerning controlled motions for NC machines has been introduced. For example, some machines are referred to as four-or five-or even six-axis machines. For a vertical milling machine three axes of control are fairly obvious, these being the usual X, Y, Z coordinate directions. A fourth or fifth axis of control would imply some form of rotary table to index the work piece or possibly to provide angular motion 5of the work head. Thus, in NC terminology an axis of control is any controlled motion of the machine elements (spindles, tables, etc). A further complication is use of the term half-axis of control; for example, many milling machines are referred to as 2.5-axis machine. This means that continuous control is possible for two motions (axes) and only linear control is possible for the third axis. Applied to vertical milling machines, 2.5axis control means contouring in the X, Y plane and linear motion only in the Z direction. With these machines three-dimensional objects have to be machined with water lines around the surface at different heights. With an alternative terminology the same machine could be called a 2CL machine (C for continuous, L for linear control). Thus, a milling machine with continuous control in the X, Y, Z directions could be termed be a three-axis machine or a 3c machine, Similarly, lathes are usually two axis or 2C machines. The degree of work precision depends almost entirely upon the accuracy of the lead screw and the rigidity of the machine structureWith this systemthere is no self-correcting action or feedback of information to the control unitIn the event of an unexpected malfunction,the control unit continues to put out pulses of electrical currentIf,for example,the table on a NC milling machine were suddenly to become overloaded,no response would be sent back to the controllerBecause stepping motors are not sensitive to load variations,many NC systems are designed to permit the motors to stall when the resisting torque exceeds the motor torqueOther systems are in use,however,which in spite of the possibility of damage to the machine structure or to the mechanical system,ale designed with special hightorque stepping motorsIn this case,the motors have sufficient capacity to“overpowerthe system in the event of almost any contingency The original NC used the closedloop systemOf the two systems,closed and open loop,closed loop is more accurate and,as a consequence,is generally more expensiveInitially,openloop systems were used almost entirely for light-duty applications because of inherent power limitations previously associated with conventional electric stepping motorsRecent advances in the development of electro hydraulic stepping motors have led to increasingly heavier machine load applications62.NC technology development trends2.1 NC system developments at home and abroad With the rapid development of computer technology, the traditional beginning of a fundamental change manufacturing, the industrial developed countries spent huge sums of money on the modern manufacturing technology research and development, to create a new model. In modern manufacturing systems, CNC technology is the key to technology, which combines microelectronics, computers, information processing, automatic detection, automatic control, such as the integration of advanced, a high-precision, high-efficiency, flexible automation, and other characteristics, the manufacturing industry Flexible automation, integrated, intelligent play the pivotal role. At present, NC technology is undergoing a fundamental change, from a special closed-loop control mode to general-purpose real-time dynamic open all closed-loop control mode. In the integrated on the basis of the CNC systems ultra-thin, ultra-light; on the basis of the intelligent, integrated computers, multimedia, fuzzy control, neural network and other technical disciplines, NC system to achieve high-speed, high-precision, Efficient control, automatic processing can be amended to regulate compensation and the parameters for an online intelligent fault diagnosis and treatment of the network based on the CAD / CAM and CNC systems integration as one machine network, makes the central government centralized control of the group control processing. The application of the technology of numerical control has not only brought the revolutionary change to traditional manufacturing industry, make the manufacturing industry become the industrialized symbol , and with the constant development of the technology of numerical control and enlargement of application, the development of he some important trades (IT , car , light industry , medical treatment ,etc. ) to the national economy and the peoples livelihood plays a more and more important role, because these trade necessary digitization that equipped has already been the main trend of modern development.For a long time, Chinas CNC system for traditional closed architecture, but only as a non-intelligent CNC machine controller. Process 7variables based on experience in the form of pre-fixed parameters, processing procedures before the actual processing by hand or through CAD / CAM and automatic programming system prepared. CAD / CAM and CNC have no feedback control link, the entire manufacturing process CNC is a closed ring-opening implementing agencies. In a complex and changing environment under the conditions of processing tool in the process of composition, workpiece material, spindle speed, feed rate, tool path, cutting depth, step, allowance and other processing parameters, not at the scene circumstances under external interference and real-time dynamic random factors, not by random amendment feedback control link CAD / CAM settings volume, in turn, affect the work of CNC machining efficiency and product quality. Clearly, the traditional fixed CNC system that controlled mode and closed architecture, limiting the CNC to the development of more intelligent control variables, can no longer meet the increasingly complex manufacturing process, therefore, the CNC technology in the potential for change inevitable. The technology of numerical control of our country started in 1958, the development course in the past 50 years can roughly be divided into 3 stages: The first stage is from 1958 to 1979, i.e. closed developing stage. In this stages, technology of foreign countries blockade and basic restriction of terms of our country, the development of the technology of numerical control is comparatively slow. During “ Sixth Five-Year Plan Period “ , “ the Seventh Five-Year Plan Period “ of the country in second stage and earlier stage in “ the Eighth Five-Year Plan Period “, introduce technology , digest and assimilate, the stage of establishing the system of production domesticization arisesing tentatively. At this stage , because of reform and opening-up and national attention , and study the improvement of the development environment and international environment, research , development and all making considerable progress in production domesticization of the products of the technology of numerical control of our country. The third stage is that on the later stage in “ the Eighth Five-Year Plan Period “ of the country and during the “ Ninth Five-Year Plan Period “, implement the research of industrialization , enter market competition stage. At this stage, made substantive progress in 8industrialization of the domestic numerical control equipment of our country. In “ the Ninth Five-Year Plan “ latter stage, domestic numerical control domestic market share of lathe reach 50% , mix domestic numerical control system (popular ) to up to 10%. Review the development course in the past 50 years of technology of numerical control of our country, especially pass the brainstorm of 4 Five-Year Plans, all in all has made following achievements.a. Have establish the foundation of the technical development of numerical control, has basically mastered the technology of modern numerical control. Our country know from numerical control system , servo urge , numerical control host computer , special plane and their basic of fittings basically already now, among them most technology have already possessed the foundation that is commercialized and developed , some technology has already, industrialization commercialized.a.Have formed the industrial base of numerical control tentatively. In tackling key problems the foundation that the achievement and some technology commercialize , set up the systematic factories of numerical control with production capacity of batch such as numerical control of Central China , spaceflight numerical control etc. Electrical machinery plant of Lanzhou, a batch of servo systems and first machine tool plant , first machine tool plant of Jinan of servo electrical machinery factory and Beijing ,etc. several numerical control host computer factories such as the numerical control in Central China. These factories have basically formed the numerical control industrial base of our country.b.Have set up research of a numerical control, development , managerial talents basic team . Though has made considerable progress in research and development and industrialization of the technology of numerical control, but we will realize soberly, the research and development of the technology of advanced numerical control of

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号