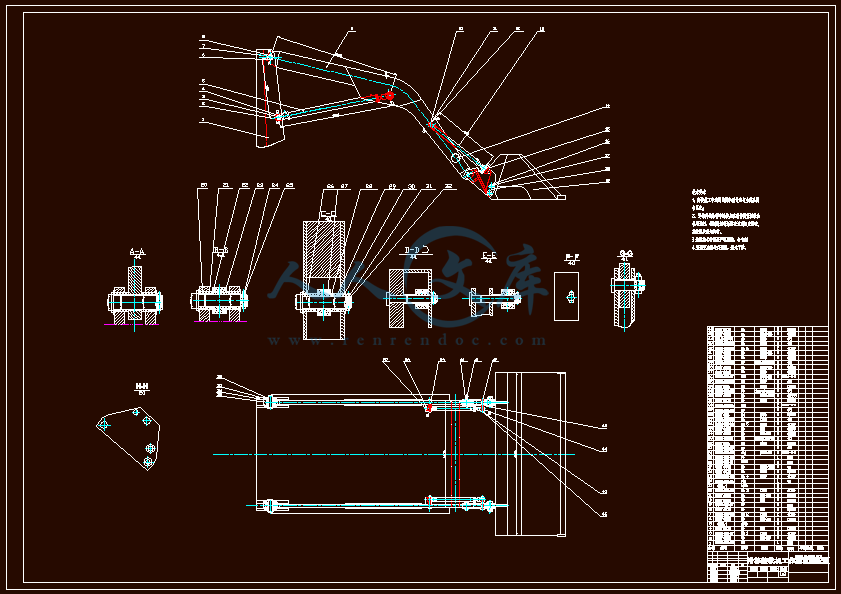

滑移式装载机机械结构设计(全套含CAD图纸)

收藏

资源目录

压缩包内文档预览:

编号:10202777

类型:共享资源

大小:8.90MB

格式:ZIP

上传时间:2018-06-15

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

40

积分

- 关 键 词:

-

滑移

装载

机械

结构设计

全套

cad

图纸

- 资源描述:

-

- 内容简介:

-

1LoadersOverviewBasic Concept.A loader is a type of construction equipment (engineering vehicle) machinery that is primarily used to “load“ material into another type of machinery (dump truck, conveyor belt, rail-car, etc.).Loaders are used mainly for uploading materials into trucks, laying pipe, clearing rubble, and digging. A loader is not the most efficient machine for digging as it cannot dig very deep below the level of its wheels, like a backhoe can. Their deep bucket can usually store about 3-6 cubic meters of earth. The front loaders bucket capacity is much bigger than a bucket capacity of a backhoe loader. Loaders are not classified as earthmoving machinery, as their primary purpose is other than earthmoving.Unlike most bulldozers, most loaders are wheeled and not tracked, although track loaders are common. They are successful where sharp edged materials in construction debris would damage rubber wheels, or where the ground is soft and muddy. Wheels provide better mobility and speed and do not damage paved roads as much as tracks but provide less traction.Unlike standard tractors fitted with a front bucket, many large loaders do not use automotive steering mechanisms. Instead, they steer by a hydraulically actuated pivot point set exactly between the front and rear axles. This is referred to as “articulated steering“ and allows the front axle to be solid, allowing it to carry greater weight. Articulated steering provides better maneuverability for a given wheelbase. Since the front wheels and attachment rotate on the same axis, the operator is able to “steer“ his load in an arc after positioning the machine, which can be useful 2the loader assembly may be a removable attachment or permanently mounted. Often the bucket can be replaced with other devices or tools-for example, many can mount forks to lift heavy pallets or shipping containers, and a hydraulically-opening “clamshell“ bucket allows a loader to act as a light dozer or scraper.In construction areas loaders are also used to transport building materials - such as bricks, pipe, metal bars, and digging tools - over short distances. Loaders are also used for snow removal, using their bucket or a snow basket, but usually using a snowplow attachment. They clear snow from streets, highways and parking lots. They sometimes load snow into dump trucks for transport.Front loaders gained popularity during the last two decades, especially in urban engineering projects and small earthmoving works. Many engineering vehicle manufacturers offer a wide range of loaders, the most notable are those of John Deere, Caterpillar, Case, Volvo, Komatsu and Liebherr.Applications1 23 4 5 637 89 1011 121. loading materials;2. earthmoving;3. forestry engineering;4. snow removing;5. underground work;6. loading and unloading;7. pipe laying;8. maintain pavement;9. land clearing;10. garden work;11. rolling compaction;12. tunnel constructionTypes1 23 445 67 89 101. mini type loader;2.small type wheel loader;3.medium type wheel loader;4.large type wheel loader;5. track-type loader;6. skid steer loader;7. underground mining loader;8. multi terrain loader;9. wheel backhoe loader;10. side dumping loaderComponents and FeaturesComponentsBasic Components51. bucket;2. front axle;3.instrumentation console;4. cab and operating system;5.engine and transmission system;6. engine hood;7. counterweight;8. rear axle;9. rear frame;10. electrical system;11. front frame;12. mudguard;13. boom;14. rocker arm cylinder;15. connecting rod;16. rocker arm;17. boom cylinder;18. frameHydro mechanical Transmission System61.engine;2. torque converter;3. power shifting transmission box;4. front axle;5. Caliper disc brake;6. wheel;7. parking brake; 8. rear axle;9. gear shift pump;10. steering pump;11. operational pump;12. wheel redactorTransmission System Arrangement1. engine;2. torque converter;3. power shift transmission box;4. rear frame;5. front frame; 6. front axle;7. transmission shaft;8. rear axleTorque Converter71. flywheel;2、4、7、11、17、19. bearing;3. torque converter rotation housing;5. elastic plate; 6. first turbine; 8. second turbine;9. stator;10. pump impeller;12. gear;13. stator shaft;14. second turbine shaft;15. first turbine shaft;16. spacer ring;18. one-way clutch gear;20. one-way clutch rollerPerformance Characteristic81. engine;2. piston pump;3. low speed piston motor;4.high peed piston motor;5. transfer caseHastate Power Train System91. Neutral-start parking brake lever;2. Track motors;3. Hastate pumps hoses;4. Hydraulic oil cooler;5. Service brakes;6. hoses ;7. Wet, multi-disc parking brakes;8. Double reduction planetary final drives;9. hydraulic filtersOperator Station of Track Loader1. Neutral-start parking brake lever;2. Track motors;3. Hastate pumps hoses;4. Hydraulic oil cooler;5. Service brakes;6. hoses ; 7. Wet, multi-disc parking brakes;8. Double reduction planetary final drives;9. hydraulic filtersStandard Equipment Specifications1. Engine:Type:Water-cooled, 4-stroke cycle;Aspiration:Turbocharged:Number of cylinders;Bore x stroke ;Piston displacement:Governor: Mechanical, all-speed control: Horsepower rating 2400 rpm (SAE J1349) /2400 rpm(SAE: J1349);Gross horsepower;Net horsepower; Meets EPA emissions regulations EPA;Fuel system :Direct injection:Lubrication system:Method:Gear pump, force-lubrication:Filter:Full-flow:; Air cleaner:Dry-type with double elements and dust evacuator, plus dust indicator:2. Transmission:Torque converter:3-element, single-stage, single-phase: Transmission.:Full power shift, countershaft, automatic.3. Axles and Final Drives:Drive system :Four-wheel drive;Front:Fixed, semi-floating: Rear:Center-pin support, semi-floating,24 total oscillation ;Reduction gear:Spiral bevel gear;Differential gear:Torque proportioning;Final reduction gear:Planetary gear, single reduction104. Brakes:Service brakes: Hydraulically-actuated, wet disc brakes actuateon four wheels;Parking brake: Wet, multi-disc brake on transmission output shaft.5. Steering System:Type:Articulated type, full-hydraulic power steering;Steering angle: 40 each direction;Minimum turning radius at the center of outside tire. 6. Boom and Bucket:Z-bar loader linkage is designed for maximum rigidity and offers powerful breakout. Rap-out loader linkage design enables shock dumping for removing sticky materials. Sealed loader linkage pins with dust seals extend greasing intervals. The bucket is made of high-tensile strength steel.7. Bucket Controls:The use of a PPC hydraulic control valve offers lighter operating effo

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号