Effects-of-operating-factors-for-an-axial-flow-corn-s_2016_Agriculture-and-N.pdf

小型钉齿玉米脱粒机的设计【原创含9张CAD图带开题报告+外文翻译】

收藏

资源目录

压缩包内文档预览:

编号:10232804

类型:共享资源

大小:3.47MB

格式:ZIP

上传时间:2018-06-25

上传人:QQ14****9609

认证信息

个人认证

郭**(实名认证)

陕西

IP属地:陕西

50

积分

- 关 键 词:

-

小型

玉米

脱粒机

设计

原创

cad

开题

报告

讲演

呈文

外文

翻译

- 资源描述:

-

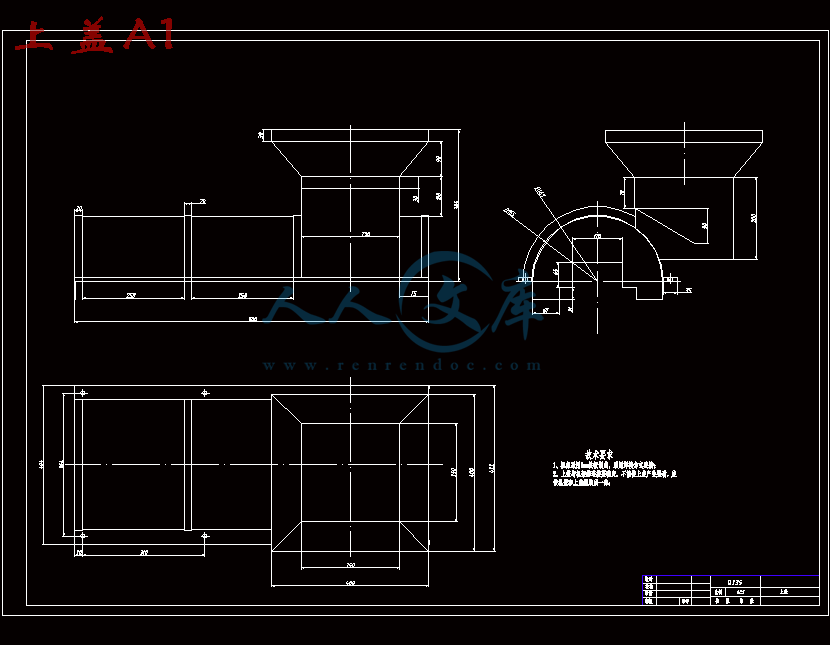

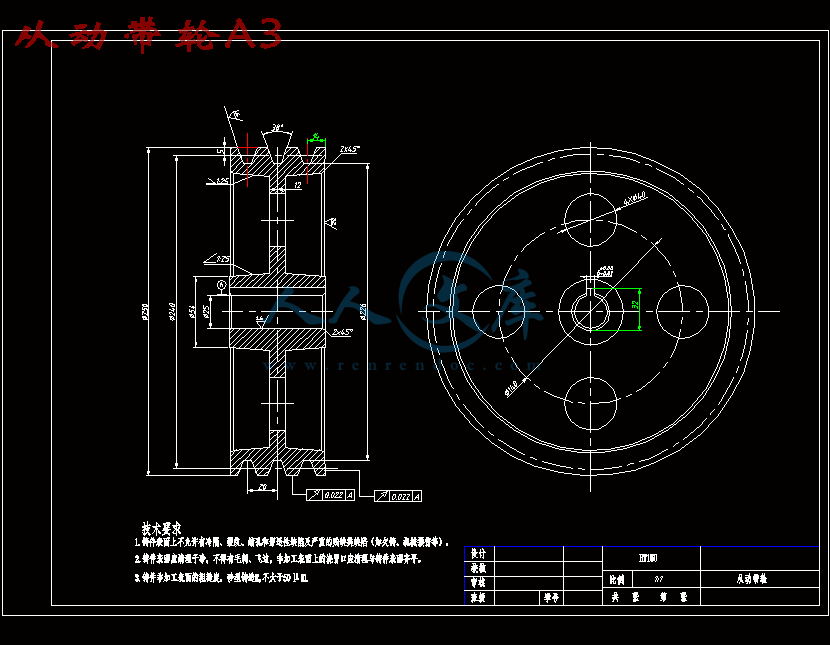

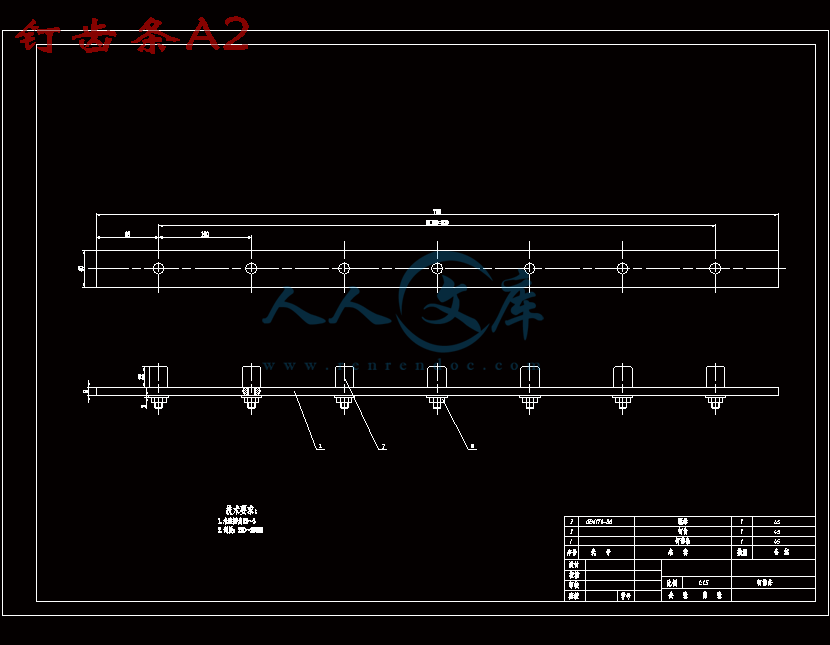

小型钉齿玉米脱粒机的设计【含9张CAD图带外文翻译】

【需要咨询购买全套设计请加QQ1459919609】图纸预览详情如下:

- 内容简介:

-

ow, KhonUnivFeed rateRotor speede studiedunitisedthree levels of rotor speed (RS). The experiments were conducted based on response surface method-3both the grain breakage and power consumption. The FR affected the power consumption but did notis importantproductionmechanism(Chuan-Udom, 2013).broken crop components remaining on the concave surfacesreduced the effectiveness of grain separation, while the powerconsumption and shelling drum speed of the peg-teeth shellerwere double that of the rasp bar sheller (Kunjara et al., 1998).breakage, with the adjustment to shell corns being economical andofanaxialin Asian2011).of the Thai, axialand Chinsuwaninclination, grainthan grain hadChinsuwan et al.rate on threshing unit losses and rice grain damage. The data ob-tained showed that the threshing unit losses decreased and thedamage increased when the rotor tangential speed was increased.Andrews et al. (1993) studied the effects of combine operatingparameters on the harvest loss in rice and reported that the feedrate, the ratio of material other than grain to that of grain, grainmoisture content, rotor speed and concave clearance affectedthreshing unit losses. Gummert et al. (1992) reported that the rotor* Corresponding author. Department of Agricultural Engineering, Faculty ofEngineering, Khon Kaen University, Khon Kaen 40002, Thailand.Contents lists available atAgriculture and NaturalsouAgriculture and Natural Resources 50 (2016) 421e425E-mail address: somchai.chuan (S. Chuan-Udom).than 1.5%. Nevertheless, with a rasp bar sheller, it was found that (2003) studied the effects of the rotor tangential speed and feedKunjara et al. (1998) discussed corn shelling in Thailand fromwhich the following information is sourced. Corn shelling has beenused and modied since 1929. The development of corn shellerequipment was mostly conducted by local manufacturers, with themost corn shellers used for de-husking being the rasp bar shellerand peg-tooth sheller. These shellers have been tested and evalu-ated to determine their best operational performance until theaccumulative losses (grain losses and grain breakage) were lessrequiringonlyeasymodication.Moreover,theprincipleow shelling unit is suitable for Thailand and conditionscountries (Singhal and Thierstein, 1987; Chuan-Udom,The study of the operations and adjustmentsow, rice combine harvester by Chuan-Udom(2009) showed that the rotor speed, guide vanemoisture content, feed rate and grain material othersignicant effects on the threshing unit losses.important components in corn production processes (Reference) thresher was highly efcient and easy to clean, with little grainIntroductionCorn is a feed raw material andindustry (Farjam et al., 2014). Cornrietyand,additionally,theharvesting/10.1016/j.anres.2016.05.0022452-316X/Production and hosting by Elsevier B.V. onorg/licenses/by-nc-nd/4.0/).affect shelling unit losses and grain breakage. Increasing the FR increased the power consumption. TheRS had a signicant impact on the shelling unit losses, grain breakage and power consumption.Increasing the RS increased the grain breakage and power consumption, but decreased the shelling unitlosses. Empirical models were formulated based on multiple linear models.Production and hosting by Elsevier B.V. on behalf of Kasetsart University. This is an open access articleunder the CC BY-NC-ND license (/licenses/by-nc-nd/4.0/).for the livestockis based on its va-isoneofthemostAshellingunit forcornhuskershellingwasoriginallydevelopedbased on a wheat threshing unit, which was efcient but the grainbreakage was relatively high (Department of Agriculture, 1996).Chuan-Udom (2013) studied the operating factors of Thai threshersaffecting corn shelling losses and found that an axial ow riceCorn shelling unitMoisture contentKeywords:ology and 2 factorial designs. The results of this study indicated that the MC signicantly affected grainbreakage and power consumption, but did not affect shelling unit losses. Increasing the MC increasedOriginal ArticleEffects of operating factors for an axial-losses and power consumptionWaree Srison,a, bSomchai Chuan-Udom,a, b, *KhwantriaDepartment of Agricultural Engineering, Faculty of Engineering, Khon Kaen UniversitybApplied Engineering for Important Crops of the North East Research Group, Khon Kaenarticle infoArticle history:Received 20 August 2015Accepted 2 May 2016Available online 26 December 2016abstractThe operating factors werconsumption. The shelling0.30 m. The factors comprjournal homepage: http:/www.journalnatural-rebehalf of Kasetsart University. Thiscorn shelling unit onSaengprachatanaraka, bKaen 40002, Thailandersity, Khon Kaen 40002, Thailandfor an axial-ow corn shelling unit that affected losses and powerwas 0.90 m long, with a diameter toward the end of the peg tooth ofthree levels of moisture content (MC), three levels of feed rate (FR), andScienceDirectR/agriculture-and-rces/is an open access article under the CC BY-NC-ND license (http:/creativecommons.speed, feed rate and louver inclination affected threshing unitlosses and that the rotor speed affected grain damage.The appropriate axial ow sheller for shelling corn requires thestudy of important factors that affect losses and the power con-sumption, namely, the rotor speed, feed rate and grain moisturecontent Therefore, the aim of this research was to study the effectsofoperatingfactorsofanaxial-owcornshellinguniton lossesandthe power consumption.Materials and methodsCorn shelling unitThis study was conducted using an axial ow corn shelling unitprovided by the Agricultural Research Development Agency (PublicOrganization), Thailand as shown in Fig. 1. The shelling unit was0.90 m long, with a diameter toward the end of the peg tooth of0.30 m, with a controllable rotor speed. There was a powermeasuring device as shown in Fig. 2. The axial ow corn shellingunit consisted of a spike-toothed cylinder. The concave portionlocated under the cylinder was made of curved steel bar. The guidevane inclination was adjustable. The chute for grain under theshelling unit was divided into nine slots. The feed rate wasadjustable by controlling the conveyer belt speed of the materialsinto the shelling unit. The experiments were performed at thelaboratory scale.This study was performed with Pioneer B-80 corn variety.Factors studied and experimental designThe range of operating factors affecting losses and the powerconsumptionofanaxialow corn shelling unit were the mois-ture content (MC), feed rate (FR) and rotor speed (RS), as shownin Table 1. Following a factorial experimental design, a largenumber of factors and degrees were required to determine thequantity of materials and the experimental unit. Thus, a 23factorial experimental design was applied, as shown in Table 2,toreduce the use of materials and the time for testing (Berger andMaurer, 2002).Testing methodEach test used 10 kg of corn. The corn was fed into the inlet ofthe shelling unit on a conveyor belt. The samples taken from thehusks and cobs outlet was screened until only corn grain remainedand the grain was weighed and subtracted from the original 10 kgof corn and the result was considered as the shelling unit loss (TL).W. Srison et al. / Agriculture and Natural Resources 50 (2016) 421e425422Fig. 1. Corn shelling unit.Fig. 2. Power measuring device.To obtain the percentage of grain breakage (GB), two 1 kg sampleswererandomlytakenfromthechute,theGBwasseparatedbyhandandtheweightof the GB was recorded. In thisexperiment,atorquetransducer with a strain gauge (KFG-2-350-D2-11L1M3R; SokkiKenyujo Co. Ltd.; Tokyo, Japan) was used. The torque meter wasinstalled on the cylinder shaft to measure the torque and tocalculate the power consumption (P).Data analysisFrom the obtained parameters, the terms TL, GB and P wereused to construct multiple line models. Then, the models wereTable 1Independent variables and their factor levels.Variable Range and Levels (coded)e0 X1; Moisture content (% wet basis) 14 21 28X2; Feed rate (t/hr) 0.5 1.5 2.5X3; Rotor speed (m/s) 8 10 12Table 2Experimental units based on a 23factorial design for losses and po-wer consumption of an axial owcorn shelling unit for the variablesmoisture content (X1), feed rate (X2) and rotor speed (X3).Experiment number X1X2X31 eee2 ee3 e e4 e5 ee6 e 7 e 8 900010 0 0 011 0 0 012 0 0 0Results and discussionThe effects of MC, FR and RS on TL, GB and P are shown inTable 3.Operating parameters affecting the shelling unit lossesThe results of ANOVA of the operating parameters affectingshelling unit losses are shown in Table 4. The results indicated thatRS had a signicant impact on shelling unit losses, whereas MC, FR,MC*FR, MC*RS, FR*RS and MC*FR*RS did not have a signicantimpact on shelling unit losses.The regression equation that determined the effect of theoperating parameters on shelling unit loss is shown in Eq. (1):Table 3Effects of moisture content (MC), feed rate(FR) and rotor speed (RS) on shelling unitlosses, grain breakage and power consumption.ExperimentnumberMC (% wetbasis)FR(t/hr)RS(m/s)Shellingunitlosses (%)Grainbreakage(%)Powerconsumption(W)114(C0)a0.5 (C0)8(C0) 2.32 0.61 1529.7321C0) 0.5 (C0)8(C0) 2.93 0.37 1439.82314(C0) 0.5 (C0)8(C0) 3.24 0.18 1417.35428) 0.5 (C0)8(C0) 2.43 2.26 1979.2452() 0.5 (C0)8(C0) 2.89 2.22 2046.66628) 0.5 (C0)8(C0) 3.33 2.47 2024.19714(C0) 2.5 ()8(C0) 2.60 0.18 2271.4281C0) 2.5 ()8(C0) 2.88 0.19 2316.37914(C0) 2.5 ()8(C0) 3.06 0.25 2316.3710 28 () 2.5 ()8(C0) 2.90 2.20 3058.06W. Srison et al. / Agriculture and Natural Resources 50 (2016) 421e425 42311 28 () 2.5 ()8(C0) 2.89 2.13 2990.6312 28 () 2.5 ()8(C0) 2.65 2.68 3058.0613 14 (C0) 0.5 (C0)12() 1.60 0.94 2069.1414 14 (C0) 0.5 (C0)12() 1.57 0.71 2046.6615 14 (C0) 0.5 (C0)12() 1.52 1.30 2091.6116 28 () 0.5 (C0)12() 1.11 2.20 2361.3217 28 () 0.5 (C0)12() 1.90 2.36 2338.8418 28 () 0.5 (C0)12() 1.60 2.47 2428.7419 14 (C0) 2.5 ()12() 1.54 0.49 2653.5020 14 (C0) 2.5 ()12() 1.53 1.06 2541.1221 14 (C0) 2.5 ()12() 1.57 0.79 2631.0222 28 () 2.5 ()12() 1.58 2.22 3215.3923 28 () 2.5 ()12() 1.54 2.68 3215.3924 28 () 2.5 ()12() 1.47 2.20 3215.3925 21 (0) 1.5 (0) 10 (0) 2.36 1.06 2586.0726 21 (0) 1.5 (0) 10 (0) 2.22 1.26 2653.5027 21 (0) 1.5 (0) 10 (0) 2.03 1.52 2563.6028 21 (0) 1.5 (0) 10 (0) 2.56 1.61 2586.07aFigures in parentheses indicate code of range and levels; C0low,applied in the analysis of the effects of parameters on losses andthe power consumption based on response surface methodologyand 23factorial designs, determining the effects of each param-eter on the coefcient of determination (R2) using the DesignExpert software package (version 7; Stat-Ease Inc; Minneapolis,MN, USA.). ANOVA was used for regression analysis of thedesign factors affecting TL, GB and P. Signicance was tested atp F18.77 F51.62 F580.58 0.0001 Model is signicant944.00 0.00012422.03 0.0001535.67 0.000153.16 0.000135.62 0.000153.16 0.00013.32 0.0841al Resources 50 (2016) 421e425 425Agricultural Machinery, 1995. Test Code and Procedure for Power GrainThresher: RNAM. Test Code & Procedures for Farm Machinery. Bangkok,Thailand, second ed.Farjam, A., Omid, M., Akram, A., Faz

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

|

2:不支持迅雷下载,请使用浏览器下载

3:不支持QQ浏览器下载,请用其他浏览器

4:下载后的文档和图纸-无水印

5:文档经过压缩,下载后原文更清晰

|

川公网安备: 51019002004831号

川公网安备: 51019002004831号