变压器储油柜用10KG干燥净化器设计【含NX三维及23张CAD图】

收藏

资源目录

压缩包内文档预览:

编号:10265471

类型:共享资源

大小:12.52MB

格式:ZIP

上传时间:2018-07-05

上传人:QQ14****9609

认证信息

个人认证

郭**(实名认证)

陕西

IP属地:陕西

50

积分

- 关 键 词:

-

变压器

储油

10

kg

干燥

净化器

设计

nx

三维

23

cad

- 资源描述:

-

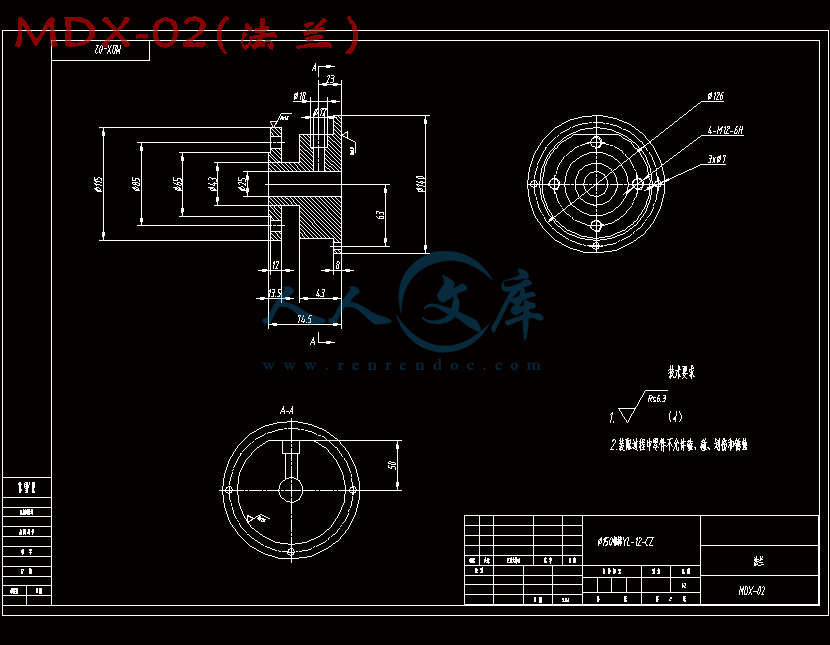

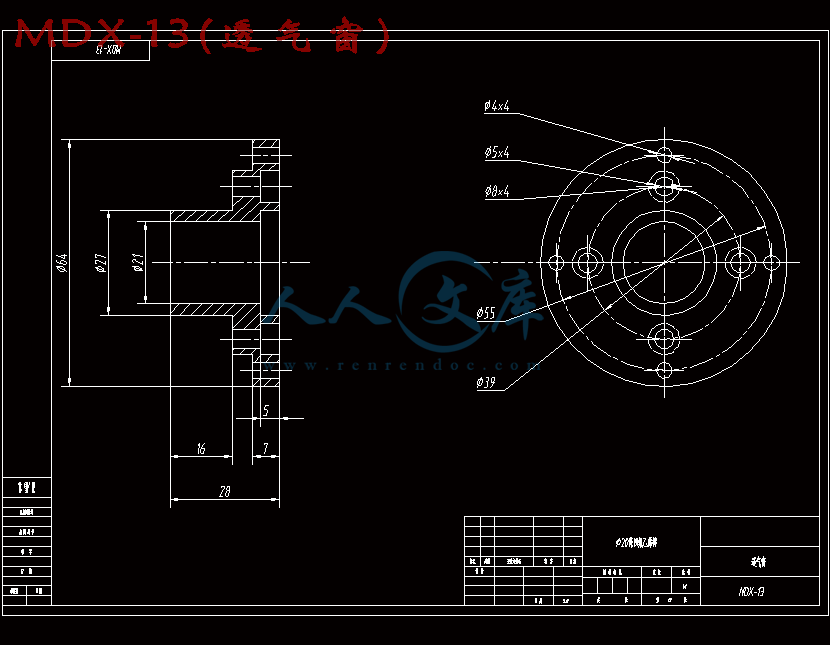

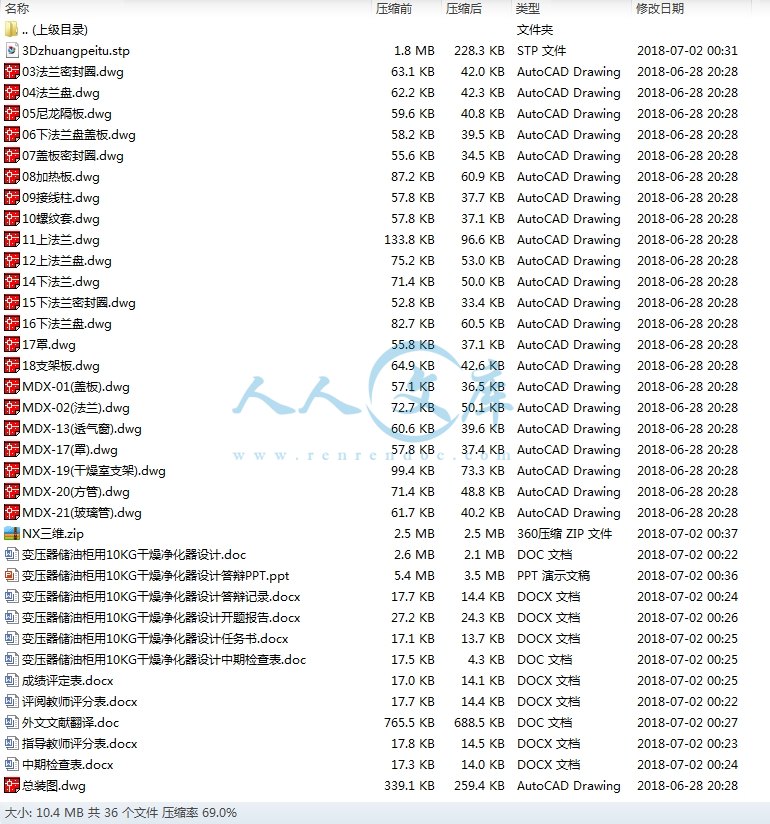

变压器储油柜用10KG干燥净化器设计【含NX三维及23张CAD图带开题报告+答辩ppt+外文翻译】

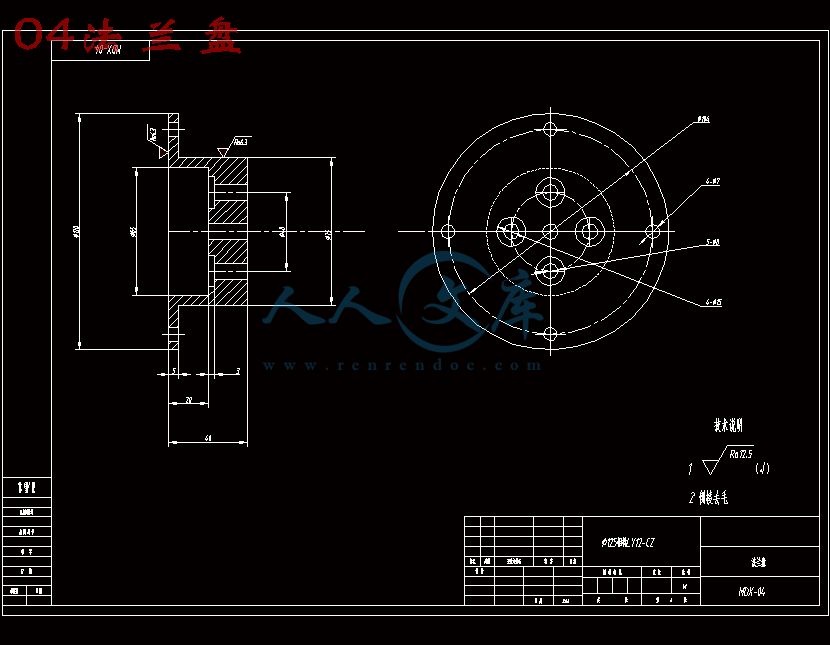

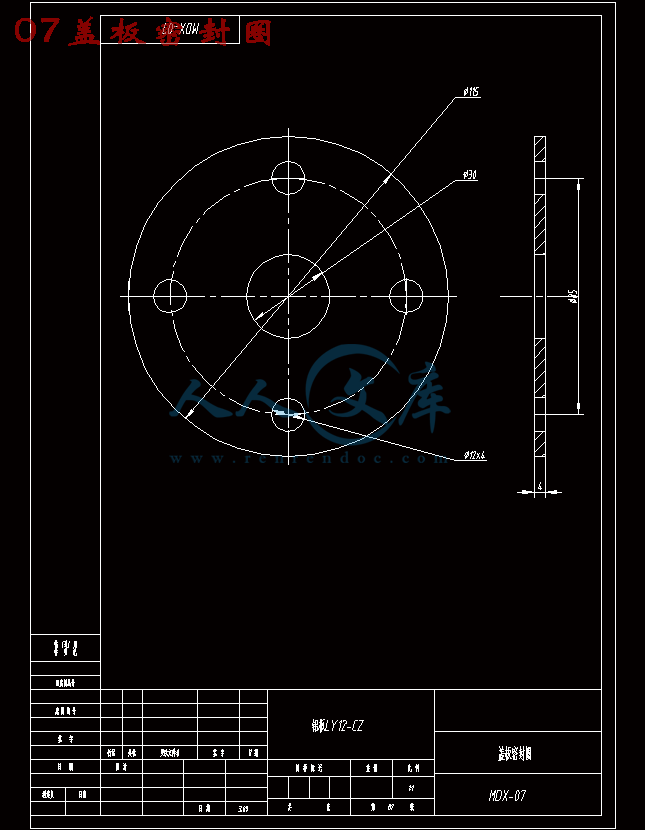

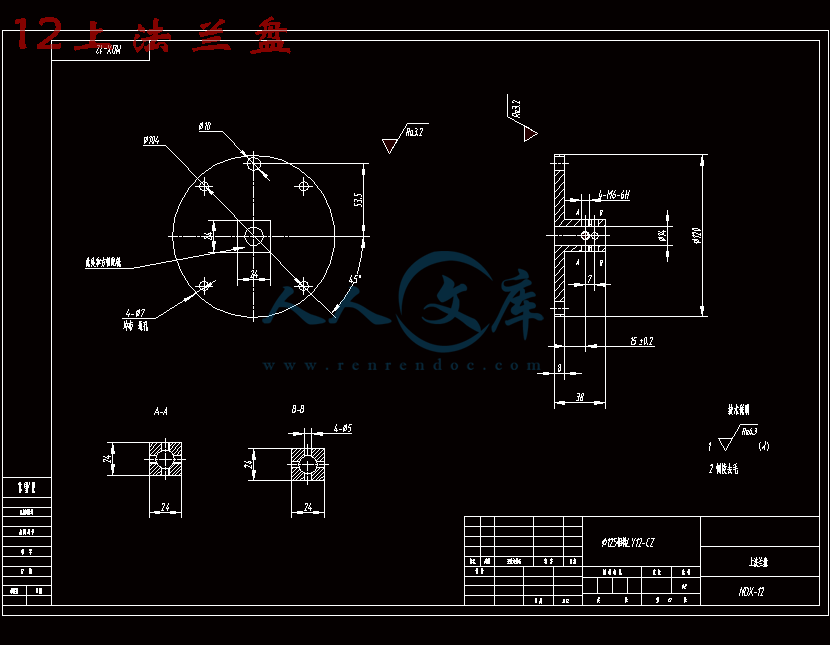

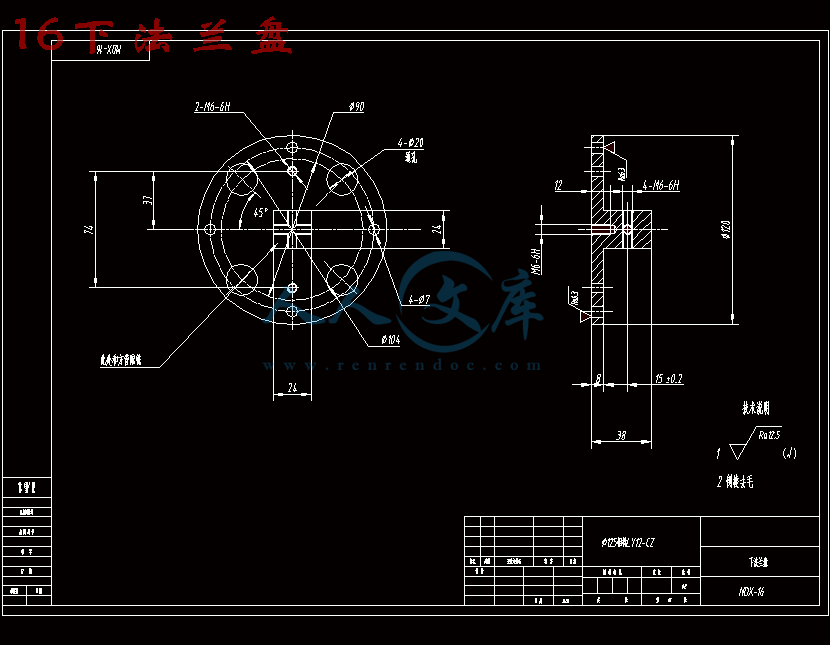

【需要咨询购买全套设计请加QQ1459919609】图纸预览详情如下:

- 内容简介:

-

附录 C 外文文献及翻译(变压器滤油机)Study of Transformer Oil Filtration MachineShreya Salvi1, A.P.Paranjape2,1M.E. student, Dept. of Electrical Power System, P.E.S. College of Engineering, Aurangabad, Maharashtra, India 2Professor, Dept. of Electrical Power System, P.E.S. College of Engineering, Aurangabad, Maharashtra, India-*-Abstract - Nearly all load bearing transformers in electric power systems around the world are filled with insulating oil i.e. transformer oil. Insulating oil plays a major role in the transformer, acting as insulating medium and as coolant. Transformers in electric power distribution and transmission systems are expected to function reliably and efficiently for uninterrupted power supply and to do this the quality of the transformer oil must be high. To maintain high quality of the transformer oil, purification of transformer oil by high vacuum transformer oil filtration machine should be conducted regularly. In this paper, we will study about the transformer oil filtration machine and how it purifies the contaminated transformer oil.Key Words: Degasification, Insulating oil, Moisture, Purification, Transformer.1. INTRODUCTIONTransformer is one of the most important and costly components of power system. Extreme reliability is demanded of electric power system, and even though the failure risk of a transformer is small, when failures occur, they lead to high repair costs, long downtime and possible safety risks. Moreover, transformers are too expensive to replace regularly and must be properly maintained to maximize their life expectancy. So for getting high performance and long functional life of the transformer, it is desired to perform various maintenance activities. Purification of transformer oil is one of these maintenance activities, since transformers life mainly depends on its insulating oil i.e. transformer oil. To purify transformer oil, high vacuum transformer oil filtration machine is used. It consists of inlet pump, filters, heaters, ionic reaction column, degassing and dehydration chamber, discharge pump, vacuum pumps etc. In this paper, we will study about the transformer oil filtration machine and how it works to purify the contaminated transformer oil.2. Insulating OilPrimarily, two kinds of basic insulation materials are widely used in the transformer, including the liquid insulation material such as insulating oil i.e. transformer oil and solid insulation material such as insulation paper. The widespread use of dielectric liquids for insulation and cooling is due to their greater electrical breakdown strength and thermal conductivity than gaseous insulators, while their ability to conform to complex geometries and self-heal means that they are often of more practical use than solid insulators. Transformer oil is highly refined mineral oil that is stable at high temperatures and has excellent electrical insulating properties. It is normally obtained by fractional distillation and subsequent treatment of crude petroleum. Hence why this oil is also known as mineral insulating oil. Transformer oil provides part of the electrical insulation between internal live parts in the transformer. It also helps cool the transformer i.e.it acts as a coolant.Causes of contamination of transformer oil are electrical disturbances and thermal decomposition. Various contaminants like moisture, sludge, dissolved gases etc. Present in the transformer oil reduces the breakdown strength of transformer oil, promotes local heating, increases the electrical conductivity and decreases the electrical and mechanical strength of the insulation system. The contaminants also decelerates the transformer efficiency. The failure of liquid insulation can cause catastrophic damage not only to the power equipment, but also to the surrounding environment. Furthermore, failure often leads to majoroperational disruption and financial loss. Purification of the transformer oil by high vacuum transformer oil filtration machine removes all these contaminants from transformer oil. The dielectric strength of fresh, thoroughly purified (filtered, degassed, dehumidified) insulating oil is several times higher than that of aged, contaminated insulating oil. Better the insulation of the transformer, longer the life of the transformer and lesser the breakdown of the transformer which eventually results in good returns on investment of the transformer asset and uninterrupted power supply.3. High Vacuum Transformer Oil FiltrationMachineTransformer oil when untreated will normally contain 50 to 60 ppm (parts per million) of water and also 10% to 12% of air by volume at saturation. In order to bring the oil in required standards, it has to be filtered to remove moisture, dissolved gases, ferrous and non-ferrous suspended particles so as to achieve the required properties of transformer oil.The high vacuum transformer oil filtration machine treats the transformer oil & switchgear oil by first heating it and then passing it through specially designed filter and then subjecting it to high vacuum treatment which dehydrates and degasifies the oil to the standard specifications after completion of the process.Fig -1: High Vacuum Transformer Oil Filtration MachineFig. 1 shows the high vacuum transformer oil filtration machine. Transformer oil filtration machines are available in various ratings starting from 100 LPH (liters per hour) to 16,000 LPH. The filtration machine is either stationary type or mobile type. The screw jacks are provided for relieving pressure on wheels at stationary conditions. It is weather proofed and suitable for outdoor use. The equipment is enclosed and protected against climatic conditions. All the components have adequate strength and rigidity to withstand the normal conditions of handling transport and usage. The plant is suitable for operation on 415 volts, three phase, 4 wire, 50 Hz, A.C. Supply.The high vacuum transformer oil filtration machine consists of:3.1 Inlet PumpInlet pump pumps the contaminated oil from transformer to oil filtration machine. It is thoroughly tested for vacuum and is suitable for continuous trouble free operation. It is provided with an automatic protection against over-pressure build-up. Interlocking arrangement is provided in between the oil inlet pump and the heater so that heater cannot be energized unless inlet pump is on. Interlocking arrangement is provided in the oil filtration machine between the inlet pump and high level float switch (located into degassing and dehydration chamber) to avoid excessive rise of oil in the degassing and dehydration chamber.3.2 HeatersThe first step in this serial process is to raise the oil temperature to a desired level, generally upto 65 Degree Celsius. This aids to give the oil latent heat which later aids to dissociate the moisture and gases from oil in the degassing and dehydration chamber. Additionally the viscosity of the oil drops which aids in better filtration to some extent. Heaters are provided in protection tubes to avoid localized overheating, hot spot & breaking oil. Heaters are thermostatically controlled. Heater elements consists of nichrome / kanthal wire filament, inserted in refractory formers which are located in protection tubes. Heater tank is adequately thermally insulated to minimize loss of heat. One suitable pressure relief valve is provided on the heater chamber to prevent any pressure rise above the acceptable limit.3.3 Filtration System3.3.1 Preliminary FilterThe main function of this filter is to prevent any damage to the inlet pump. It have strainers capable of retaining all particles above 1 mm size and also magnetic particles. Incoming oil is passed through this filter. It is possible to clean the strainer without dismantling the filter from the pipeline.3.3.2 Filter PressFilter press shall consist of filters held between metallic discs. It is suitable for removal of particles bigger than 50 microns. This is useful for removal of sludge content in the used oil.3.3.3 Cartridge FilterNon-hygroscopic throw away type cartridge filters of one micron rating is provided. This cartridge elements have large dust holding capacity. The replacement of cartridge elements is very easy and can be done without any special tools. Compound (pressure / vacuum) gauge is provided on filter vessel for inlet pressure indication in order to ascertain condition of cartridge elements. Aeration is provided on the filter vessel to aerate the vessel during draining. The cartridge type filter facilitates to achieve desired value of particle size in micron.3.4 Ionic Reaction ColumnAn ionic reaction column is provided in high vacuum transformer oil filtration machine to reduce the acidity in the oil. It is an optional component in high vacuum transformer oil filtration machine which is provided if the customer demands it.3.5 Degassing and Dehydration ChamberThe third step in the oil filtration machine is dehydration and degasification of the transformer oil. In degassing and dehydration chamber, dissolved gases and moisture from the transformer oil is removed. It has mild steel welded construction. The chamber is able to withstand the vacuum to which it is subjected. Efficiently spread Raschig rings are placed in the degassing and dehydration chamber. Raschig rings are pieces of tubes which are approximately equal in length and diameter. Usually, Copper or Aluminum Raschig rings are used in high vacuum transformer oil filtration machine. The surface area offered by the Raschig rings is sufficient to form a thin film of oil and facilitates removal of dissolved gases and moisture at the rated flow rate of oil. A sight glass with illuminating lamp is provided for observation of oil flow in the degassing and dehydration chamber. One float switch on the degassing and dehydration chamber is provided for preventing excess rise of oil level and is electrically interlocked with the inlet pump. Another float switch to control the low level of the oil in degassing and dehydration chamber is provided and it is electrically interlocked with the discharge pump. Two or three stages are separated by a siphon seal. One airing valve is provided for airing the degassing and dehydration chamber.Fig -2: Circuit Diagram of High Vacuum Transformer Oil Filtration Machine3.6 Vacuum Pumping SystemVacuum pumps are provided for evacuation of degassing and dehydration chamber. These pumps are of imported make.3.7 Discharge PumpA discharge pump is provided in high vacuum transformer oil filtration machine for sucking oil from the degassing and dehydration chamber held under vacuum. They are fully tested for pressure and vacuum leak rate. Interlocking arrangement are provided between low level float switch (located in degassing and dehydration chamber) and discharge pump to prevent dry running of discharge pump.3.8 Oil HosesTwo nitrile rubber hoses with flanged end connection on both sides are provided, one for oil inlet & one for oil outlet. They are capable of handling the transformer oil at 100 Degrees Celsius (maximum) and vacuum.Fig -3: Transformer Oil Before and After FiltrationAfter three to five passes in the high vacuum transformer oil filtration machine, the transformer oil gets purified. Fig. 3 shows the transformer oil before and after filtration from high vacuum transformer oil filtration machine. The brown colored oil is unfiltered oil whereas pale yellow colored oil is filtered (or purified) oil. Fig. 2 shows the circuit diagram of high vacuum transformer oil filtration machine. The dielectric properties of oil may vary depending upon the content of gas, moisture, suspended particles and contaminants. Even new oil absorbs gas and moisture while in storage. Therefore sometimes oil is to be treated before use. Degassing and dehumidification of oil is also necessary periodically, during use, because dielectric properties will be affected due to the absorption of gas and moisture in service at different weather conditions.4. CONCLUSIONSThis paper is related to the study of high vacuum transformer oil filtration machine and how its various components remove the contaminants like moisture, dissolved gases, sludge contents etc. from the transformer oil. Regular purification of transformer oil maintains its high quality, thus assures long and consistent results from the transfor变压器滤油机的研究Paranjape,施利亚.萨尔维(印度马哈拉施特拉邦奥兰加巴德工程学院电力系)摘要:在世界各地的电力系统中,几乎所有的负载变压器都有绝缘油,即变压器油。绝缘油在变压器中起着重要的作用,起到绝缘介质和冷却剂的作用。变压器在电力分配和传输系统中,预期能够可靠有效地为不间断电源供电,并做到这一点,变压器油的质量必须很高。为了保持变压器油的高质量,应定期进行高真空变压器油过滤机的变压器油净化。本文对变压器滤油机进行了研究,并对其进行了净化处理。关 键 词:脱气作用,绝缘油,水分,净化,变压器,2017 年1 介绍变压器是电力系统中最重要、最昂贵的部件之一。电力系统的可靠性要求极高,即使变压器的故障风险很小。当故障发生时,它们会导致高维修成本、长时间停机和可能的安全风险。此外,变压器太昂贵,不能定期更换,必须妥善保养,以最大限度地延长寿命,因此:为了获得高性能和长寿命的变压器,需要进行各种维护活动。变压器油的净化是其中一项维护工作,因为变压器的寿命主要取决于其绝缘油即变压器油,为了净化变压器油,使用了高真空变压器油过滤机。它由进口泵、过滤器、加热器、离子反应柱、脱气和脱水室、排气泵、真空泵等组成。本文对变压器滤油机进行了研究,并对其工作原理进行了研究。2 绝缘油绝缘油主要有两种基本绝缘材料在变压器中广泛使用,包括绝缘油等液体绝缘材料,变压器油和绝缘纸等固体绝缘材料。绝缘和冷却介质的广泛使用是由于它们比气体绝缘体更强的电击穿强度和导热性。符合复杂几何和自愈的能力意味着它们通常比固体绝缘体更实用。变压器油是一种高度精炼的矿物油,在高温下稳定,具有良好的电气绝缘性能,它通常是通过分馏和原油的后续处理获得的。因此,这种油也被称为矿物绝缘油。变压器油提供变压器内部带电部件之间的电气绝缘部分。它也有助于冷却变压器,冷却剂的作用。变压器油污染的原因是电干扰和热分解,各种污染物如湿气、污泥、溶解气体等,在变压器油中存在降低变压器油的击穿强度,促进局部加热,提高电导率,降低绝缘系统的电气和机械强度。此外,污染物也会减慢变压器的效率。液体绝缘的失效不仅会对电力设备造成灾难性的破坏,还会对周围环境造成灾难性的破坏,而且失败常常导致重大的业务中断和财务损失。采用高真空变压器滤油机净化变压器油,从变压器油中去除所有污染物。新鲜、纯化(过滤、除气、除湿)绝缘油的电介质强度要比老化的、受污染的绝缘油高好几倍,因此:改善变压器的绝缘,延长变压器的寿命,减少变压器的故障,最终使变压器的资产和不间断电源的投资得到良好的回报。3 高真空变压器滤油机变压器油在未经处理的情况下,变压器油通常含有 50 至 60 ppm(百万分之一)的水,以及 10%到 12%的空气饱和量。为了使油达到要求的标准,必须过滤掉水分、溶解气体、亚铁和非铁的悬浮颗粒,以达到变压器油的要求。高真空变压器油过滤机先对变压器油和开关柜油进行加热,然后经过特殊设计的过滤器,然后将其置于高真空处理,在完成工艺后,将油脱水和脱气,达到标准规格。如图 3.1 高真空变压器滤油机图 3.1 高真空变压器滤油机图 3.1 是高真空变压器滤油机。变压器滤油机从每小时 100 公升(升)到16000 公升,可提供各种等级。滤油机可分为固定式或移动式。螺旋千斤顶是用来在固定条件下减轻车轮压力的。它是防风雨的,适合户外使用。设备被封闭起来,以防气候变化,所有部件都有足够的强度和刚度来承受运输和使用的正常情况,并且该装置适用于 415 伏特、三相、4 线、50hz、A.C.供货。高真空变压器滤油机包括以下几个部分:3.1 进口泵进口泵将受污染的油从变压器泵入滤油机,它经过彻底的真空测试,适用于连续无故障运行。它具有自动保护,防止压力过大。在油泵和加热器之间设有联锁装置,除非进气泵开启,否则加热器无法通电。在进口泵和高水平浮子开关( 位于脱气和脱

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号