摘 要

本文首先对起重夹钳技术的发展及应用情况、国内外的发展状况及发展趋势,通过对50kg起重机的设计方案的确定,包括针对本设计选取起重机的型号,确定为臂架式起重机,然后对起重机结构的各个部件进行设计,包括夹持机构、吊臂、钳臂、轴、自动开关装置和设备稳定性分析等等的设计。采用了机械设计的一般设计方法,机械设计辅助软件AutoCAD和Pro/e,设计制作出起重夹钳设备,吊起重量达50Kg,起升速度达0.1m/s,运行速度达0.5m/s,搬运物体快速便捷,无卡壳,设备运行良好。

通过了解学习掌握夹钳装置的工作原理,对起重夹钳装置的结构进行分类与分析,通过分析从而确定起重机设计方案夹钳装置的设计,传动装置方案的设计以及分析设备的稳定性。

关键字:起重机;起重夹钳;机构设计;自动开关装置;稳定性

ABSTRACT

This paper firstly lifting clamp technology development and application, domestic and foreign development and development trend of 50kg crane, through the design scheme based on the determination of design, including selecting the model, determine crane for arm, then to pose crane components of the crane structure design, including holding mechanism, the arm, clamp arm, axle, automatic switch devices and equipment stability analysis and so on design. Adopted the general design method of mechanical design, mechanical design support software AutoCAD and Pro/e, design a lifting clamp device, lift the weight of hoisting speed, 50Kg of 0.1 m/s, operation speed reaches 0.5 m/s, handling objects without jam, fast and convenient, equipment operation is good.

By understanding learn clamp device's working principle, the structure of the crane clamp device classified and analysis, through the analysis to determine crane design scheme clamp device design, transmission device scheme design and analysis equipment stability.

Keywords: Lifting appliance; Clamping devices; Design of structure; Automatic

control device; Stability

目 录

摘 要 I

ABSTRACT II

1 起重机简介 1

1.1现代起重机的特征和发展趋向 1

1.2国产起重机与国外产品的差距 5

2起重夹钳简介 7

2.1 国内外起重夹钳发展状况 7

2.2 常用夹钳装置的发展与应用 7

2.3.1 螺杆夹紧式 8

2.3.2 夹钳自重夹紧式 9

2.3.3 夹钳装置自重夹紧式 12

2.3.4 钢绳张力附加夹紧式 13

3 设计目的及主要内容 15

3.1 设计的基本内容 15

3.2 设计目的 15

4 50kg 起重机的设计方案的确定 15

4.1 50kg起重机的设计思想 15

4.2 50kg起重机种类的选择与确定 15

4.3 臂架式起重机的工作原理 16

4.4 50kg起重机电机的选择 17

4.5 50kg起重机的传动装置方案的设计 17

4.5.1功率与效率 17

4.5.2速度 18

4.5.3外廓尺寸、质量和成本 18

4.6 50kg起重机结构的设计方案 19

4.6.1起重机构件的材料选择 19

4.6.2 起重机构件的设计方案 20

5 50 kg起重夹钳主机的总体设计 21

5.1 起重夹钳设计思想 21

5.2 50kg起重夹钳工作原理 22

5.3 起重夹钳的夹持机构 22

5.4 吊臂的设计 22

5.4.1吊臂的材料的选择 23

5.4.2吊臂的尺寸计算 23

5.5 钳臂的设计 23

5.5.1钳臂的材料的选择 23

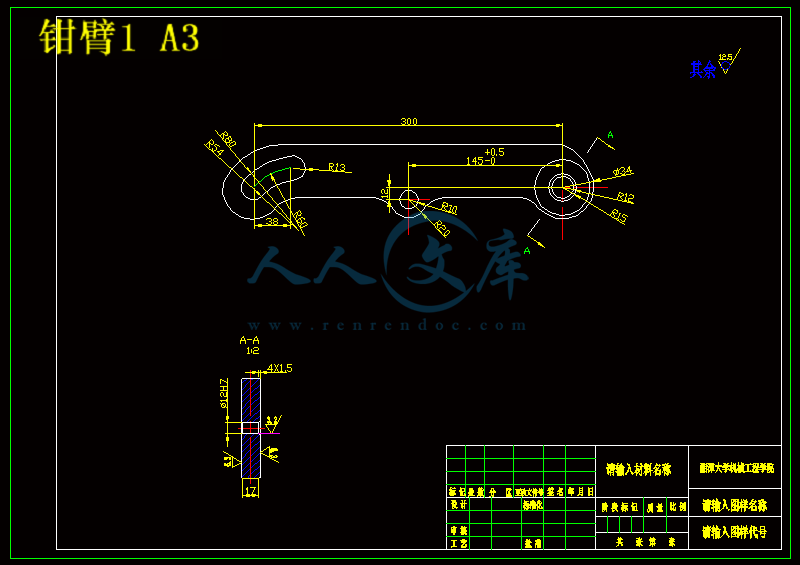

5.5.2钳臂1的设计 23

5.5.3钳臂2的设计 24

5.6 轴的设计 27

5.6.1轴的材料选择 27

5.6.2主轴的设计 28

5.6.3轴1的设计 29

5.6.4轴2的设计 30

5.6.5吊轴的设计 30

6 起重夹钳主要部件的工艺 31

6.1 吊臂的工艺 31

6.2 钳臂的工艺 31

6.3 轴的工艺 31

7 自动开关装置的设计 32

7.1自动开关装置的材料选择 32

7.2自动开关装置的结构设计 32

8 设备的稳定性分析 34

8.1温度对系统稳定性的影响 34

8.2机械加工及整体装配对系统稳定性的影响 34

9 润滑剂的选择 35

10 结论及前景 36

10.1 结论 24

10.2 前景 25

参考文献 37

致 谢 38

1. 起重机械简介

起重机械是现代工业企业中实现生产过程机械化、自动化、减轻繁重体力劳动、提高劳动生产率的重要工具和设备。如在港口码头和铁路车站,没有起重机械,装卸工作就不能进行;在冶金生产中.起重机械已用于金属生产的全部过程;现代建筑工程,不能离开起重机械;在农业和林场,最困难、最费力的工作也由起重机械来完成;在核发电站中,采用特殊的起重机,用以代替人的操作去担当对人体健康有严重危害的作业。随着科学技术和生产的发展.起重机械在不断地完善和发展之中。

1.1现代起重机的特征和发展趋向

川公网安备: 51019002004831号

川公网安备: 51019002004831号