目录

第1章 前言··········································································1

1.1 国内外起重机发展情况·······················································1

1.2 桥式起重机定义及特点·······················································4

1.3 实习地点及实习内容··························································4

第2章 总体设计···································································4

2.1 概述·············································································5

2.2 传动方案的确定·······························································6

2.3 基本参数······································································10

第3章 起升机构的设计计算···················································12

3.1 选择钢丝绳···································································12

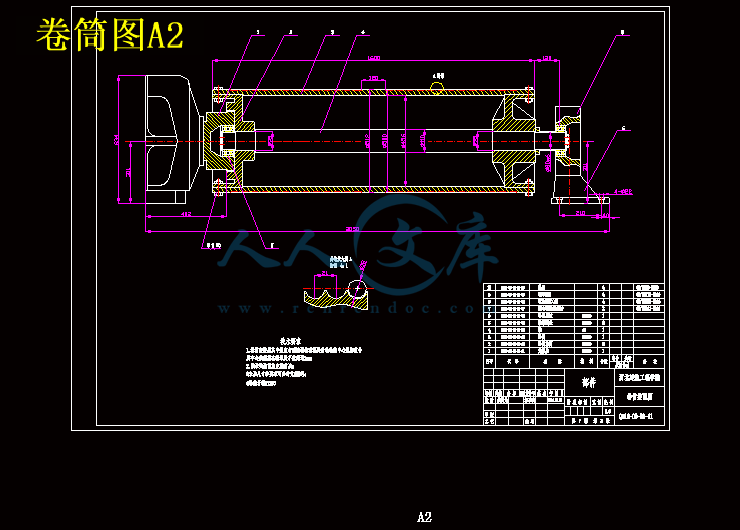

3.2 滑轮和卷筒的计算···························································13

3.3 计算静功率···································································15

3.4 选择电动机···································································15

3.5 验算电动机的发热条件······················································15

3.6 减速机的初选································································16

3.7 校核减速机···································································16

3.8 制动器的选择································································17

3.9 联动器的选择································································17

3.10 验算起动时间·······························································18

3.11 浮动轴强度验算····························································19

第4章 运行机构的设计计算···················································21

4.1 确定机构传动方案···························································21

4.2 选择车轮与轨道并验算其强度··············································21

4.3 运行阻力计算································································23

4.4 选择电动机···································································24

4.5 验算电动机发热条件························································25

4.6 选择减速器···································································25

4.7 验算运行机构和实际所需功率··············································25

4.8 验算起动时间································································26

4.9 验算起动不打滑条件························································27

4.10 制动器的选择·······························································27

4.11 选择联轴器··································································28

4.12 验算低速浮动轴强度·······················································29

第5章 零部件的设计计算·····················································31

5.1 滑轮的尺寸计算与选择······················································31

5.2吊钩组的选择·································································32

5.3 车轮轴的设计计算···························································35第6章 零部件的设计计算·····················································38

6.1 梁Ⅰ···········································································38

6.2 梁Ⅱ···········································································40

6.3 梁Ⅲ···········································································42

6.4 梁Ⅵ···········································································44

6.5 梁Ⅴ···········································································48

第7章 毕业设计小节····························································53

参考文献············································································54

附:英文原文

英文译文

毕业实习报告

第1章 前言

1.1国内外起重机发展概况

起重运输机械行业在我国从上世纪五六十年代开始建立并逐步发展壮大,该行业已形成了各种门类的产品范围和庞大的企业群体,服务于国民经济各行业。随着我国经济的快速发展,起重运输机械制造业也取得了长足进步。2005年起重运输机械行业销售额达到1272亿元,“十五”期间平均每年增长超过30%,2006年依然保持着持续增长的态势,目前市场前景非常好。近年来,国家重点发展能源(其中煤炭工业迅猛发展,起重运输机械制造业将提供所需的竖井提升设备、斜井防爆下运带式输送机、防爆移置式带式输送机、装车机、露天矿连续开采输送设备、用于洗选设备的各种输送设备等)、电力(各种电站专用桥式/门式起重机、料场用物料搬运装卸设备、输煤给煤栈桥内物料输送设备、环保排灰输送设备、水电站用闸门启闭机械、升船机、核电站废料处理专用起重机等将有较大需求)、石化(起重运输机械制造业将提供所需的自动灌装和包装码垛设备、仓储专用设备、厂内和车间内物料搬运装卸设备等)、冶金(对各种冶金起重机、厂内和车间内物料搬运装卸设备、料场堆取料与混匀料设备等将有较大需求)、造船、交通等工业领域(需要大量的高效、节能、低污染、智能化、柔性化、成套化的物料搬运装卸设备)。

川公网安备: 51019002004831号

川公网安备: 51019002004831号