摘 要

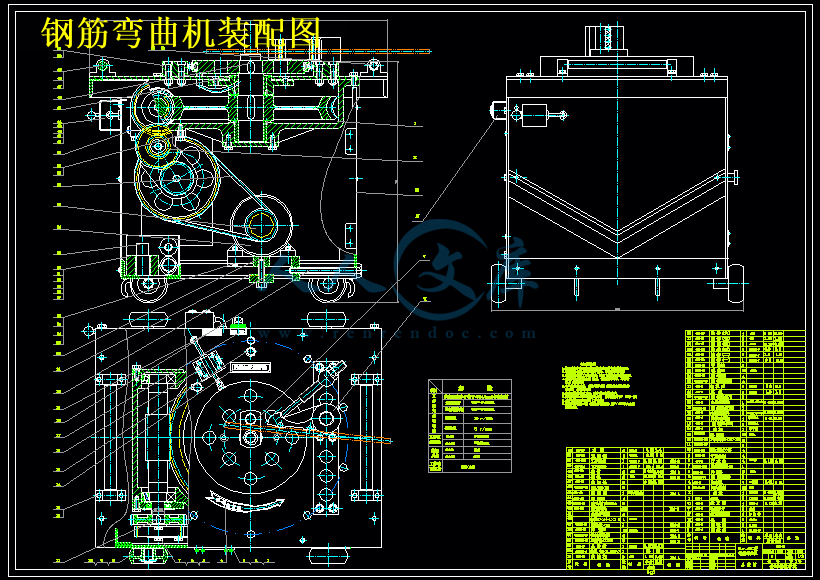

钢筋弯曲机是建筑工业常用的工程机械之一,主要用于各种型号的钢筋的弯曲,以用于工程在施工工地上。如何更有效提高机械生产效率,减少工人劳动强度,提高钢筋加工角度精度以及有更好的安全措施是钢筋制作中被普遍关注的问题。本文设计的GW40钢筋弯曲机适用于建筑行业弯曲钢筋之用。本机工作程序简单,弯曲形状一致,调整简单,操作方便,性能稳定.它能将Q23540圆钢或8—36螺纹钢筋弯曲成工程中所需的各种形状。

本次设计先由两种典型的传动方案入手,分别对其传动精度和传动效率进行分析,从而选择传动方案。然后简单说明其主要的工作装置的设计。通过对钢筋弯曲所需扭矩的计算选择电动机,再初步确定其传动装置的运动和动力参数。最后分别对V带、圆柱齿轮、蜗轮蜗杆、轴等进行相关的设计和计算。

通过此次对钢筋弯曲机的结构设计与运动分析,使我的理论和实际联系的更加紧密,丰富了实践经验,从中发现并弥补了好多自身不足之处,获益匪浅。

关键词: 钢筋弯曲机;弯矩;主轴扭矩。

Abstract

Steel bending machine is commonly used in the construction industry,one of construction machinery,mainly for various types of bending steel bars for construction site.How to more effectively improve mechanical production efficiency more effectively, reduce labor intensity, improve the processing precision Angle steel and have a better security is a universal concern in che progress of steel making.The designed GW40 reinforced bending machineIn this pape is applicable to bend steel in the construction industry.Working procedure of the machine is simple, curved shape of the same ajustment is simple, easy to operate, stable performance.It will round or Q23540 thread 8-32 bending steel into works of various of forms required for.

In this design firstly the two typical transmission scheme of its transmission precision and respectively on transmission efficiency is analyzed, and choose transmission scheme. And then that the simple the main job of the design of the device. Through the calculation of bending torque required reinforced the choice of motor, and preliminary determine its transmission device sports and dynamic parameters. Finally, the V belt, cylindrical gears, worm and shafts of related is designed and calculated.

Through the reinforced bending machine to the structural design and movement analysis, It makes my theory and actual connection more closely, richs my practical experience, findsand makes up a lot of my own shortcomings, benefit.

Keyword: Steel bending machine;Bending moment;Spindle torque.

目录

1 绪论 1

2 钢筋弯曲机的方案与选择 3

2.1 引言 3

2.2 典型的钢筋弯曲机传动方案 3

2.3 钢筋弯曲机的传动精度 4

2.4 钢筋弯曲机的传动效率 5

3 弯矩的计算与电动机的选择 7

3.1 工作装置的设计 7

3.2 弯矩的计算 11

3.3 电动机的选择 12

3.4 计算传动装置的运动和动力参数 12

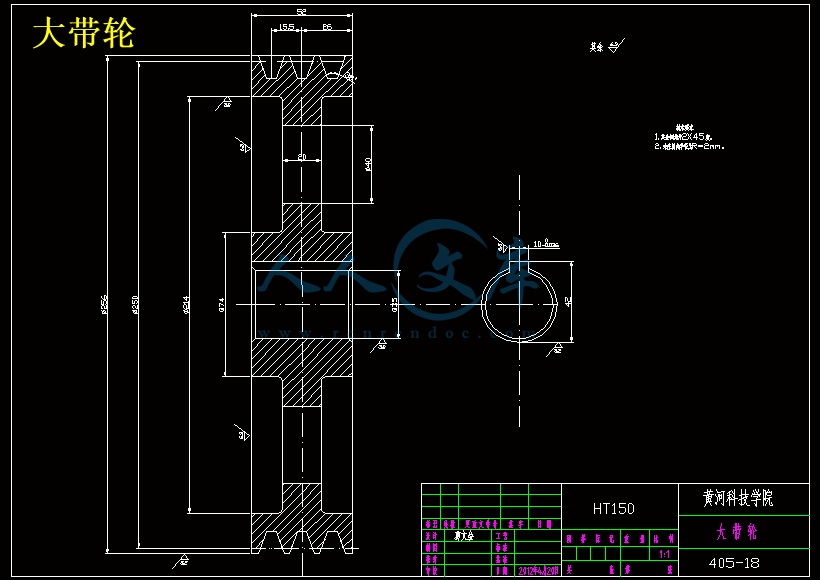

4 V带传动设计 15

5 圆柱齿轮的设计 17

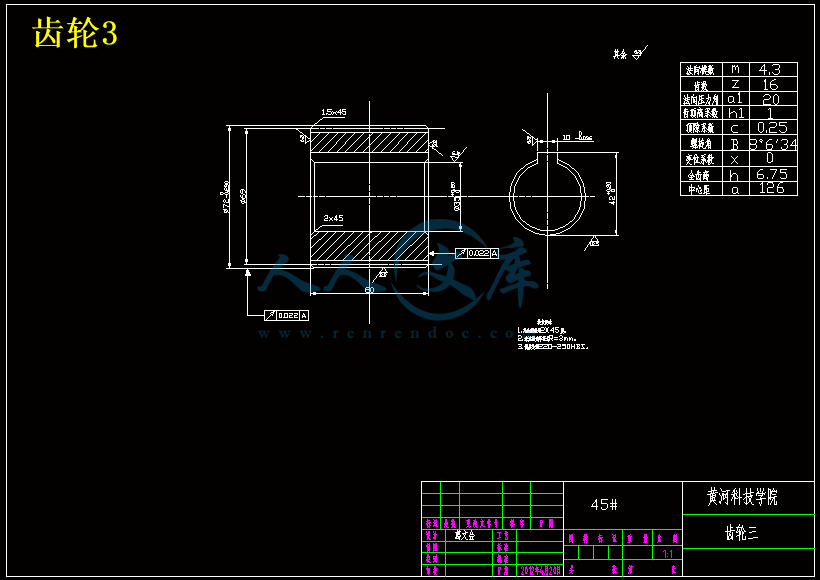

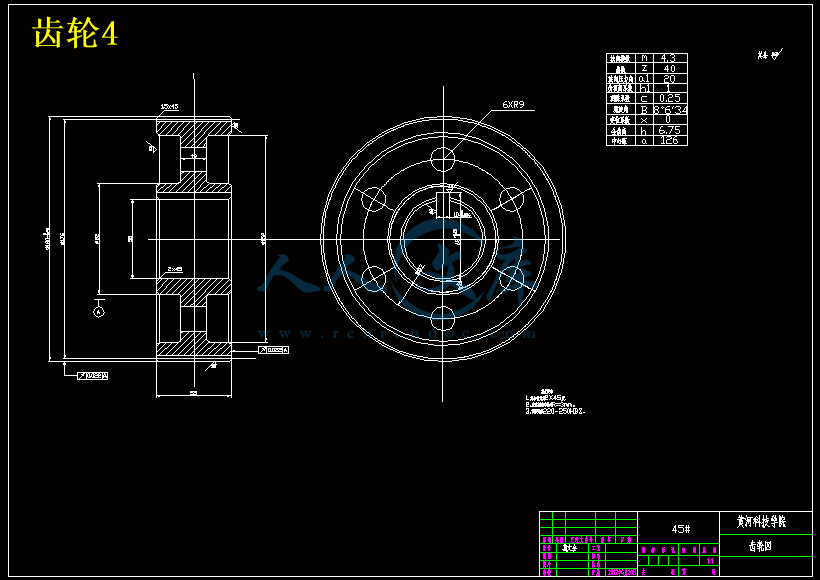

5.1高速级齿轮传动的设计计算 17

5.2低速级齿轮传动的设计计算 19

6 蜗轮蜗杆的设计 22

7 轴的设计 24

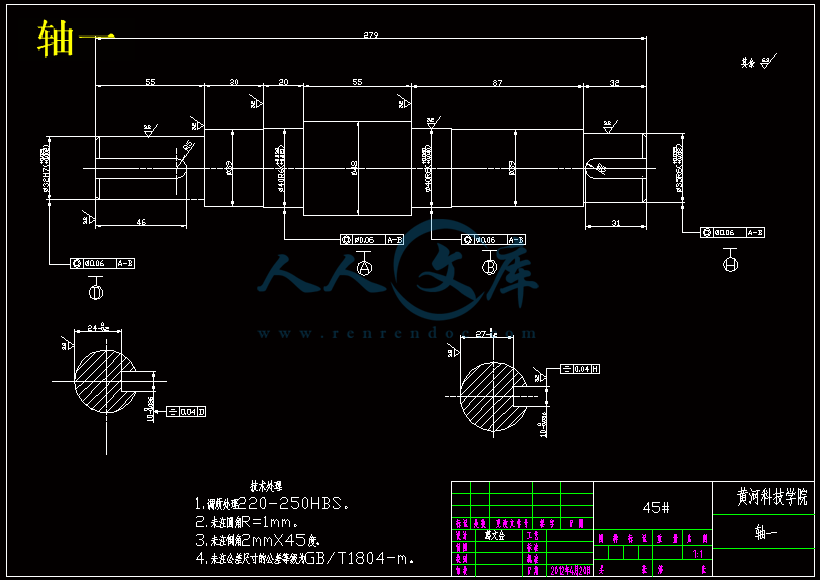

7.1 Ⅰ轴的设计 24

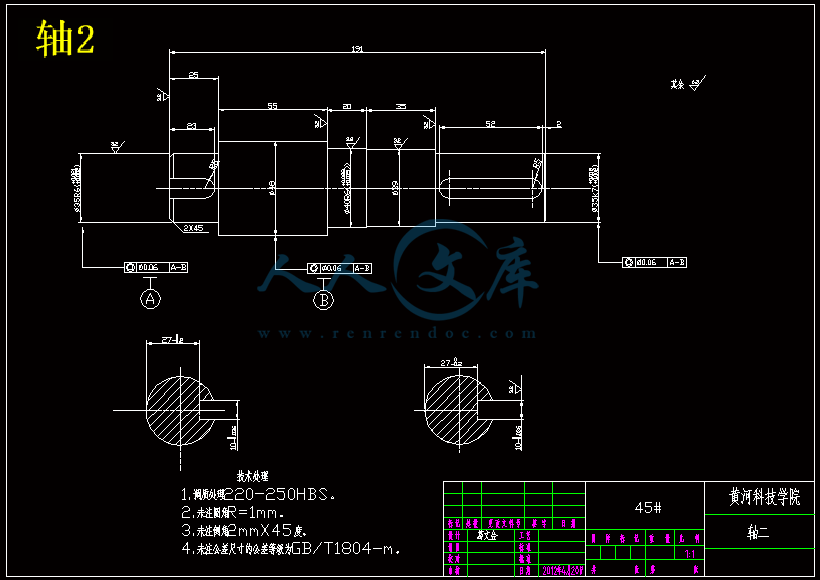

7.2 Ⅱ轴设计 27

7.3主轴的设计 27

结论 29

参考文献 30

1 绪论

钢筋弯曲机是钢筋加工必不可少的设备之一,它主要用于各类建筑工程中对钢筋的弯曲.钢筋弯曲机通常与切断机配套使用,其应用十分广泛.随着国家投资拉动的效果显现,尤其是国家大力开展高铁的建设,钢筋弯曲机的生产销售增长迅速.与其他的钢筋切断机、弯箍机、调直切断机的的情况类似,河南省长葛市已经形成了该类机械的生产基地.国产产品大多能满足使用需求,但也有一些产品的质量不能满足国家标准的要求.河南长葛本地的钢筋弯曲机生产现状与质量水平反映了国产钢筋弯曲机的现状.

我国工程建筑机械行业近几年之所以得到快速发展,一方面通过引进国外先进技术提升自身产品档次和国内劳动力成本低廉是一个原因,另一方面国家连续多年实施积极的财政政策更是促使行业增长的根本动因。

各厂家的钢筋弯曲机的构造基本相同.钢筋弯曲机的传动方案有以下2种:“带一两级齿轮一蜗轮蜗杆传动”和“带一三级齿轮传动”[2].采用蜗轮蜗杆传动的钢筋弯曲机,其传动效率不如齿轮传动的弯曲机.也就是说,在同样的驱动电机功率条件下,齿轮传动的弯曲机弯曲同直径的钢筋显得更轻松.但蜗轮蜗杆传动的自锁特性,使工作中弯曲的定位精度会更高些.目前,以“带一两级齿轮一蜗轮蜗杆传动”方案的弯曲机的生产、应用较为普遍,市场占有率高.

川公网安备: 51019002004831号

川公网安备: 51019002004831号