目录

第1章 绪论··········································································1

1.1 钻机发展的一般情况··························································1

1.2 钻机特点及设计要求··························································1

1.3 钻机的“三化”原则···························································3

第2章 总体设计···································································5

2.1 概述············································································5

2.2 总体参数·······································································5

2.3 工作原理及主要部····························································6

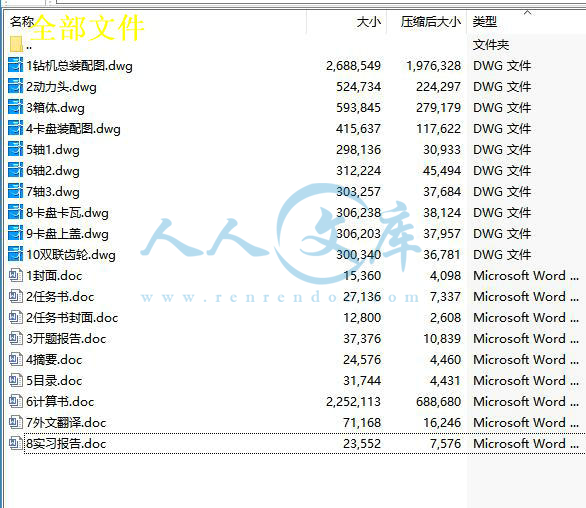

第3章 卡盘设计···································································9

3.1 卡盘结构简介·································································9

3.2 基本参数的确定·····························································10

第4章 动力头的设计计算······················································12

4.1 概述···········································································12

4.2 变速箱的总体设计···························································13

4.3 变速箱传动齿轮的设计计算················································15

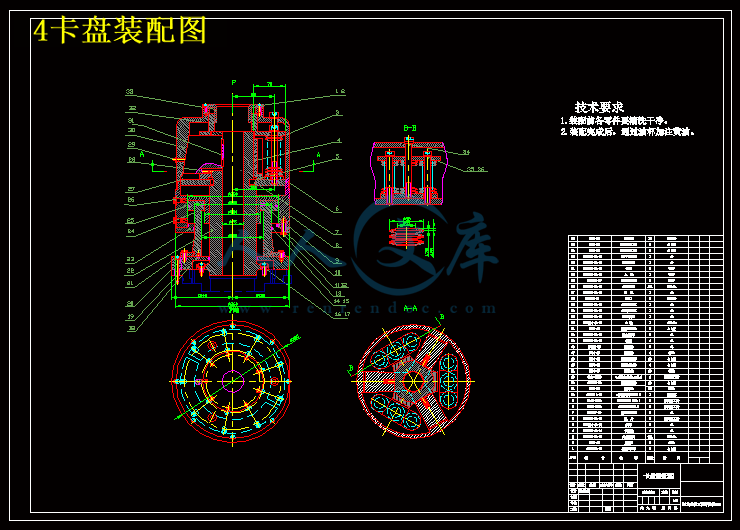

4.4 变速箱传动轴的设计计算···················································26

4.5 动力头的泵及电机的选择···················································44

第5章 给进机构的设计计算··················································46

5.1 液压给进机构的分析、选择·················································46

5.2 给进液压缸的设计计算的选择·············································48

第6 钻塔的设计及校核·························································55

6.1 钻塔及升降工具·····························································55

6.2 塔身的强度、稳定性及刚度验算············································62

第7章 毕业设计小节····························································65

参考文献············································································66

第1章 绪论

岩心钻机主要用于固体矿床的勘探,也用于工程勘探,水文地质勘探和其它用途的岩心钻探。岩心钻探的孔深变化较大,一般从几米到几千米之间,钻孔口径较小,一般钻孔口径在几毫米到一百多毫米。钻进底层以基岩为主,钻孔过程中要求取出能够满足分析和化验要求的一定数量和质量的岩心。

1.1钻机发展的一般情况

早期的钻机是由人力驱动的简单冲击式机械,经常长期不断演变、发展,成为现代具有机动动力驱动的各种冲击式钻机。冲击式钻机作为唯一的钻探机械,在世界上一直沿用了相当长的历史时期。这种钻机钻孔有如下缺点:效率低,无法取出岩心;只能钻垂直孔;钻孔过程中不能及时排出岩屑等。随着社会的不断发展,这种钻机已逐渐不能适应要求。19世纪中期以后,出现了回转式钻机。回转式钻机具有钻进效率高;可取出完整的岩心;能钻进各种倾角的钻孔;有利于多种钻探工艺和方法的使用等优点,因此发展很快,并迅速在钻探领域中占据了主导地位。

现在,我国不仅可以成套生产各种钻探机械,而且有许多产品已形成具有我国特点的系列。产品的品种逐渐齐全、质量不断提高、性能更加完善。某些产品已进入国际市场。

1.2钻机的特点及设计要求

钻机与其它机械有某些共同之处,但钻机具有独特的生产对象和使用条件,岩心钻机是主要用于固体矿床的普查与勘探,也用于工程勘察、水文地质勘探和其他用途的岩心钻探。岩心钻探的孔深度变化较大,钻孔口径较小,钻进地层以基岩为主。由于各种矿体在地下的产状不同,为求得倾斜矿体的真实厚度,便于精确计算储量,常常需要钻进不同倾角的钻孔。因而形成了自身的一些特点:

(1)钻进方法和钻进工艺的多样性

钻探生产采用的钻探方法和钻进工艺是多种多样的。就钻进方法而言,按破碎岩石的方法可分为冲击、回转、震动、复合式等几种;按采用的破岩材料分为:钻粒钻进、硬质合金钻进、金刚石钻进、超硬材料钻进;按是否取芯分为取芯钻进和全面钻进就钻进工艺而言可分为正循环钻进,局部反循环钻进和全面钻进。而且随着钻探生产的发展,科技的进步,会出现更多的钻探方法和钻探工艺,这就产生了能实现不同钻进方法和钻进工艺的各种类型的钻机。

(2)使用条件的复杂性

钻机工作的区域广泛,从平原到海洋、从地面到地下、从热带到寒带,几乎地球的每个地方都可能成为钻机工作的地方。不同地区有不同的环境气候条件这就带来钻机使用条件的复杂性。加之露天作业机械,作业对象为岩石,一般用以产生污染的泥浆做冲洗液,这一进步造成钻机工作条件的恶化,为适应这些条件,钻机必须满足一些特殊要求。

(3)类型与结构的多样性

川公网安备: 51019002004831号

川公网安备: 51019002004831号