目录

第1章 前言·······················································1

1.1塔式起重机概述··············································1

1.2塔式起重机的发展情况········································1

1.3塔式起重机的发展趋势·······································3

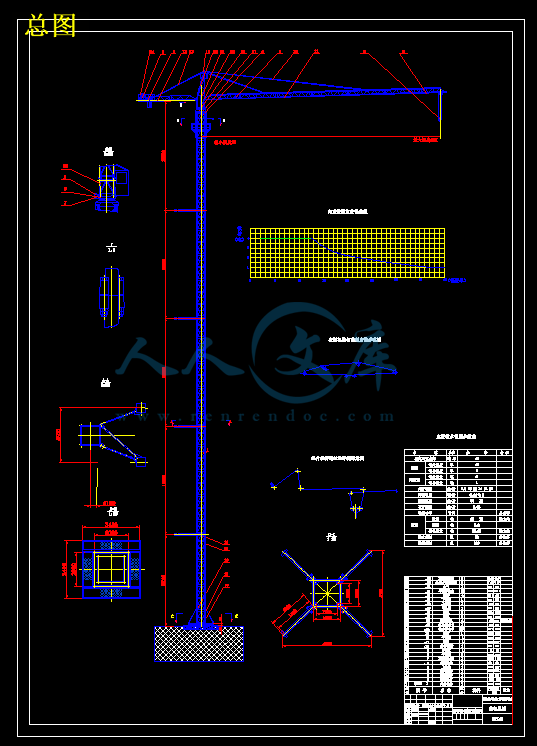

第2章 总体设计··················································5

2.1 概述······················································· 5

2.2 确定总体设计方案············································5

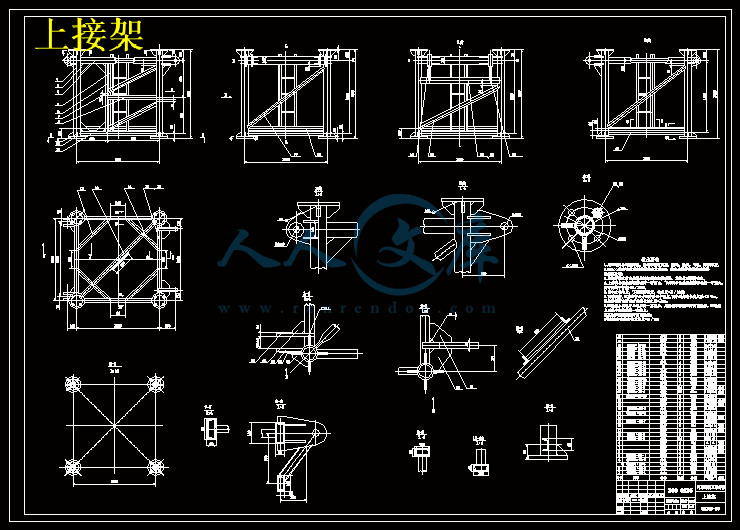

2.2.1 金属结构···············································5

2.2.2 工作机构···············································22

2.2.3 安全保护装置···········································29

2.3 总体设计设计总则···········································32

2.3.1 整机工作级别 ··········································32

2.3.2 机构工作级别···········································32

2.3.3主要技术性能参数······································· 33

2.4 平衡重的计算···············································33

2.5 起重特性曲线···············································35

2.6 塔机风力计算·············································· 36

2.6.1 工作工况Ⅰ············································37

2.6.2 工作工况Ⅱ············································41

2.6.3 非工作工况Ⅲ···········································43

2.7整机的抗倾翻稳定性·········································45

2.7.1工作工况Ⅰ············································46

2.7.2工作工况Ⅱ············································47

2.7.3非工作工况Ⅲ··········································49

2.7.4工作工况Ⅳ············································50

2.8固定基础稳定性计算·········································51

第3章 塔身的有限元分析设计···································53

3.1 塔身模型简化···············································53

3.2 有限元分析计算·············································54

3.2.1 方案一···············································54

3.2.2 方案二··············································79

3.2.3 方案三··············································98

第4章 塔身的受力分析计算····································121

4.1 稳定性校核················································121

4.2 塔身的刚度检算············································122

4.3 塔身的强度校核············································124

4.4 链接套焊缝强度的计算······································125

4.5 塔身腹杆的计算············································126

4.6 高强度螺栓强度的计算······································127

第5章 毕业设计小结···········································129

致谢·····························································130

主要参考文献····················································131

毕业实习报告

附:英文翻译

英文原文

第1章 前言

1.1 塔式起重机概述

塔式起重机是一种塔身竖立起重臂回转的起重机械。在工业与民用建筑施工中塔式起重机是完成预制构件及其他建筑材料与工具等吊装工作的主要设备。在高层建筑施工中其幅度利用率比其他类型起重机高。由于塔式起重机能靠近建筑物,其幅度利用率可达全幅度的80%,普通履带式、轮胎式起重机幅度利用率不超过50%,而且随着建筑物高度的增加还会急剧地减小。因此,塔式起重机在高层工业和民用建筑施工的使用中一直处于领先地位。应用塔式起重机对于加快施工进度、缩短工期、降低工程造价起着重要的作用。同时,为了适应建筑物结构件的预制装配化、工厂化等新工艺、新技术应用的不断扩大,现在的塔式起重机必须具备下列特点:

1.起升高度和工作幅度较大,起重力矩大。

2.工作速度高,具有安装微动性能及良好的调速性能。

3.要求装拆、运输方便迅速,以适应频繁转移工地的需

要。

QTZ40型自升式塔式起重机,其吊臂长40米,最大起重量4吨,额定起重力矩40吨米。是一种结构合理、性能比较优异的产品,比较目前国内外同规格同类型的塔机具有更多的优点,能满足高层建筑施工的需要,可用于建筑材料和构件的调运和安装,并能在市内狭窄地区和丘陵地带建筑施工。整机结构不算太大,可满足中小型施工的要求。

本机以基本高度(独立式)30米。用户需高层附着施工,只需提出另行订货要求,即可增加某些部件实现本机的最大设计高度100米,也就是附着高层施工可建高楼32层以上。

1.2 塔式起重机发展情况

塔式起重机是在二次世界大战后才真正获得发展的。战后各国面临着重建家园的艰巨任务,浩大的建筑工程量迫切需要大量性能良好的塔式起重机。欧洲率先成功,1923年成功制成第一台比较完整的塔式起重机,

川公网安备: 51019002004831号

川公网安备: 51019002004831号