摘 要

在机械加工中,常常会碰到圆锥孔的测量问题。圆锥孔的主要控制参数是锥孔锥度和锥孔端面直径尺寸。在圆锥孔大小端端面直径尺寸已知的情况下,圆锥孔的锥度可以通过简单的计算获得。故测量圆锥孔端面直径尺寸显得特别重要。圆锥孔由于结构的特殊性导致其端面直径不易测量。在机械加工中,通常采用锥度塞规涂色法作为圆锥孔加工和终检的量具,通过塞规与圆锥孔的接触面积来判断锥度和尺寸是否合格;也可用正弦规或三坐标测量仪等进行检测。但这些测量方式或者效率较低,或者成本过高,难以适应现场批量生产时的检测需要。特别是对那些精度要求较高的圆锥孔,由于缺少合适的现场测量工具,往往很难保证达到要求的精度[1]。本文设计一种基于虚交点的圆锥孔端面尺寸数显测量装置,可在机直接测量,不需计算,数显直读,且结构简单,测量范围大,有效地解决了生产现场检测锥孔端面直径的问题,也可用于间接测量椎孔的锥度。

关键词:圆锥孔端面直径,测量装置,精度分析,容栅位移传感器

Based on the virtual end-point of intersection of the conical hole size digital measuring device

Abstract

In machining, the often encountered problem of cone-hole measurement. Conical hole is the main control parameters and cone taper taper hole diameter face hole. Hole in the cone diameter the size of end-to-end face of known cases, the cone of the taper hole can be obtained through simple calculation. Therefore, measurement of end-cone diameter hole is of particular importance. Conical hole as a result of the specificity of the structure led to easy measurement of the diameter of its end. In machining, taper plug gauge used as a coloring process and the end of conical hole measuring location, with the cone through the plug hole to determine the contact area and dimensions of taper is qualified; also be used sinusoidal regulation or instrument, such as CMM test. However, these measurement or less efficient, or cost is too high, it is difficult to adapt to the scene at the time of detection of the need for mass production. Especially for those who require a higher accuracy of the conical holes, the field due to the lack of suitable measurement tools is often very difficult to guarantee the required accuracy. In this paper, the design of a virtual point of intersection of the cone-based end-hole-size digital display measuring device can be directly measured in the machine, without calculation, direct-reading digital display and simple structure, wide measurement range, an effective solution to the production scene detection end taper hole diameter also can be used for indirect measurement of the taper foramen.

Keywords: conical end hole diameter measuring devices, precision analysis, capacitive displacement sensor

目录

1 绪论 1

1.1 目前对几何测量的研究现状 1

1.1.1 几何量测量的基本概念 1

1.1.2 计量器具的基本技术性能指标 1

1.1.3 测量方法的分类 2

1.1.4 测量量具的分类 3

1.1.5 几何测量仪的新进展 4

1.2 目前对锥孔端面直径测量装置的研究现状 5

1.3 本次设计的意义和主要内容 5

2 装置的测量原理和结构 6

2.1 装置的测量原理 7

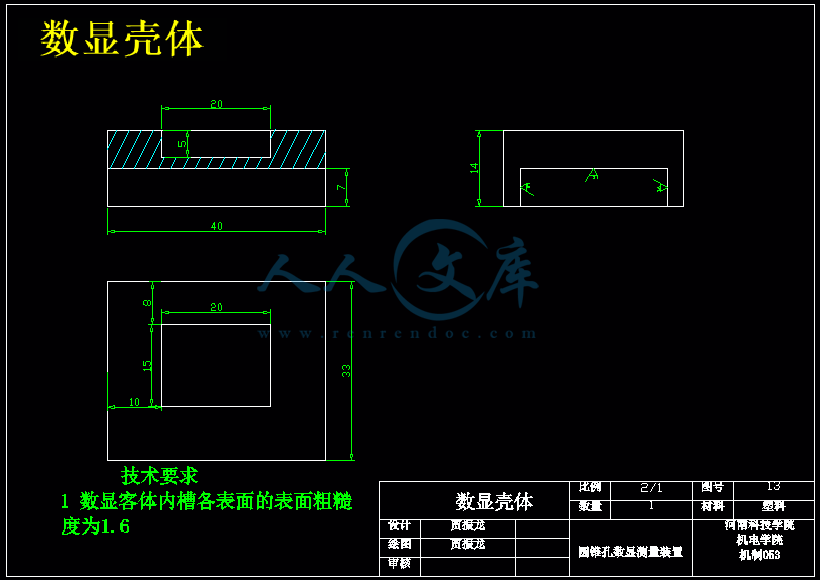

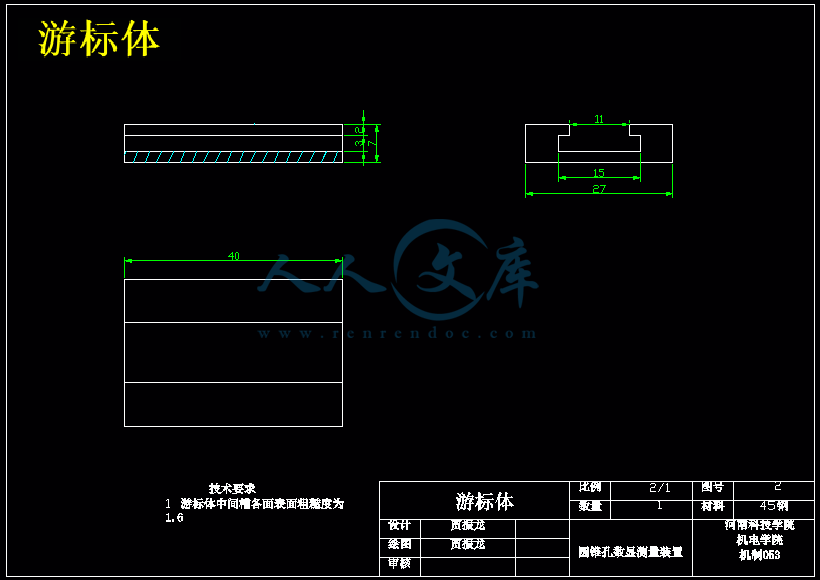

2.2 装置的结构 8

3 装置的测量范围分析 8

3.1 最小测量直径的确定 8

3.2 最大测量直径的确定 9

3.3可测圆锥孔的锥度确定 10

4装置的结构设计 13

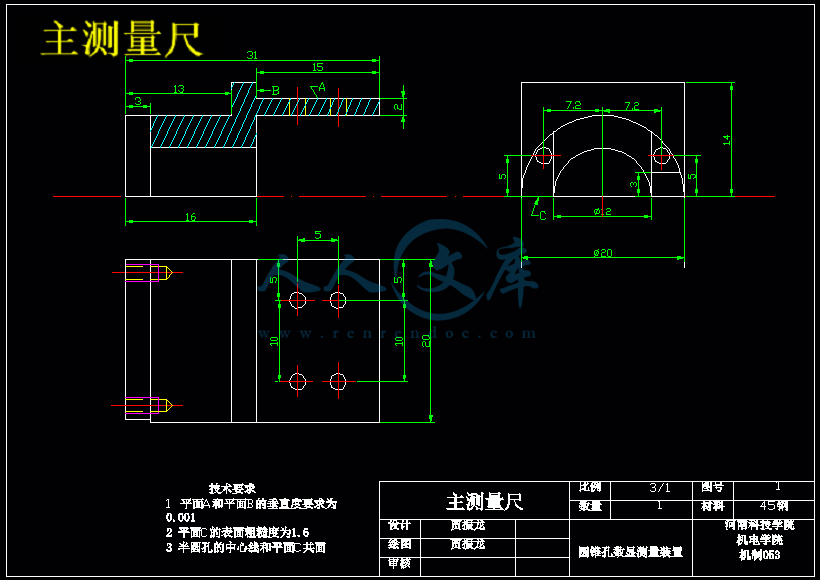

4.1卡脚结构设计 13

4.2不完全铰链结构设计 13

4.3定位机构设计 14

4.4数显系统选择 14

5装置测量精度的分析 15

5.1主测量尺不完全铰链中心线与主测量尺定位面不共面(误差为δ1)对测量精度的影响 16

5.2主测量尺卡脚不完全铰链中心线与主测量卡脚工作面不共面(误差为δ2)对测量精度的影响 17

5.3 改善和提高装置测量精度的措施 17

6注意事项 19

6.1安装量具时注意事项 19

6.2应用注意事项 19

7 结语 20

致谢 20

参考文献 21

1 绪论

1.1 目前对几何测量的研究现状

1.1.1 几何量测量的基本概念

零件加工后,其几何量需加以测量或检验,以确定它们是否符合零件图上给定的技术要求。几何量测量是指为了确定被测几何量的量值,将被测几何量X与作为计量单位的标准量E进行比较,从而得出两者比值q的过程。这可用下式表示:

川公网安备: 51019002004831号

川公网安备: 51019002004831号