【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘要

自动伸缩门是一款机电一体化的产品,它由控制系统实现电机的转动,再由电机通过一系列传动装置,带动门体运动。本文首先阐述了自动伸缩门产生的背景,它在当前社会中的发展状况,以及对它进行研究的意义。继而根据已知条件对相关参数进行计算,选择合适的电动机。然后设计减速器传动方式,确定传动方式之后再依次对实现传动的各个零件(包括齿轮、轴、传动链、链轮)的各个参数进一步计算,接着要对设计完的零件进行强度校核。最后,对自动伸缩门的控制系统进行了设计,本文采用单片机进行系统控制,从而实现电动机的正转、反转、停转,汉字显示方式控制,无线遥控控制等,再根据这些功能来选择实现这些功能所需要的硬件设备,然后将这些设备正确连接来完成硬件系统的设计。

关键词: 伸缩门;减速器;控制系统

Abstract

Automatically retractable door is a product of mechatronics. Under the control of the system, it can make the motor rotate, and then, through a series of gearing, the motor drive the whole door to move. This paper first describes the background to generate automatic retractable door, its development in the current society, and the significance to study it. Then to calculate of the relevant parameters based on the known conditions and select the appropriate motor. Next, we should determine the way of transmission, after which the parameters of the various transmission parts need to be further calculated, including the design of gears, the design of shafts and the design of transmission chain and sprocket wheels. Afterwards, the intensity of each part will be checked. Finally, the control system of automatically retractable doors is designed. In this paper, we use single-chip to achieve system control, which can realize the normal-reverse transfer of the motor, the way of characters display, and wireless remote control. To implement these functions, we must choose necessary hardware devices, and these devices should be properly connected to complete the design of the hardware system.

Keywords retractable door reducer control system

目 录

摘要 I

关键词: I

Abstract II

1 绪论 1

1.1 课题研究内容 1

1.2 自动伸缩门的背景、发展及研究意义 1

2 减速器的设计 3

2.1电动机的选择 3

2.2 传动比的计算及分配 4

2.3 计算传动装置的运动和动力参数 5

2.4齿轮设计 6

2.4.1高速级圆锥齿轮设计 6

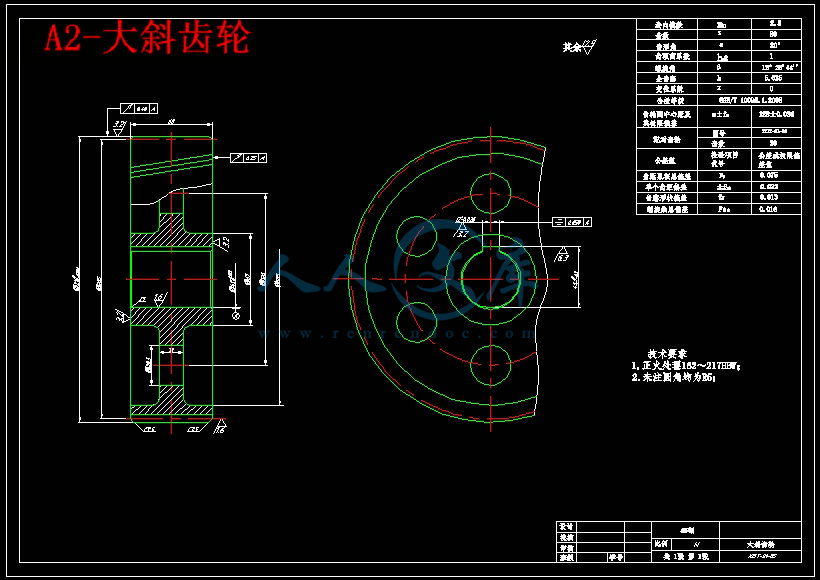

2.4.2低速级斜齿圆柱齿轮设计 11

2.5轴的设计 18

2.5.1高速轴的设计与计算 18

2.5.3 中间轴的设计与计算 24

2.5.3 低速轴设计 30

3 链传动设计 37

4 控制器设计 39

4.1 总体设计 40

4.2 硬件选择 40

4.2.1 电机控制 40

4.2.2 遥控电路 40

4.2.3 汉字显示模块 41

4.3 硬件连接原理图 41

5 门体设计 43

5.1 总体设计 43

5.2 结构设计 44

结论 45

致谢 46

参考文献 47

1 绪论

1.1 课题研究内容

本课题研究的对象是自动伸缩门,它主要由机头、门体和行走轮组成,其中机头是其核心部分,内部包括电动机、控制系统、以及减速装置。工作时,由控制系统控制电动机的正转和反转,然后通过一系列的减速装置带动行走轮行走,从而实现伸缩门的前进与后退。

本课题的主要研究的是与本专业联系紧密的电动机和减速装置部分。首先根据原始参数选择合适的电动机,然后选择合适的传动机构。为实现门体的正常运动,本设计拟选用圆锥-圆柱齿轮传动,然后通过链传动带动行走轮行走。

1.2 自动伸缩门的背景、发展及研究意义

在20世纪,自动门在我国并不是很普遍,其核心技术也很落后,尤其是它内部的控制系统,当时在我国根本无法研制出来,因此很多都是从西方国家进口而来。但后来,随着科学技术的不断发展,我们自己也渐渐可以开发出自动伸缩门生产的整套流程。自动伸缩门从产生到投入使用已经有一段时间,它的兴起是在1996年,那段时间,很多厂家抓住这个契机大量生产,市面上的伸缩门的种类非常多,这样自然而然带来的就是伸缩门的质量问题,相当一部分该产品很不符合使用要求,存在着许多隐患。于是针对这个问题,国家于1997年颁发了通知,要求相关部门及研究院,修编一套自动伸缩门的规格,其目标是向国内外先进企业看齐。

此后随着人民生活水平的提高,市场需求的逐渐扩大,科技水平的日益发达,自动伸缩门的功能越来越强大,应用也越来越广泛。虽然在国内它的起步比较晚,但相对来说其发展还是比较迅速的。如今,自动门在日常生活中可以说是随处可见,学校、工厂、医院等各个企事业单位均使用自动伸缩门作为自己的门面,不仅方便了车辆的进出与管理,同事还节省了人力物力。

因此,对自动伸缩门进行研究对改善我们的日常生活,促进社会经济效益有着极其重要的意义。

1.3 文章结构

本文首先对本课题进行简单的介绍,并阐述自动伸缩门产生的背景,它在当前社会中的发展状况,以及对它进行研究的意义。

第二章主要对实现传动的减速器进行设计。包括电动机选型,传动比分配以及相关参数计算,还有传动零部件的设计。

第三章主要对链传动进行设计,它主要用来实现减速器输出轴到伸缩门滚轮之间的传动。

第四章主要对自动伸缩门的控制系统进行设计。主要通过单片机实现对电动机的正转、反转、停转,汉字显示方式以及无线遥控的控制,并作出硬件连接原理图。

最后主要进行了门体结构的设计,并总结本次设计过程,对设计中提供帮助的老师同学表示感谢。

川公网安备: 51019002004831号

川公网安备: 51019002004831号