Effect of Nd and Y on the microstructure and mechanical.pdf

机械毕业设计-行星齿轮的三维建模与运动仿真【含CAD图纸、三维模型、论文】

收藏

资源目录

压缩包内文档预览:

编号:11708344

类型:共享资源

大小:79.22MB

格式:ZIP

上传时间:2018-12-16

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

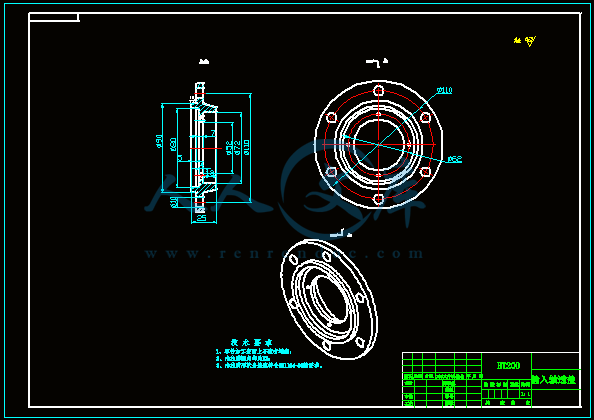

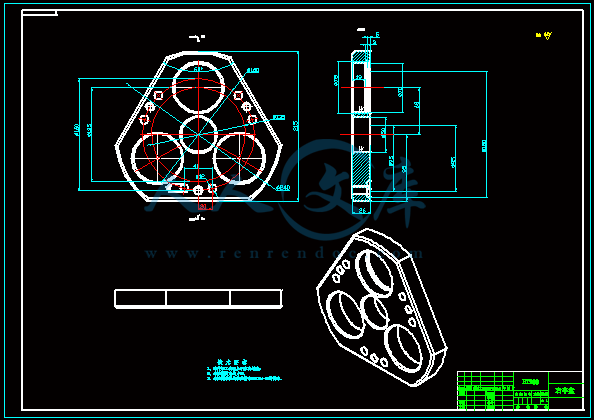

含CAD图纸、三维模型、论文

机械

毕业设计

行星

齿轮

三维

建模

运动

仿真

cad

图纸

模型

论文

- 资源描述:

-

- 内容简介:

-

Materials Science and Engineering A 445446 (2007) 16 Effect of Nd and Y on the microstructure and mechanical properties of ZK60 H.T. Zhou a, , Z.D. Zhang a , C.M. al form Abstract tensile sho grains. and the with grain combination dynamic the allo both Nd and K 1. Introduction Mg alloys are the lightest structural alloy, and hence they are moti specific strength requirements properties. parts backs are mechanical by hot mechanical strength e still is low compared to aluminum alloy. From this point of view, many researchers devote their efforts to improve its mechanical properties. Recently, it is reported that extruded Mg alloys con- 0921-5093/$ doi: likely to be applicable to many structural parts in auto- ve and aero industries due to high specific strength, high stiffness and good damping capacity 1,2. However, of most current Mg alloys cannot meet the strength of general structures because of some undesirable Therefore, applications of Mg alloys as structural are still very limited. In order to overcome these draw- and widen the application fields of Mg alloys, researchers trying any kinds of methods. It has been demonstrated that properties of Mg alloys are significantly improved grain refinement through adding rare earth metals (RE) and working 3,4. As well known, ZK60 alloy has highest properties among all the Mg alloys such as high at room temperature and elevated temperature 5.How- ver, its strength at room temperature and elevated temperature Corresponding author. Tel.: +86 731 8830257; fax: +86 731 8830257. E-mail address: htzhou (H.T. Zhou). taining RE exhibit excellent mechanical properties 6,7.For instance, Ma et al. studied on extruded ZK60-RE alloys and suggested that hot extrusion could improve tensile properties of ZK60-RE 8. Singh and Tsai 9 and Zhang et al. 10 studied the effect of Y on microstructure and mechanical properties of ZK60 alloy. They point out that Y enhances the yield strength and elevated temperature strength by forming new phases of (WMg 3 ZnY 2 ) and (IMg 3 Zn 6 Y) which have high hardiness, thermal stability, high corrosion resistance, low coefficient of friction, low interfacial energy, etc. 11,12. Subsequently, these new phases can effectively obstruct the slip of dislocation during hot deformation. Although the mechanical properties of ZK60 alloy could be improved by an addition of Y, the expected prop- erties is not reachable. Therefore, in this study, we initialize this article to study the effects of Nd addition and combination addition of Nd and Y on microstructure and tensile properties of ZK60 alloy. Furthermore, the relationship between the ten- sile properties and microstructure is investigated in hot extruded alloys. see front matter 2006 Published by Elsevier B.V. 10.1016/j.msea.2006.04.028 a School of Materials Science and Engineering, Centr b School of Materials Science and Engineering, Shanghai Received 26 July 2005; received in revised The effect of neodium (Nd) and yttrium (Y) on the microstructure and w that an addition of neodium and yttrium both brings about precipitation After hot extrusion, the alloy added with Nd and the alloy with Nd pining effect of particles or precipitates. As a result, very finer grains size of the alloy with Nd is relatively large. This suggested that the recrystallization, and leads to either the increase of both the melting alloys or the increase of the yield strength and tensile strength of the ZK60 and the alloy with Nd are higher than that of the alloy with 2006 Published by Elsevier B.V. eywords: ZK60 alloy; Neodium; Yttrium; Extrusion; Tensile properties alloy Liu a , Q.W. Wang b South University, Changsha 410083, PR China Jiao Tong University, Shanghai 200030, PR China 29 March 2006; accepted 12 April 2006 properties of ZK60 alloy are investigated. Experimental results of a new Mg 41 Nd 5 and Mg 3 Zn 6 Y (I) phases and refine the as-cast Y are greatly refined through dynamic recrystallization by means of size of 48H9262m are obtained in the alloy with Nd and Y. However, the of Nd and Y addition has a great effect on grain refining during temperatures of the eutectic phases and the melting temperature of y with Nd and Y at room temperature. In contrast, the elongation of Y. 2 H.T. Zhou et al. / Materials Science and Engineering A 445446 (2007) 16 Table 1 Chemical composition Composition (wt.%) Mg Zn Zr Y Nd Alloy A Bulk 5.54 0.54 Allo Allo 2. T mix the purring, to into into 420 at specimens from 10 are phase dif HNO 3. 3.1. respecti composed phase. marily as Meanwhile, allo size as be and Nd constant allo triple indicates ( in much in by Fig. 1. Microstructure in as-cast: (a) A alloy, (b) B alloy and (c) C alloy. phase and I phase (Mg 3 Zn 6 Y), further identifying C alloy has I phase (Mg 3 Zn 6 Y, icosahedral quasicrystal structure) except Mg 41 Nd 5 . The formation of cluster compounds can be ascribed to the increase of total amount of Nd and Y 14. However, W phase (Mg 3 Zn 3 Y 2 ) and Z phase (Mg 12 ZnY) cannot be found by y B Bulk 5.53 0.55 2.13 y C Bulk 5.56 0.53 1.54 2.14 Experimental procedures The chemical compositions of the studied alloys are listed in able 1. The alloys was prepared in furnace under protection of a ed gas atmosphere of SF6 (1 vol.%) and CO 2 (BAL). When molten alloy reaches 780 C, it is purred for about 300 s. After the molten alloy is hold for 15 min to allow inclusions settle to the bottom of the crucible. Then, the metal is poured a medium furnace. At 680 C, the molten metal is poured ingots with size of 90 mm. The ingots are solutionzed at C for 18 h. They are extruded into long rods of 20 mm 390 C, respectively, with an extrusion ratio of 20:1. Tensile of 5 mm diameter and 66 mm length are machined out these extruded rods. The size of tensile testing specimens is mm wide and 66 mm long. The microstructure of specimens analyzed by a light microscopy (OM, LEICA MEF4M), and analysis is performed by means of a D/MAS-IIIA X-ray fractometer (XRD). All the specimens are etched with 4% 3 solution in alcohol. Results Microstructure of as-cast ZK60 alloys Fig. 1 shows microstructures of as-cast A, B and C alloys, vely. It can be seen from Fig. 1a that A (ZK60) alloy is of primary H9251 (Mg) matrix and eutectic H9252 (Mg 2 Zn 3 ) The H9252 phase precipitates as discontinuous network pri- at grain boundaries. When there is Nd addition named B alloy, more second phase precipitated, as shown in Fig. 1b. Nd and Y are added together to ZK60 alloy called C y, it seems to be that much more compounds appear, and the of the compounds is smaller than that of A and B alloys shown in Fig. 1c. Consequently, different grain sizes can found among A, B and C alloys in the sequence of 90, 60 40H9262m, respectively. Therefore, it could be concluded that and Y have an effect on refinement of ZK60 alloy. This is with the result of Luo 13. Fig. 2 shows SEM microstructure images of B and C ys. It is found that there are some cluster compounds at grain boundaries as seen A of Fig. 2a. EDAX analysis that its chemical composition formula is Mg 41 Nd 5 n Mg :n Nd = 1.25:0.14/10.8:1.2). This is conformed by XRD seen Fig. 3. When Nd and Y are added together into ZK60 alloy, more cluster compounds appear at triple grain boundaries which there are some paralleled laths. They are identified XRD for C alloy. It can be seen that there exists Mg 41 Nd 5 XRD addition surpassed (Mg and EDAX analysis in this experiment. Clearly, yttrium brought about the formation of I phase in alloy C, and the formation of W phase (Mg 3 Zn 3 Y 2 ) and Z phase 12 ZnY). H.T. Zhou et al. / Materials Science and Engineering A 445446 (2007) 16 3 (a) B and and is secondary the certain further found of second allo of as of and This temperature (340 further increases 3.2. were occurred size In phase that at small, found of that role hand, are pinning fine be is 3.3. e ultimate B (A allo proof and where to size. B increase B 4. Fig. 2. SEM images: Fig. 4 shows the map distribution of B and C alloys for Nd Y. It is found that Nd and Y exist both in grain boundaries in matrix. However, in some area, the content of Nd or Y very high. As seen from Fig. 4a and c, it suggests that the phases are likely to contain more Nd or yttrium than matrix. This may be used to explain the phenomenon that amount of secondary phases exists in alloys B and C. This conforms the results are agreement with XRD results. Fig. 5 shows the DTA analysis results of alloys B and C. It is that the first endothermic peak appeared at the temperature about 463.3 C for alloy B and 485.7 C for alloy C, while the peak appeared at 617.5 C for B alloy and 615 C for C y The first peaks can be thought as the melting temperatures the eutectic phases, and the second peaks can be thought the melting temperature of the alloys (solution temperature alloy). We can conclude that the combined addition of Nd Y to ZK60 alloy greatly increases the eutectic temperature. is agreement with yttrium can greatly increase the eutectic over the eutectic temperature of MgZn binary alloy C) 10,15. Results of the DTA analysis of this experiment suggest that the eutectic temperature of MgZnZr alloy with increasing total content of Nd and Y. Microstructure evolution of the hot extruded alloys Fig. 6 shows optical microstructures of alloys A, B and C that extruded at 390 C. It is found that all the three alloys have dynamic recrystallization (DRX). However, the grain and the amount distribution of second phase are different. hot extruded alloys A as shown in Fig. 6a, there is no second on the matrix. The size of DRX grain is large compared to of alloys B and C. There seems a little growth of grains even this temperature. In the alloys B and C, DRX grain size is very and DRX also completed. Full details on matrix can be with characteristics of some second phases. The grain size alloy C is the smallest among the three alloys. This suggests the combined addition of Nd and Y plays an important during process of dynamic recrystallization. On the other DRX grains of alloy C with an average size of about 4H9262m cast tensile H9251 and tion allo by reaction tion liquid/solid the v alloy and (b) C alloy. very fine and uniform. This may relate to the fact that the effects of both broken secondary phase particles and precipitates can suppress the growth of DRX grains. It can concluded that grain refinement by dynamic recrystallization very effective even at this temperature in ZK60 alloy. Mechanical properties of extruded alloys Fig. 7 shows the mechanical properties of the three xtruded alloys at 390 C. As shown in the figures, the tensile strength and yield strength of alloys A, and C increase, while the ductility of them decreases alloy: 0.2 = 270.2 MPa, b = 320.5 MPa, = 12%; B y: 0.2 = 316.2 MPa, b = 373.2 MPa, = 8%; C alloy: 0.2 = 376.2 MPa, b = 389.0 MPa, = 6%). Clearly, the 0.2% of stress strongly depends on the grain size in Mg alloy 16 obey the role of HallPetch relationship y = 0 + Kd 1/2 , y is the yield stress, 0 the lattice friction stress related move individual dislocation, K a constant and d is the grain Thus, this can explain why the tensile properties of alloys and C are higher than that of A (ZK60) alloy. In addition, the of ultimate tensile strength and yield strength of alloys and C may be related to the second phase strengthening. Discussion Alloys A, B and C have different microstructure both in as- and in extruded state. Subsequently, it brings to different properties. Firstly, as in as-cast state, alloy A consists of Mg and H9252 (Mg 2 Zn 3 ) phase. When Nd is added into A alloy, Nd with Y is together added into A forming C alloy, in addi- toH9252(Mg 2 Zn 3 ) phase, the new phases appear as Mg 41 Nd 5 in y B, and Mg 41 Nd 5 +Mg 3 Zn 6 Y in alloy C. This is identified XRD and SEM. During solidification process the peritectic should occur first. Owing to the no equilibrium distribu- the solute atoms of Zn and RE are pushed to the front of the interface formed along the grain boundaries while in interior of the grain only the Zr-rich zone is present. This is erified by Fig. 4. From Fig. 1, we conclude that the grain refin- 4 H.T. Zhou et al. / Materials Science and Engineering A 445446 (2007) 16 ing agreement e in ing across relati grain the ing Fig. 3. XRD diffraction: (a) A alloy, (b) B alloy and (c) C alloy. effect of Nd and Y element exists in Mg alloy. This is good with experiment observations 17,18. Secondly, as in xtruded state, Mg 41 Nd 5 in alloy B, and Mg 41 Nd 5 +Mg 3 Zn 6 Y alloy C are destroyed and broken into small particles. Dur- hot extrusion, many fine particles homogeneously distribute the matrix. These thermally stable second phases with a vely high meting point can pin grain boundaries and impede growth during hot deformation, especially I phase. Due to low interfacial energy of I phase/matrix interface, the bond- at the I phase/interface is relatively strong 12 so that I phase Fig. and deformation. ond lar are a diameter by 4. Map distribution: (a) Nd alloy B, (b) Nd alloy C and (c) Y alloy C. precipitates were relatively difficult to be moved during hot Thirdly, concentrated strain in the vicinity of sec- phases can introduce sites of high dislocation density and ge orientation gradient (particle deformation zone). Such sites ideal for nucleation of recrystallized grains. It is known that particle deformation zone may extend to a distance of even one from the surface of the particles and may be disoriented tens of degrees from the adjacent matrix. In these deformation H.T. Zhou et al. / Materials Science and Engineering A 445446 (2007) 16 5 zones, grains moted second gro v particles B the on e the on Delta1 where ment, the than 5. Mg6Zn0.5Zr2Nd studied precipitation refine added dynamic ticles Fig. 5. DTA trace of as-cast: (a) alloy B and (b) alloy C. second particles can stimulate nucleation of recrystallized 19,20. Thus, nucleation of recrystallization can be pro- by Nd and Y addition in ZK60 alloy through forming phases. In addition, the second phases can hinder grain wth during recrstallization 20. As a result, alloy C exhibits ery finer grains. This is attributed to much more disperse finer than alloys A and B. Therefore, the strength of alloys and C is much higher. This suggests that second phase, except effect of grain refining, has a strong strengthening effect the strength of MgZnZr alloys, especially that the I phase xhibit obviously a strong strengthen effect 10. According to well known HallPetch relation, the yield strength depends the grain size as follows 16: 0.2 = Kd 1/2 (1) Delta1 0.2 is the increase in yield stress due to grain refine- K a constant and d is the grain size. So, grain refinement by DRX process has an influence on alloys B and C are higher that of ZK60 alloy. Summary The microstructure and mechanical properties of ZK60, and Mg6Zn0.5Zr2Nd1.5Y alloys are in this article. Some neodium and yttrium brings about of a new Mg 41 Nd 5 and Mg 3 Zn 6 Y (I) phases and the as-cast grains with an addition of Nd and Y. The alloy with Nd and the alloy with Nd and Y are refined through recrystallization by means of the pining effect of par- or precipitates. This suggested that the combination of Fig. (c) Nd dynamic both melting strength 6. Optical microstructures extruded at 390 C: (a) A alloy, (b) B alloy and C alloy. and Y addition has a great effect on grain refining during recrystallization, and leads to either the increase of the melting temperatures of the eutectic phases and the temperature of the alloys or the increase of the yield and tensile strength of the alloy with Nd and Y at room 6 H.T. Zhou et al. / Materials Science and Engineering A 445446 (2007) 16 Fig. 7. The tensile properties of the extruded alloys at 390 C: A alloy, B alloy and

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

|

2:不支持迅雷下载,请使用浏览器下载

3:不支持QQ浏览器下载,请用其他浏览器

4:下载后的文档和图纸-无水印

5:文档经过压缩,下载后原文更清晰

|

川公网安备: 51019002004831号

川公网安备: 51019002004831号