【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

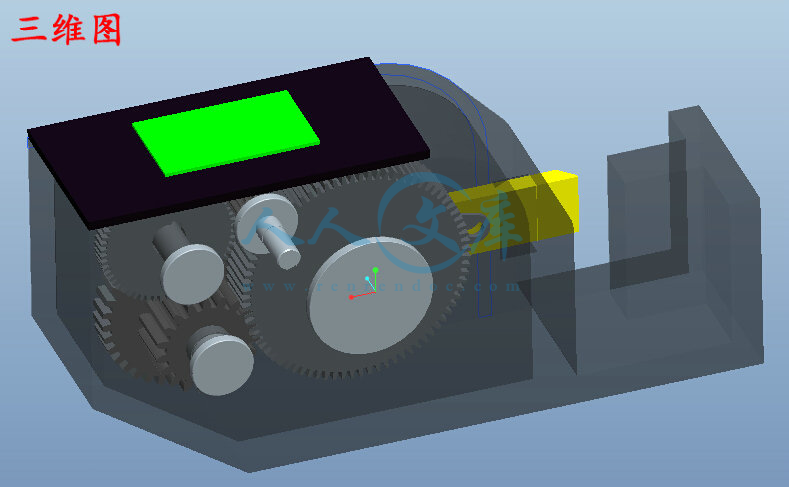

GQ50钢筋切断机结构设计与运动仿真

【摘要】

钢筋切断机是把钢筋切成所需长度的专用机械,在大型建筑工地上的应用非常广泛。钢筋切断机分为机械传动和液压传动两种。机械传动式钢筋切断机,工作时大都采用电动机经一级三角带传动和三级齿轮传动减速后,带动曲轴旋转,曲轴推动连杆使滑块和动刀片在机座的滑道中作往复直线运动,使活动刀片和固定刀片相错而切断钢筋。GQ50型钢筋切断机,其剪切运动是由一偏心轮连杆机构完成的。但是由于切断机机体内腔狭小,在装配曲轴连杆时比较困难。尤其是在使用中发生故障需要维修时,拆卸曲轴连杆更加不容易,给维修造成很大的不变,因此在不改变设备功能的情况下,我对曲轴连杆机构做了一些改进。改进后的偏心轮结构直接从机体的注册孔中装入和取出。而不必拆卸连杆,大大简化了装配程序,减轻的工人的劳动强度。同时也极大的方便了维修,还简化了零件的工艺过程,取得良好的经济效益。

【关键词】:钢筋切断机;偏心轮;曲轴连杆机构

GQ50 reinforcing steel cutter structural design and movement simulation

Abstract

Reinforcing steel cutting machine is used to cut the required length of steel machinery specialized for large construction sites in the application of very extensive. Reinforcing steel cutting machine into mechanical transmission and hydraulic transmission of two. Mechanical transmission reinforced cutting machine, working mostly used as a V-belt drive motor and gear drive slow down after three, driven crankshaft rotation, promoting the crankshaft and connecting rod to move the slider blade in the frame of the chute in a reciprocating linear motion So that the activities of the blade and a fixed blade and cut off the wrong steel. GQ50-steel cutter, whose movement from one type of the crankshaft linkage to complete. However, due to cut off the small inner cavity of the body, in the assembly when the crankshaft link more difficult. Especially in the use of a fault in need of repair, demolition crank link more difficult to repair a big change, so do not change the function of the equipment under the circumstances, we have made some improvement to crank linkage. The improved structure of the cam directly from the body of the aircraft registered in the hole and packed out. Without dismantling the link, greatly simplifies the assembly, reducing labor intensity of workers. But also greatly facilitate the maintenance, has also simplified the process of parts and achieved good economic returns.

Key words: steel cutting machine, the structure design, proe, virtual assembling, movement

simulation

目录

1 绪论 1

1.1 钢筋切断机的研究现状 1

1.2 本次设计的任务 2

1.3 本次设计目的与意义 3

2 钢筋切断机的总体设计 4

2.1 钢筋切断机的基本介绍 4

2.2 GQ50型钢筋切断机的改良方向 5

2.3钢筋切断机的工作原理 6

2.4 钢筋切断机的基本结构 6

2.4.1 GQ50型钢筋切断机主传动机构的设计方案的确定 6

2.4.2 GQ50型钢筋切断机主传动机构设计的基本思路 7

2.4.3 GQ50型钢筋切断机主传动机构设计的方法 7

3 方案设计比较 8

3.1驱动装置方案选择 8

3.1.1液压驱动 8

3.1.2 手动驱动 8

3.1.3 电机驱动 8

3.2传动装置方案选择 9

3.2.1 液压传动 9

3.2.2 带传动 9

3.2.3 齿轮传动 9

3.2.4 组合传动 9

3.3执行装置方案选择 9

3.3.1曲柄滑块机构 9

3.3.2齿轮齿条机构 10

3.3.3凸轮机构 10

4 钢筋切断机传动设计 12

4.1电动机的选择 12

4.2 基本传动数据计算 12

4.2.1传动比的分配 12

4.2.2 各轴的运动及动力参数分析 13

4.3 带传动的设计 14

4.3.1带型的选择 14

4.3.2带轮基准直径的确定 14

4.3.3带速的确定 15

4.3.4中心距、带长及包角的确定 15

4.3.5确定带的根数 16

4.4 齿轮传动的设计 16

4.4.1选材料、确定初步参数 16

4.4.2齿面疲劳强度计算 18

4.4.3齿根抗弯疲劳强度验算 20

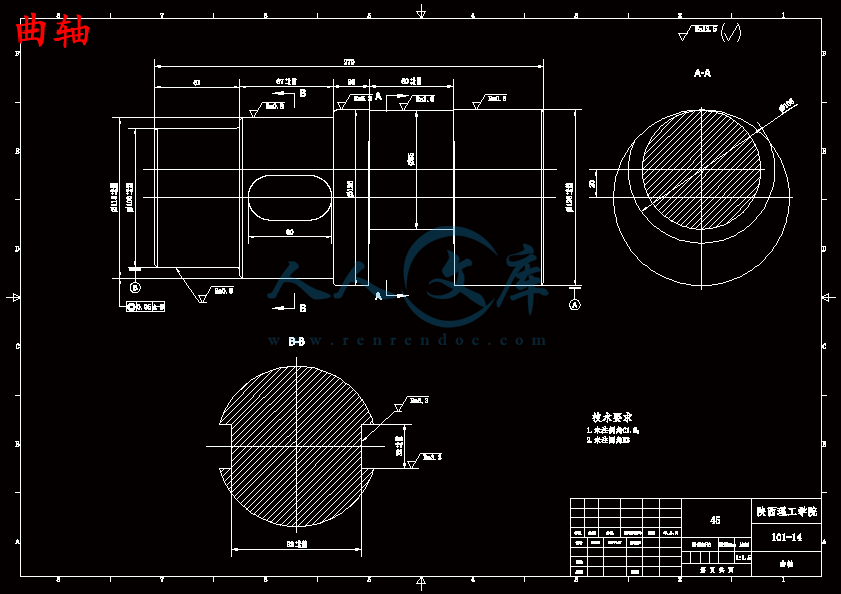

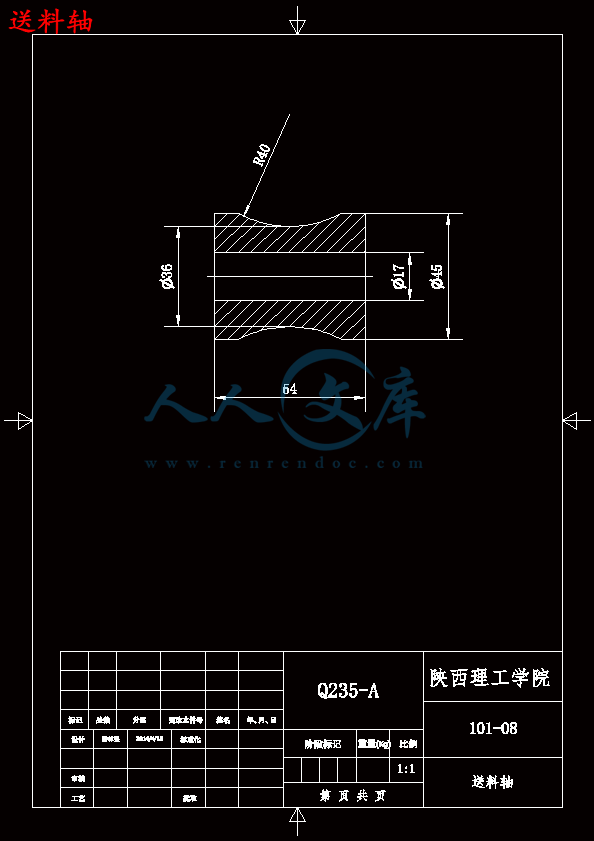

4.5 轴的设计 21

4.6键的选取与校核 22

4.6.1键的选取 22

4.6.2键强度的校核 22

4.7轴承的组合设计 23

4.8连杆的设计 24

4.9切断钢筋需用力计算 24

4.10减速器附件的选择 25

5 钢筋切断机的摩擦、磨损和润滑 26

6 机械式钢筋切断机调整及保养的使用 27

6.1 钢筋切断机的使用调整 27

6.2 钢筋切断机的保养 28

6.3钢筋切断机的一般安全的规定 29

7 建模与仿真 30

7.1 三维软件的介绍 30

7.2 钢筋切断机的建模与仿真 31

7.2.1 钢筋切断机主要零件的三维建模 31

7.2.2 GQ50型钢筋切断机主传动机构的装配与仿真 40

致谢 43

参考文献 44

川公网安备: 51019002004831号

川公网安备: 51019002004831号