目 录

1 前言……………………………………………………………………………………………1

2 总体方案设计……………………………………………………………………………………2

2.1机械部分改造成直接经济损失述…………………………………………………………2

2.2 数控系统部分设计………………………………………………………………………3

3 机械部分改选设计…………………………………………………………………………4

3.1 横向进给系统的设计与计算……………………………………………………………4

3.2 数控车床的传动装置设计…………………………………………………………………7

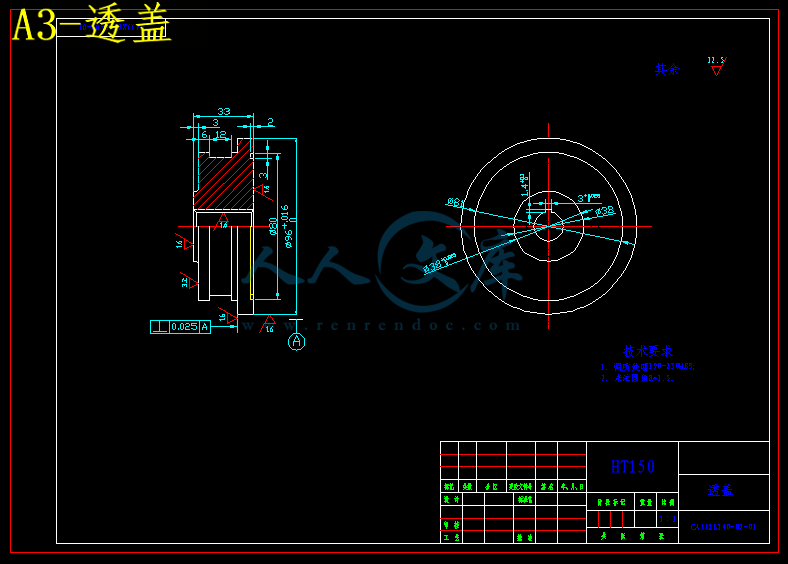

3.3 自动转位刀架的设计………………………………………………………………11

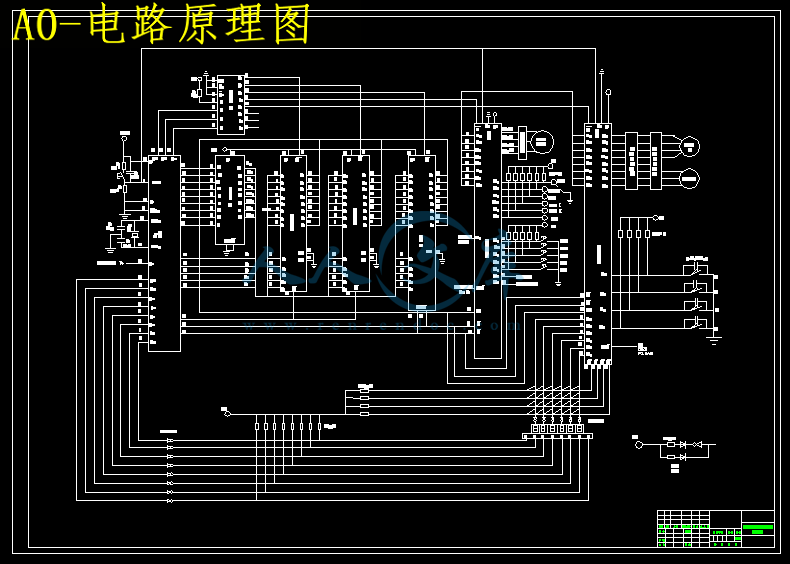

4 微机数控系统设计……………………………………………………………………………13

4.1 概述…………………………………………………………………………………………13

4.2 数控系统的硬件电路设计……………………………………………………………13

4.3 软件设计………………………………………………………………………………………18

5 结论………………………………………………………………………………………………33

参考文献………………………………………………………………………………………34

1 前言

国外利用数字计算机进行控制加工是从40年代开始的。1952年美国麻省理工学院在一台立式铣床上装了一套试验性的数控系统,成功地实现同时控制三轴的运动,它成了世界上第一台数控机床。此后,从60年代开始,其他一些工业国家如德国、日本等陆续地开发生产及使用数控机床。1974年微处理机直接用于数控机床,进一步促进了数控机床的普及应用和大力发展。随着数控机床的功能越来越完善,可靠性和性能越来越高,它在制造业中逐渐担当了越来越重要的角色。

我国数控机床的研制是从1958年开始的,经历了几十年的发展,直至80年代后引进了日本、美国、西班牙等国数控伺服及伺服系统技术后,我国的数控技术才有质的飞跃,应用面逐渐铺开,数控技术产业才逐步形成规模。

由于现代工业的飞速发展,市场需求变的越来越多样化,多品种、中小批量甚至单件生产占有相当大的比重,普通机床已越来越不能满足现代加工工艺及提高劳动生产率的要求。如果设备全部更新替换,不仅资金投入太大,成本太高,而且原有设备的闲置又将造成极大的浪费。如今科学技术发展很快,特别是微电子技术和计算机技术的发展更快,应用到数控系统上,它既能提高机床的自动化程度,又能提高加工精度,所以最经济的办法就是进行普通机床的数控改造。这样既可以提高加工生产率,改善加工工艺,还可以减少资金投入,减轻工人的劳动强度,缩短订购新的数控机床的交货周期时间。实践已经证明普通车床的经济型数控改造具有重大的实际价值,为此,在旧有车床上进行数控改造有着较好的市场前景。

本课题来源于生产实践。将CA6140型普通车床改造成经济型数控车床,应能实

现CA6140车床原有功能,在机床的精度、性能等方面除保持原来状况外还有所提高。在整个设计过程中满足以下几点要求:

a.横向(X向) 进给脉冲当量为0.005mm /脉冲;

b.进给速度范围:向 3 ~ 1000mm/min (无级调速)

快进速度:X向 1000 ~ 3000mm/min内任意设定;

c.原车床的主传动系统予以保留,横向进给系统由微机实现开环控制,两轴联动;

d.刀架采用自动转位刀架,具有切削螺纹的功能;

e.改造方便,成本低。

该设计的总体思路是采用以8031单片机为核心的数控装置控制加工过程。微机通过I/O接口发出驱动脉冲,经过光电隔离进入步进电机的驱动控制线路,驱动控制线路接受来自数控车床控制系统的进给脉冲信号,并将该信号转换为控制步进电机各定子绕组依次通电、断电的信号,使步进电机运转。步进电机的转子带动滚珠丝杠转动,从而使工作台产生移动,实现纵向、横向的进给运动。由于步进电机需要的驱动电压较高,电流较大,如果将I/O输出信号直接与功率放大器相连,将会引起强电干扰,轻则影响单片机程序运行,重则导致单片机接口电路的损坏,所以在接口电路与功率放大器之间加上隔离电路,实现电气隔离。

2 总体方案设计

由于该设计是经济型数控改造,在考虑具体方案时,应遵守的基本原则是在满足使用要求的前提下,对机床的改动尽可能少,以降低成本。

2.1 机械部分改造

横向进给机构的改造:拆掉原手动刀架和小拖板,安装上数控刀架;拆掉普通丝杆、光杆进给箱和溜板箱,换上滚珠丝杠螺母副;保留原手动机构,用于调整操作,原有的支撑结构也保留,采用一级齿轮减速,步进电机、齿轮箱体安装在中拖板的后侧。

川公网安备: 51019002004831号

川公网安备: 51019002004831号