新型半挂汽车列车车架有限元分析[4张CAD图纸和文档资料]

收藏

资源目录

压缩包内文档预览:

编号:14508806

类型:共享资源

大小:1.52MB

格式:RAR

上传时间:2019-02-10

上传人:好资料QQ****51605

认证信息

个人认证

孙**(实名认证)

江苏

IP属地:江苏

100

积分

- 关 键 词:

-

4张CAD图纸和文档资料

新型

汽车

列车

车架

有限元分析

cad

图纸

以及

文档

资料

- 资源描述:

-

【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

目 录

第1章 绪 论 1

1.1我国半挂汽车列车生产制造发展现状 1

1.2 本设计研究的目的和意义 3

1.3本课题研究内容 4

第2章 新型半挂汽车列车车架结构分析 5

2.1半挂汽车列车的主要结构介绍 5

2.2新型半挂汽车列车车架的特点 12

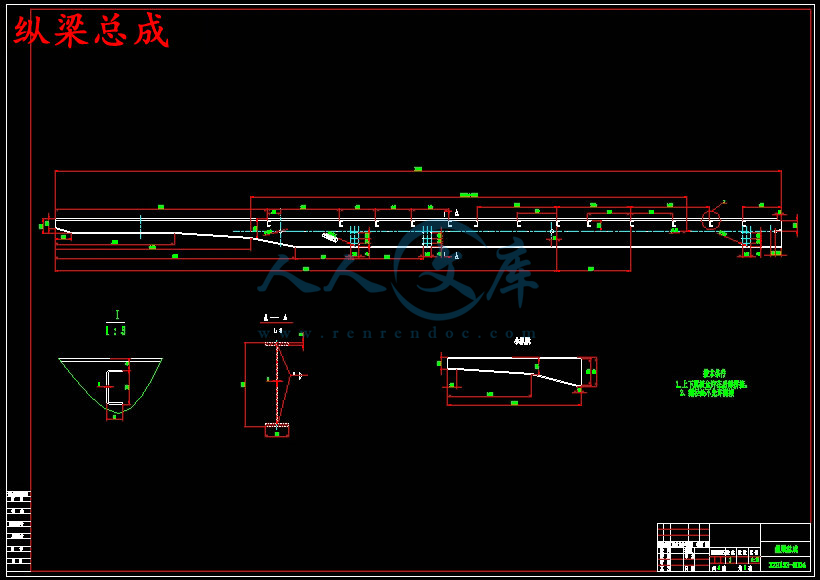

2.3新型半挂汽车列车车架结构总体布置设计 17

2.4新型半挂汽车列车纵梁设计 18

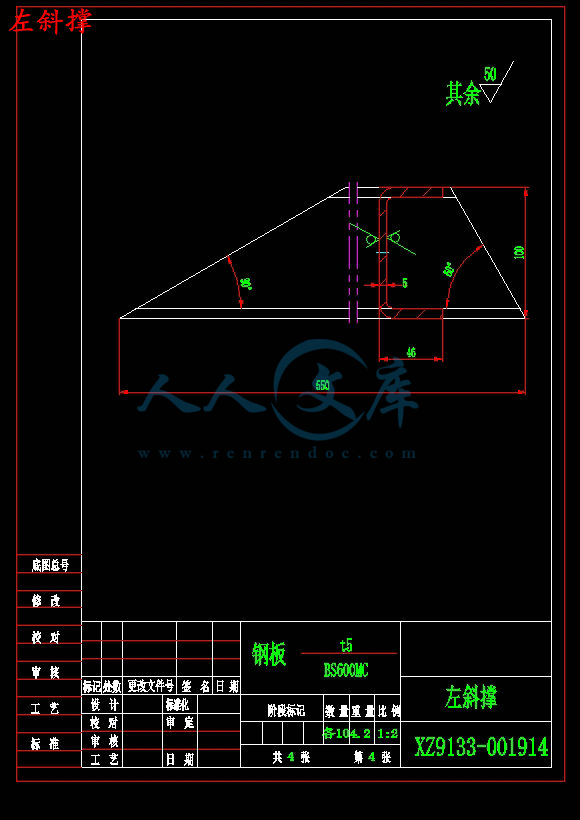

2.5新型半挂汽车列车车架主要零、部件设计 19

第3章 新型半挂汽车列车车架设计ANSYS有限元分析 24

3.1有限元分析的原理与方法 24

3.2 ANSYS软件简介 26

3.3新型半挂汽车列车车架ANSYS有限元分析 26

3.4计算结果 31

3.5应力分析 32

总结及展望 35

参考文献 36

第1章 绪 论

1.1我国半挂汽车列车生产制造发展现状

近些年来,随着国家经济的发展,交通运输业较为发达。就运输途径和形式来讲,当前世界各国均以公路运输为主。据有关资料介绍,美国公路运输占75%,英国为72.3%,俄罗斯为70%,而且车型在向大型和重型发展。随着公路运输事业的快速发展和汽车拖挂运输的普及,半挂汽车列车已经成为道路货运的主要运输工具,而半挂汽车列车制造业已经成为汽车工业的重要组成部分。为了促进我国半挂汽车列车生产制造的发展,并为用户提供优质产品,国内不少企业结合自己的生产实际需要,吸取国外同行业的先进经验,不断提高产品质量,开发具有科技含量高的产品(如多种专用的半挂汽车列车),为不同的运输客户服务,提高车辆的运输效率,增加生产经济效益,从而形成生产、销售、使用的良性循环。

我国商品的异地交流发展迅速,由于物流发展对半挂汽车列车的需求,半挂汽车列车生产制造规模不断扩大,产量增加,所以在国内专用车生产制造方面,半挂汽车列车比例不断增大,从多年前少量、小规模生产制造状况发展到今天,占据了专用车较大比例。以2002年为例,专用车生产分别为:厢式汽车:33104辆;罐式汽车:15595辆;起重举升车:7534辆;特种结构汽车:4530辆;其它改装汽车5498辆,而半挂汽车列车生产量为45752辆,居专用汽车生产量第一位。

半挂汽车列车产量在专用车中的比例不断增大,其主要原因在于半挂汽车列车具有价格比较低廉、运输效率快、载重量大,以及运费较低等优点。另外,半挂汽车列车和其他货车比较,在运输综合经济效益方面,有着更大的优势条件,特别是在码头、货物的集装箱运输方面表现得更为突出和明显。

与其他车型相比,半挂汽车列车毕竟属于技术含量较低,生产工艺简单,而且又是劳动密集型产品。特别是目前半挂汽车列车三大总成(车轴、支架、牵引销及支座)已经形成了专业化批量生产,外购关键总成,然后就能组装成型,所以半挂汽车列车生产厂家主要是自己制造车架。正是由于如此,使得进入行业的门坎较低,因此不少企业都把投资的目光转移到这一行业,而也正是这些企业的进入风潮导致如下局面:非正规厂家的产品粗制滥造,用户在产品质量和性能上得不到应有的保障,路边野店的拼装车以正规企业无法相比拟的价格优势几乎占据着半挂汽车列车市场的半壁江山;用户单纯看重价格,购买行为不规范,曾经一度造成半挂汽车列车生产和销售市场上的混乱局面。近几年来,经过国家“双超”治理,产品行业标准限定,以及半挂汽车列车单独上牌等相关管理措施出台与贯彻实施,半挂汽车列车生产制造技术以及产品质量有了不断的改善与提高。

- 内容简介:

-

外文资料翻译Electromechanical integration technology and its application An electromechanical integration technology development Mechatronics is the machinery, micro-, control, aircraft, information processing, and other cross-disciplinary integration, and its development and progress depends on the progress of technology and development, the main direction of development of a digital, intelligent, modular, and human nature , miniaturization, integration, with source and green. 1.1 Digital Microcontroller and the development of a number of mechanical and electrical products of the base, such as the continuous development of CNC machine tools and robots, and the rapid rise of the computer network for the digital design and manufacturing paved the way for, such as virtual design and computer integrated manufacturing. Digital request electromechanical integration software products with high reliability, easy operability, maintainability, self-diagnostic capabilities, and friendly man-machine interface. Digital will facilitate the realization of long-distance operation, diagnosis and repair. Intelligent 1.2 Mechanical and electrical products that require a certain degree of intelligence, it is similar to the logical thinking, reasoning judgement, autonomous decision-making capabilities. For example, in the CNC machine increase interactive features, set up Intelligent I / O interface and intelligent database technology, will use, operation and maintenance of bring great convenience. With fuzzy control, neural network, gray, wavelet theory, chaos and bifurcation, such as artificial intelligence and technological progress and development and the development of mechanical and electrical integration technology has opened up a vast world. Modular 1.3 As electromechanical integration products and manufacturers wide variety of research and development of a standard mechanical interface, dynamic interface, the environment interface modules electromechanical integration products is a complex and promising work. If the development is set to slow down. VVVF integrated motor drive unit with vision, image processing, identification and location of the motor functions, such as integrated control unit. Thus, in product development, design, we can use these standards modular unit quickly develop new products. 1.4 Network As the popularity of the network, network-based remote control and monitoring of various technical ascendant. The remote control device itself is the integration of mechanical and electrical products, fieldbus technology to household appliances and LAN network possible, use a home network to connect various home appliances into a computer as the center of computer integrated appliances system, so that people in the home can be full enjoyment of the benefits of various high-tech, therefore, electromechanical integration products should be no doubt North Korea networks. 1.5 humanity Electromechanical integration of the end-use product is targeted, how to give people electromechanical integration of intelligent products, emotion and humanity is becoming more and more important, electromechanical integration products in addition to improving performance, it also urged the color, shape and so on and environmental coordination, the use of these products, or for a person to enjoy, such as home robot is the highest state of human-machine integration. 1.6 miniaturization Micro-fine processing technology is a necessity in the development, but also the need to improve efficiency. MEMS (Micro Electronic Mechanical Systems, or MEMS) refers to quantities can be produced by the micro-collection agencies, micro-sensors, micro actuators and signal processing and control circuit until interface, communication and power is one of the micro-devices or systems . Since 1986 the United States at Stanford University developed the first medical microprobe, 1988 at the University of California, Berkeley developed the first micro-motor, both at home and abroad in MEMS technology, materials and micro-mechanism much progress has been made, the development of all sorts MEMS devices and systems, such as the various micro-sensors (pressure sensors, micro-accelerometer, micro-tactile sensor), various micro-component (micro-film, micro-beam, microprobes, micro-link, micro-gear, micro-bearings, micro-pump , microcoil and micro-robot, etc.). 1.7 Integration Integration includes a mutual penetration of various technologies, and integration of various products of different structural optimization and composite, and included in the production process at the same time processing, assembly, testing, management, and other processes. In order to achieve more variety, small batch production of automation and high efficiency, the system should have a more extensive flexible. First system can be divided into several levels, allowing the system to function dispersed, and security and coordination with other parts of the operation, and then through software and hardware at various levels will be organically linked to its optimal performance, the most powerful. 1.8 with source of Electromechanical integration refers to the product itself with energy, such as solar cells, fuel cells and large-capacity battery. As on many occasions not be able to use electricity, which campaigns for the mechanical and electrical integration products, has a unique power source comes with the benefits. Sources with the integration of mechanical and electrical product development direction of. Green 1.9 The development of technology in peoples lives brought great changes in the material at the same time has also brought rich resources, deterioration of the ecological environment consequences. Therefore, people calling for the protection of the environment, regression, and achieving sustainable development in the concept of green products such calls have emerged. Green products is low-power, low-wood consumption, clean, comfortable, coordination and utilization of renewable products. In its design, manufacture, use and destruction of human beings should be in line with environmental protection and health requirements, electromechanical integration of green products is mainly refers to the use of time is not pollute the ecological environment, at the end of product life, and regeneration of decomposition products. 2 electromechanical integration in the application of technology in the iron and steel In the iron and steel enterprises, the integration of mechanical and electrical systems are at the core microprocessor, the computer, industrial computer, data communications, display devices, meters and the combination of technologies such as organic, assembled by the merger means for the realization of a large-scale integrated system create conditions for effective integration, enhanced system control precision, quality and reliability. Electromechanical integration technology in the iron and steel enterprises in the mainly used in the following areas:2.1 Intelligent Control Technology (IC) As a large-scale iron and steel, high-speed continuous and the characteristics of the traditional control technologies encountered insurmountable difficulties, it is necessary to adopt very intelligent control technology. Control technologies include intelligent expert system, neural and fuzzy control, intelligent control techniques in steel product design, manufacturing, control, product quality and diagnostic equipment, and other aspects, such as blast furnace control system, electric furnace and continuous casting plant, steel rolling system , steelmaking - Casting integrated scheduling system - rolling, cold rolling, etc. 2.2 Distributed Control System (DCS) Distributed control system uses a central command for the control of a number of Taiwan-site monitoring and intelligent computer control unit. Distributed control systems can be two, three or more levels. Using computers to concentrate on the production process monitoring, operation, management and decentralized control. With monitoring and control technologies, and the functions of distributed control system more and more. Not only can be achieved control of the production process, but also can be achieved online optimization, the production process real-time scheduling, production planning statistical management functions, as a measurement, control, integration of the integrated system. DCS control functions with diverse features and easy operation, the system can be extended, easy maintenance and high reliability characteristics. DCS is decentralized and centralized control monitoring, fault-minor, and the system has the chain protection features, the use of manual control system failure operational measures, the system is highly reliable. Distributed control system and centralized control system compared to their more functional, with a higher level of security. Is the large-scale integration of mechanical and electrical systems main trend. 2.3 Open Control System (OCS) Open Control System (Open Control System) is the development of computer technology led by the new structure concept. Open means a standard for the exchange of information in order consensus and support this standard design systems, different manufacturers products can be compatible and interoperable, and the sharing of resources. Industrial control systems through open communication network so that all control equipment, management, computer interconnections, to achieve control and management, administration, integrated decision-making, through fieldbus to the scene and control room instrumentation control equipment interconnected to achieve integrated measurement and control of. 2.4 Computer Integrated Manufacturing System (CIMS) CIMS is the iron and steel enterprises will be and the production and operation, production management and process control connecting to achieve from raw materials into the plant, production and processing of shipments to the entire production process and the overall integration process control. Currently iron and steel enterprises have basically achieved process automation, but this kind of automated island of single automation lack of information resources and the sharing of the unified management of the production process, can hardly meet the requirements of the iron and steel production. Future competition iron and steel enterprises is the focus of many varieties, small batch production, cheap and of good quality, timely delivery of goods. In order to improve productivity, saving energy, reducing staff and the existing inventory, accelerate cash flow, production, operation and management of the overall optimization, the key is to strengthen the management, access to the benefits of raising the competitiveness of businesses. The United States, Japan and some other large-scale iron and steel enterprises in the 1980s has been widely realization of CIMS. 2.5 Fieldbus Technology (FBT) Fieldbus Technology (Fied Bus Technology) is the connection settings in the field of instrumentation installed in the control room and control devices for digital, bi-directional, multi-station communication link. Fieldbus technology used to replace the existing signal transmission technology (such as 4 to 20 mA, DC DC transmission), it will enable more information in the field of Intelligent Instrumentation devices and higher-level control system in th

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号