【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

随着我国国民经济的快速发展,越来越的汽车进入家庭,使得我国城市停车难问题日益加剧。立体车库成为目前解决停车难问题的重要方式之一,其中以升降横移式立体车库应用最为广泛。

本次设计的主要内容是自动立体车库的结构设计。而自动立体车库按结构可分为升降横移类、垂直循环类、水平循环类、平面移动类、巷道堆垛类、垂直升降类、简易升降类等。本文主要对两层式升降横移自动立体车库进行详细的结构设计和对关键部位受力分析并校核。

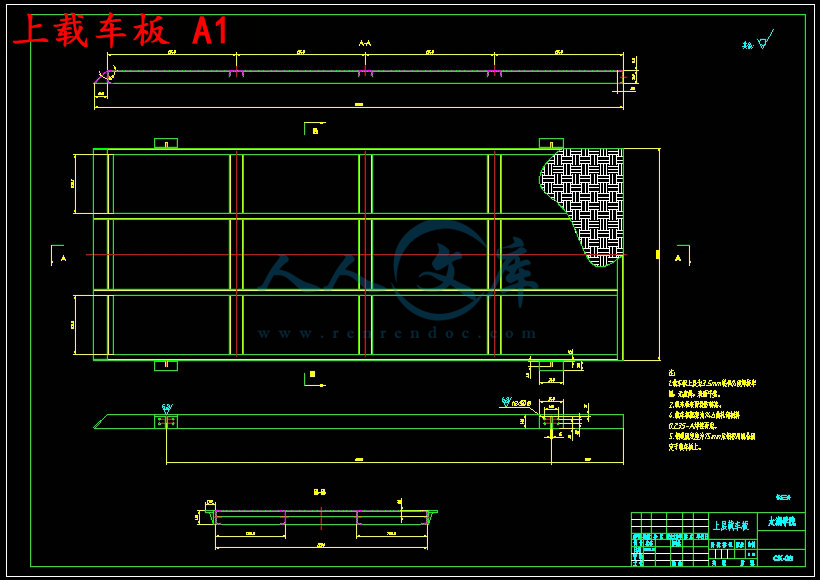

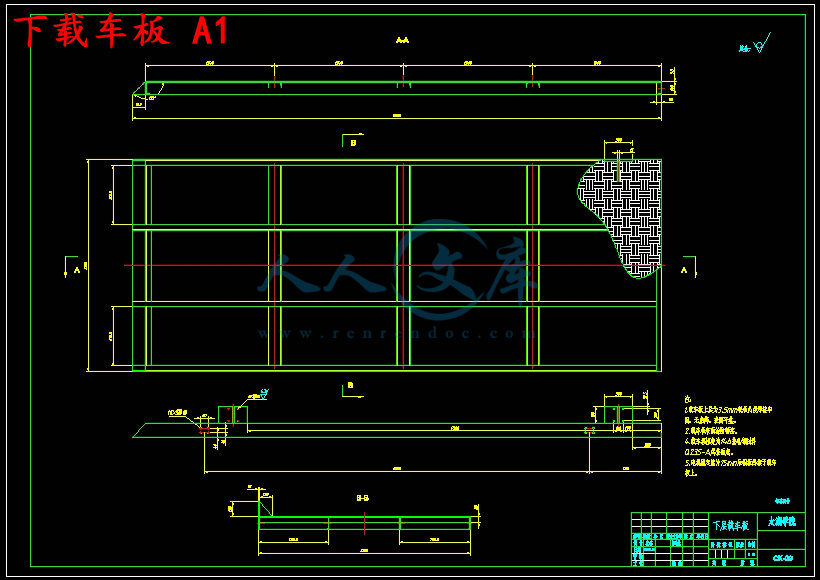

四柱结构型式钢结构车库由于其结构较为简单有较大使用范围,本文对其进行详细设计。文中主要对自动立体车库的横梁,纵梁,支撑柱以及载车板进行详细的受力分析和校核。另外,本文中的自动立体车库采用了液压系统进行传动,区别与采用电动机驱动的自动车库。由于液压传动的优点,车库在升降或是横移过程中会更加稳定,减少了运动中所产生的噪音,使其适用于更多场合。在车库的设计中还介绍了车库运行中重要的安全防护装置。

除此之外,还绘制了总装图、零件图。

关键词:自动立体车库;结构设计;液压

Abstract

With the development of the national economy in our country, more and more cars are entering the common families. Stereo garage becomes the first choice for solving the problems of hard parking. Especially, lift-sliding type stereo garage is the most widely used.

The main content of this design is the design of automatic stereo garage, the stereo garage is including lift-sliding type, vertical circulation type, level of circulation, plane mobile, laneway type, vertical lifting, simple movements and etc. The main contents of this paper is about the design structure of two layers of lifting and transferring automatic stereo garage and the force analysis and check by the key parts of stereo garage.

Four-column type steel structure garage has a large range of use because of its simple structure. The main content of this paper is the force analysis and check by the beams, stringers, support columns and car carrying boards. In addition, automatic stereo garage use hydraulic system for driving, it has difference between using the motor-driven automatic garage. Because of the advantages of hydraulic transmission, the garage will be more stable in process. This makes it suitable for more occasions. The design of the garage is also introduced the safety protection device in the running of garage.

In addition, the paper includes drawn up the assembly diagram, parts diagram.

Keywords: automatic stereo garage; structure design; hydraulic

目 录

摘 要 III

Abstract IV

目 录 V

1 绪论 1

1.1 本课题研究的内容及意义 1

1.2国内外的发展概况 2

1.3本章小结 4

2 自动立体车库的总体设计方案 5

2.1 升降横移自动立体车库选型 5

2.2 自动立体车库提升方式的选择 6

2.3 自动立体车库的其他部件 6

2.4 自动立体车库的设计参数 7

2.5 二层式升降横移自动立体车库结构设计的内容及要求 7

2.6 本章小结 7

3 自动立体车库主体框架设计 8

3.1立体车库的工作原理 8

3.2自动立体车库钢结构设计 8

3.2.1 支撑柱设计 9

3.2.2 横梁受力分析 12

3.2.3 纵梁受力分析 13

3.3 载车板受力分析校核 15

3.4本章小结 16

4 自动立体车库的传动系统 17

4.1 上层载车板提升装置设计 17

4.1.1 升降传动系统设计 17

4.1.2 升降液压系统设计 19

4.1.3 升降液压系统链轮设计 20

4.1.4 升降液压系统传动轴设计 21

4.2 横移液压系统设计 22

4.3本章小结 24

5 车库的配套系统 25

5.1 安全系统 25

5.2 立体车库的控制系统 26

5.3 本章小结 28

6 结论与展望 29

6.1结论 29

6.2不足之处及未来展望 29

致 谢 30

参考文献 31

附 录 32

1 绪论

1.1 本课题研究的内容及意义

本课题研究的内容是:自动立体车库的结构设计,包括自动立体车库的总体方案设计,有关零件部件的选型计算,结构强度校核及液压系统设计,并绘制出装配图和零件图纸。

本课题研究的意义是:自动立体车库是我国的新兴产业,具有广阔的发展前景。随着我国经济快速的发展,城市交通拥堵和停车难的问题成了影响城市发展的重要因素之一,传统的车库己经不能适应城市发展的要求,再加上我国汽车保有量的不断增加,自动立体车库成为解决这一问题的必然途径[1]。机械式立体车库具有空间利用率高,节省城市有限的土地资源;具有建造成本较低、建造周期较短;车辆停放入车库快速便捷、自动车库更加安全,还具有节约能源等优点。同时自动立体车库还可以在有限的土地上停放更多的车辆,便于集中管理,减少管理费用和人员等的优势,在各个小区或空地都可以根据当地的实际情况进行立体车库的建设,可大大缓解这些地方停车难的问题,这对现在车库紧张的小区和其他人员较多的公共场所提供了很好的解决方法。因此,机械式立体车库具有广阔的应用前景。

而自动立体车库的结构设计是车库建设及运行的重要环节,其设计水平与质量直接影响到用户的安全和建造成本。合理的结构设计可最大限度的利用有限的土地空间,缓解城市中停车难的问题。而目前我国自动立体车库加工生产厂家没有统一的标准:大多数自动立体车库行业的生产厂家大多以国外现有产品或技术为基础进行制造,对产品创新开发能力差,没有自己的知识产权;我国对立体车库的新技术引入研究较少,而对立体车库的主体结构框架钢研究和优化才刚刚起步,不能形成较大的生产加工规模。机械式自动立体车库种类较多,按照现在立体车库的发展,可将它分为巷道堆垛式立体车库,垂直升降式立体车库,垂直循环式立体车库,圆形水平循环式立体车库等。

根据运行方式和结构特点可分为:升降横移式立体车库,水平循环式立体车库,垂直循环式立体车库,多层循环式立体车库,堆垛式立体车库,平面移动式立体车库,垂直升降式立体车库,简易升降式立体车库等八大类[2]。

1、升降横移式立体车库:整机特点,可有效利用空间,提高空间利用率达数倍。存取车快捷便利,其结构使用跨梁结构设计,使车辆出入无障碍。采用PLC控制,自动化程度高,人机界面好,多种操作方式可选配,操作简便,同时环保节能,低噪音。但下层车库必须有一空位用于车库升降。

川公网安备: 51019002004831号

川公网安备: 51019002004831号