目 录

1前言 1

2 组合机床总体设计 3

2.1 组合机床工艺方案的制定 3

2.1.1工艺基准面的分析 3

2.1.2加工工艺的分析 3

2.1.3 确定机床完成工艺时的一些限制 3

2.2 组合机床配置型式的选择 3

2.2.1组合机床配置型式 3

2.2.2 选择机床配置型式和结构方案的一些问题 3

2.3确定切削用量及选择刀具 4

2.3.1选择切削用量 4

2.3.2 计算切削力、切削扭矩及切削功率 6

2.3.3选择刀具结构 10

2.4组合机床总体设计--三图一卡 10

2.4.1被加工零件工序图 10

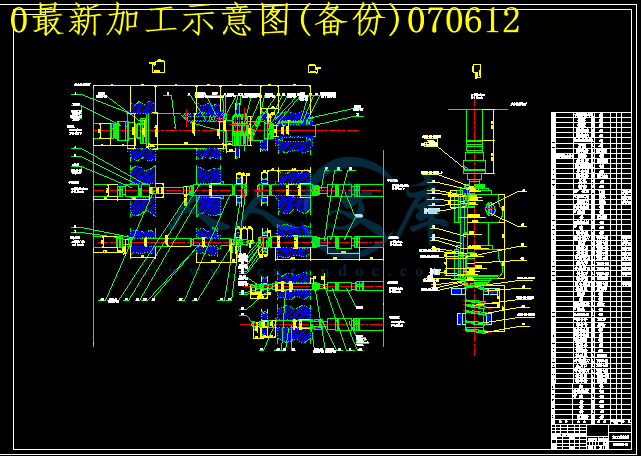

2.4.2 加工示意图 11

2.4.3机床尺寸联系图 13

2.4.4机床生产率计算卡 16

3 夹具设计 18

3.1夹具设计的基本要求和步骤 18

3.1.1夹具设计的基本要求 18

3.1.2夹具设计的步骤 18

3.2定位方案的确定 19

3.2.1零件的工艺性分析 19

3.2.2定位方案的论证 19

3.2.3误差分析 20

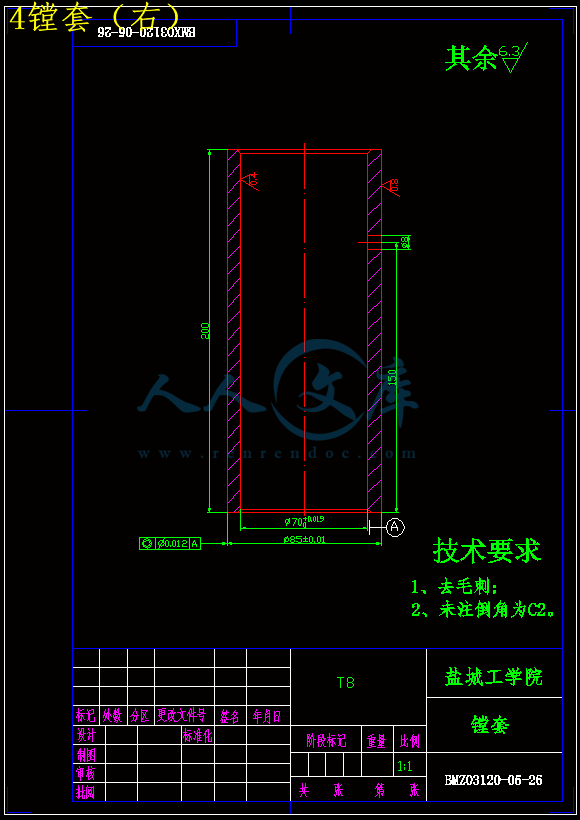

3.2.4导向装置 22

3.3夹紧方案的确定 22

3.3.1夹紧装置的确定 22

3.3.2夹紧力的确定 24

3.3.3 油缸的选择 25

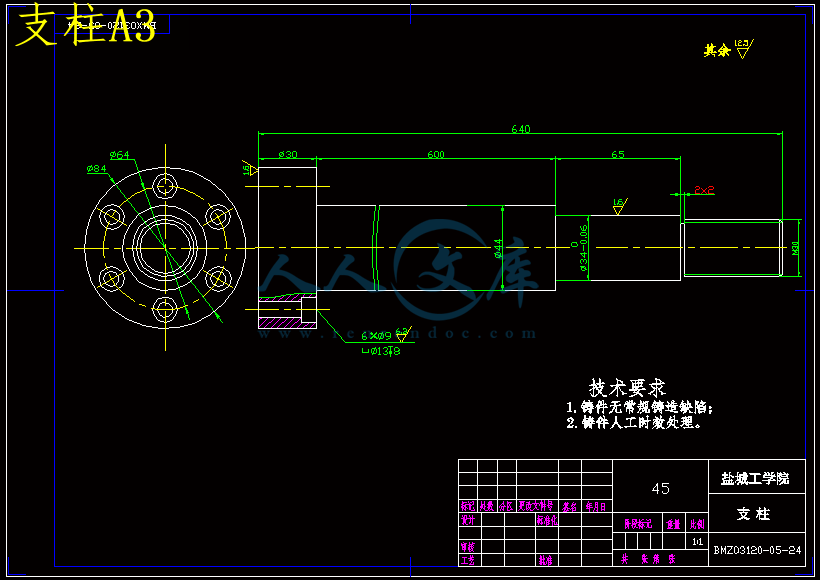

3.4夹具体的设计 26

4结论 27

参考文献 28

致谢 29

附录 30

1前言

组合机床是根据加工需要,以大量通用部件为基础,配以少量专用部件组成的一种高效专用机床。组合机床主要用于平面加工和孔加工。平面加工包括铣平面、车端面、刮平面;孔加工包括钻、扩、铰、镗孔以及倒角、切槽、攻螺纹等。组合机床最适宜于加工各种大中型箱体类零件,如气缸体、气缸盖、变速箱体等零件。目前,组合机床在汽车、拖拉机、仪器仪表、军工及缝纫机、柴油机、纺织、航空等部门,应用越来越普遍。组合机床主要适用于棱体类零件和杂体的孔面加工,生产效率高,研制周期短,便于设计、制造和使用维修,配置灵活,且自动化程度高,劳动强度低。在将来,组合机床将向五个方面发展:高速化、高精度化、复合化、高科技含量化以及环保化。同时,在自动化方面,将会进一步提高。

组合机床的设计,目前基本上有两种情况:其一,是根据具体加工对象的具体情况进行专门设计,这是当前最普遍的做法。其二,随着组合机床在我国机械行业的广泛使用,广大工人总结自己生产和使用组合机床的经验,发现组合机床不仅在其组成部件方面有共性,可设计成通用部件,而且一些行业在完成一定工艺范围内组合机床是极其相似的,有可能设计为通用机床,这种机床称为“专能组合机床”。这种组合机床就不需要每次按具体加工对象进行专门设计和生产,而是可以设计成通用品种,组织成批生产,然后按被加工的零件的具体需要,配以简单的夹具及刀具,即可组成加工一定对象的高效率设备。

在组合机床设计过程中,为了降低组合机床的制造成本,应尽可能地使用通用件和标准件。目前,我国设计制造的组合机床,其通用部件和标准件约占部件总数的70~80%,其它20~30%是专用零部件。考虑到近年来,各种通用件和标准件都出台了新的标准及标注方法,为了方便以后组合机床的维修,整个组合机床的通用件和标准件配置,都采用了新标准。

本毕业设计课题是ZH1105柴油机气缸体三面钻镗孔组合机床的设计,来源于江动集团江淮动力股份有限公司。本组合机床有四人完成,本人将进行总体及夹具设计。组合机床的设计过程包括前期调研,总体设计,技术设计和工作设计。总体设计,包括工艺分析、定位基准的选择、滑台型式的选择、通过选择切削用量选择刀具;还需编制“三图一卡”,即加工工序图,加工示意图,机床联系尺寸图,生产率计算卡。技术设计就是根据总体设计已经确定的“三图一卡”,设计主轴箱等专用部件正式总图;工作设计即绘制各个专用部件的施工图样,编制各零部件明细表。

夹具设计是组合机床设计中的一个重要组成部分,是按照某一道工序的加工要求,把一些事先制造好的标准件和部件进行组装而成的夹具,夹具通常由使用单位根据要求自行设计和制造,适用于产品固定且批量较大的生产中。其设计过程主要包括:对机床总体设计方案的论证、定位夹紧方案的论证、定位误差分析、夹紧力的计算、夹紧缸的选用。本组合机床夹具属于专用夹具,其定位装置、夹紧装置、夹具体、导向装置和其它一些元件,均为自行设计、加工。在设计中,尽量考虑使用标准件和通用件,来缩短设计周期,减少机床后续改造的零件报废率,提高经济效益。

通过设计,本组合机床能满足加工需求,保证加工精度,机床运转平稳,工作可靠,结构简单,装卸方便,便于维修、调整。各动力部分采用了电器控制,使用操作方便。提高了工作效率,预计能达到设计要求。

2.组合机床总体设计

2.1组合机床工艺方案的制定

2.1.1 工艺基面的分析

选择工艺基面和夹压部位是制定工艺方案的极其重要的问题。工艺基面选择的正确,将能实现最大限度的工序集中,从而减少机床台数,也是保证加工精度的重要条件。

2.1.2 加工工艺的分析

分析被加工零件的工艺,亦是制定工艺方案的极其重要的问题,我们要认真的分析被加工零件加工工艺的需要和组合机床完成工艺的可能,正确的确定组合机床的加工方案。

2.1.3 确定机床完成工艺时的一些限制

a. 孔间中心距的限制 在确定组合机床完成工艺时,要考虑可同时加工的最小孔中心距。由于主轴箱的主轴结构的设备导向的需要,所以近距离孔能否在同一多轴箱上同一工位加工受其限制。

b. 工件结构工艺性不好的限制 有些工件结构工艺性不好,如箱体多层壁上的同轴线的孔径中间大两头小时,则进刀困难。当孔径大于Ф50mm时,可采用让刀的办法。多层壁同轴孔,为便于布置中间导向装置,孔中心离箱体侧壁间距离也应够。

2.2 组合机床配置型式的选择

2.2.1 组合机床的配置型式

组合机床有大型和小型两种,大、小型组合机床虽有其共性,但又都有其特殊性。无论是适用范围,配置型式,通用部件和驱动方式都各有特点。

a.工位组合机床 单工位组合机床通常是用于加工一个或两个工件,特别适合用于大中型箱体的加工。根据配置动力部件的数量,这类机床可以从单面或同时从几个方面对工件进行加工。

b.工序组合机床 很多组合机床是按工件能够变位来配置的,工件的变位有手动和机动的方式。这类机床工序集中程度高,如回转多工位机床的辅助时间和机动时间相重合,生产效率高,适用于大批量生产、需要多部位加工的中小零件。

2.2.2 选择机床配置型式和结构方案的一些问题:

A. 被加工零件的特点对配置型式和结构方案的影响

a.加工精度要求的影响;

b.机床生产率的影响;

c.被加工零件的大小、形状、加工部位特点的影响。

B. 机床配置型式和结构方案应注意的其它问题

a. 适当提高工序集中程度 在确定机床的配置型式和结构方案时,要合理 解决工序集中的问题。在一个动力头上安装多轴,同时加工多孔来集中工序,是组合机床最基本的方法,在一台机床上主轴数量有达150根左右的。但是,也不应当无限制的增加主轴数量,要考虑到动力头及主轴箱的性能和尺寸,并保证调整和更换刀具的方便性。

b. 注意排除切削和操作使用的方便性 在多工位机床上应特别注意前一道工序遗留在孔中的切屑对后一道工序的影响。在选择多面机床时,应慎重考虑操作的方便性,要合适的确定装料高度,对于加工一般箱体件带固定式夹具的机床,一般采取850毫米,对于较小的工件可稍高一些。

c.夹具形式对机床方案的影响 选择机床配置型式时要考虑夹具结构的实现可能性和工作的可靠性。在决定加工一个工件的成套机床或流水线上个机床的型式时,还应当注意,使机床与夹具的形式尽量一致,尤其是粗精加工机床。这样不仅有利于保证加工精度,而且便于设计、制造和维修,也提高了机床之间的通用化程度。

川公网安备: 51019002004831号

川公网安备: 51019002004831号