目 录

1 前 言 1

2 总体设计 3

2.1滚齿机工作原理 3

2.1.1加工直齿轮时机床的运动和传动原理 3

2.1.2加工斜齿圆柱齿轮时的运动和传动原理 3

2.2拟定选择传动方案 4

2.3 主切削力的估算及电动机的选择 8

3 机床床身装配结构设计 9

3.1 滚齿机床身的特性 9

3.2 滚齿机床身的结构分析 9

3.3 床身材料的选择 10

3.4 床身导轨及机床的润滑 11

4 差动机构设计 13

4.1 总传动比的计算 13

4.2 传动比的分配 13

4.3 设计计算 14

4.3.1 螺旋伞齿轮的设计 14

4.3.2 运动合成机构设计 15

4.3.3差动蜗轮设计 16

4.3.4圆柱直齿轮的设计 20

5 结束语 25

参考文献 26

致 谢 27

附件清单 28

1 前 言

齿轮加工机床是一种技术含量高而且机构复杂的机床系统,由于齿轮使用的量大面广,齿轮加工机床已成为机械等行业的关键设备。特别是,随着汽车行业的高速发展,对齿轮的需求量日益增加,对齿轮加工的效率、质量及加工成本的要求愈来愈高,使齿轮加工机床在汽车、摩托车等行业中占有越来越重要的作用。滚齿机是齿轮加工机床中的一种,其占齿轮加工机床拥有量的40%~50%。它主要用来加工圆柱齿轮和蜗轮等。传统滚齿机在加工过程中有以下特点:

a.滚削钢齿轮时,应用切削液可提高刀具寿命,改善加工表面的质量和利于排出切削热而不致引起机床的热变形;

b.机床漏、混油严重;

c.加工成本高;

d.生产效率低下,加工质量差,难以满足现代企业生产的要求。

近几年,我国在滚齿机设计技术方面研究的主要内容经历了从传统机械式滚齿机通过数控改造发展为2-3轴(直线运动轴)实用型数控高效滚齿机,到全新的六轴四联动数控高速滚齿机的开发。滚齿机加工(钢件)全部采用湿式滚齿方式。目前,国内主要滚齿机制造商重庆机床厂及南京二机床有限责任公司生产的系列数控高效滚齿机已采取全密封护罩加油雾分离器和磁力排屑器的方式部分地解决环保问题。世界上滚齿机产量最大的制造商——重庆机床厂从2001 年开始研究面向绿色制造的高速干切滚齿技术,2002年初研制成功既能干切又能湿切的YKS3112六轴四联动数控高速滚齿机,2003年初又开始研制面向绿色制造的YE3116CNC7高速干式切削滚齿机,即将进入商品化阶段。

在提高生产效率、降低制造成本的同时,做到环境保护、清洁加工是当前国外先进发达国家对机床研究的最前沿技术。如美国、德国及日本,他们的部分公司生产的滚齿机都是全数控式的,中小规格滚齿机都在朝着高速方向发展,所有高效机床均采用了全密封护罩加油雾分离器及磁力排屑器的方式部分地解决环保问题。面向绿色制造的先进滚齿机主要有带有全密封护罩和油雾分离器的湿切滚齿机、低温冷风切削滚齿机、高速干式切削滚齿机等类别,其中高速干式切削滚齿机以其高速、高效、不使用切削液、单件生产成本低等优势将成为面向绿色制造的滚齿机今后发展的主要趋势。

随着工业的发展,先进技术的不断更新进步,对加工设备的要求也不断提高,在机床的设计中,需要对其组成部件进行严密的分析和计算。机床床身等支承件的重量要占机床总重量的80%-85%,因此对支承件的单位重量、刚度提出了较高的要求。在重量轻的条件下,需要保证支承件具有足够的静刚度。所以对支承件材料的选择、分布、支承件壁厚和开孔位置的合理性提出了要求,必须进行分析计算。

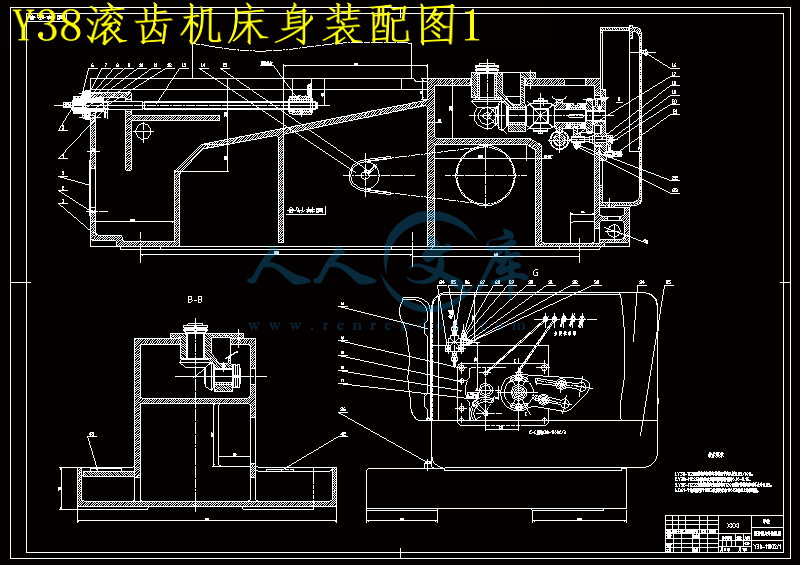

我所设计的课题来源于生产实践,是滚齿机床身部件结构设计。该床身为箱形结构,与底座铸成一个整体,左上部是方形导轨,留安放工作台之用;右上部是用来固定刀架、立柱;床身内部安装差动机构;床身后端连出分齿挂轮架;背面为主传动牙箱;左面底盘为冷却箱;右面底盘为润滑油箱;主电动机和冷却电动机都安装在床身上,方形导轨中间装一丝杆供移动工作台之用,分度挂轮架处的手柄供铣正齿轮或者斜齿轮时操纵使用。床身结构的静、动态特性对床身的机械特性、机床产品质量、机床的动态加工精度具有重要意义。

通过市场调查,对国内现有机型进行对比分析。选择适合于我国目前的生产水平使用的机型作为参考,改进其不足,以达到各方面的要求。床身结构的静、动态特性与机床产品的整体性能有着密切的关系,提高床身的机械特性,对于提高机床产品质量,保证机车的动态加工精度具有重要意义。传统的结构大件设计方法,往往仅注重床身件静态性能、制造工艺性以及外形美观协调等方面的要求,而忽略了它对产品动态性能的影响。结构件的动态特性与其尺寸、形状、材料等有着密切关系。我所设计的滚齿机床身,其技术要求如下:

a.机床能满足强度、刚度、寿命、工艺性与经济性等方面的要求;

b.机床要求运行平稳、工件可靠、结构合理、装卸方便、便于维修与调整;

c.机床应能满足加工要求,保证加工精度。

本次设计的滚齿机床身的预期效果是:

a.能满足机床的基本要求,如强度、刚度、寿命、工艺性与经济性等;

b.运行可靠,便于维修和装卸;

c.保证加工质量和精度要求。

由于我国的工业水平发展与发达国家相比还有一定的差距,齿轮加工生产在质量、精度等方面还需要进行提高。因此必须对现有机床进行优化改造。当前,齿轮加工行业对制造精度、生产效率、质量及清洁等都有着非常高的要求,所以我们必须集思广益,通过学习、研究来进行机床的设计。

从毕业设计布置任务开始,就必须投入全部精力,因为整个设计过程中必须考虑各方面的问题。首先,对滚齿机的形状和工作原理都很陌生,必须要到工厂参观实习;其次,所学的理论知识只是一些最基本的机械常识,根本不能达到设计的要求。因此,还要查阅大量的资料、图纸、说明书等信息来补充自己的不足之处。要顺利完成这次设计,对我们提出了以下要求。

扎实的专业知识是设计的基本条件,并且要做到开拓创新、举一反三。整个设计也就是不断复习和学习的过程。其次要有丰富的实践经验,因为只靠资料是不够的,通过指导老师的带领,我们到盐城市机床厂进行参观实习,并且向企业的技术人员询问相关的原理。只有这样,设计的成果在合理性、经济性、工艺性、实用性等方面才能满足要求。

2 总体设计

2.1滚齿机工作原理

滚齿加工是依照交错轴螺旋齿轮啮合原理进行的。用齿轮滚刀加工的过程,就相当于一对螺旋齿轮啮合的过程。将其中的一个齿轮的齿数减少到几个或一个,螺旋角增大到很大,成螺杆状,再开槽并铲背,使其具有切削性能,就成了齿轮滚刀。机床使滚刀和工件保持一对螺旋齿轮副啮合关系作相关旋转运动时,就可在工件上滚切出具有渐开线齿廓的齿槽。滚齿时,切出的齿廓是滚刀切削刃运动轨迹的包络线。所以,滚齿时齿廓的成形方法是展成法,即成形运动是滚刀旋转运动和工件旋转运动组成的复合运动,这个复合运动称为展成运动。再加上滚刀沿工件轴线垂直进给运动就可切出一个齿长。

川公网安备: 51019002004831号

川公网安备: 51019002004831号