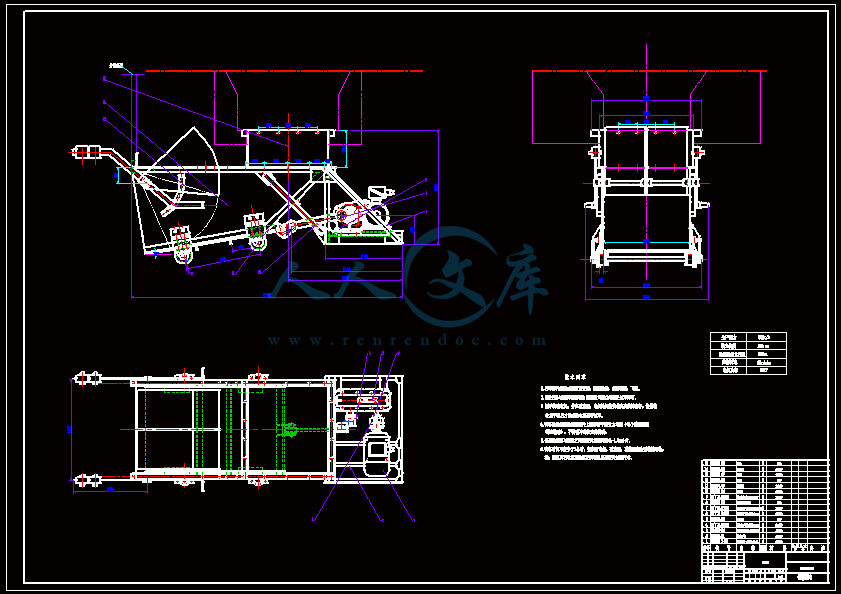

GMJ880往复式给煤机设计【含CAD图纸、说明书文档】

收藏

资源目录

压缩包内文档预览:

编号:15967418

类型:共享资源

大小:1.76MB

格式:ZIP

上传时间:2019-03-10

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

含CAD图纸、说明书文档

GMJ880往复式给煤机设计【含CAD图纸

说明书文档】

- 资源描述:

-

- 内容简介:

-

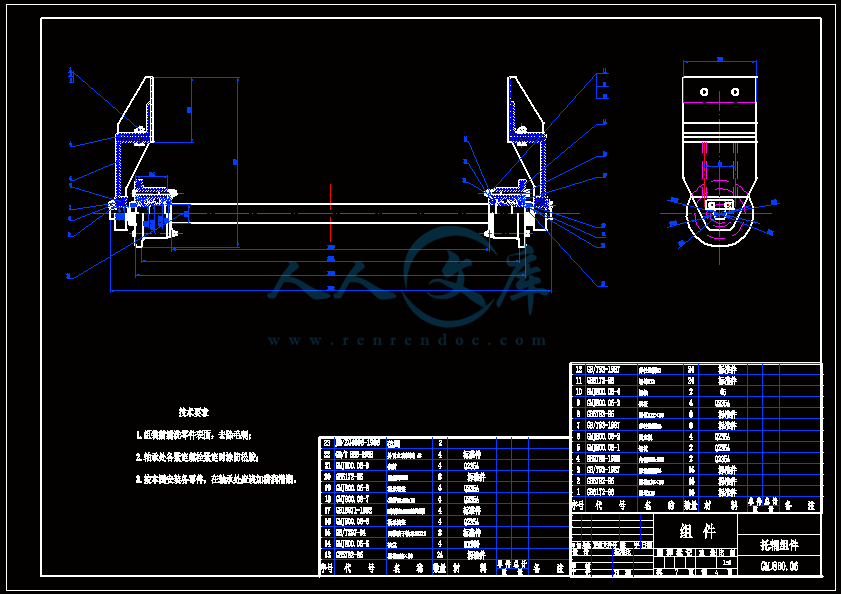

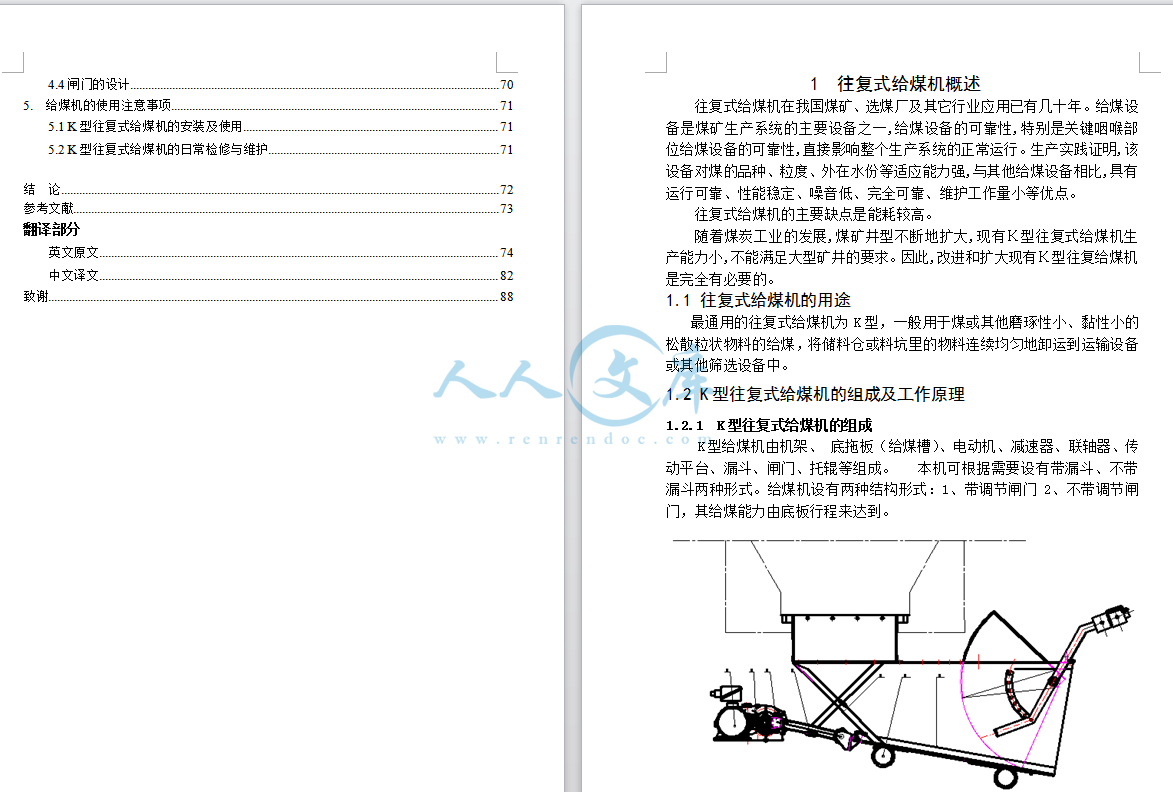

毕业论文任务书任务下达日期:20* 年 2月 28 日毕业论文日期:20*年 3 月 7 日 至 20*年 6 月10日毕业论文题目:往复式给煤机毕业论文专题题目:毕业论文主要内容和要求:主要内容:了解往复式给煤机的用途、构成及工作原理,设计一台单曲柄往复式给煤机。设计参数:给煤量:880t/h ;最大给料粒度:500mm。基本要求:1.设计完成总体方案设计;2.设计完成主减速器装配图;3.完成主要传动组件、零件的工作图设计;4.编写主要零件的加工工艺;5.编写完成整体设计计算说明书。院长签字: 指导教师签字:英文原文Conditions, improve and energy-saving measures Reciprocating coal feederEquipment of the coal mine production system is one of the main equipment, the reliability of it, in particular parts of the throat is the key to the reliability of such equipment, will directly affect the normal operation of production systems. At present, Chinas coal mines to the coal used primarily is reciprocating coal feeder and coal to power vibration machine, In recent years, the electric machine vibration to the development of coal faster serialization and standardization has been formed; and reciprocating coal feeder 60 from the 20th centurys stereotypes, the series of improvement and expansion of the work has been carried out. With the rapid development of the coal industry, coal type is also growing well, the existing reciprocating coal feeder Coal is no longer able to meet the selection requirements of production systems. It is precisely for this reason that,We are on the basis of the coal feeder for the use of a large number of studies,development of the large-scale reciprocating coal feeder, include 800t / h, 1000t / h, 1500t / h, 2000t / h, Reciprocating the earliest development of coal feeder 60 in the early 20th century, 70 years, based on the NGW, the replacement of the drive into K series, and are still in use. Reciprocating coal feeder of K series has a total of five models: K-0, K-1, K-2, K-3, K-4, K-4 is the largest production capacity, but still only 590t / h. The development of Reciprocating coal feeder has no different between abroad and national, it doesnt have a higher technological content, but the price is 4 to 5 times in similar products.1、The own structure superiority of reciprocating coal feeder1) Structure simple, the service quantity is small .In the reciprocating coal feeder, the electric motor and Reduce use the standard letter, other majorities are the Welding parts, the vulnerable part are few, Under bad conditions in the coal mine, its serviceability deeply Praised by the use of units.2) The performance is stable The reciprocation type stoker to the coal trademark, the size composition, request and so on moisture content, physical property is lax, when comes to expect the non-uniformity, the moisture content does not stabilize also clamps has the big lump coal, Rubber Belt, the wood and the steel wire, and so on ,still could the normal work.3) The noise is low the reciprocation type stoker right and wrong Vibration has the source for material equipment. its noise only to have the electric motor and the reduction gear, but these two noises very are all low .Especially in the mine shaft or Bunker and so on the enclosed place,the noise is unable to proliferate, this point is electrically operated is unable for the material machine to achieve.4) Installs conveniently, is highly small The reciprocation type stoker generally installs in Bunker the warehouse mouth, does not need other configuration warehouse mouth strobe distill trough and the support of motor, the installment may reach ones goal instantly, the adjustment work load is small, but electrically operated stoker because cannot directly withstand the warehouse pressure, needs moreover to place the warehouse mouth transition Chute under, compares, the reciprocation type stoker hold highly slightly, has saved the floor space and the investment.2、Large-scale reciprocation types deceive the coal machine structural style characteristic .We through carry on the analysis to the former stoker investigation, has carried on the thorough computation to the structure pattern, to the essential stress spot like tank, the double connecting rod, the base held the roller and so on to carry on the stress analysis, carried on the examination computation using the finite element principle. Altogether has following five characteristics.1) Entire machine uses the frame Themselves to be possible to unload the type Because considered the mine shaft transportation the convenience and the mine shaft industry and mining limit, entire machine uses a minute writing style, moreover considered the mineshaft welding inconvenient, uses the bolt vice- joint, the side bar to consider the external drum the possibility and the wear the need, lays down in the flank Reinforced inside Lining, strengthened the whole rigidity and the intensity.2) Increases Dao ban the guidance and the blocking In makes the reciprocal motion under Dao ban to additionally build several groups of requests rollers wheel, on the one hand changes Dao ban the sliding friction for to roll the friction, reduced the attrition, on the other hand also causes Dao ban the rigidity enhancement. Moreover, for prevented Dao ban is transporting Moves in the process to have runs the leaning phenomenon, in Dao ban two sides installments guidance wheel. 3) Uses the hyperbolic trough drive type The stoker drive uses the hard tooth face reduction gear,ordinary plug shaft coupling (but non- fluid strength coupler), double output shaft form, like this, not only reduced the cost moreover to cause the unilateral Axis radial direction load only is the bottom surface thrust force one half, is carried the condition big improvement, moreover, further enhanced the stability which Dao ban moved.4)Carries on the optimization to the Dao ban structure Formerly K series stoker plate strobe, the material had many problems in shipping, for estimated could not enhance the key also lay in this. Therefore, we have carried on the optimization to Dao ban designs for the steps and ladders, Not only caused the material process load to enlarge, more over the Dao ban itself intensity also obtained further enhances.5) Changes the fan strobe for the manual plate strobe Controls expects how many the key to be decided by the strobe,the strobe always uses the fan structure in the former K series, but discovered from the field use, the fan strobe and the warehouse wall frequently bump, the scene often when installs the strobe can not but knock the warehouse wall a part, causes the warehouse wall the intensity to weaken, based on, we uses the manual plate strobe,matches the guidance wheel under the damper plate, simultaneously has the positioning device on the axis.3. Reciprocating the transformation of coal feeder3.1 、The transformation of Link(1)Transformation of the former coal feeder K4 transmission parts .As shown in Figure 1, The drive for: The Reducer driven by a motor ,and Crank driven by the reducer, Qu Shui driven the floor of reciprocating coal feeder do a straight line reciprocating motion.1、Motor 2、Reducer 3、Crank 4、Bearing 5、Qu Shui Fig1 Transformation of the former coal feeder transmission parts diagramAs a result of the use of coal , it more easily fit into the bearing impurities, the poor maintenance will damage bearings, the damaged bearings would be detect serious mechanical, electrical accident if failed to timely detection,either Qu Shui is to pull off or motor is burning. If shortage of the motor and spare parts and components, it will occur on a longer time, so transformation is necessary (for this transformation).(2) Transmission parts of K4 reciprocating coal feeder after improvedTransmission principle has not changed, Figure 2, Changed the eccentric into crank, The circumference of the eccentric into a tank at the top of open, Linked with a good off-type tungsten deposit matching tile sets, tile sets and through the connecting shaft connected to the coal feeder floor, Is actually an eccentric crank into the sliding bearings, When the motor drive reducer and eccentric wheel rotation, the eccentric wheel with the tile sets with connections on the drive shaft to the coal feeder and do a straight line reciprocating motion plate, reaching to the purpose of coal.1、motor 2、Reducer 3、Eccentric 4、Sets of gold-watt tungsten5、Connecting shaft 6、Oil CupFig2 Modified coal feeder transmission parts diagram3.2 Structural Analysis and Improvement(1) Improve diskK series reciprocating coal feeder plate stroke adjustment is achieved through the disc, Structural diagram of its components as shown in Figure 3, According to long-term use found that the parts have the following shortcomings: D hole and journals connected with the use of the transition, the actual connection is not reliable in use, the journal often off; the pins connected with hole O1 often break, it can not guarantee that the needs of the trip back and forth movement. In view of the above shortcomings, we improved the disc as follows in actual use: D-hole match with the journal use space , and to expand the Chamfer of D hole, welding the disk with the journal. In this way, not only increase the reliability of the connection, but also facilitate the replacement of damaged parts. According to crank structure, in diameter position with o1, additional o2, o3, o4 3 months Hole, As shown in Figure 2. after location the hole and 5, when the hole o1 and 1, o1 and 2, o1 and 3, o1 and 4 through the fastening pin, the respective o4 and 4, o3 and 4, o2 and 4, o4 center coincide with the 1 . Thus the connection about Crank with the disc can be achieved three pin fastening, an increase of the reliability of connection.Fig3Diagram of disk(2) Improvement of the disc crankBy the above analysis, if the crank in Figure 4 into a 60 hole 1,2,3,4 are cloth, the holes in the disk o1, o2, o3, o4 also as 60 are cloth, can be multi-pin fastening (analysis omitted). Another way is change crank disk body into a flange-type connection, as shown in Figure 5. O with the crank journal hole distance o1 is eccentricity, eccentricity is calculated asR2=R21+R22-2R1R2icos360/nFormula in REccentricity, That is, half the trip back and forthR1Crank eccentricityR2Journal of the hole disk eccentricitynThe number of bolt holesThe range of i from 1,2, ., n, In this way, can be flange-type crank drive mechanism of the series size, travel back and forth in a certain range can be selected arbitrarily.Fig4Diagram of crank and disk1 5Hole6Crank7DiscFig5Crank and disk mechanism after improved(3) Improvement of gate fan-shapedK series fan gate of the coal feeder is adjustment inconvenience, high failure rate, after card in prison by the debris was not easy to restore, we will change the flat fan-shaped gate into flatboard gate in the actual use. Welding angle iron on the side board, as a channel with the flat gate, their number can be change in order to achieve adjustment to the amount of coal, then achieve the purpose of removal of large pieces of debris.(4) Anti-wear lining side increaseK Series medial side to the coal machine wear, and replacement costs and time-consuming work, and to the security threats brought about by the construction personnel. We increase Anti-wear to improve the life of the reciprocating coal feeder, the connection of lining and side panels use welding, in addition to peripheral welding, the intermediate slotted plug with the solder side.4、 Power consumption analysis and energy-saving measures of Reciprocating coal feederPower consumption analysis and energy-saving measures of Reciprocating coal feeder used ultra High Molecular Weight Polyethylene material for lining, Friction coefficient of coal and fixed side decreased, the running resistance decreased 7%, corresponding, 7% reduction in power consumption motor.It is limited to reduce the friction coefficient of Bottom of reciprocating coal feeder and coal, this is because when Masayuki, coal in the feeder chute body of reciprocating coal feeder is between the friction in its dealings and the floor under the front-end , then move to the coal feeder. The friction of Bottom of reciprocating coal feeder and coal is greater than the dynamic resistance when coal accelerated and the Friction of side board friction, in order to ensure that coal and bottom line is no relative sliding when moving forward. Therefore, the friction coefficient of coal and floor should not be between the lower coefficient of friction. I funnel tilted position using the modified reciprocating coal feeder, coal bunker to avoid the exit of the pressure acting on the activities of floor, floor to reduce the activities of running resistance, reciprocating coal feeder is an effective energy-saving measures. I used chute tilt position, I need to increase the coal bunker to the high floor space, increasing the volume of civil works. However, to increase coal bunker limited height (K-4 type reciprocating coal feeder to improve 0.6m), and significantly reduce operating costs, an integrated energy-saving benefits are obvious. Fixed side of coal and reduce the friction coefficient, but also a certain degree of energy saving effect. Coal between the floor and activities should not reduce the coefficient of friction.Develops the large-scale reciprocation type stoker, met our country coal need to develop, Expanded in the coal mine production system design to give the coal equipment the shaping scope. In particular in Ji Ning two mine pits success uses, for me The country provided has been new large-scale for the coal equipment, should give the vigorously promoted use. The transformation and Apply of reciprocating coal feeder played a role in the Development of reciprocating coal feeder.中文译文往复式给煤机的状况、改进及节能措施给煤设备是煤矿生产系统的主要设备之一,给煤设备的可靠性,特别是关键咽喉部位给煤设备的可靠性,直接影响整个生产系统的正常运行。目前,我国煤矿使用的给煤设备主要是往复式给煤机和电振给煤机,近年来,电振式给煤机发展较快,已形成系列化和标准化;而往复式给煤机自20世纪60年代定型后,系列的改进和扩大工作一直没有进行。随着煤炭工业的迅猛发展,煤矿井型也在不断扩大,现有的往复式给煤机已不再能满足煤矿生产系统的选型要求。正是基于这个原因,我们在对给煤机使用情况大量调研的基础上,研制了800t/h、1000t/h、1500t/h、2000t/h的大型往复式给煤机,往复式给煤机最早研制于20世纪60年代初,70年代,在NGW基础上,更换了驱动装置,改为K系列,并一直沿用至今。K系列给煤机共有五种型号:K-0、K-1、K-2、K-3、K-4,其中K-4生产能力最大,但也只有590t/h。国外给煤机发展状况也与国内大相径庭,并没有更高的技术含量,但价格却是国内同类产品的4-5倍。1、往复式给煤机其自身结构的优越性1) 结构简单,维修量小在往复式给煤机中,电动机和减速器均采用标准件,其余大部分是焊接件,易损坏部件少,用在煤矿恶劣条件下,其适用性深受使用单位的好评。2) 性能稳定往复式给煤机对煤的牌号,粒度组成,水分、物理性质等要求不严,当来料不均匀,水分不稳定且夹有大块煤、橡胶带、木头及钢丝等时,仍能正常工作。3) 噪音低往复式给煤机是非振动式给料设备其噪音发生源只有电动机和减速器,而这两个的噪音都很低。尤其在井下或煤仓等封闭型场所,噪音无法扩散,这一点是电动给料机所无法达到的。4) 安装方便、高度小往复式给煤机一般安装在煤仓仓口,不需另外配制仓口闸门馏槽及电动机支座,安装可一步到位,调整工作量小,而电动给煤机由于不能直接承受仓压,需要另外安放仓口过渡溜槽,相比之下,往复式给煤机占有高度小,节省了建筑面积和投资。2、大型往复式绐煤机的结构形式特点我们通过对以往给煤机的调查进行分析,对结构型式进行了周密的计算,对关键受力部位如槽箱、双连杆、底部托辊等进行了受力分析,利用有限元原理进行校核计算。共有以下五个特点。1)整机采用框袈可卸式由于考虑到井下运输的方便和井下工矿的限制,整机采用分体式,而且考虑到井下焊接的不便,尽 用螺栓副联接,侧板考虑到外鼓的可能与内壁磨损的需要,在外侧加筋内侧铺设衬板,加强了整体的刚度和强度。2) 增加导板的导向与支撑装置在做往复运动的导板下增设几组托辊轮,一方面变导板的滑动摩擦为滚动磨擦,减少了磨损,另一方面也使导板的刚度提高。另外,为防止导板在运动过程中有跑偏现象,在导板两侧安装导向轮。3) 对导板结构进行优化以往K系列给煤机的平板闸门,物料在运送中存在不少问题,给料量一直不能提高的关键也在于此。为此,我们对导板进行了优化,设计为阶梯型,不但使物料处理量加大了,而且导板本身的强度也得到进一步地提高。4) 变扇型闸门为手动平板闸门控制来料多少的关键取决于闸门,闸门在以往的K系列中一直采用扇型结构,但从现场使用中发现,扇型闸门与仓壁经常相碰,现场往往在安装闸门时不得不把仓壁敲去一部分,使仓壁的强度削弱,基于次,我们采用手动平板闸门,在闸板下配导向轮,同时在轴上配有定位装置。3往复式给煤机的改造3.1连杆的改造1)改造前K4给煤机传动部分如图1所示,该传动方式为:由电动机带动减速机再带动曲柄、曲拐使给煤机底板作往复直线运动。1、电动机 2、减速器 3、曲柄 4、轴承 5、曲拐 图1 改造前给煤机传动部分简

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号