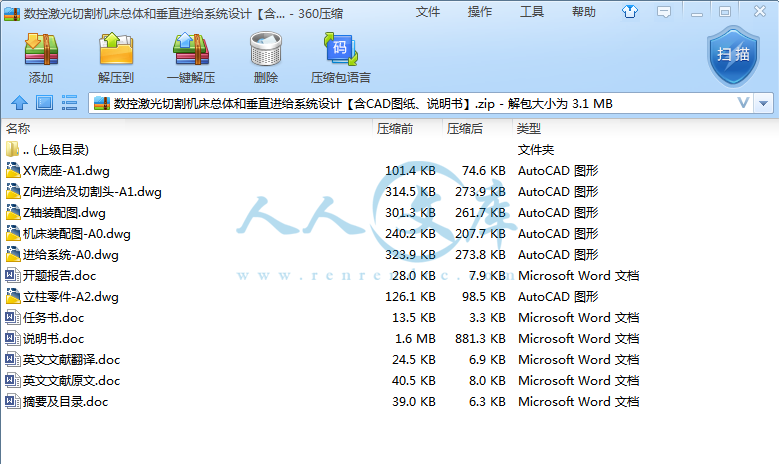

数控激光切割机床总体和垂直进给系统设计【含CAD图纸、说明书】

收藏

资源目录

压缩包内文档预览:(预览前20页/共42页)

编号:16060616

类型:共享资源

大小:2.06MB

格式:ZIP

上传时间:2019-03-11

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

含CAD图纸、说明书

数控激光切割机设计说明书

数控激光切割机床

CAD图纸】

CAD图纸和说明书

设计【含CAD图纸】

数控激光切割机床

数控激光切割机设计

含CAD图纸

设计CAD图纸

- 资源描述:

-

- 内容简介:

-

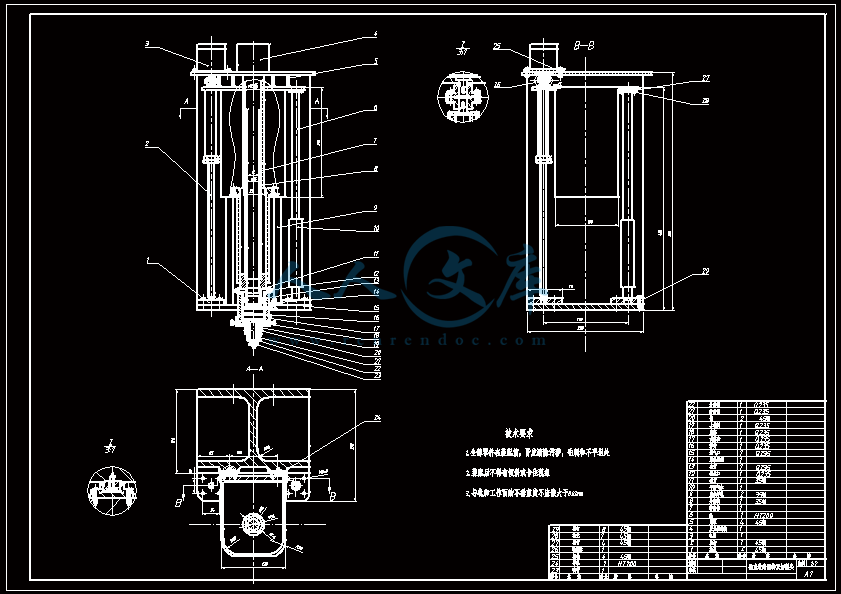

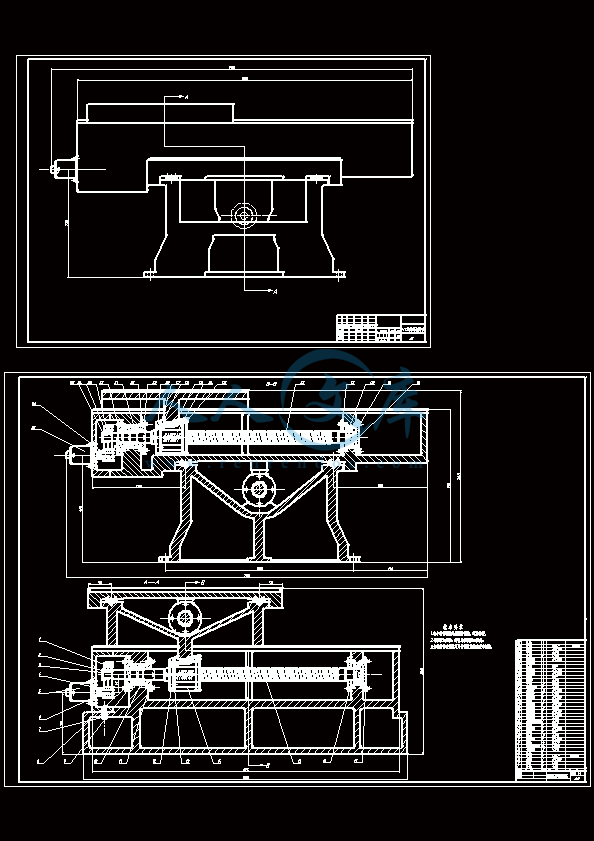

毕业设计(论文)任务书 机电工程学 院 机械设计制造及其自动化 系(教研室)系(教研室)主任: (签名) 日学生姓名: 专业: 机械设计制造及其自动化 1 设计(论文)题目及专题:数控激光切割机床总体和垂直进给系统设计 2 学生设计(论文)时间:自 2015年 1月30 日开始至 2015 年5月 25 日止3 设计(论文)所用资源和参考资料:上一学期所搜集的相关文献资料;相关教材及机械设计、工艺手册;要求熟练使用AutoCAD、PRO/E绘图软件。4 设计(论文)应完成的主要内容: 分析数控激光切割机床的整体传动方案;垂直进给系统结构的总体方案设计;零部件的校核与设计相关的计算 ;装配图的设计、零件工作图的设计;本设计的优缺点分析 ;编写设计说明书;5 提交设计(论文)形式(设计说明与图纸或论文等)及要求:零件图、装配图(Pro/E或AutoCAD完成),折合0号图2.5张;编写的设计说明书不少于40页 ;课题相关论文的翻译(英译中,不少于2000字)一篇;6 发题时间: 日指导教师: (签名)学 生: (签名) 开题报告学 生 姓 名学 院专业及班级学 号指 导 教 师 年03月15日 毕业设计(论文)开题报告题 目数控激光切割机床总体和垂直进给系统设计作者姓名 所学专业机械设计制造及其自动化1、 研究的意义,同类研究工作国内外现状、存在问题(列出主要参考文献)、研究的意义:激光切割机是光、机、电一体化高度集成设备,科技含量高,与传统机加工相比,激光切割机的加工精度更高、柔性化好,有利于提高材料的利用率,降低产品成本,减轻工人负担,对制造业来说,可以说是一场技术革命。激光切割加工是用不可见的光束代替了传统的机械刀,具有精度高,切割快速,不局限于切割图案限制,自动排版节省材料,切口平滑,加工成本低等特点,将逐渐改进或取代于传统的金属切割工艺设备。激光刀头的机械部分与工件无接触,在工作中不会对工件表面造成划伤;激光切割速度快,切口光滑平整,一般无需后续加工;切割热影响区小,板材变形小,切缝窄(0.1mm0.3mm);切口没有机械应力,无剪切毛刺;加工精度高,重复性好,不损伤材料表面;数控编程,可加工任意的平面图,可以对幅面很大的整板切割,无需开模具,经济省时。参考文献:1 张学仁.数控电火花线切割加工技术. 哈尔滨:哈尔滨工业出版社,2000、国内外现状:激光被誉为二十世纪最重大的科学发现之一,它刚一问世就引起了材料科学家的高度重视。1971年11月,美国通用汽车公司率先使用一台250W CO2激光器进行利用激光辐射提高材料耐磨性能的试验研究,并于1974年成功地完成了汽车转向器壳内表面(可锻铸铁材质)激光淬火工艺研究,淬硬部位的耐磨性能比未处理之前提高了10倍。这是激光表面改性技术的首次工业应用。多年以来,世界各国投入了大量资金和人力进行激光器、激光加工设备和激光加工对材料学的研究,促使激光加工得到了飞速发展,并获得了巨大的经济效益和社会效益。如今在中国,激光技术已在工业、农业、医学、军工以及人们的现代生活中得到广泛的应用,并且正逐步实现激光技术产业化,国家也将其列为“九五”攻关重点项目之一。“十五”的主要工作是促进激光加工产业的发展,保持激光器年产值20的平均增长率,实现年产值200亿元以上;在工业生产应用中普及和推广加工技术,重点完成电子、汽车、钢铁、石油、造船、航空等传统工业应用激光技术进行改造的示范工程;为信息、材料、生物、能源、空间、海洋等六大高科技领域提供崭新的激光设备和仪器。、存在问题:近年来,我国从日、德、美、西班牙等国家先后引进数控机床先进技术和合作、合资生产,解决了机床的可靠性、稳定性问题,数控机床开始正式生产和使用,并逐步向前发展。激光切割的适用对象主要是难切割材料,如高强度、高韧性材料以及精密细小和形状复杂的零件,因而数控激光切割在我国制造业中正发挥出巨大的优越性。任何东西都有两面性,有了优点也会有缺点。不是所有的材质都可以使用激光切割加工的,不同的激光机切割不同的材质,不得不承认不够线切割好,因为线切割可以对任何的材质进行切割。主要问题还有研发投入少,市场无序竞争,创新意识不足,企业之间合作太少。2、研究目标、内容和拟解决的关键问题(根据任务要求进一步具体化)、研究目标:数控激光切割机床总体和垂直进给系统设计、研究内容:(1)分析数控激光切割机床的整体传动方案;(2)垂直进给系统结构的总体方案设计;(3)零部件的校核与设计相关的计算 ;(4)装配图的设计、零件工作图的设计;(5)本设计的优缺点分析 ;(6)编写设计说明书.、拟解决的关键问题:(1) 激光切割头;(2) 横向纵向进给系统;(3) 垂直进给系统;其中,横向纵向及垂直进给系统全部由伺服电机来驱动。2、 特色与创新之处 本品在导轨上使用直线滚动导轨,相对于普通机床所用导轨,直线滚动导轨定位精度高,降低机床造价并节约电力,还可以长期维持机床的高精度。在激光刀头方面,普通数控激光切割机Z轴拖动重量在5kg以上时,应采用重力平衡设施,而高性能数控激光切割机的Z轴拖动重量在2kg以上就必须施加重力平衡设施, 本品采用气缸拖动方式该方式重量轻、体积小、易安装,还可根据要求调整气缸的平衡力。3、 拟采取的研究方法、步骤、技术路线 设计本产品应该先实地考察现有的数控激光切割机床,并观察其工作特点,比较不激光切割机床以及其他切割机比如线切割,水切割之间的差异,得出现有的激光切割机床的优点和劣势。然后取长补短,提出整体方案。再把方案给指导老师批阅,听取老师的建议,改正不合理的地方,一步步完善方案,最后进过细致的设计,分析,计算以得到最终的方案。 技术路线:一,总体方案分析二,机械部分XY工作台和Z轴机构设计 三,滚珠丝杠传动系统设计 四,导轨选择 五,步进电机及传动系统设计 六,刚度分析 七,消除齿侧间隙和预紧 八,数控系统的设计 4、 拟使用的主要设计、分析软件及仪器设备 Auto-CAD计算机辅助绘图软件6、参考文献1 张学仁.数控电火花线切割加工技术. 哈尔滨:哈尔滨工业出版社20002 李广弟.单片机基础.北京:北京航空航天大学出版社出版,20023 郑玉华.典型机械(电)产品构造. 北京:北京科学出版社,20064 陈婵娟.数控机床设计. 北京:化学工业出版社,20065 李秉操.单片机原理及其在工业控制中的应用. 陕西:陕西电子编辑部1991注:1、开题报告是本科生毕业设计(论文)的一个重要组成部分。学生应根据毕业设计(论文)任务书的要求和文献调研结果,在开始撰写论文之前写出开题报告。2、参考文献按下列格式(A为期刊,B为专著)A:序号、作者(外文姓前名后,名缩写,不加缩写点,3人以上作者只写前3人,后用“等”代替。)、题名、期刊名(外文可缩写,不加缩写点)年份、卷号(期号):起止页码。B:序号、作者、书名、版次、(初版不写)、出版地、出版单位、出版时间、页码。3、表中各项可加附页。 摘 要 激光切割的适用对象主要是难切割材料,如高强度、高韧性材料以及精密细小和形状复杂的零件,因而数控激光切割在我国制造业中正发挥出巨大的优性。本文设计了一台单片机控制的数控激光切割机床,主要完成了:机床整体结构设计,Z轴、XY轴的结构设计计算、滚珠丝杠、直线滚动导轨的选择及其强度分析;以步进电机为进给驱动的驱动系统及其传动机构的分析设计计算。关键词:CNC;激光切割机床;结构;设计ABSTRACTLaser cutting machine tool was usually used for the hard-cutting material, such as high-strength material, high precision ductile materials, and smart and complicated components. So, CNC laser cutting has been playing an important role in Chinas manufacturing industry.This paper describes the design of a SCM-controlled CNC laser cutting machine tools. More attention was paid on the overall machine design, Z axis, XY axis in the design, ball-screw and the choice of linear motion guide and intensity analysis; the drive system into which stepper motor was put and the analysis of the drive system design.KeyWords:CNC;laser cutting machine tools;architectured;esign目 录第1章 绪论11.1 课题背景11.2 本课题主要研究内容11.3 国内外研究现状2第2章 总体方案的拟定32.1设计任务32.2总体方案的选择和拟定3第3章 激光切割系统的设计53.1 激光器5 3.1.1激光器的组成5 3.1.2激光切的分类53.2 激光切割设备6 3.2.1激光切割设备的组成6 3.2.2激光切割用的激光器8 3.2.3激光切割用割炬93.3激光切割头设计10第4章 传动系统设计12 4.1 XY工作台设计12 4.1.1主要设计参数及依据12 4.1.2XY进给系统手里分析12 4.1.3初步确定工作台尺寸及估算质量124.2 Z轴随动系统设计134.3 滚珠丝赶副设计计算 14 4.3.1滚珠丝杆的特点14 4.3.2主要参数14 4.3.3导程计算15 4.3.4确定当量转速与当量载荷16 4.3.5初选滚珠丝杆副17 4.3.6确定允许的最小螺纹底径17 4.3.7确定滚珠丝杆副的规格代号18 4.3.8确定丝杆副的预紧力18 4.3.9行程补偿值与拉伸力18 4.3.10确定滚珠丝杆副支承用的轴承代号,规格19 4.3.11滚珠丝杆副工作图设计20 4.3.12传动系统刚度20 4.3.13刚度验算和精度选择21 4.3.14验算临界压缩载荷22 4.3.15验算临界转速23 4.3.16效率验算23第5章 导轨的选定255.1 主要要求及种类25 5.1.1对导轨的基本要求25 5.1.2导轨的技术要求25 5.1.3分类及特点255.2 导轨的选用26第6章 步进电机及其传动机构的确定286.1 步进电机的选用28 6.1.1脉冲当量和步距角28 6.1.2步进电机上起动力矩的近似计算28 6.1.3确定步进电机最高工作频率296.2 齿轮传动机构的确定29 6.2.1传动比的确定29 6.2.2齿轮结构主要参数的确定306.3 步进电机惯性负载的计算30第7章 传动系统刚度分析337.1 根据工作台不出现爬行的条件来确定传动系统刚度337.2 根据微量进给的灵敏度来确定传动系统的刚度33第8章 消隙方法与预紧358.1 消隙方法35 8.1.1偏心轴套调整法35 8.1.2锥度齿轮调整法35 8.1.3双片齿轮错齿调整法368.2 预紧37第9章 结论38参考文献39致谢40 v VSS motion control for a laser-cutting machineAbstract An advanced position-tracking control algorithm has been developed and applied to a CNC motion controller in a laser-cutting machine. The drive trains of the laser-cutting machine are composed of belt-drives. The elastic servomechanism can be described by a two-mass system interconnected by a spring. Owing to the presence of elasticity, friction and disturbances, the closed-loop performance using a conventional control approach is limited. Therefore, the motion control algorithm is derived using the variable system structure control theory. It is shown that the proposed control e!ectively suppresses the mechanical vibrations and ensures compensation of the system uncertainties. Thus, accurate position tracking is guaranteed.1. Introduction For many industrial drives, the performance of motion control is of particular importance. Rapid dynamic behaviour and accurate position trajectory tracking are of the highest interest. Applications such as machine tools have to satisfy these high demands. Rapid movement with high accuracy at high speed is demanded for laser cutting machines too. This paper describes motion control algorithm for a low-cost laser-cutting machine that has been built on the base of a planar Cartesian table with two degrees-of-freedom (Fig. 1). The drive trains of the laser-cutting machine are composed of belt-drives with a timing belt. The use of timing belts in the drive system is attractive because of their high speed, high efficiency, long travel lengths and low-cost (Haus, 1996). On the other hand, they yield more uncertain dynamics and a higher transmission error ( Kagotani, Koyama & Ueda, 1993). Consequently, belt-drives suffer from lower repeatability and accuracy. Moreover, the belt-drive dynamics include more resonance frequencies, which are a destabilising factor in a feedback control (Moon, 1997). Therefore, a conventional control approach like PI, PD or PID control fails to achieve acceptable performance. Plant parameter variations, uncertain dynamics and load torque disturbances, as well as mechanical vibrations, are factors that have to be addressed to guarantee robust system stability and the high performance of the system. An advanced robust motion control scheme is introduced in this paper, which deals with the issues related to motion control of the drives with timing belts. The control scheme is developed on the basis of the motion control algorithm introduced by Jezernik, Curk and Harnik (1994). It possesses robust properties against the disturbances that are associated with a nominal plant model, as it has been developed with the use of the variable structure system (VSS) theory (Utkin, 1992). The crucial part of the control scheme is the asymptotic disturbance estimator. However, as shown in this paper, it fails to stabilise resonant belt dynamics, since it was developed for a rigid robot mechanism. Therefore, this paper introduces an improved motion control scheme, which suppresses the vibrations that would arise due to the non-rigid, elastic drive. Consequently, a rapid response with low position tracking error is guaranteed.The paper is set out as follows. The laser-cutting machine is presented and the control plant model of the machine drives is developed in Section 2. In Section 3, the VSS control regarding the elastic servomechanism is discussed and the derivation of the motion control scheme is described. Section 4 presents the experimental results and a follow-up discussion. The paper is summarized and concluded in Section 5.2. The control plant2.1. The machine descriptionThe laser-cutting machine consists of the XY horizontal table and a laser system (Fig. 1). The fundamental components of the laser system are: the power supply unit, which is placed off the table and thus is not considered in the motion control design; the laser-beam source, which generates the laser beam (the laser-generator);the laser-head, which directs the laser beam onto the desired position in the cutting plane.The table has to move and position the laser head in a horizontal plane. This is achieved by the means of a drive system with two independent motion axes. They provide movement along the Cartesians XY axes of 2 and 1m, respectively. The X-drive provides the motion of the laser-head in X-direction. The drive and the laser-head as well as the laser-generator are placed on the bridge to ensure a high-quality optical path for the laser-beam. The movement of the bridge along the Y-axis is provided by the Y-drive. The laser-head represents the X-drive load, while the Y-drive is loaded by the bridge, which carries the complete X-drive system, the laser-head, and the laser-generator. The loads slide over the frictionless slide surface.The positioning system consists of the motion controller, the amplifiers, the DC-motors and the drive trains. The X-drive train is composed of a gearbox and a belt-drive (Fig. 2). The gearbox reduces the motor speed, while the belt-drive converts rotary motion into linear motion. The belt-drive consists of a timing belt and of two pulleys: a driving pulley and a driven pulley that stretch the belt. The Y-drive train is more complex. The heavy bridge is driven by two parallel belt-drives; each bridge-side is connected to one of the belt-drives. The driving pulleys of the belt-drives are linked to the driving axis, which is driven via the additional belt-drive and the gearbox is used to reduce the speed of the motor.2.2. AssumptionsThe machine drives represent a complex non-linear distributed parameter system. The high-order system possesses several resonant frequencies that can be observed by the drives step response (see Section 4). From a control design perspective, difficulties arise from mechanical vibrations that are met in the desired control bandwidth (10 Hz). On the other hand, the design objective is to have a high-performance control system while simultaneously reducing the complexity of the controller. Therefore, a simple mathematical model would only consider the first-order resonance and neglect high-order dynamics. In other words, the design model of the control plant will closely match the frequency response of the real system up to the first resonance. Next, the controller should be adequately designed to cope with the higher-order resonance in such a way that the resonance peaks drop significantly to maintain the system stability. Thus, according to the signal analysis and the drives features, the following assumptions could be made:the DC-servos operating in the current control mode ensure a high-dynamic torque response on the motor axis with a negligible time constant;the small backlash in the gearboxes and the backlash of the belt-drives due to the applied pre-tension of the timing belts is negligible;a rigid link between a motor shaft and a driving pulley of the belt-drive could be adopted;the inertia of the belt-drives driven pulleys is negligible in comparison to other components of the drive system.Using the assumptions above, dynamic modeling could be reduced to a two-mass model of the belt-drives that only includes the first resonance. In the control design, the uncertain positioning of the load due to the low repeatability and accuracy of the belt-drive has to be considered as well.Note, that no attention is paid to the coupled dynamics of the Y-drive due to the parallel driving, thus, the double belt-drive is considered as an equivalent single belt-drive.3. The motion control algorithmThe erroneous control model with structured and unstructured uncertainties demands a robust control law. VSS control ensures robust stability for the systems with a non-accurate model, namely, it has been proven in the VSS theory that the closed-loop behavior is determined by selection of a sliding manifold. The goal of the VSS control design is to find a control input so that the motion of the system states is restricted to the sliding manifold. If the system states are restricted to the sliding manifold then the sliding mode occurs. The conventional approach utilises discontinuous switching control to guarantee a sliding motion in the sliding mode. The sliding motion is governed by the reduced order system, which is not affected by system uncertainties. Consequently, the sliding motion is insensitive to disturbance and parameter variations (Utkin, 1992).The essential part of VSS control is its discontinuous control action. In the control of electrical motor drives power switching is normal. In this case, the conventional continuous-time/discontinuous VSS control approach can be successfully applied. However, in many control applications the discontinuous VSS control fails, and chattering arises (SabanovicH, Jezernik, & Wada, 1996; Young, Utkin & OG zguK ner, 1999). Chattering is an undesirable phenomenon in the control of mechanical systems, since the demanded performance cannot be achieved, or even worsemechanical parts of the servo system can be destroyed. The main causes of the chattering are neglected high-order control plant dynamics, actuator dynamics, sensor noise, and computer controlled discrete-time implementation in sampled-data systems. Since the main purpose of VSS control is to reject disturbances and to desensitise the system against unknown parametric perturbations, the need to evoke discontinuous feedback control vanishes if the disturbance is sufficiently compensated for, e.g. by the use of a disturbance estimator (Jezernik et al., 1994; Kawamura, Itoh & Sakamoto, 1994). Jezernik has developed a control algorithm for a rigid robot mechanism by combining conventional VSS theory and the disturbance estimation approach. However, the rigid body assumption, which neglects the presence of distributed or concentrated elasticity, can make that control input frequencies of the switcher excite neglected resonant modes. Furthermore, in discrete-time systems discontinuous control fails to ensure the sliding mode and has to be replaced by continuous control (Young et al., 1999). Avoiding discontinuous-feedback control issues associated with unmodelled dynamics and related chattering are no longer critical. Chattering becomes a non-issue.In plants where control actuators have limited bandwidth there are two possibilities: actuator bandwidth is outside the required closed-loop bandwidth, or, the desired closed-loop bandwidth is beyond the actuator bandwidth. In the fist case, the actuator dynamics are to be considered as the non-modelled dynamics. Consequently, the sliding mode using discontinuous VSS control cannot occur, because the control plant input is continuous. Therefore, the disturbance estimation approach is preferred rather than VSS disturbance rejection. In the second case, the actuator dynamics are to be lumped together with the plant. The matching conditions (DrazenovicH, 1969) for disturbance rejection and insensitivity to parameter variations in the sliding mode are violated. This results from having dominant dynamics inserted between the physical input to the plant and the controller output. When unmatched disturbances exist the VSS control cannot guarantee the invariant sliding motion. This restriction may be relaxed by i

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号