DN1200氨吸收塔设计3(全套CAD图+说明书+开题报告+翻译)

收藏

资源目录

压缩包内文档预览:(预览前20页/共68页)

编号:1670175

类型:共享资源

大小:2.84MB

格式:ZIP

上传时间:2017-09-04

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

30

积分

- 关 键 词:

-

dn1200

吸收塔

设计

全套

cad

说明书

仿单

开题

报告

讲演

呈文

翻译

- 资源描述:

-

- 内容简介:

-

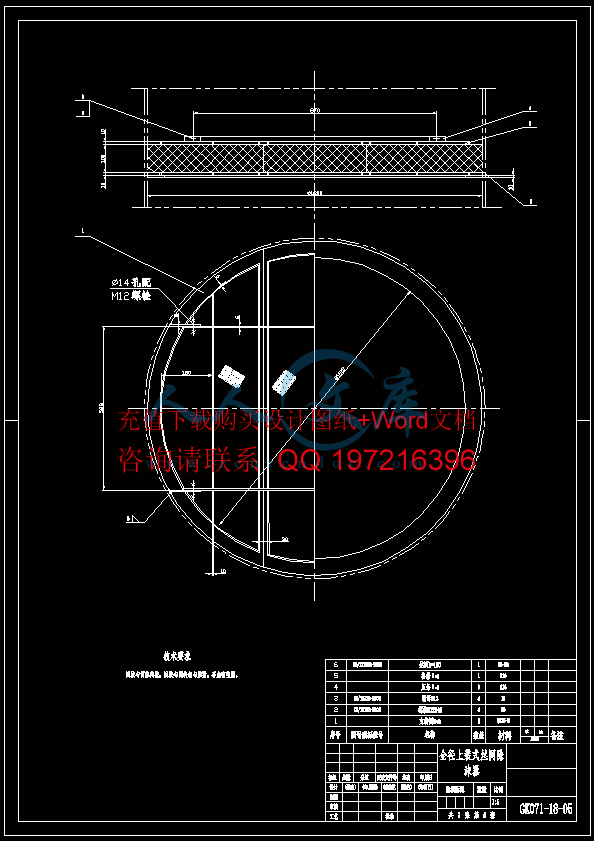

毕业设计(论文)题 目 DN1200氨吸收塔设计 学院名称 机械工程学院 指导教师 职 称 班 级 学 号 学生姓名 2011年 5 月 30 日 毕业设计(论文)任务书学 院: 机械工程学院 题 目: DN1200氨吸收塔设计 起止时间: 学 生 姓 名: 专 业 班 级: 指 导 老 师: 教研室主任: 院 长: 20 年 1月 6日设计(论文)内容及要求:一、 已知设计参数:用20的清水吸收混合气中的氨,混合气中含氨10%,其余为空气。操作压力为1.01105pa,操作温度40,混合气流量10000m3/h,吸收剂用量为最小用量的1.1倍,气相体积吸收总系数为200kmol/( m3.h)氨的回收率为95%,环境 衡阳室外二、设计内容及设计工作量要求:(1)按所给设计参数完成氨吸收塔的设计;(2)绘制设计图纸总计3张零号以上,其中要求手工绘图1张壹号以上;(3)设计说明书字数不少于1.5万字,并要求统一用A4纸打印;(4)翻译3千左右汉字量的与毕业设计有关的英文资料;(5)撰写相当于3百汉字的英文摘要。三、主要参考资料: 化工设备设计全书(塔设备) 化工原理 化工工艺设计手册 GB150-1998钢制压力容器 指导教师: 年 月 日生毕业设计(论文)开题报告设计(论文)题目DN1200氨吸收塔设计设计(论文)题目来源自选设计(论文)题目类型工程设计起止时间一、 设计(论文)依据及研究意义:氨是化工生产中极为重要的生产原料。硝酸、各种含氮的无机盐及有机中间体、磺胺药、聚氨酯、聚酰胺纤维和丁腈橡胶等都需直接以氨为原料;液氨常用作制冷剂;尿素的主要用途:一、肥料作用;二、其他工业用。因此,氨在现实中需求量是比较大的,而氨又是工业废气中污染环境的因素之一,因此对于氨的回收有环保和经济上的双重意义,符合现代可持续发展的理念。二、 设计(论文)主要研究的内容、预期目标(技术方案、路线):本次设计的是气混合气流量为10000 m3/h的氨吸收塔。设计包括的主要内容:物料衡算、热量衡算、塔设备的工艺设计(塔内径、塔高、封头、填料、进出口接管及裙座等)等。并对其进行强度计算及校核,绘制图纸等。技术方案及路线:1.收集资料;2.物料衡算及工艺计算;3.塔结构设计和强度设计及校核;4.绘制施工图;5.设计说明书制订。三、设计(论文)的研究重点及难点:重点是:物料衡算、热量衡算和塔设备的尺寸计算和确定以及强度计算和校核。难点是:1、其难点为塔内的物料及热量衡算,并对其进行比较准确的计算。2、由于本次设计的塔是满足常压下大能力的生产,其难点是对塔高、塔内径以及壁厚等进行比较优化的设计。三、由于本次设计的塔为高压塔而且考虑了各种载荷,其难点是对塔体以及一些塔内件的强度计算及校核。四、设计(论文)研究方法及步骤(进度安排):1月6日至1月10日:了解我们所要设计的试验装置,为进行设计做准备; 1月10日至2月17日:查阅资料,找设计依据,理出设计思路; 2月18日至3月28日:算数据,求得设计的各种依据; 3月29日至5月18日:设计,画出设计图纸; 5月19日至5月26日;整理图纸,进行打印。写出设计说明书并校核。 5月26日至5月31日:准备答辩。五、进行设计(论文)所需条件: 1、要有充分的资料(在图书馆查阅与尿素合成相关的书籍,进行筛选,选出有用的信息)。 2、设计所需设计方法、软件、工具等。六、指导教师意见: 签名: 年 月 日中文摘要:本次设计的是气混合气流量为10000的氨吸收塔。根据工艺条件选用填料塔来完成此任务。填料塔的设计包括的主要内容:物料衡算、热量衡算、塔设备的工艺设计(塔内径、塔高、封头、填料、进出口接管及裙座等)等。并对其进行强度计算以及校核,绘制图纸等。技术方案及路线:首先进行物料衡算和热量衡算,然后进行塔设备的尺寸计算,主要包括塔的高度确定和填料层高度的计算,以及对塔附件(吊柱、液体分布器、人孔、手孔、裙座等)的计算与选择,最后进行强度计算和校核。关键词:氨吸收;填料塔;物料衡算;强度计算;Abstract: This design is about of an ammonia absorption tower whose operated pressure is 1.01105 pa, the operated temperature is 40 and the gas mixture flow of 10000 m3/h. Select packed tower to accomplish this task in accordance of technique. Packed tower design includes the main elements: technique calculation, tower equipment process design (inner diameter, height, head, padding, import and export and the supporting seat, etc.). Calculated and collate the strength of them, and drawing. Technical programs and routes: first material balance and heat balance, and then proceed to calculate the size of tower equipment, including the height of tower and fill to identify, as well as the calculation and choice of the tower annex (hanging column, liquid distributor, manhole, hand hole, support, etc.), the final calculated and check for strength.Keywords: ammonia; absorption tower; packed tower; strength counting.目录目录1引言1第一章 工艺计算21.1吸收剂用量及吸收溶液深度21.1.1惰性气体流量21.1.2 最小气液比21.1.3最小吸收剂用量41.1.4吸收液浓度41.2泛液速度41.2.1 塔顶混合气体平均分子量41.2.2填料的选择51.2.3泛点气速51.3塔径的估算71.4液体喷淋密度的验算71.5填料层高度的计算81.5.1传质单元数的计算81.5.2传质单元数的计算81.5.3填料层的分段101.5.4填料层压降的计算10第二章 塔结构的设计122.1塔内件及附件的选择122.1.1除沫器的选择122.1.2填料支承装置的选择122.1.3液体分布器132.1.4液体再分布器142.1.5 裙座结构设计152.1.6 人孔的设计与选择162.1.7塔吊柱的选择162.1.8接管的选择192.1.9 接管法兰的选择192.1.10压力容器法兰的选择20第三章 塔的设计及强度校核213.1塔体和封头的厚度计算213.1.1材料的选择213.1.2筒体厚度的确定213.1.3封头壁厚计算223.2塔体载荷分析233.2.1质量载荷233.2.2自振周期的计算243.2.3塔体的风载荷及风力矩253.2.4地震载荷与地震弯矩的计算273.3塔体的强度及稳定性校核313.3.1 塔体的轴向应力313.3.2 轴向应力校核313.4 裙座的强度及稳定性较核323.4.1裙座各危险截面的校核323.4.2焊缝强度的校核333.5裙座基础环333.5.1 基础环内外径确定333.5.2基础环的厚度设计343.6地脚螺栓计算353.7水压试验时塔的强度和稳定性验算35第四章 开孔和开孔补强设计364.1开孔及补强说明364.2 开孔补强设计计算414.2.1 封头开孔补强设计计算414.2.2人孔开孔补强设计计算43第五章 主要制造工艺455.1 椭圆封头部件的制造455.2筒节的主要制造工艺455.3总装465.4 主要件的热处理475.5主要检验要求47参考文献:48附录一 外文原稿:49附录二 外文翻译:56谢 辞62第 5 页 共 62 页 附件2毕业设计 (论文)装订格式及打印规范一、 装订顺序1、封面页:首页为封面,按照学校统一设计的封面样式打印;2、毕业设计(论文)任务书页; 3、开题报告;4、中文摘要和关键词页:摘要的字数在200至300字之间,关键词在3至5个之间;5、英文摘要和关键词页:根据中文摘要和关键词翻译;6、目录页:应有小节对应的页码;7、正文页;8、参考文献页;9、谢辞二、打印规范1、论文以A4标准页面排版(21*29.7cm),1.5倍行距,字体、字号要求如下:标题用粗黑体:一级标题三号,二级标题小三号,三级标题四号;正文用宋体小四号。2、章节目序号(标题序号):(1)按照正式出版物的惯例,标题编号顺序规定如下:1、1.1、1.1.1(2)论文标题一律从“1、”开始。3、图表标号:图1.1 图1.2 图2.1 图2.2 (与图名称一起标在图正下方,用5号宋体,如图1.1,GDP按年度增长率)表1.1 表1.2 表2.1 表2.2 (与表名一起标在表正上方,如表1.1职工情况一览表)4、中文摘要和关键词:摘要:关键词:;其中:摘要和关键词这两个词用宋体加粗,小四号,摘要内容和关键词内容用楷体四小号;5、英文摘要和关键词:参照中文摘要和关键词;用Times New Roman体;6、论文正文:空二行后书写正文,正文的第一段为“引言”,但不加小标题。7、参考文献列示格式(5号宋体):书籍格式:编号作者,作者.书名M.出版地:出版社,出版时间期刊格式:编号作者,作者.文章题目J.期刊名,年份(期数):起页码止页码报纸格式:编号作者,作者.文章题目N. 报纸名,年月日,第几版注意:网络文献一般不作为参考文献。8、页眉必须打印“南华大学学院毕业设计(或论文)” ,居中(5号宋体);9、正文必须打上页码,页码格式为“第X页,共X页”;居中打印(5号宋体);论文前面的中英文摘要页、目录页用小写、顺序编页。10、所有论文请用WORD98以上版本打印。浮阀塔设计计算结果汇总序号项目单位数值1回流比R3.662精馏段平均温度90.83精馏段平均压力kPa109.34气相流量m3/s1.425液相流量m3/s0.00416实际塔板数317精馏段塔板数188提馏段塔板数129精馏段有效段高度m10.210提馏段有效段高度m6.611人孔高度m0.812精馏塔有效段高度m1813塔径m1.614板间距m0.615溢流形式单溢流16降液管形式弓形降液管17堰长m1.17118堰宽m0.2519堰高m0.066920板上液层高度m0.0621堰上液层高度m0.016122降液管底隙高度m0.03523安定区宽度m0.0524边缘区宽度m0.07525有效传质面积m215.80126开孔区面积m20.22227浮阀直径m0.03928阀孔数目12029孔中心距m0.330开孔率0.1331阀孔气速m/s9.9132稳定系数3.433每层塔板压降Pa0.8附录一 外文原稿:Anhydrous Ammonia Pressure Vessels In The Pulp And Paper IndustryThe purpose of this article is to ensure that pulp and paper operating companies, their engineering consultants, and inspection contractors are informed about stress corrosion cracking in anhydrous ammonia service. The information was written by a task group of the TAPPI Engineering Division Nondestructive Testing and Quality Control Subcommittee.Bacteria in some activated sludge effluent treatment systems require supplementary food. In some cases, this food is provided by ammonia and phosphoric acid which are stored on the mill site. Ammonia is commonly stored as anhydrous liquid ammonia in carbon steel vessels at ambient temperature and 16 bar (250 psig) pressure.These vessels can be subject to stress corrosion cracking (SCC).SCC could cause release of ammonia, which is a hazardous chemical. SCC of carbon steel vessels in anhydrous ammonia service is somewhat analogous to that experienced in continuous digesters. For example, the importances of stress relief during fabrication and of in-service inspection are common to both.This article concerns storage in horizontal pressure vessels at ambient temperature, as this type of vessel is used in pulp and paper applications. Large refrigerated storage tanks are used for atmospheric pressure storage in the chemical industry.History of Scc In Ammonia Storage VesselsThe history of SCC in carbon steel ammonia storage vessels was reviewed by Loginow (1) and is also briefly summarized in a NACE Technical Committee Report entitled “Integrity of Equipment in Anhydrous Ammonia Storage and Handling” (2). In the 1950s, liquefied ammonia began to be injected directly into soil for fertilization. Failure of carbon steel storage vessels by SCC began to occur. These failures were unexpected since liquefied ammonia had been used for many years in the refrigeration, chemical, and metal heat treating industries without reported problems.Investigation confirmed SCC to be the cause of cracking. Three recommendations were made in 1962 that still form the basis of modern codes: Pressure vessels should be fully stress relieved. Extreme care should be used to eliminate oxygen from ammonia systems. Ammonia should contain at least 0.2% water to inhibit SCC.Loginow reported that adoption of these recommendations practically eliminated SCC in carbon steel vessels in the agriculture industry. However, in a recent Western Canadian survey SCC was found in 100 of 117 field storage vessels inspected by wet fluorescent magnetic particle testing (WFMT) (3).Despite the above measures SCC continued to occur in road transport tanks constructed from high strength steels, in refrigerated storage vessels and in vessels which had been weld repaired but not subsequently stress relieved. An additional recommendation to limit steel tensile or yield strength was embodied in the U.S. and British ammonia storage codes, respectively (4, 5). ANSI K61.1Nominal tensile no greater than 70,000 psi (580 MPa) U.K. CodeMinimum specified yield strength shall not exceed 350 MPa (51,000 psi).PRACTICAL CONSIDERATIONSThis article is concerned mainly with practical considerations important to pulp and paper mills already possessing anhydrous ammonia storage vessels or planning to fabricate such vessels. In view of the industrys experience with SCC in continuous digesters the governing objectives should be to control fabrication and inspection to prevent, or at least minimize, in-service problems including over-reaction to relatively minor crack indications. Guidance is available in the published codes and detailed information is available from some ammonia suppliers.FabricationThe two main objectives in fabrication should be to provide the most crack resistant vessel possible at reasonable cost and to ensure that an adequate inspection baseline is available for interpretation of subsequent in-service inspections.ASME Section VIII Division 1 does not require stress relief for anhydrous ammonia storage pressure vessels unless the owner specifies a lethal service designation.The lethal service designation requires radiographic testing (RT) of all butt welded joints plus post weld heat treatment.ANSI K-61.1-1989, “American National Standard Safety Requirements for the Storage and Handling of Anhydrous Ammonia,” adds several requirements: Fabrication to ASME Section VIII Division 1 Table UW 12 at a joint efficiency less than 80% is not allowed. Inspection and testing under UG-90(c) (2) (multiple, duplicate pressure vessel fabrication) is not allowed. Steel used for pressure containing parts shall have a nominal tensile strength no greater than 580MPa (70,000 psi). The minimum design pressure for ambient temperature storage shall be 16 bar (250 psig). Post weld heat treatment is mandatory and a furnace of sufficient size to accommodate the entire vessel is recommended. Welded attachments may be made to pads after post weld heat treatment. Horizontal vessels shall be mounted on saddles which extend over at least one third of the shells circumference. Thermal expansion and contraction shall be allowed for and means provided to prevent corrosion between the shell and the saddles.The 1986 British Code “Storage of Anhydrous Ammonia under Pressure in the United Kingdom” requires: Steel must have specified minimum yield strength less than 350 MPa (51,000 psi). Weld filler must have minimal strength overmatch compared with the base plate. 100% magnetic particle inspection of all internal welds in order to provide a record against which all future inspections of the vessel can be assessed. No welding is permitted after stress relief without subsequent local stress relief. Concrete saddles are prohibited. Support must be on continuously welded steel saddles attached before stress relief.Although the British Code does not state that magneti particle inspection should be by WFMT it is generally agreed that WFMT is the most sensitive technique and should be used for inspection of ammonia storage vessels. All inspection should be performed by qualified technicians. SNT-TC-1A Level II is a recommended minimum.One pulp and paper company has added the following requirements for fabrication of such vessels: Incorporation of a “corrosion allowance” of at least 1.6 mm (1/16 in.) to permit minor defect chasing during in-service inspections and to provide a margin against pitting which may occur if water is allowed to enter an out of service vessel. All weld toes profiled by grinding prior to wet fluorescent magnetic particle testing (WFMT). All WFMT indications greater than 1.6 mm (1/16 in.) to be removed by grinding before post weld heat treatment. Shear wave ultrasonic testing (UT) of nozzle-to-shell welds permitted if RT is judged impractical. WFMT to be repeated after final hydrotest test of the vessel and the report retained by the owner. Vessel to be dried completely after hydrotest test and nitrogen padded until filled with ammonia.Valves, piping, and fittingsBoth the ANSI and U.K. codes address piping, valves, and fittings. A detailed summary is beyond the scope of this article, but some points are worth noting. ANSI K61.1 requires all nonrefrigerated ammonia piping to meet the requirements of ANSI/ASME B31.3 “Chemical Plant and Petroleum Refinery Piping.” The U.K. Code states copper and copper bearing alloys shall not be used.ANSI/ASME B31.3 requires a minimum of 5% of piping welds be radiographically tested. Valves and other apparatus should be rated for ammonia service and should not contain copper or copper alloy components.In one case, a nickel rupture disc corroded to failure at its periphery due to formation of an ammonia solution at a gasketed joint exposed to the weather.In-service inspectionVessel entry Liquid or gaseous ammonia is hazardous and in some jurisdictions release of ammonia vapor to the atmosphere is prohibited by law. Vessels must be properly purged by water and/or steam. Detailed procedures for vessel purging and entry are available from ammonia suppliers (6).Inspection procedures The ANSI standard does not address in-service inspection but does state weld repair or alteration must conform to the current edition of the National Board Inspection Code (NBIC).The 1992 edition of the NBIC includes nonmandatory guidelines for inspection of liquid ammonia vessels (7).These guidelines recommend: Power buffing or light sandblasting as surface preparation for inspection All interior welds be examined by WFMT. Cracks should be removed by grinding without encroaching on the minimum thickness required by ASME Section VIII and the original design. Weld repairs, regardless of size, should be post weld heat treated wherever possible.Light grinding does increase the sensitivity of WFMT compared to sandblasting or power buffing (8). For example the NBIC mandates grinding as surface preparation for deaerator inspection. The omission of grinding in the guidelines for ammonia vessel in-service inspection may be due to concern that rough grinding may produce residual stress sufficient to initiate SCC in anhydrous ammonia service. If welds have been properly profiled for WFMT on initial fabrication, then grinding for in-service inspection should not be needed.The NBIC guidelines also state that other inspection methods such as acoustic emission or ultrasonics may be used and that fracture mechanics may be used to assess the integrity of vessels where complete removal of cracks is not practical.Normally the only corrosion that occurs in anhydrous ammonia vessels is due to water ingress during out of service periods. Shallow pitting, however, has been found in the bottom of some vessels beneath oily deposits. The source of oil is presumed to be from compressors used to handle the ammonia.In view of concerns over air contamination due to vessel entry and residual stress imparted by grinding nonintrusive inspection, techniques like acoustic emission and UT could be considered by vessel owners. The British Code does not mention nonintrusive inspection of ambient temperature pressure vessels but does state that, if acoustic emission is to be used for spherical storage vessels, a reference base should be taken during initial hydrotesting. Nonintrusive inspection is being used in other industries (9).Vessel refilling Safety procedures should be established for refilling a vessel that has been emptied for inspection. It is also very important to purge the vessel of air to prevent the occurrence of SCC. Detailed instructions are available from ammonia suppliers (10). If a vessel is not to be returned to service immediately after inspection, then care should be taken to dry it and possibly nitrogen-pad it depending on the time it will remain out of service.Inspection frequency Neither the ANSI document nor the NBIC deals with inspection frequency. The British Code recommends the following: WFMT inspection of 100% of all internal butt welds within the first three years of service WFMT re-inspection within 2 years if significant defects are found Subsequent to no significant defects being found, any subsequent inspection should include WFMT of all Tee junctions and 10% of the total length of butt welds In no case should the subsequent examination interval exceed 6 years.It is apparent from the above that latitude can exist for in-service inspection techniques and frequencies. Each owner should determine inspection frequency in conjunction with the appropriate authority. Some jurisdictions require a 3-year inspection frequency.SUMMARYThe use of carbon steel pressure vessels for storage of anhydrous ammonia in the pulp and paper industry could be a non-event or deteriorate into a cycle of inspection and repair. This article has highlighted major concerns related to SCC. There is a wealth of additional information available on all considerations related to these vessels from the ANSI and British Codes, the NACE document, ammonia suppliers, and the current technical literature. The American Institute of Chemical Engineers (AIChE) holds the annual AIChE Ammonia Safety Symposium aimed at finding ways to safely manufacture, transport, and store ammonia and related chemicals. The proceedings of these symposia are published by AIChE. It is recommended that any owner of such vessels keep aware of current expertise.Reid is materials and corrosion section head with MacMillan Bloedel Research, 4225 Kincaid St., Burnaby, BC, Canada V5G 4P5.Task group members: Craig Reid; R.S. Charlton, Levelton Associates Consulting Engrs.; R.C. Faloon, MQSInspections Inc.; and W. E. Boudreau, Belle Testing Inc.Literature cited1. Loginow,A.W. , Materials Performance 25 (12): 18(1986). 2. NACE Technical Committee report 5A192, Integrity of Equipment in Anhydrous Ammonia Storage and Handling, Houston, NACE Storage Tank, Spokane, 1992.3. Stephens, J. D. and Vidalin, F., 1994 AIChE Ammonia Symposium Notes, American Institute of Chemical Engineers, New York, p. 9. 4. Compressed Gas Association Inc., American National Standard Safety Requirements for the Storage and Handling of Anhydrous Ammonia ANSI K61.1-1989, Arlington, VA, 1989 (CGA Pamphlet G-2.1-1989).5. Storage of Anhydrous Ammonia Under Pressure in the United Kingdom, London, Her Majestys Stationery Office, 1986. (Health and Safety Booklet HS/G 30)6. Cominco Fertilizers (U.S.) Inc., Decommissioning an Ammonia Storage Tank, Spokane, 1992.7. The National Board of Boiler and Pressure Vessel Inspectors, National Board Inspection Code: A Manual for Boiler and Pressure Vessel Inspectors, Columbus, OH, 1992, p.197.8. Reid, J. C. and Reid, C., TAPPI 1992 Engineering Conference Proceedings, TAPPI PRESS, Atlanta, Book I, p.163.9. Conley, M. J., Sture, A., and Williams, D., “Ammonia Vessel Integrity Program: A Modern Approach, 1990 AIChE Ammonia Symposium Notes, New York, AIChE, 1990.10. Cominco Fertilizers (U.S.) Inc., “Commissioning an Ammonia Storage Tank”, Spokane, 1992.附录二 外文翻译:纸浆和造纸行业中的无水氨压力容器本文的目的是为了确保纸浆和纸张经营公司,他们的工程顾问,承建商了解在脱水氨设备中的应力腐蚀开裂现象。这篇资料是由美国纸浆与造纸工业技术协会无损检测工程部和质量控制小组委员会共同编写。细菌生存在一些活性污泥污水处理系统中需要充足的食物。在某些情况下,这种食品是氨和磷酸的储存现场。氨通常以无水液氨的形式贮存在室温和1.6MPa(250 磅)的压力的碳钢容器中。这些容器可能会受到应力腐蚀开裂(SCC)。应力腐蚀开裂可能导致氨泄露,这是一种危险化学品。用于无水氨设备的碳钢容器中的SCC是有点类似于连续蒸煮罐的经验。例如,减少压力的引入在生产和在役检查过程都是很常见的。本文关注在常温下的卧式压力容器,像这类型容器通常用于纸浆和造纸的应用。大型冷藏储罐在化工行业一般是常压储存。SCC在氨储罐的历史SCC在碳钢氨储存容器的历史是由Loginow(1)审查通过,也是在简要回顾了NACE技术委员会报告题为“完整的设备在无水氨的储存和处理”(2)。在20世纪50年代,液氨作为肥料直接注入土壤。碳钢贮存容器由于应力腐蚀开裂而导致的故障开始出现。这些故障是意外,因为液氨已用于在制冷,化工多年,金属热处理行业没有报告的问题。 调查结果证应力腐蚀是开裂的原因。1962年提出了三条建议构成了现代条例的基础: 压力容器应充分消除应力。 要特别小心是消除氨系统中的氧气。 氨应该包含至少0.2的水,以抑制应力腐蚀开裂。Loginow报告说,采用这些建议能有效避免应力腐蚀发生在农业用碳钢容器中。然而,最近的加拿大西部的调查显示通过湿荧光磁粉探伤检查(WFMT)(3)发现117处农场的储罐中有100处发生了应力腐蚀开裂。 尽管采用了上述措施,SCC仍然发生在由高强度钢建造的公路运输油罐、冷藏储存容器以及作了焊接修复却没后续的应力消除的容器。另外一条建议被纳入美国和英国的氨储存条例,以限制钢材的拉伸或屈服强度。 ANSI K61.1 -名义抗拉强度不超过70,000磅(580兆帕) 英国条例指定的最低屈服强度不超过350兆帕(51,000磅)。实用的考虑 本文主要关注是实际问题对于已拥有无水氨贮存容器的纸浆和造纸厂或计划制作这类容器的重要性。以连续蒸发罐中SCC的经验来看,执行目标应该是控制制造和检验,以避免或至少减少在运行中的问题,包括过度反应相对轻微裂缝的迹象。从一些氨的供应商提供公开条例和规范资料可以得到相关的指导。制造 制作中的两个主要目标应是提为抗裂容器供合理的成本,并确保为后续在役检验的解释有适当的检验基线可用。ASME第1部第VIII节没有要求无水氨存储压力容器要应力消除,除非拥有者指定了一个致命的部件名称。指定的致命部件需要焊接接头的焊后热处理加所有对接射线检测(RT)。美国国家标准化组织(ANSI)K 61.1 - 1989,“美国国家标准无水氨的存储和处理安全要求”增加了几个要求: 制造符合ASME第一部第VIII节UW12表的效率不能低于80。 基于UG-90(c)检查和测试是不允许的。 用于压力容器部件的钢材的标称抗拉强度应当不低于580MPa(70,000 psi)。 室温储罐的最低设计压力应当为16bar(250 psig)的。 必须进行焊后热处理,要求足够大的熔炉来适应整个容器。附件的焊接点可能要进行热处理 卧式压力容器应当安装在鞍座超过至少有一个壳体的周长三分之一。应允许热膨胀和收缩和给出以防止壳体和鞍座之间腐蚀的方法。1986年英国章程“英国常压无水氨储存”要求: 钢材的指定最低屈服强度必须小于350兆帕(51,000磅)。 焊接填充物的最小强度必须高于于比母材强度。 100的内部焊缝磁粉探伤,对未来所有的容器检查提供可以评估的纪录。 没有后续局部应力消除的应力消除后允许无焊接 混凝土鞍座是禁止的。 钢制鞍座连续焊接必须在应力释放之前。虽然英国规范并没有规定磁化粒子检查应当进行湿荧光磁粉实验,人们普遍认为,WFMT是最灵敏的技术,应该用于检验氨贮存容器。所有的检查应该由合格的技术人员来完成。SNT-TC-1A II级是建议的最低水平。其中纸浆和造纸公司已对这些容器的制造增加了下列要求: 设立“腐蚀裕量”至少1.6毫米(1 / 16英寸),允许在役检验中出现的微小缺陷,并在容器

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号