资源目录

压缩包内文档预览:

编号:17121946

类型:共享资源

大小:5.48MB

格式:ZIP

上传时间:2019-03-27

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

含CAD图纸、三维模型

含CAD图纸

含CAD图

三维CAD图纸

CADCAD

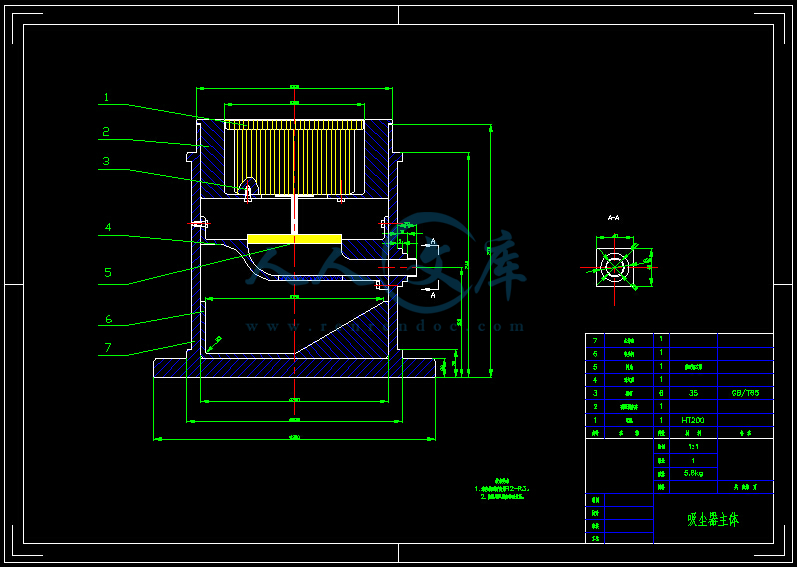

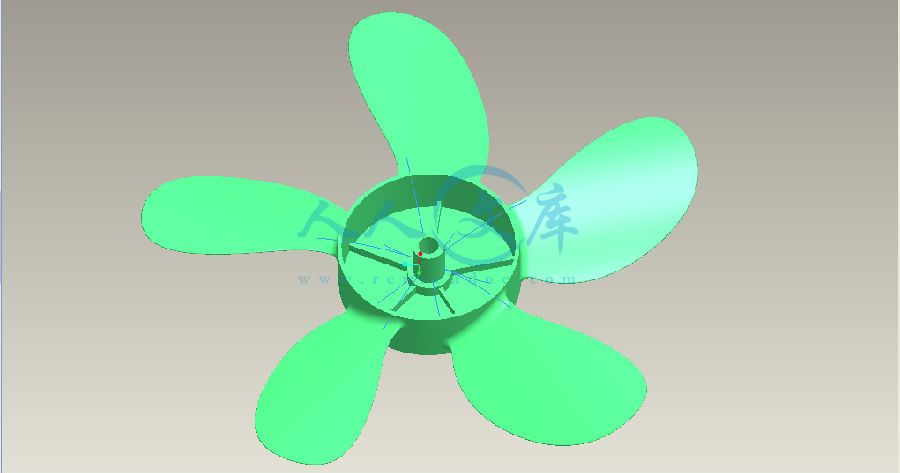

吸尘器设计CAD图纸

CAD图纸】吸尘器

的设计【含CAD图纸】

- 资源描述:

-

- 内容简介:

-

毕业设计(论文)任务书系 部指导教师职 称学生姓名专业班级学 号论文题目小型吸尘器的设计论文内容目标及进度要求内容1、了解吸尘器的种类及适用的环境;2、掌握吸尘器的结构、工作原理; 3、所设计的吸尘器要求真空度,噪声。 要求:1、 收集资料(相关的书籍5本以上,文献资料不少于10篇);2、 绘制工作原理图;3、 将机械图绘制成三维装配图;4、 撰写论文要符合论文规范要求,不少于10000字;5、 翻译相关英文文献一篇,不少于3000字(英译汉)。 进度1、15 周,主要进行毕业设计准备工作,熟悉题目,收集资料,进行毕业实习,明确研究目的和任务,构思总体方案;2、611周,设计计算,绘图;3、1215周,编写毕业设计论文,准备毕业设计答辩。 指导教师签名: 年 月 日系 部审 核此表由指导教师填写 由所在系部审核毕业论文附件材料学生姓名:学 号:所在系部:专业班级:指导教师:日 期:年五月(目录1 英文文献翻译11.1 Principle and Application of the gearhead11.2减速机的原理及应用62 专业阅读书目92.1 Pro/E Wildfire 3.0三维设计基础与工程范例92.2 机械设计基础102.3 Pro/E野火4.0从入门到精通102.4 机械设计102.5 电机学112.6 机械制造工艺学112.7 Pro/E实用教程122.8 机械振动基础122.9 机电传动与控制132.10 现代机械概念设计与运用131 英文文献翻译1.1 Principle and Application of the gearheadThe reducer is a power to convey, using the gear speed converters, the number of deceleration to the desired rotational speed of the rotary motor (motor), and the institutions of the larger torque. Reducer of a wide range of institutions for the transmission of power and movement. Traces of it can be seen in almost all kinds of mechanical drive system from the transport ships, automobiles, motorcycles, construction heavy machinery, processing machinery and automated production equipment used in the machinery industry, daily life home appliances, watches and so on. applications from large power transmission, to a small load, the precise angle transmission can be seen to slow down the application of machine, and in industrial applications, the reducer to slow down and increase the torque function. Therefore widely used in the speed and torque conversion equipment.The reducer is the prime mover and between independent closed gear to reduce speed and increase torque to meet the needs of the work, the growth rate is also used in some cases, known as the accelerator.Many different types of reducer, gear reducer, worm gear reducers, planetary reducer, reducer as well as their combination with each other up in accordance with the drive type can be divided into; in accordance with the transmission of the series can be divided into single-stage and multistage reducer; accordance with the gear The shape can be divided into cylindrical gear reducer, bevel gear reducer and a tapered cylindrical gear reducer; in accordance with the arrangement of the drive can be divided into the expansion, Split and coaxial reducer.Reducer transmission parts (gears or worm), shaft, bearings, cabinet and its annex. Its basic structure has three parts: 1) gear, shaft and bearing assembly; 2) box; 3) reducer attachments.Made one of the pinion and shaft, said gear shaft, such a structure for the related small case of the gear diameter and the diameter of the shaft, the shaft diameter d, the gear tooth root diameter of the circle for the df when the df- d 6 7mn this structure should be used. When the df-d 6 7mn with gear and shaft separated into two parts of the structure, such as low-speed shaft and gear. The gear and shaft of the week to a fixed level key to link the shaft parts shaft shoulder, sleeve and bearing cap for axial fixation. The two axes are deep groove ball bearings. This combination is used to bear radial load and a small axial load. When the axial load is large, angular contact ball bearings, tapered roller bearings or deep groove ball bearings and thrust bearing composite structures. Figure, the bearing is spun using the gear rotation thin oil lubrication. Box seat Petroleum pool of lubricant, the spinning gear splashes splashing into the lid of the inner wall of the flow along the inner wall surface groove of binning, the lead tank into the bearings. When the oil-soaked gear circumferential speed 2m / s, grease lubricated bearings should be used, to avoid possible splashes of light oil to wash away grease, can be used to block the oil ring to separate. To prevent oil loss and outside dust entering the box, equipped with a sealing element between the bearing cover and overhanging shaft.The box is a key component of the reducer. It is the base of transmission parts, should have sufficient strength and stiffness.The box is usually gray cast iron, cast steel box can also be used for overload or shock load reducer. Monomer production reducer, in order to simplify processes, reduce costs, can be welded steel plate box.The cabinet is manufactured from gray cast iron. The gray cast iron with good casting properties and damping properties. In order to facilitate the installation and removal of the shaft parts, the box is made along the axis line of the horizontal split. On lid and lower box into one bolt connection. Bearing bolts should be as close as possible to the bearing hole, next to the bearing boss should have sufficient supporting surface, in order to place the coupling bolts, and to ensure that the need to tighten the bolt wrench space. In order to ensure that the cabinet have sufficient rigidity and support ribs in the vicinity of the bearing hole. Ensure reducer placed on the basis of stability and minimize cabinet base plane of the machining area, the cabinet base is generally not used to complete the plane. Graph reducer box seat underside are two vertical long bar machining surface.In order to ensure the normal work of the reducer, gears, shafts, bearing assembly and the box structure designed to give enough attention, but also taking into account the reducer lubricant pool oiling, oil discharge, check the oil level, processing and cover when the disassembly repair and box seat accurate positioning, loading and other auxiliary parts and components a reasonable choice and design.1) inspection holes to check transmission parts meshing to the box into the lubricating oil, inspection holes should be the appropriate place in the box set. Inspection hole can directly observe the gear meshing parts at the top of the upper lid. In peacetime, the inspection hole cover, screw the lid on.2) ventilators reducer work, cabinets temperature increases, the expansion of gases, pressure, freedom of discharged inside the thermal expansion of air, the balance of internal and external pressures to keep the box does not result in the lubricant along the sub-box surface or shaft extension seals and other gap leakage, usually in the box at the top of the installation of ventilation.3) bearing cap fixed axial position of the shaft parts and carry axial load bearing holes at both ends of the bearing cap closed. The bearing cover flange and embedded two. The figure is a flange type bearing caps, hex bolts in the box on the overhang of the shaft at the bearing cap is a through-hole, which is equipped with a sealing device. Advantages of the flange bearing cover is removable, convenient adjustment bearing and embedded bearing cover compared to the number of parts, more of a larger size, uneven appearance.4) the locating pin in order to ensure that each removable lid, still maintain the accuracy of the bearing hole manufacturing process, before finishing the bearing bore, equipped with the locating pin on the lid and the box seat connection flange. Two positioning used taper pins and placed in the box vertical on both sides of the connection flange, symmetrical box should be symmetrical arrangement, in order to avoid the wrong equipment.5) oil level indicator to check reducer oil level in oil tank, oil tanks to keep the right amount of oil, is generally easy to observe in the box, the more stable parts of the oil surface, installation of oil level indicator, used in Figure the oil surface indicator is the oil gauge.6) oil drain plug oil, emissions from waste oil and cleaning agents should be set up in the box seat at the bottom of the oil pool at the lowest oil hole, usually using the plug the oil hole blocking the oil drain plug and box joints should leak-proof with gasket.7) Kai box screws to strengthen the sealing effect, usually in the assembly in the box split surface coated with sodium silicate or sealant, and thus demolition is often difficult to close openings due to cementation. To do this often in the appropriate place to cover the connection flange, processing 1 to 2 screw holes, screwed into the cylindrical side or end of the Kai Kai box with the box screw. Kai box rotating screw and it will be on the cover from the top. Small reducer or not to set the resource box screws with a screwdriver to pry open the lid when Kai Gai, Kai box the size of the screw in the flange joint bolts.8) The lifting device when the reducer weight more than 25kg, in order to facilitate the handling, lifting devices set up in the box, as in cast out of the box on the lug or hook. Graph equipped with two rings, screw on the lid under the box seat cast four hooks.Since the 1960s, China has developed JB1130-70 cylindrical gear reducer and a number of general-purpose reducer Standard OEM-made supporting the use of the formation of a number of reducer professional production plant. At present, hundreds of national production reducer enterprise, an annual output of general-purpose reducer 250 000, have contributed to the development of Chinas machinery products.Most of the 1960s, the reducer is a reference to the Soviet Union the 1940s and 1950s technology, and later, despite the development, but limited to the design, level of technology and equipment conditions, the overall level and international level have a greater gap .Since the reform and opening up, Chinas introduction of a number of advanced processing equipment, by introducing, digesting and absorbing foreign advanced technology and scientific research, and gradually master a variety of high-speed and low speed and heavy gear design and manufacturing technology. The quality of materials and heat treatment and gear machining accuracy are greatly improved, the manufacturing precision of the common cylindrical gear from JB179-60 8-9 to GB10095-88 6 high-speed gear manufacturing precision can be stabilized at 4-5 level. Part of the reducer using hardened, volume and quality significantly reduced carrying capacity, life, drive efficiency have been greatly improved, energy-saving and improving the overall level of the host played a significant role.Our own design and manufacture of high-speed gear reduction (increase) the power of the accelerator has reached 42000kW gear circumferential speed of 150m / s or more. However, the technical level of the majority of our gear is not high, and old products can not be replaced immediately, the old and new coexist transition will experience a longer period of time.1.2减速机的原理及应用减速机是一种动力传达机构,利用齿轮的速度转换器,将电机(马达)的回转数减速到所要的回转数,并得到较大转矩的机构。在目前用于传递动力与运动的机构中,减速机的应用范围相当广泛。几乎在各式机械的传动系统中都可以见到它的踪迹,从交通工具的船舶、汽车、机车,建筑用的重型机具,机械工业所用的加工机具及自动化生产设备,到日常生活中常见的家电,钟表等等.其应用从大动力的传输工作,到小负荷,精确的角度传输都可以见到减速机的应用,且在工业应用上,减速机具有减速及增加转矩功能。因此广泛应用在速度与扭矩的转换设备。减速器是原动机和工作机之间的独立的闭式传动装置,用来降低转速和增大转矩,以满足工作需要,在某些场合也用来增速,称为增速器。减速器的种类很多,按照传动类型可分为齿轮减速器、蜗杆减速器和行星减速器以及它们互相组合起来的减速器;按照传动的级数可分为单级和多级减速器;按照齿轮形状可分为圆柱齿轮减速器、圆锥齿轮减速器和圆锥一圆柱齿轮减速器;按照传动的布置形式又可分为展开式、分流式和同轴式减速器。减速器主要由传动零件(齿轮或蜗杆)、轴、轴承、箱体及其附件所组成。其基本结构有三大部分:1)齿轮、轴及轴承组合;2)箱体;3)减速器附件。小齿轮与轴制成一体,称齿轮轴,这种结构用于齿轮直径与轴的直径相关不大的情况下,如果轴的直径为d,齿轮齿根圆的直径为df,则当df-d67mn时,应采用这种结构。而当df-d67mn时,采用齿轮与轴分开为两个零件的结构,如低速轴与大齿轮。此时齿轮与轴的周向固定平键联接,轴上零件利用轴肩、轴套和轴承盖作轴向固定。两轴均采用了深沟球轴承。这种组合,用于承受径向载荷和不大的轴向载荷的情况。当轴向载荷较大时,应采用角接触球轴承、圆锥滚子轴承或深沟球轴承与推力轴承的组合结构。图中,轴承是利用齿轮旋转时溅起的稀油,进行润滑。箱座中油池的润滑油,被旋转的齿轮溅起飞溅到箱盖的内壁上,沿内壁流到分箱面坡口后,通过导油槽流入轴承。当浸油齿轮圆周速度2m/s时,应采用润滑脂润滑轴承,为避免可能溅起的稀油冲掉润滑脂,可采用挡油环将其分开。为防止润滑油流失和外界灰尘进入箱内,在轴承端盖和外伸轴之间装有密封元件。箱体是减速器的重要组成部件。它是传动零件的基座,应具有足够的强度和刚度。箱体通常用灰铸铁制造,对于重载或有冲击载荷的减速器也可以采用铸钢箱体。单体生产的减速器,为了简化工艺、降低成本,可采用钢板焊接的箱体。箱体是由灰铸铁制造的。灰铸铁具有很好的铸造性能和减振性能。为了便于轴系部件的安装和拆卸,箱体制成沿轴心线水平剖分式。上箱盖和下箱体用螺栓联接成一体。轴承座的联接螺栓应尽量靠近轴承座孔,而轴承座旁的凸台,应具有足够的承托面,以便放置联接螺栓,并保证旋紧螺栓时需要的扳手空间。为保证箱体具有足够的刚度,在轴承孔附近加支撑肋。为保证减速器安置在基础上的稳定性并尽可能减少箱体底座平面的机械加工面积,箱体底座一般不采用完整的平面。图中减速器下箱座底面是采用两纵向长条形加工基面。为了保证减速器的正常工作,除了对齿轮、轴、轴承组合和箱体的结构设计给予足够的重视外,还应考虑到为减速器润滑油池注油、排油、检查油面高度、加工及拆装检修时箱盖与箱座的精确定位、吊装等辅助零件和部件的合理选择和设计。1)检查孔为检查传动零件的啮合情况,并向箱内注入润滑油,应在箱体的适当位置设置检查孔。检查孔设在上箱盖顶部能直接观察到齿轮啮合部位处。平时,检查孔的盖板用螺钉固定在箱盖上。2)通气器减速器工作时,箱体内温度升高,气体膨胀,压力增大,为使箱内热胀空气能自由排出,以保持箱内外压力平衡,不致使润滑油沿分箱面或轴伸密封件等其他缝隙渗漏,通常在箱体顶部装设通气器。3)轴承盖为固定轴系部件的轴向位置并承受轴向载荷,轴承座孔两端用轴承盖封闭。轴承盖有凸缘式和嵌入式两种。图中采用的是凸缘式轴承盖,利用六角螺栓固定在箱体上,外伸轴处的轴承盖是通孔,其中装有密封装置。凸缘式轴承盖的优点是拆装、调整轴承方便,但和嵌入式轴承盖相比,零件数目较多,尺寸较大,外观不平整。 4)定位销为保证每次拆装箱盖时,仍保持轴承座孔制造加工时的精度,应在精加工轴承孔前,在箱盖与箱座的联接凸缘上配装定位销。图中采用的两个定位圆锥销,安置在箱体纵向两侧联接凸缘上,对称箱体应呈对称布置,以免错装。5)油面指示器检查减速器内油池油面的高度,经常保持油池内有适量的油,一般在箱体便于观察、油面较稳定的部位,装设油面指示器,图中采用的油面指示器是油标尺。6)放油螺塞换油时,排放污油和清洗剂,应在箱座底部,油池的最低位置处开设放油孔,平时用螺塞将放油孔堵住,放油螺塞和箱体接合面间应加防漏用的垫圈。 7)启箱螺钉为加强密封效果,通常在装配时于箱体剖分面上涂以水玻璃或密封胶,因而在拆卸时往往因胶结紧密难于开盖。为此常在箱盖联接凸缘的适当位置,加工出12个螺孔,旋入启箱用的圆柱端或平端的启箱螺钉。旋动启箱螺钉便可将上箱盖顶起。小型减速器也可不设启箱螺钉,启盖时用起子撬开箱盖,启箱螺钉的大小可同于凸缘联接螺栓。8)起吊装置当减速器重量超过25kg时,为了便于搬运,在箱体设置起吊装置,如在箱体上铸出吊耳或吊钩等。图中上箱盖装有两个吊环螺钉,下箱座铸出四个吊钩。自20世纪60年代以来,我国先后制订了JB113070圆柱齿轮减速器等一批通用减速器的标淮,除主机厂自制配套使用外,还形成了一批减速器专业生产厂。目前,全国生产减速器的企业有数百家,年产通用减速器25万台左右,对发展我国的机械产品作出了贡献。 20世纪60年代的减速器大多是参照苏联20世纪4050年代的技术制造的,后来虽有所发展,但限于当时的设计、工艺水平及装备条件,其总体水平与国际水平有较大差距。改革开放以来,我国引进一批先进加工装备,通过引进、消化、吸收国外先进技术和科研攻关,逐步掌握了各种高速和低速重载齿轮装置的设计制造技术。材料和热处理质量及齿轮加工精度均有较大提高,通用圆柱齿轮的制造精度可从JB17960的89级提高到GB1009588的6级,高速齿轮的制造精度可稳定在45级。部分减速器采用硬齿面后,体积和质量明显减小,承载能力、使用寿命、传动效率有了较大的提高,对节能和提高主机的总体水平起到很大的作用。 我国自行设计制造的高速齿轮减(增)速器的功率已达42000kW ,齿轮圆周速度达150m/s以上。但是,我国大多数减速器的技术水平还不高,老产品不可能立即被取代,新老产品并存过渡会经历一段较长的时间。2 专业阅读书目2.1 Pro/E Wildfire 3.0三维设计基础与工程范例 内容摘要:本书全面介绍了Pro/E Wildfire 3.0中文版的特点和基本功能。全书共17章,主要分为四部分内容,第一部分包括第110章,主要介绍Pro/E的基础知识,适合Pro/E的初学者阅读。第二部分包括第1113章,主要介绍Pro/E在机械行业中一些典型零件的设计方法,适合对Pro/E具有一定基础的中级用户阅读。第三部分包括第1416章,主要介绍Pro/E参数化造型设计复杂产品的高级应用技巧,适合Pro/E的高级用户阅读和使用。第四部分即最后一章专门介绍Pro/E在机构运动仿真方面的强大功能,也是属于高级用户应当掌握的内容。本书的写作思想立足于实际问题的应用设计,目标是使读者在掌握基础知识的同时,通过实例分析,开拓思路,掌握方法,提高对知识综合运用的能力。突出“设计理念”和“工程应用”两个重点,通过对某些工程应用实例的分析和讲解,不仅介绍了Pro/E在机械产品设计方面的使用技巧,而且分析了典型机械产品设计的基本思路,并通过循序渐进的练习使读者真正掌握利用Pro/E进行计算机辅助设计的高级应用技巧。书中选择的实例也是在产品设计和实际工作中经常会遇到的,如使用Pro/E的参数化设计快速生成齿轮,绘制由数学方程精确描述的凸轮实际廓线,建立系列化产品的螺栓零件族表,利用曲面造型完成复杂零件的实体造型设计,通过对Pro/E中的装配机构添加运动副和驱动器来真正实现机构产品的运动仿真等。(温建民. Pro/E Wildfire 3.0三维设计基础与工程范例M. 北京:清华大学出版社,2008)2.2 机械设计基础 内容摘要:本书体现理论与实践一体化教学方式,将原有的理论力学、工程力学按照机械设计的要求改为平面机构的静力分析 、机械零件的工作能力分析以及基本机构和机械零部件的原理、设计和校核等内容。内容包括概论、平面机构的静力分析、机械零件的工作能力分析、常用机构、螺纹联接和螺旋传动、齿轮传动、轮系、其他机械传动、轴、轴承、联接、其他常用零部件和机械创新设计等共13章。本书综合机械设计知识、技能、能力的培养,着重培养学习者的职业素质和能力。本书不仅可以满足机电一体化专业、机械制造与控制专业、数控技术专业、模具设计与制造专业的教学需要,同时也可以作为机械工程技术人员的培训教材。(罗红专.机械设计基础M.北京:机械工业出版社,2011)2.3 Pro/E野火4.0从入门到精通 内容摘要:本书从零开始,注重基础,详细阐述了ProENGINEER WiIdfi re 4.0的基本设计原理。同时结合典型实例,全面介绍了ProfENGINEER Wildfire 4.0各功能模块的使用方法和技巧。读者在掌握本书内容的基础上注重实践,将所学知识融会贯通,即可真正领略三维实体造型的风采和魅力。本书采用全新的教学模式,从易到难地组织每个章节的内容。全书共分11章,主要内容包括ProE 40野火版入门知识、管理ProE野火版工作环境、视角操作与自定义设置、2D草绘基础、图元编辑与尺寸标注,三维造型设计和基础特征、曲面的创建与应用、创建基础实体特征、创建放置实体特征、实体特征编辑、编辑曲面特征、创建圆角和拔模特征、装配零件、工程图,机械设计等通用模块的知识点。(王咏梅.Pro/E野火4.0从入门到精通M.北京:电子工业出版社,2008)2.4 机械设计 内容摘要:在本版的修订过程中,编者仍试图从满足教学基本要求、贯彻少而精的原则出发,力求做到精选内容、适当拓宽知识面、反映学科新成就,但深度适中、篇幅不大,以期保持一本简明、实用教材的特色。为了适应我国加入WTO后的形势要求,这次修订考虑到扩大知识面、反映新成就和照顾某些专业的需要,增补了正弦加速度从动件运动规律、活齿传动、回转件平衡精度、窄V带传动设计、滚动轴承静强度计算、液体润滑轴承承载量计算、梅花形弹性联轴器、内张式制动器等内容。删去了一些比较烦琐的推导、论证和陈旧内容,如斜齿轮当量齿数、锥齿轮背锥、等加速等减速从动件运动规律、双圆弧齿轮、动平衡机操作过程等。参照国内外学科发展的现状,本版更新了若干设计计算方法,还根据新近颁布的国家标准、规范对书中的术语、图表、数据进行了订正、补充和更新。(杨可桢.机械设计M.北京:高等教育出版社,2010)2.5 电机学 内容摘要: 本书主要阐述电气自动化和电力系统中常用的直流电机、变压器、异步电机和同步电机的基本原理、结构及运行性能,并对电机实验和电机控制的内容做了一定的介绍,以适应教学改革发展的实际需要。书中各章均附有小结、习题及思考题。本书的编写方针是:推陈出新,博采众长,通俗实用,深入浅出,承上启下。通过学习本书,可以为学好电气工程类各专业后续课程打好坚实的基础。 本书可作为高等学校电气工程类各专业的教材,亦可供有关技术人员参考。(阎治安.电机学M.陕西:西安交通大学出版社,2006)2.6 机械制造工艺学 内容摘要:为了适应新形势下普通高等学校本科人才培养需求,在总结专业教学实践和工程实践经验的基础上,根据专业教学指导委员会所制定的大纲编写本书。注重能力,突出实用 针对当今社会人才需求,加强学生的能力培养内容。机械制造工艺是机械行业的一项重要和主要工程技术。教材强化了所阐述知识内容的实用性,强化了例题和实例与工程实际的联系,并对部分例题进行了较详细解答。内容包括机械

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号